On-line detection method and system for wafer

A wafer and inspection station technology, applied in the field of wafer online inspection methods and systems, can solve problems such as delaying product time, reducing inspection effects, and failing to make full use of inspection station inspection capabilities, so as to improve rationality and prevent product production time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

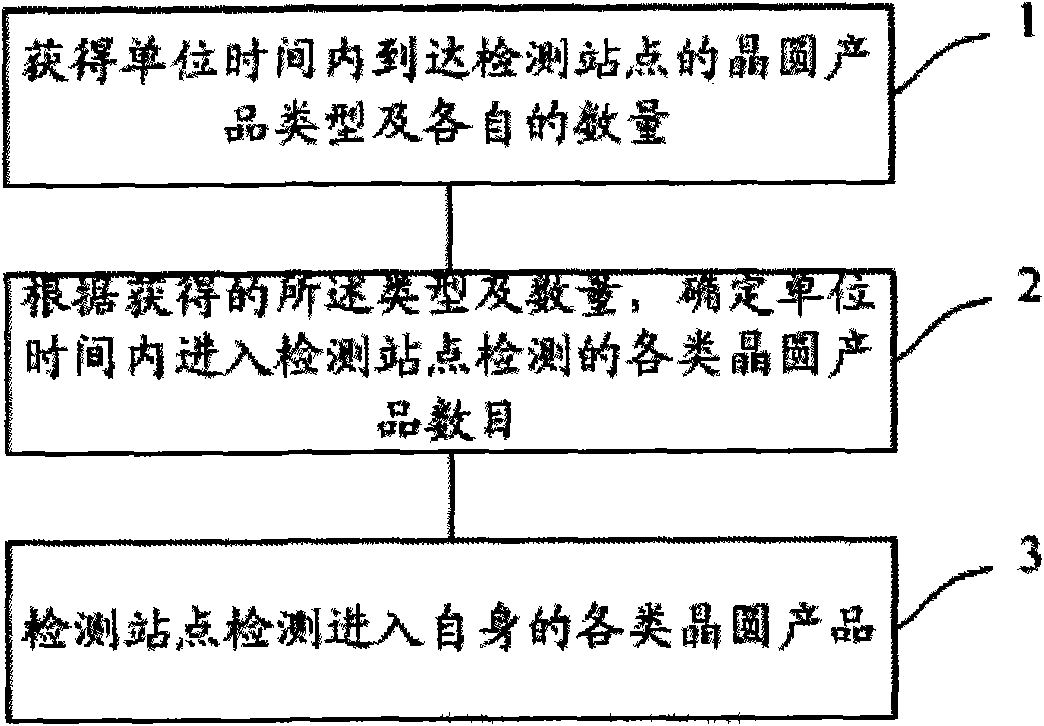

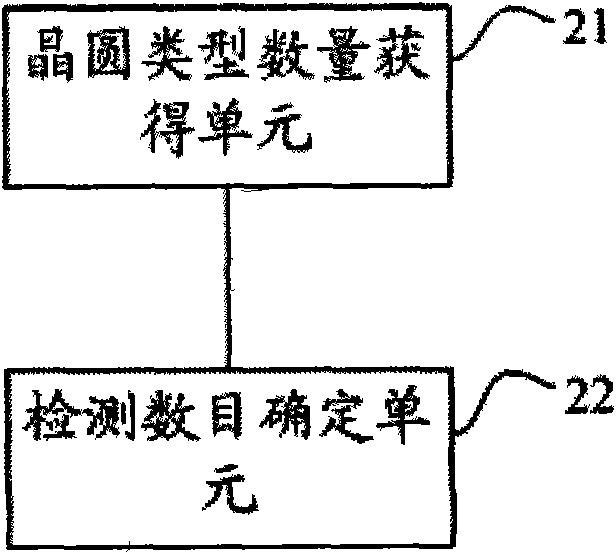

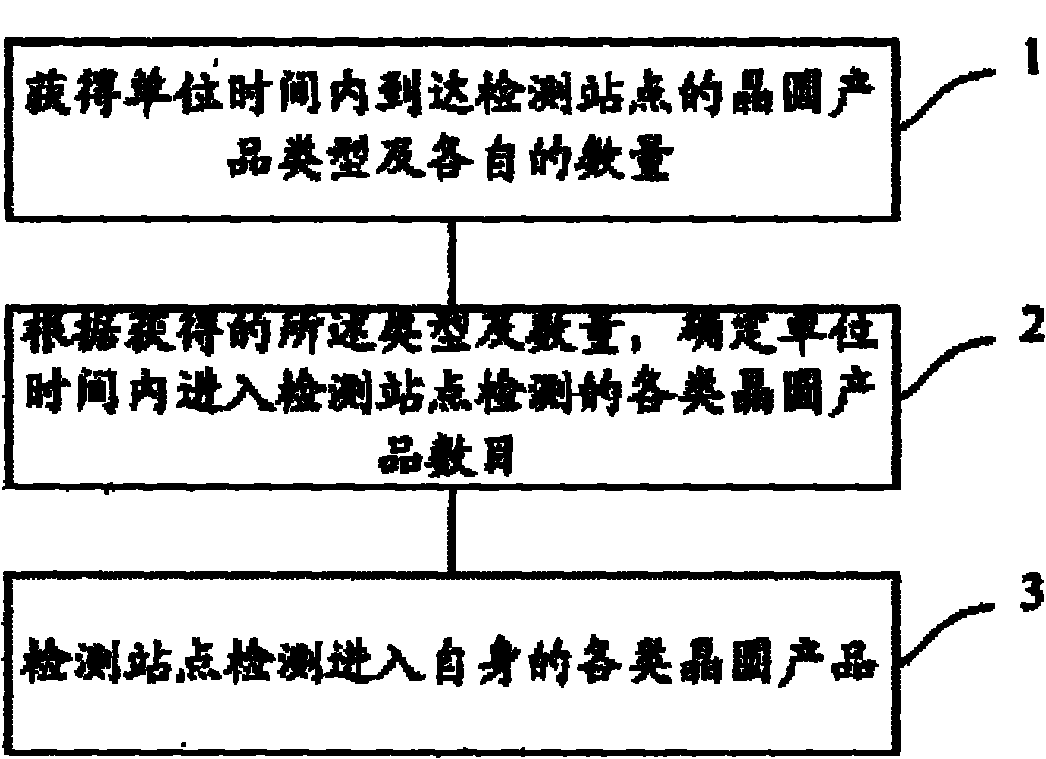

[0018] First, obtain the type of wafer product that arrives at the inspection site from the dispatch order, which is a well-known term in the art, including the type of product produced, and information such as which stations each product needs to pass through; then for various wafer products , respectively perform the following operations a1 to a3 until the number of all types of wafer products arriving at the inspection site is calculated:

[0019] a1, determine the processing sites that this type of wafer products need to pass through before the testing site;

[0020] a2, add up the time it takes for each processing site to process the wafer product in process and the time for the wafer product in process to wait for processing before the processing site;

[0021] In step a2, obtaining the time that the wafer product waits for processing before the processing site can also be realized in a variety of ways, preferably in this embodiment, it also includes determining the wait...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com