Inductance coupling coil and plasma device

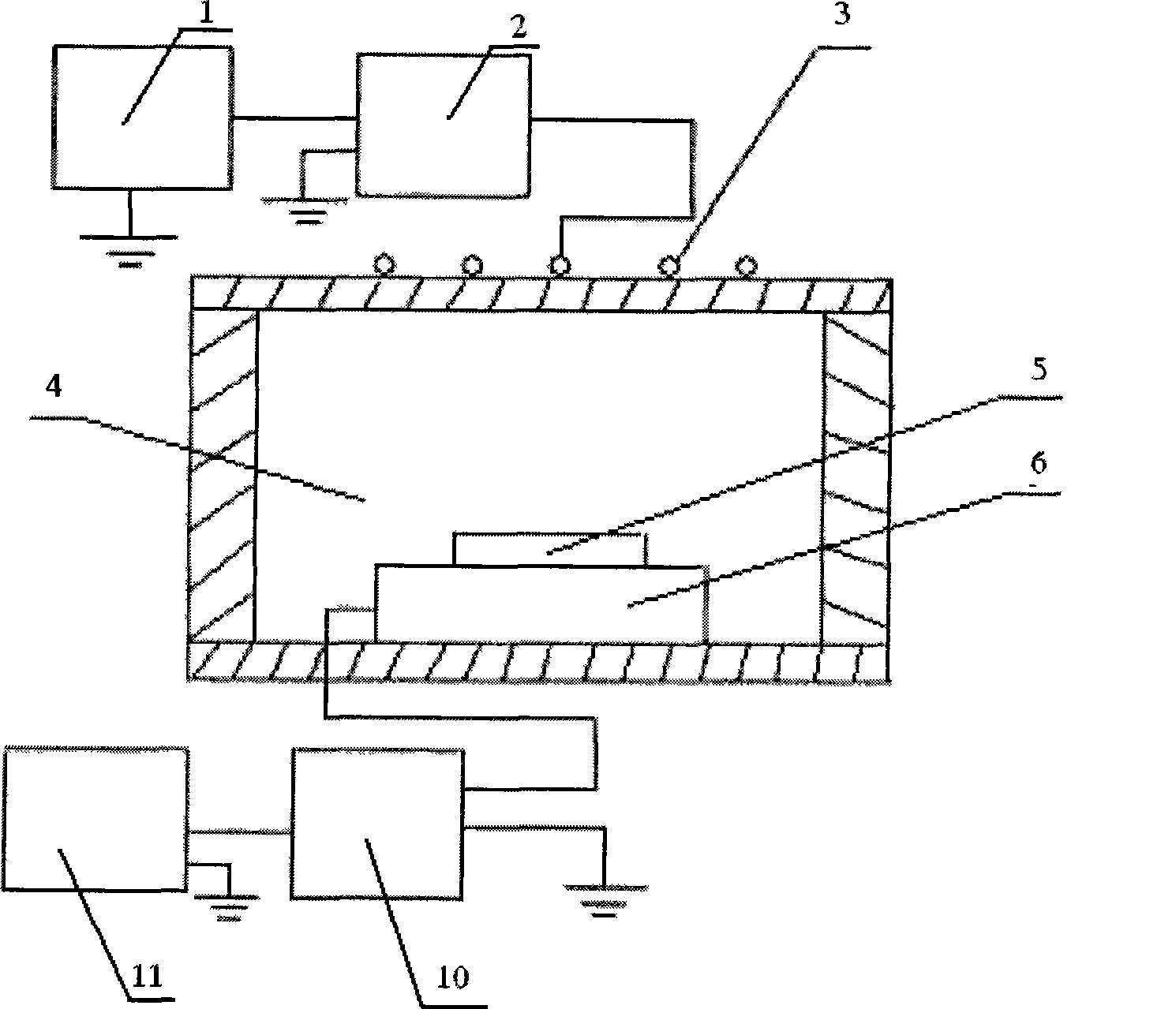

An inductively coupled coil and inductive coupling technology, applied in the directions of plasma, coils, inductors, etc., can solve the problem of uneven plasma density distribution, and achieve the effect of improving distribution uniformity, small difference in chemical reaction rate, and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

