Laser sealing method and system

A sealing system and laser technology, applied in the field of laser sealing methods and systems, can solve problems such as warpage and easy failure, and achieve the effects of improved sealing quality, high efficiency, and avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

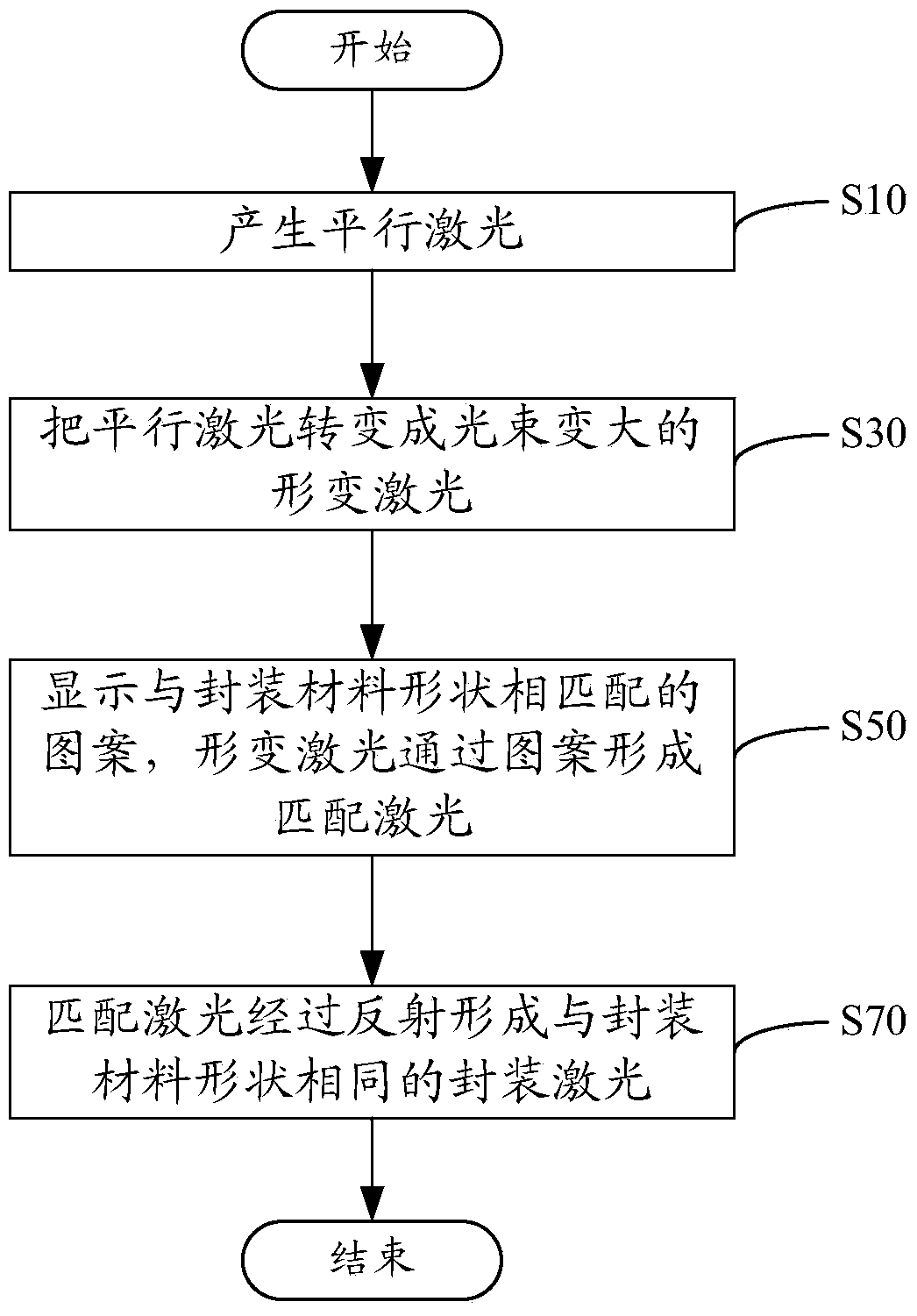

[0025] Attached figure 1 , Laser sealing methods include:

[0026] S10: Generate parallel laser light. Specifically, a group of parallel laser light is generated by the laser.

