System and method for testing bending fatigue reliability of low dimensional conducting material

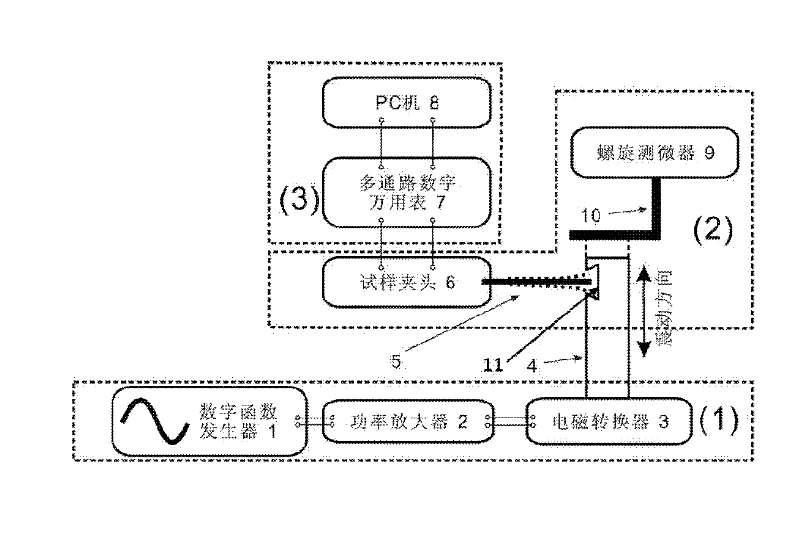

A conductive material, bending fatigue technology, applied in the field of bending fatigue reliability test system, can solve the problems of large fatigue life measurement error of conductive film material, inability to accurately measure crack initiation life, fatigue and other problems, to achieve a wide range of fatigue test, measurement Precise, easy-to-prepare results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

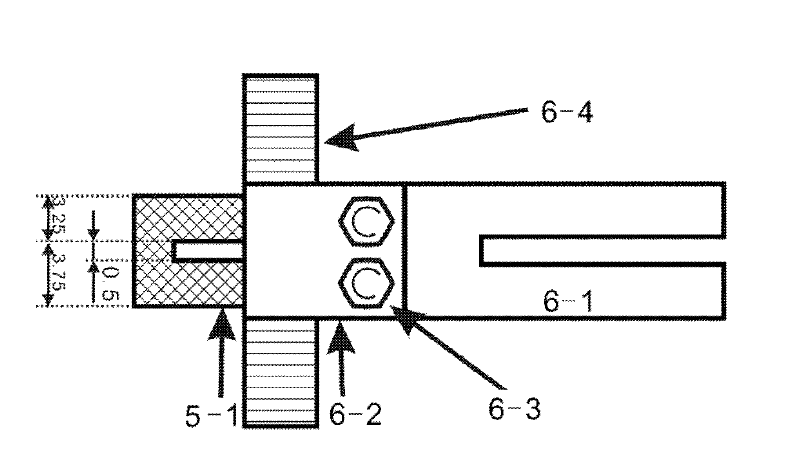

[0063] The metal nickel foil with a thickness of 50μm is mechanically polished and electrolytically polished, the thickness of the tested conductive sample 5 is 34μm, and it is cut into a U-shaped small-scale tested conductive sample 5-1, and the sample is fixed on On the sample holder 6, the effective length of the cantilever beam is selected as 3mm, and the assembly diagram of the sample and the sample holder 6 device is shown in Figure 2. Before the fatigue test, the uniaxial tensile test was used to obtain the tensile stress-strain curve of the nickel foil to obtain the constitutive relationship in the finite element simulation. Using the constitutive relationship, the maximum strain at the root of the sample was calculated to be 1.0921%. A sine wave with a frequency of 50 Hz is selected as the loading fatigue waveform, the sample amplitude is 2 mm, and the tension-compression symmetric fatigue loading is adopted. From the real-time resistance value of the sample measured d...

Embodiment 2

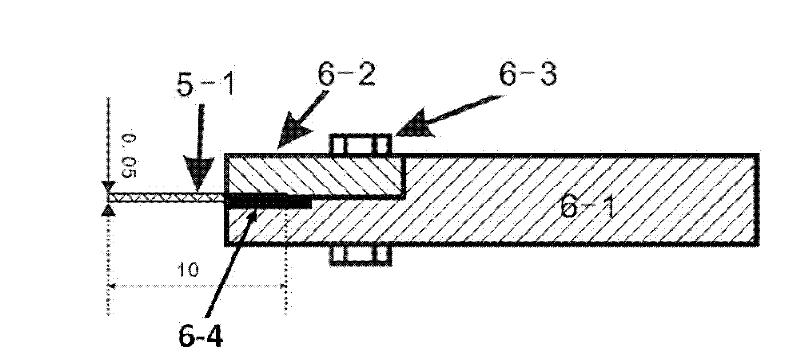

[0065] The drawn pure copper wire with a diameter of 25μm is bent into an arc, and its two ends are fixed on the clamp 6. The length of the filament cantilever is selected to be 3.5mm, as shown in the assembly drawing Figure 4 Shown. Before the fatigue test, the tensile stress-strain curve of the copper wire was obtained by the uniaxial tensile test to obtain the constitutive relationship in the finite element simulation. The maximum strain at the root of the sample was calculated by using the constitutive relationship to be 8.5%. A sine wave with a frequency of 50 Hz is selected as the loading fatigue waveform, the amplitude of the sample is 2 mm, and the tension-compression symmetrical fatigue loading is adopted. A multi-channel digital multimeter was used to collect the resistance value of the sample during the fatigue experiment. From the real-time resistance value of the sample measured during the fatigue experiment, the relative change rate of the sample resistance is ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com