Vehicle body and rubber-tired train

A car body and train technology, which is applied to the upper structure of motor vehicles, vehicle components, and passenger cars, can solve problems such as stress concentration and uneven distribution of braking force, and achieve the effects of avoiding stress concentration and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

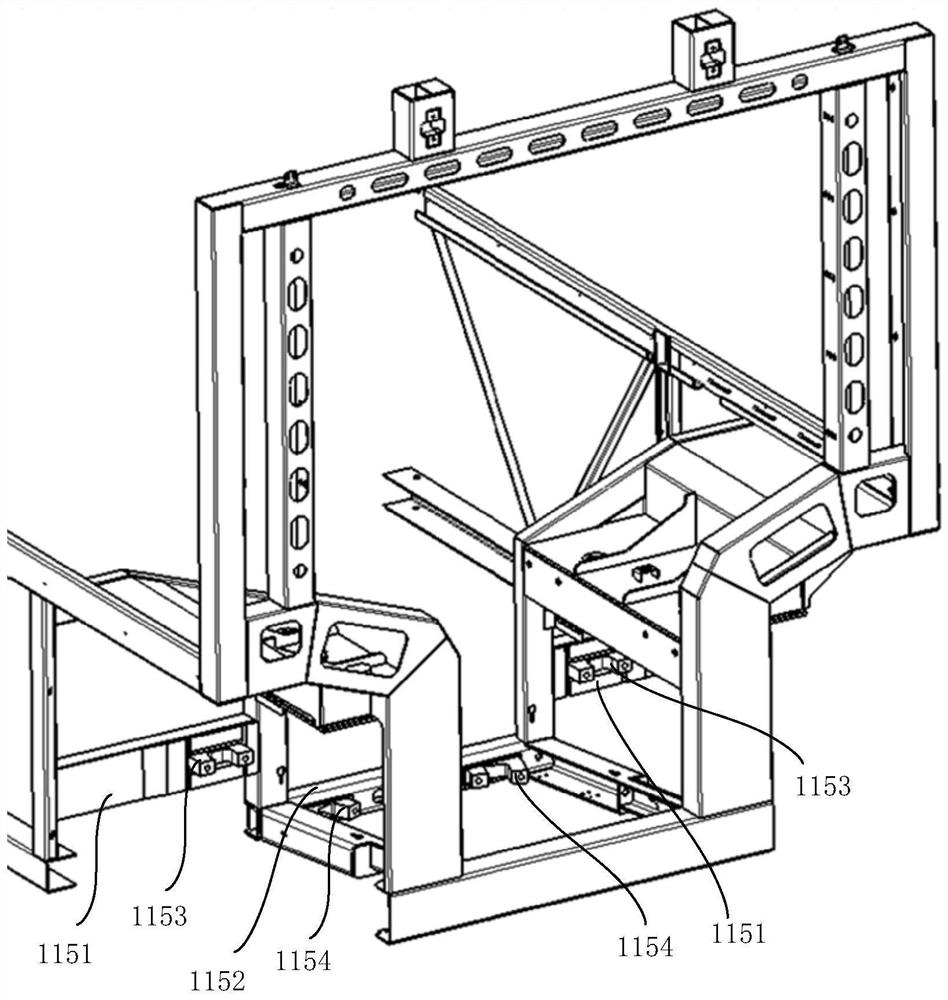

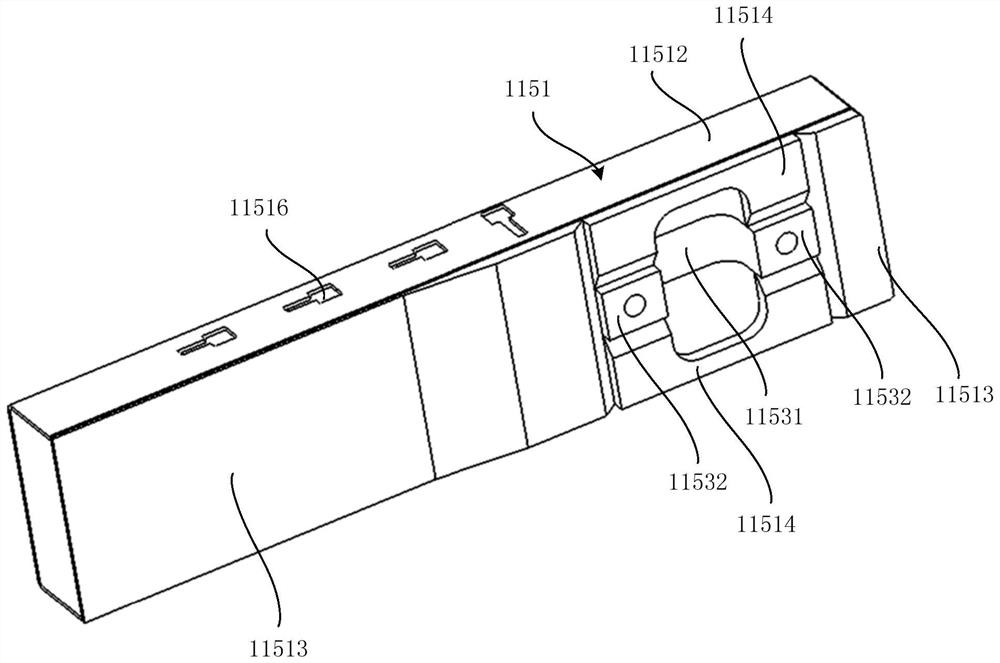

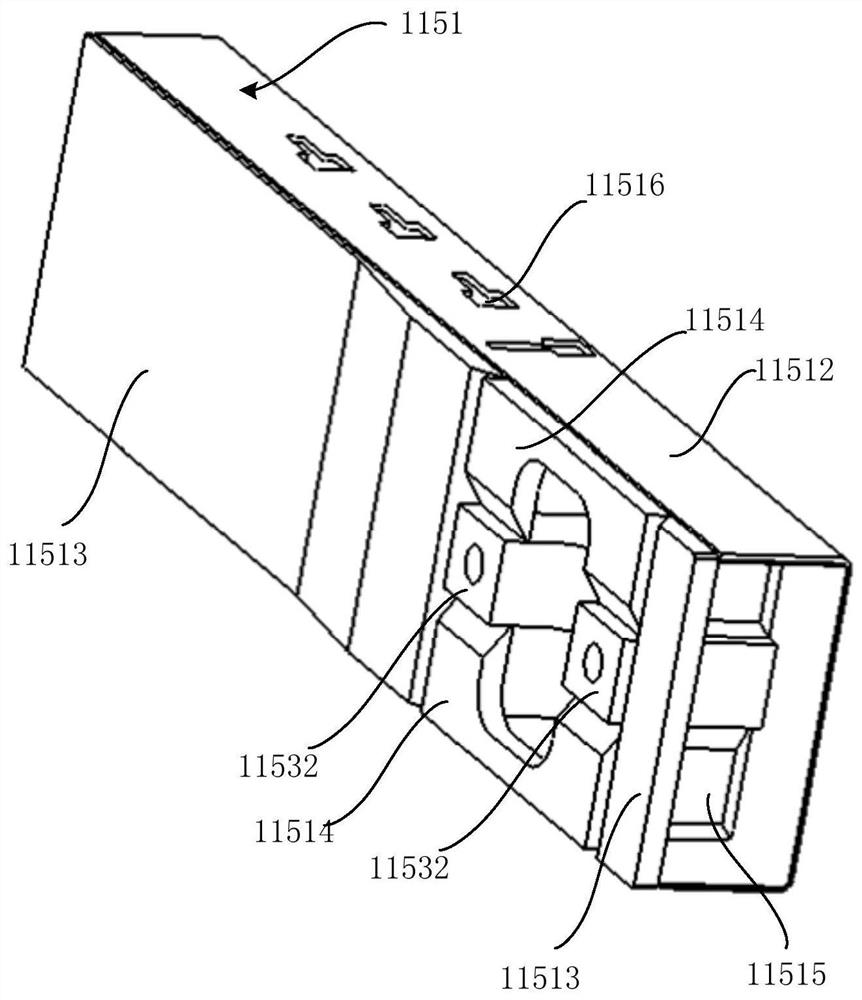

[0038] This embodiment provides a car body, which is applied to a low-floor train with rubber tires, and includes an underframe and a top plate oppositely arranged, and a car body side wall and a car body end wall connecting the under frame and the top plate, wherein the above car body It can be a motor car body or an intermediate car body. For the convenience of description, this embodiment takes the connection structure between the motor car body and the trailer bogie as an example for illustration. It is clear to those skilled in the art that the connection structure between the intermediate car body and the trailer bogie is exactly the same as the connection structure between the motor car body and the trailer bogie, and will not be repeated in this embodiment. The car body end wall is used to connect the trailer traction device on the trailer bogie to transmit traction or braking force between the trailer bogie and the motor car body, and to adapt to the relative movement ...

Embodiment 2

[0061] This embodiment provides a rubber-tyred train, which includes a plurality of end-to-end carriages. The car bodies of the carriages are as described in the first embodiment above, and two adjacent car bodies are connected by trailer bogies.

[0062] Since the rubber-tyred train of this embodiment adopts the car body described in the first embodiment above, it can utilize two first traction assemblies and two second traction assemblies to jointly transmit the tractive force and control between the trailer bogie and the car body. Power reduces the load on each towing component, while evenly distributing traction and braking forces to the entire car body frame and trailer bogie to avoid stress concentration.

[0063] Figure 8 Shown in is a schematic diagram of the connection structure between the trailer bogie and the vehicle body provided by an embodiment of the present application; Figure 9 Shown in is a schematic structural diagram of the trailer traction device provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com