Pre-alignment device and pre-alignment method applied to same

A pre-alignment and initial position technology, applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve problems such as machine downtime, no sensor to detect wafers, and impact on wafer product output, etc., to achieve The effect of improving detection efficiency, increasing output, and preventing machine downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]At present, before the machine fails, during the process that the machine transports the wafer to the pre-alignment device for calibration, the pre-alignment device does not detect the position of the wafer, and the pre-alignment device does not The sensor is used to detect the position information of the wafer; until the pre-alignment device cannot find the gap of the wafer and the machine is shut down, the engineer will not know the process of the machine transporting the wafer to the pre-alignment device for position calibration , there is a problem with the position of the machine to place the wafer on the carrier table in the pre-alignment device, and then the machine must not be stopped to manually calibrate the position of the machine to place the wafer. In this way, the calibration efficiency of the machine is seriously affected, thereby affecting the output of wafer products.

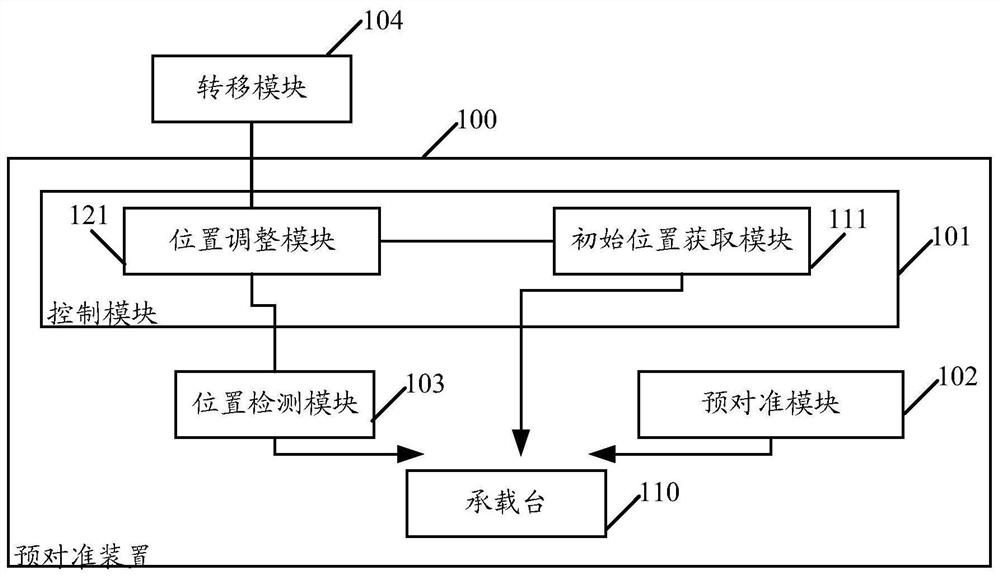

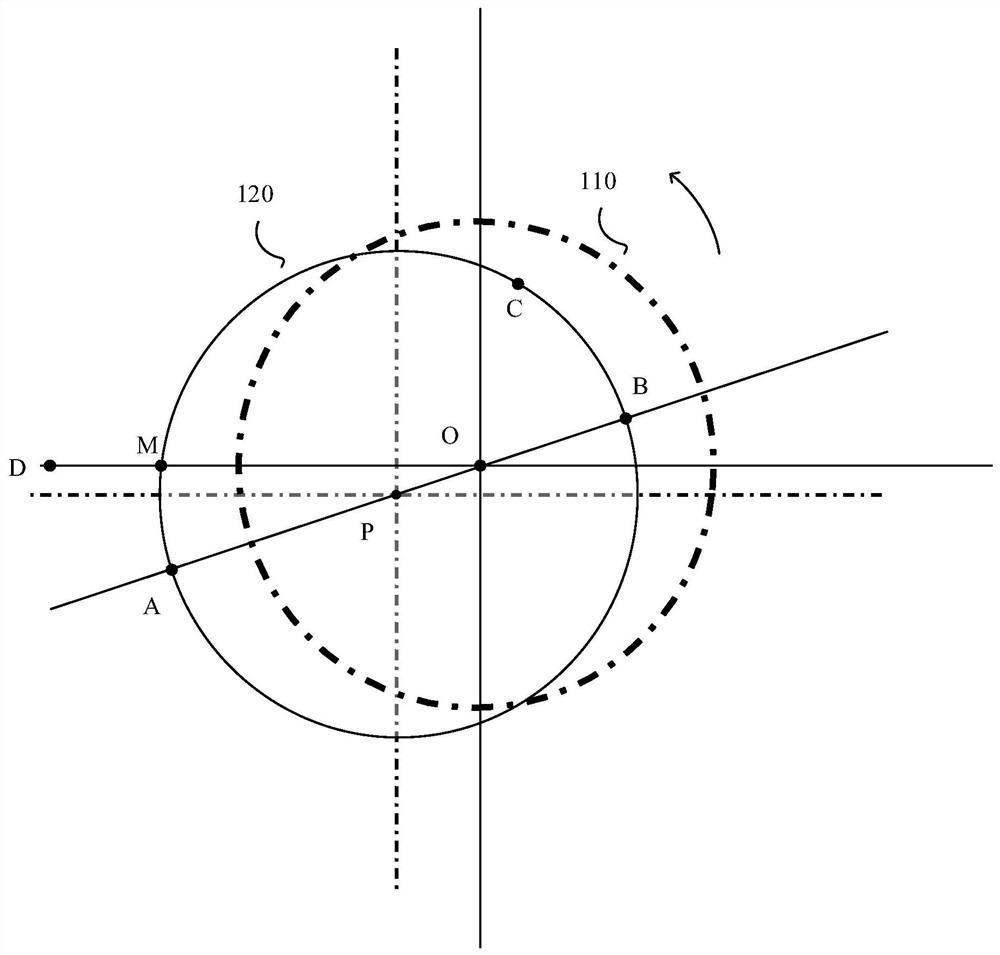

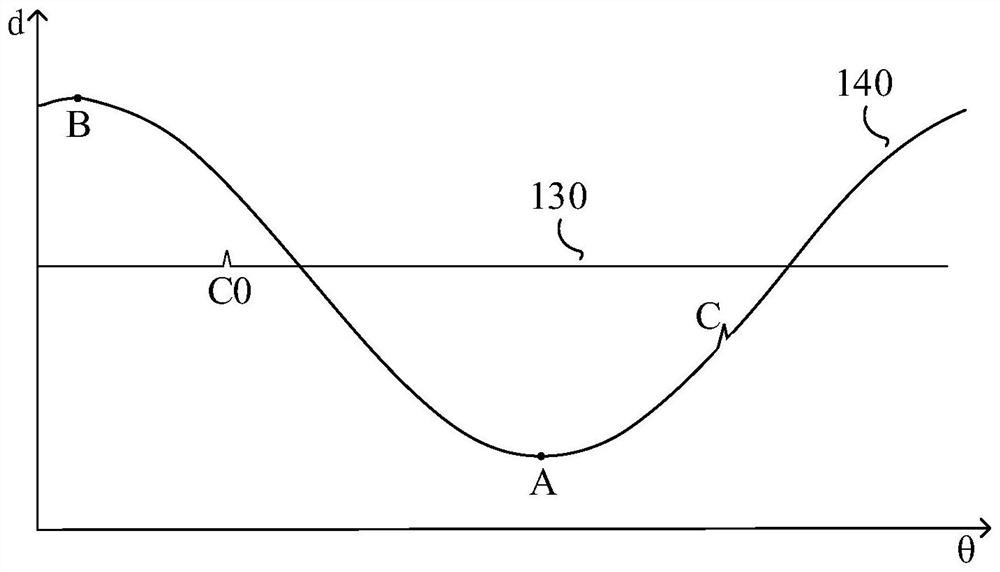

[0032] In order to solve the above problems, the first embodiment of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com