In situ evaluation system and method of reliability of thin-film materials on flexible electronic substrate

A technology of thin film materials and electronic substrates, which is applied in the direction of testing the strength of materials by applying a stable bending force, can solve the problems that the resistance method of non-conductive thin film materials is not applicable, and the cracking and strain errors of thin film materials are large, so as to achieve simple preparation and improve testing The effect of high precision and high test precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

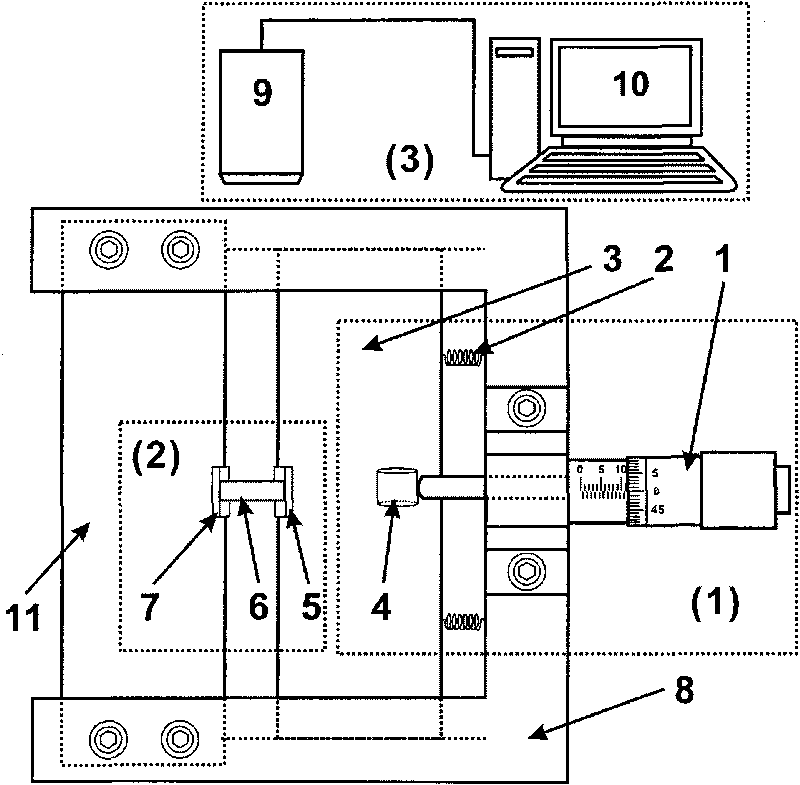

[0056] The principle diagram of the in-situ evaluation system of the present invention is as figure 1 shown.

