Tool apron and processing method thereof

A processing method and technology of tool holders, applied in the direction of cutters, agricultural machinery and tools, etc., can solve the problems of large internal stress of the tool holder, easy damage of the tool holder, and unreasonable structure, so as to achieve balanced force and avoid stress Larger, stress-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the drawings and specific embodiments.

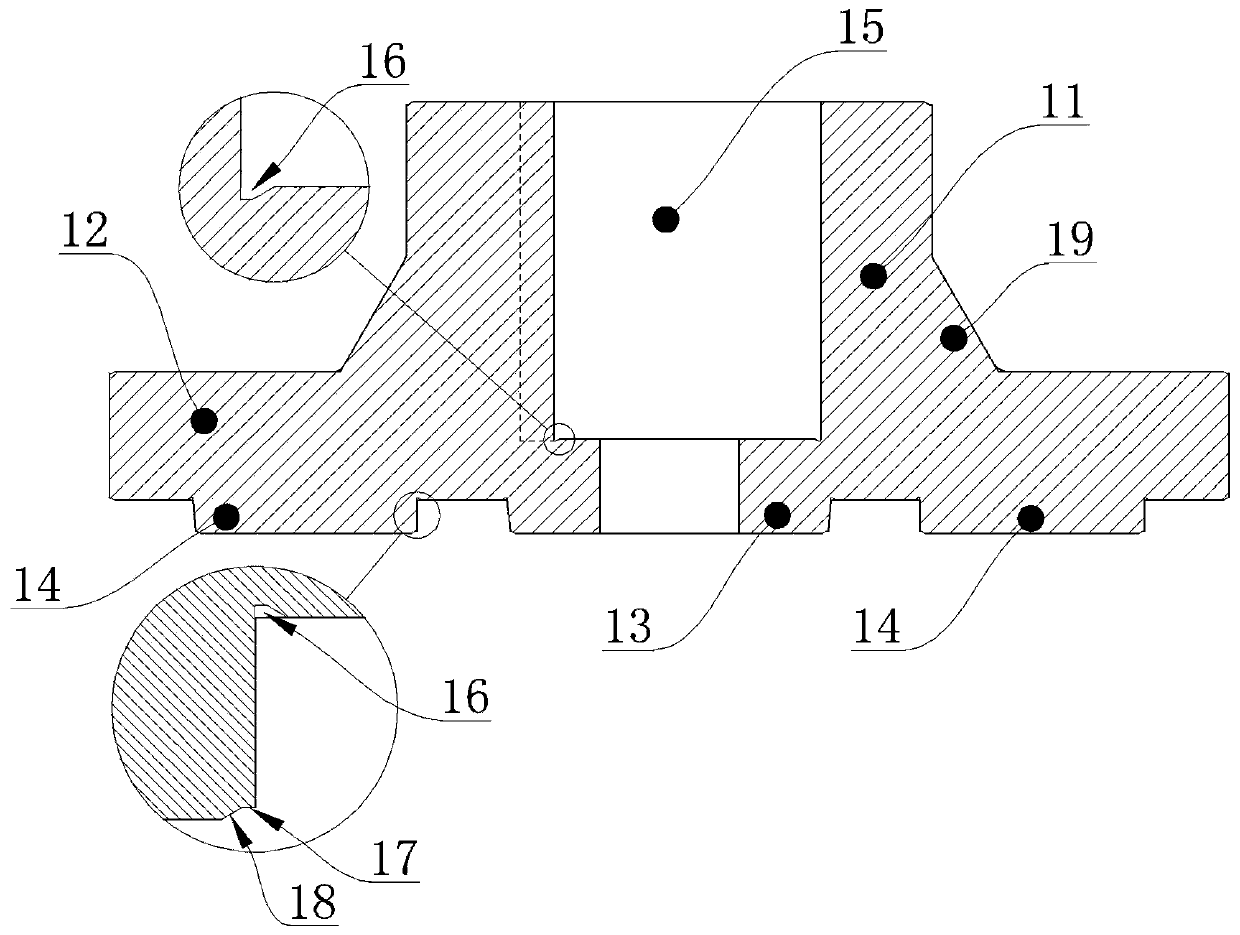

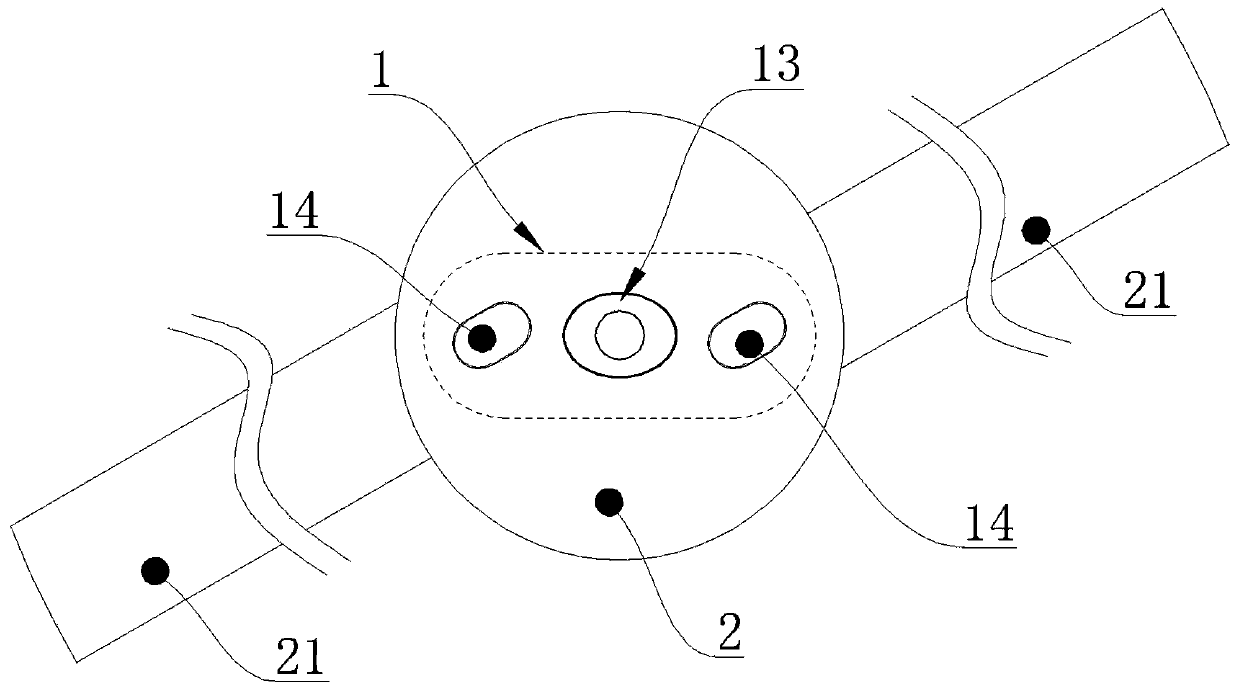

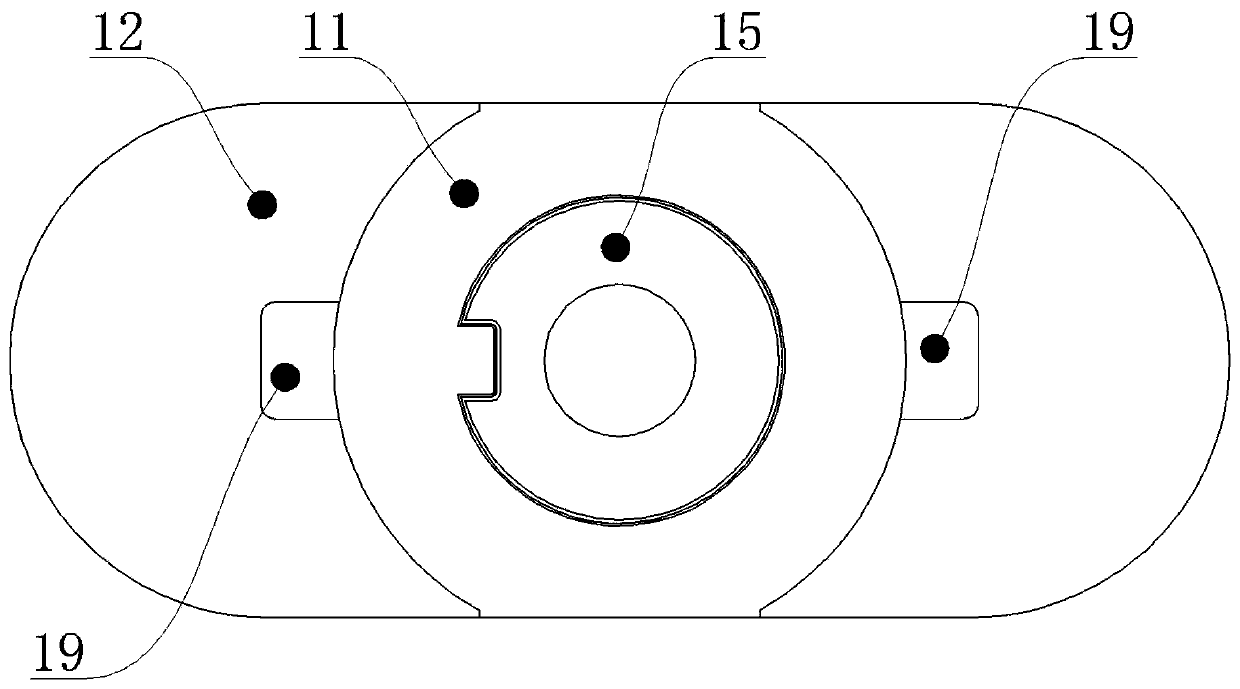

[0032] Such as Figure 1 to Figure 3 As shown, a kind of tool holder includes a mounting seat 11 formed by die-casting through a powder metallurgy process, one end of the mounting seat 11 is provided with a connecting seat 12, and both sides of the connecting seat 21 are provided with reinforcing ribs 19, and the mounting seat 11 is also provided with a connecting seat 12. One end is provided with a mounting protrusion 13 and a positioning protrusion 14 for installing the tool 2, and a number of annular stress grooves 16 are arranged on the mounting seat 11, and the annular stress grooves 16 respectively surround the outer circumference of the mounting protrusion 13 / positioning protrusion 14, through an integrated The annular stress groove 16 is formed by type die-casting to facilitate pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com