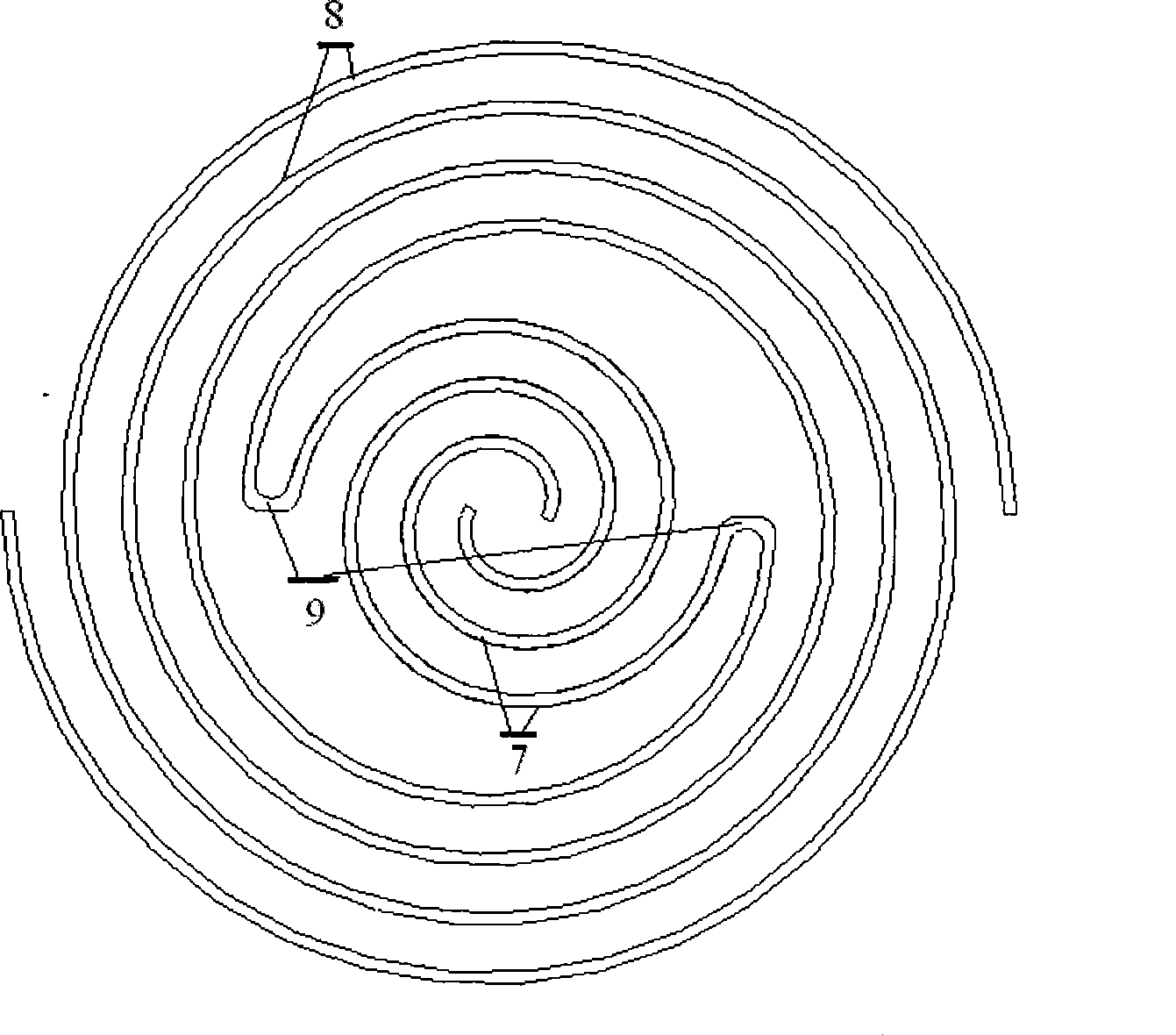

[0027] Such as image 3 As shown in the schematic diagram of the inductive coupling coil structure, the inductive coupling coil includes two identical branches, each branch is composed of an inner coil 7 and an outer coil 8, and the end of the inner coil 7 and the beginning of the outer coil 8 are connected in series by a connecting section 9; The inner and outer coils of the two branches are symmetrically nested and coplanar. The inner coil 7 and the outer coil 8 of each branch are helical and have opposite winding directions, that is, when the inner coil 7 is wound clockwise, the outer coil 8 is wound counterclockwise, or when the inner coil 7 is wound in the opposite direction When clockwise, the winding direction of the outer coil 8 is clockwise. The entire coil is a planar coil.

Embodiment 2

[0029] Such as Figure 4 As shown in the schematic diagram of the structure of the inductive coupling coil, the inductive coupling coil includes two identical branches. Each branch is composed of an inner coil 7 and an outer coil 8. The end of the inner coil 7 and the beginning of the outer coil 8 are connected in series by a connecting section 9. The inner and outer coils of the two branches are symmetrically nested and coplanar. The inner coil 7 of each branch is arc-shaped, and the outer coil 8 is spiral-shaped. The winding directions of the inner coil 7 and the outer coil 8 are opposite, that is, when the inner coil 7 is wound clockwise, the outer coil 8 is wound counterclockwise. Or when the winding direction of the inner coil 7 is counterclockwise, the winding direction of the outer coil 8 is clockwise. The entire coil is a planar coil.

Embodiment 3

[0031] Such as Figure 5 As shown in the schematic diagram of the structure of the inductive coupling coil, the inductive coupling coil includes two identical branches. Each branch is composed of an inner coil 7 and an outer coil 8. The end of the inner coil 7 and the beginning of the outer coil 8 are connected in series by a connecting section 9. The inner and outer coils of the two branches are symmetrically nested and coplanar. The inner coil 7 of each branched coil is arc-shaped, and the outer coil 8 is formed by connecting multiple arc-shaped coils with successively increasing radii of curvature through the outer coil connecting section 15 in series. The winding directions of the inner coil 7 and the outer coil 8 are opposite, that is, when the inner coil 7 is wound clockwise, the outer coil 8 is wound counterclockwise, or when the inner coil 7 is wound counterclockwise, the outer coil 8 The winding direction is clockwise. The entire coil is a planar coil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com