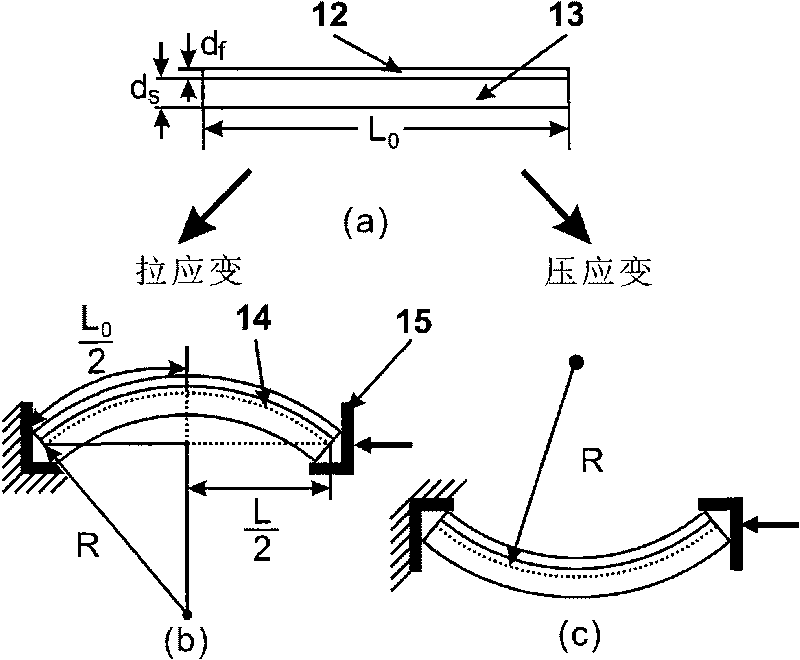

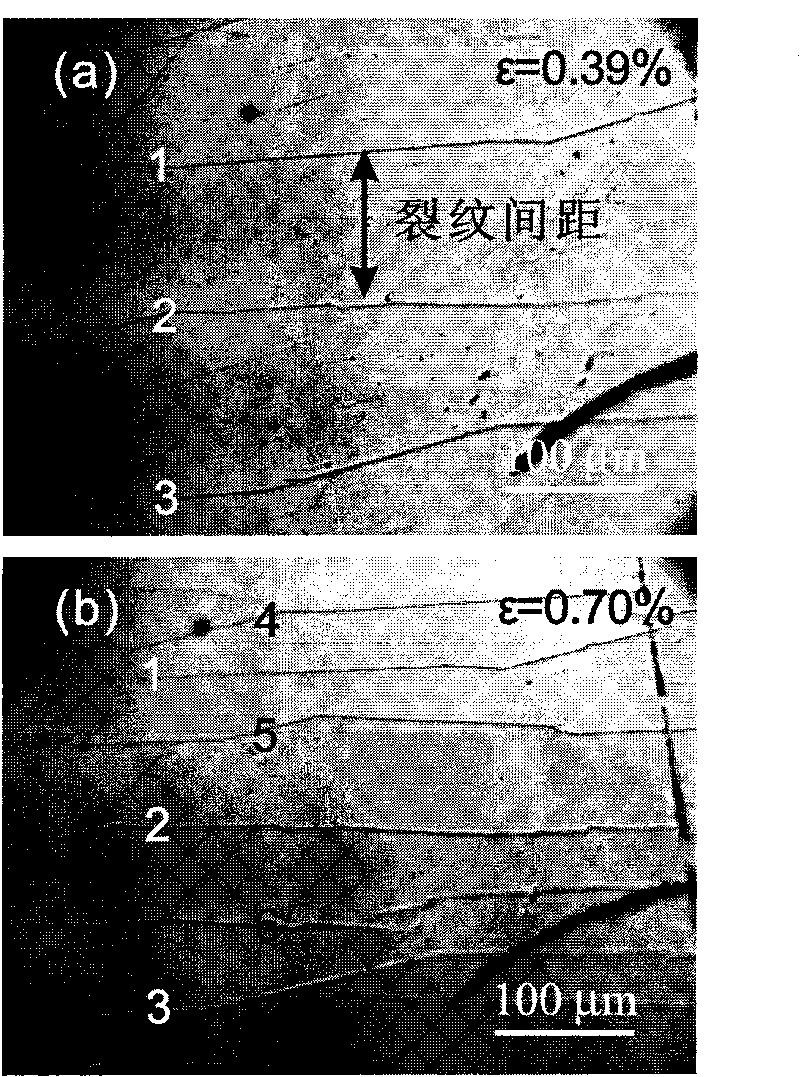

[0057] Cu-Ni multilayer films with a total thickness of 1 μm and a single layer thickness of 50 nm were prepared on a polyimide substrate with a thickness of 125 μm by magnetron sputtering. Cut the sample into a rectangle with a size of 12 mm x 2 mm. First, according to the original length of the sample, adjust the distance between the movable end of the simply supported beam and the fixed end of the simply supported beam of the test system to an appropriate distance that matches the size of the sample. according to figure 2 In the placement state shown in (b), the sample is placed above the simple support point 15, and the translational slider 3 is driven by the screw micrometer 1 and the balance spring 2 to move slightly horizontally, and the sample 6 is positively bent, so that the Cu-Ni multilayer film on polyimide substrate exerts constant tensile strain. Re...

Embodiment 2

[0059] Cu-Ta multilayer films with a total thickness of 1 μm and a single layer thickness of 50 nm were prepared on a polyimide substrate with a thickness of 125 μm by magnetron sputtering. Cut the sample into a rectangle with a size of 12 mm x 2 mm. First, adjust the distance between the movable end of the simply supported beam and the fixed end of the simply supported beam of the test system to an appropriate distance according to the original length of the sample, such as figure 2 As shown in (c), in this placement state, the sample is placed on a simple support point, and the translational slider 3 is driven to move horizontally by the screw micrometer 1 and the balance spring 2, and the sample 6 is reversed, so that the polyimide The Cu-Ta multilayer film on the substrate exerts a constant compressive strain. Record the distance L of the simple support point, and simultaneously collect images of the surface topography of the sample through a high-power optical microscop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com