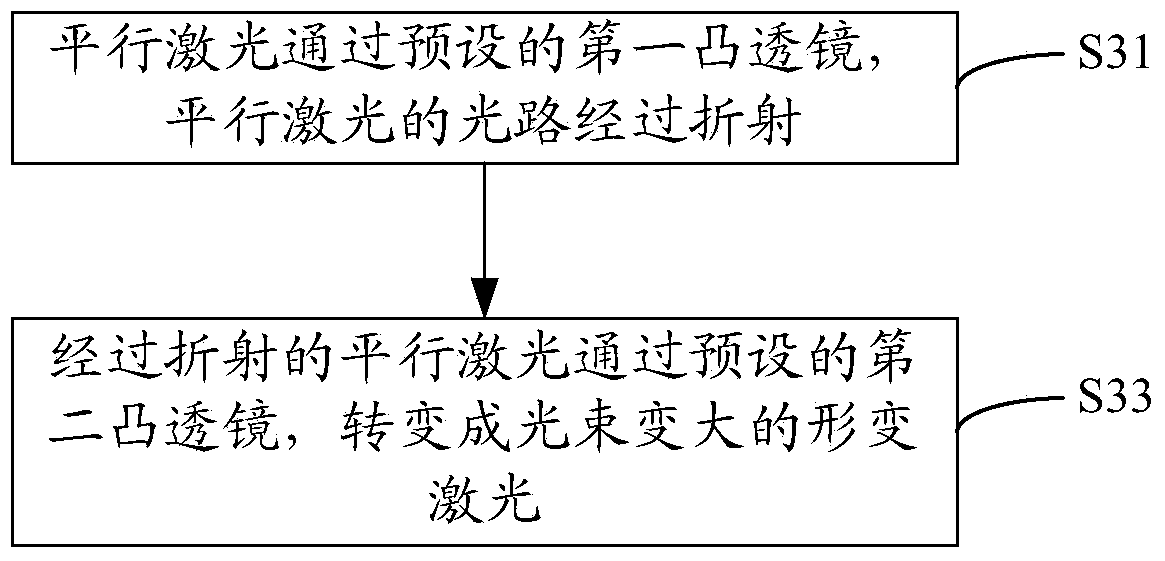

[0027] S30: Transform the parallel laser into a deformed laser with a larger beam. Specifically, generally speaking, the beam of the parallel laser generated by the laser is not large enough, and it needs to be reshaped to transform the parallel laser into a deformed laser with a larger beam. It can be understood that the size of the beam can be adjusted according to requirements.

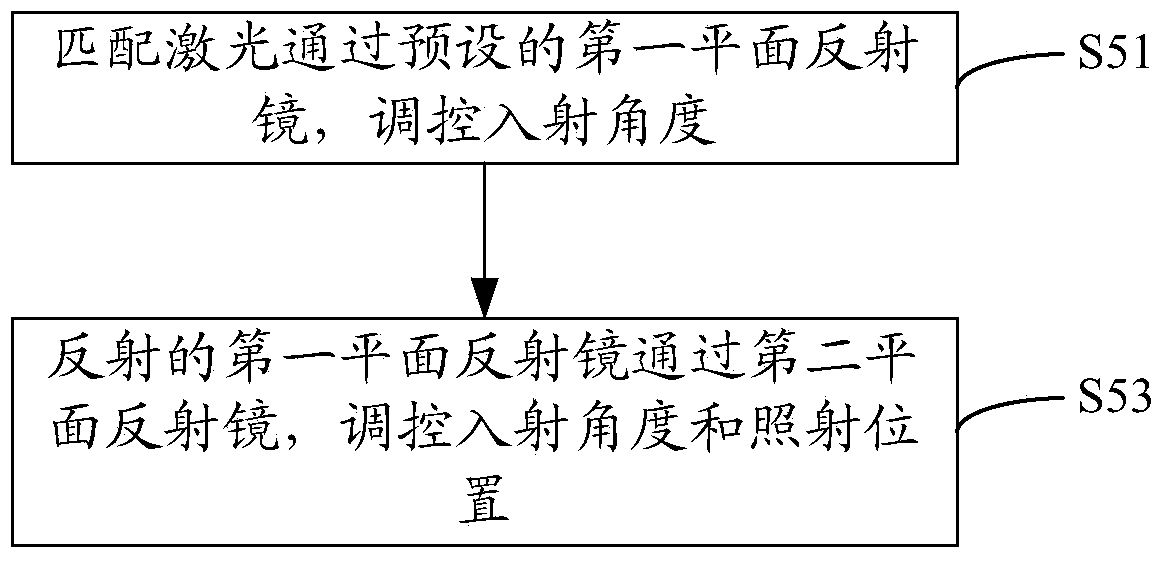

[0028] S50: Display a pattern matching the shape of the packaging material, and the deformation laser forms a matching laser through the pattern. Specifically, for example, a large-size packaging substrate is to be laser packaged, and a pattern matching the shape of the packaging material to be laser-sealed (for example, a pattern reduced in a certain proportion) is obtained in advance, and the deformation laser passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com