Focused ion beam sample preparation method for precisely positioning front-layer defects

A technology of focusing ion beams and precise positioning, which is applied in the preparation of test samples, material analysis by measuring secondary emissions, etc. It can solve the problems of optical lens observation quality, optical lens pollution, and impact on positioning, etc., to save defects The effect of positioning time, improving yield, and avoiding product loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

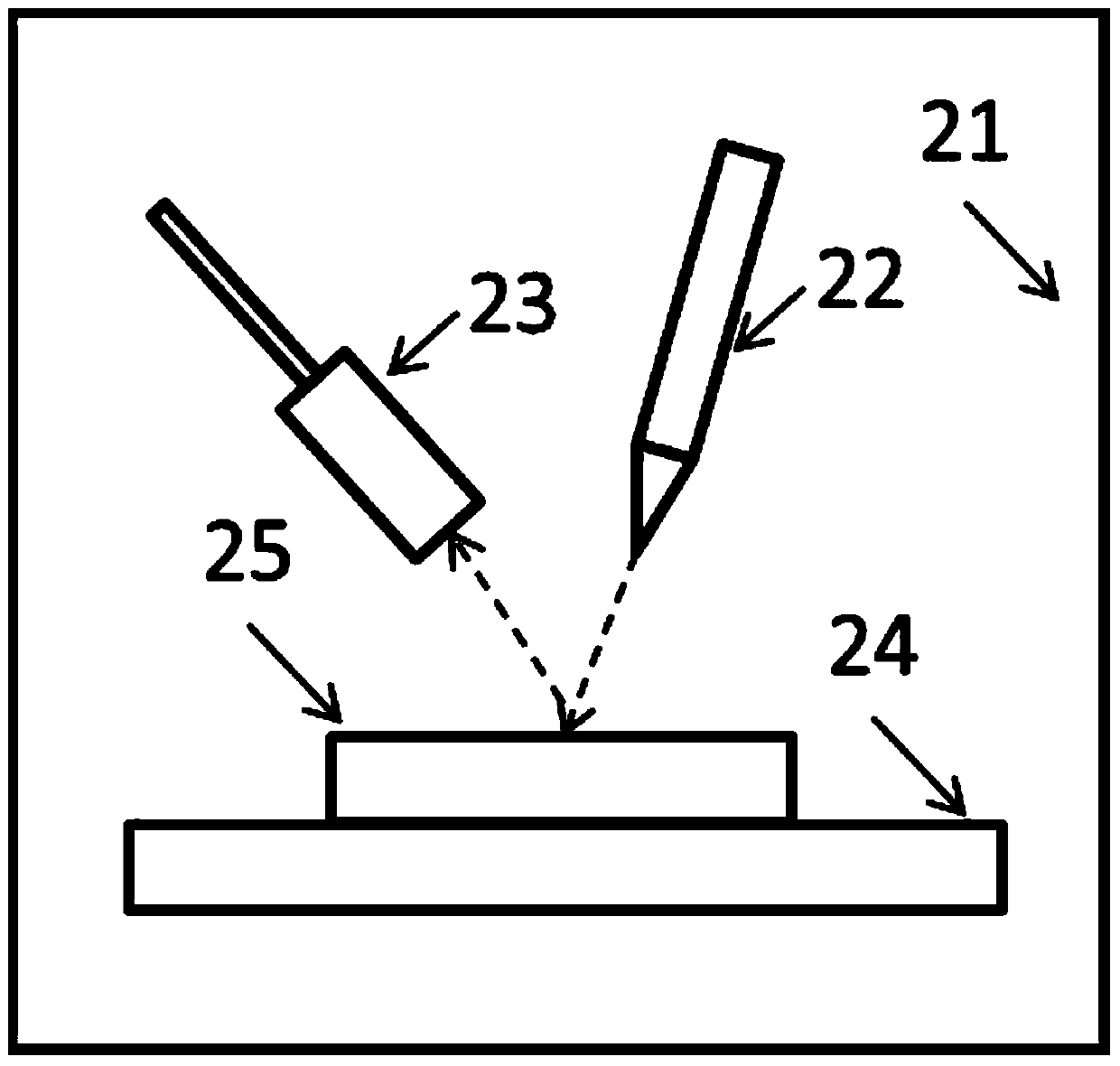

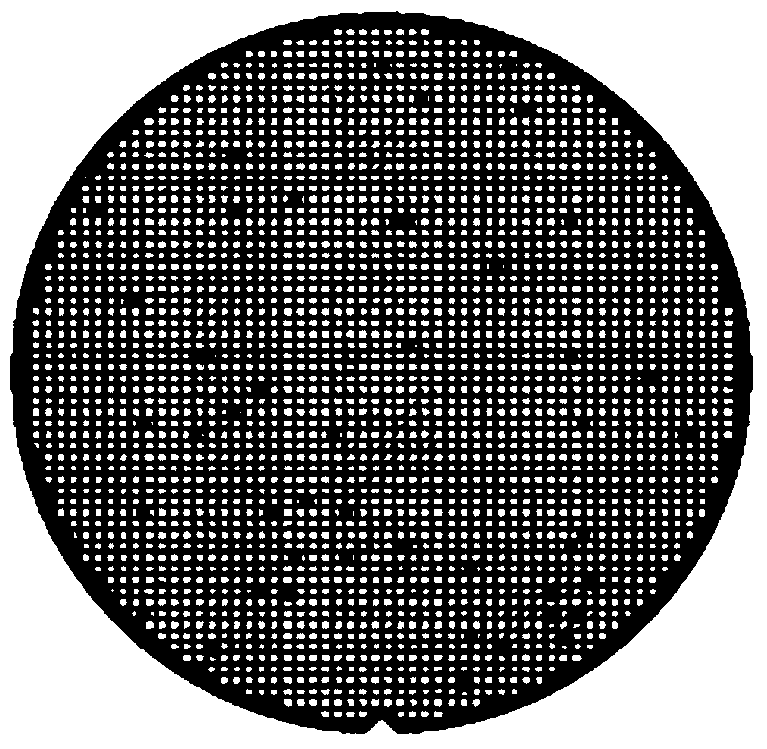

[0021] On-line defect inspection is performed on the wafer to find out the defects; in the case of finding out the