Method for cleaning solar cell silicon wafer after polishing

A technology for polishing solar cells and silicon wafers, which is applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., which can solve problems such as efficiency reduction and leakage, and achieve good texturing effects and a wide process control window , The effect of increasing the open circuit voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

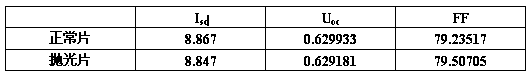

Embodiment 1

[0026] The method for cleaning solar cell silicon wafers after polishing of the present invention is used to clean the silicon wafers after polishing and before texturing, and the specific processing steps of polishing, cleaning and texturing of solar cell silicon wafers are as follows:

[0027] 1. Chemically clean the silicon wafer, and polish both sides of the silicon wafer with hot alkali.

[0028] 1. Cleaning the polished silicon wafer with hydrofluoric acid can remove the residual alkali in the polishing process.

[0029] , Perform mixed acid pickling, alkali cleaning, acid cleaning, and water washing on silicon wafers. Wherein the mixed acid adopts the mixed acid of hydrofluoric acid and nitric acid, and the volume ratio of hydrofluoric acid to nitric acid and water is 1:3:2; the sodium hydroxide solution with a mass fraction of 5% is used for alkali cleaning; then The volume fraction of the acid is 10% mixed acid of hydrofluoric acid and hydrochloric acid for a...

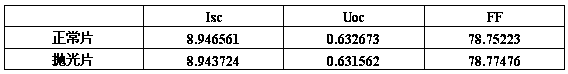

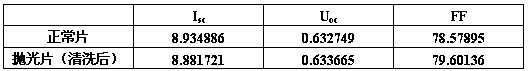

Embodiment 2

[0044] The method for cleaning solar cell silicon wafers after polishing of the present invention is used to clean the silicon wafers after polishing and before texturing, and the specific processing steps of polishing, cleaning and texturing of solar cell silicon wafers are as follows:

[0045] 1. Chemically clean silicon wafers and perform double-sided polishing process.

[0046] , Cleaning the silicon wafer with hydrofluoric acid can remove the residual alkali in the polishing process;

[0047] 3. Perform mixed acid pickling, alkali cleaning, acid cleaning, and water washing on silicon wafers. Wherein mixed acid adopts the mixed acid of hydrofluoric acid, nitric acid and sulfuric acid, and the volume ratio of hydrofluoric acid, nitric acid, sulfuric acid and water is 1:3:1:2; Then carry out alkaline cleaning with 3% potassium hydroxide solution; Then Use a mixed acid of hydrofluoric acid and hydrochloric acid with a volume fraction of 10% hydrofluoric acid for acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com