defects, use a scanning electron microscope (SEM) or an optical microscope (OM, optical microscope) to observe the specific shape of the defect and infer the cause of the defect.

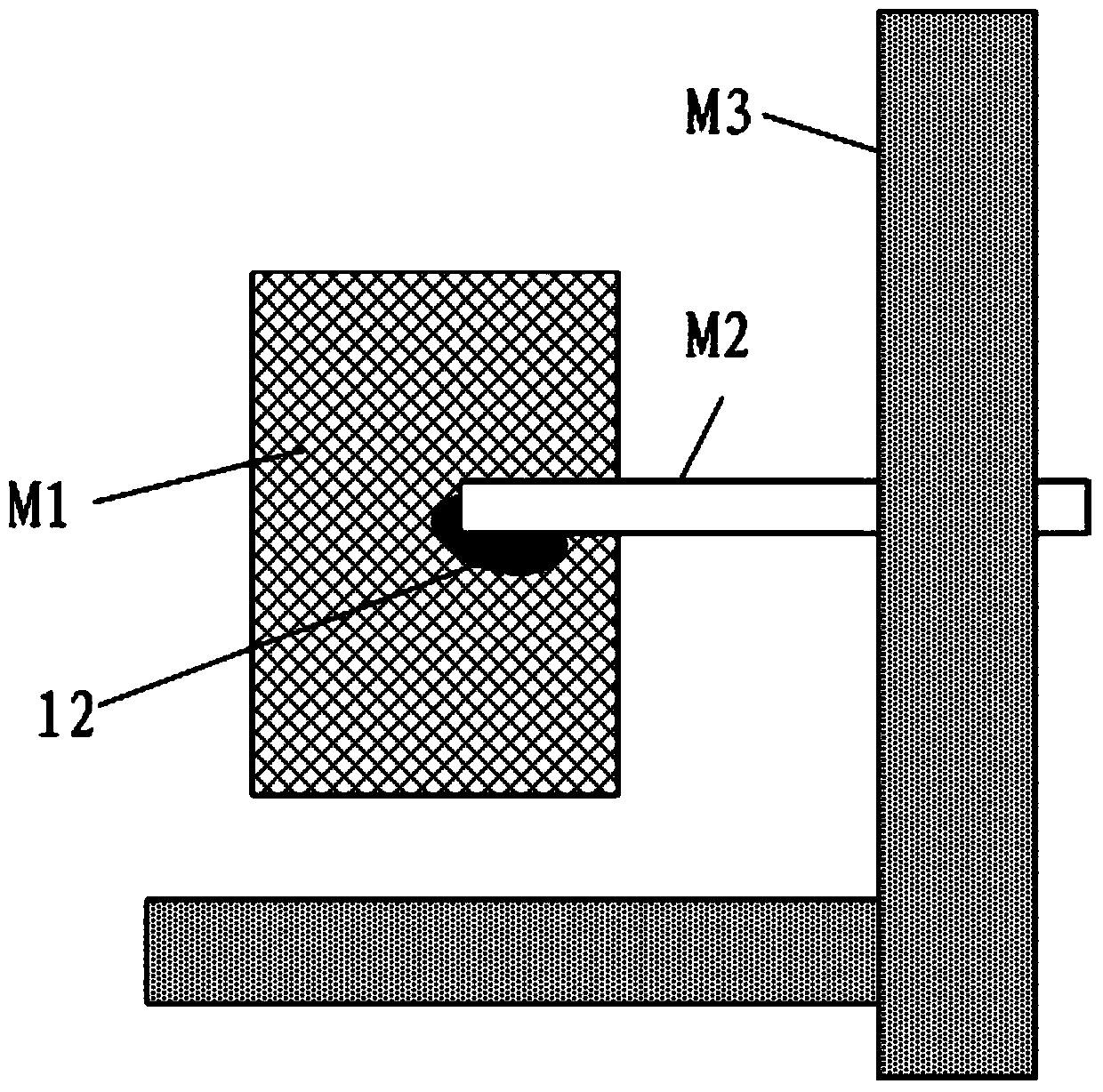

[0022] If the scanning electron microscope SEM cannot observe the defect or determine the cause of the defect, and the observation results of the optical microscope OM cannot determine the cause of the defect, then use the focused ion beam machine FIB failure analysis method to conduct a cross-sectional analysis of the defect, and according to the results Determine the cause of the defect.

[0023] If the scanning electron microscope SEM can observe the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com