Film deposition apparatus

A deposition device and film layer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as unbalanced curvature distribution, and achieve the effect of improving quality and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

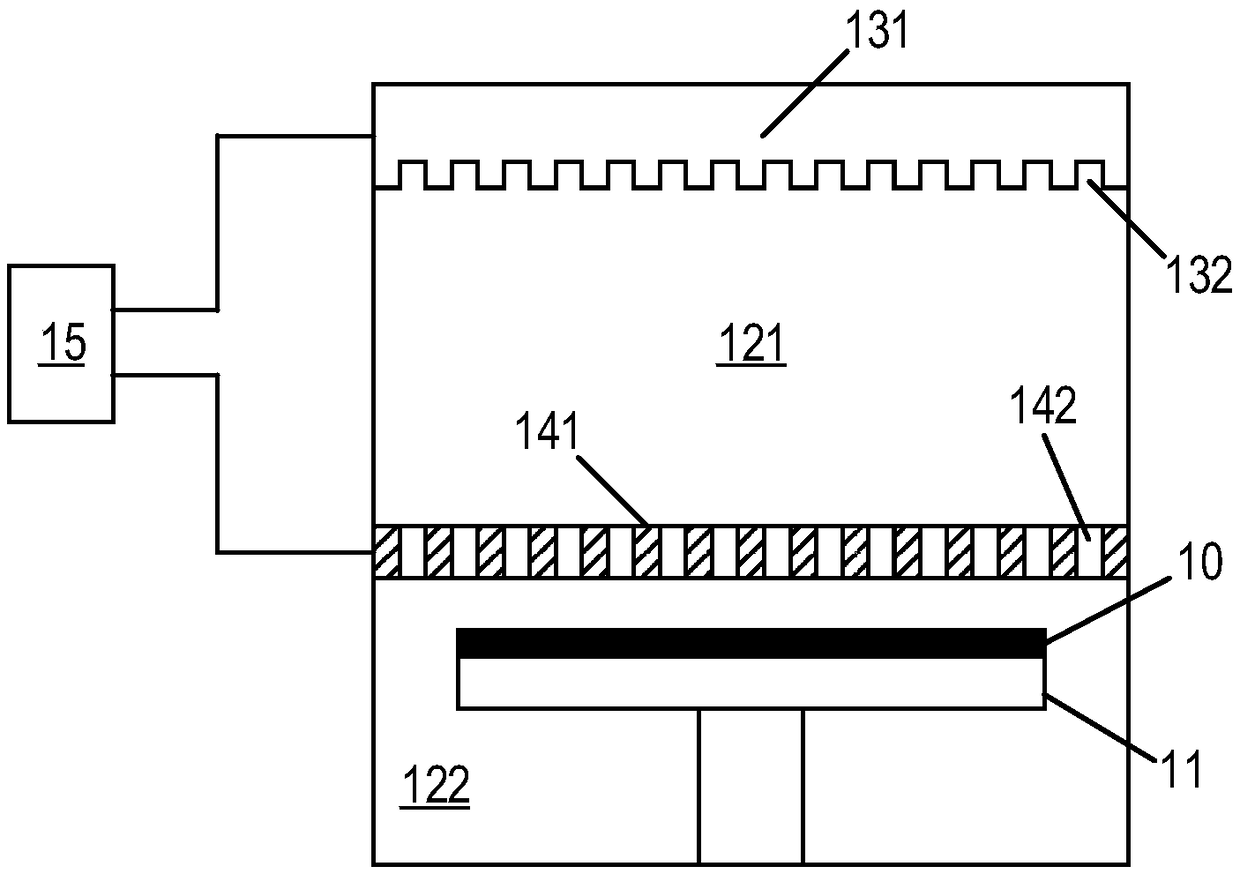

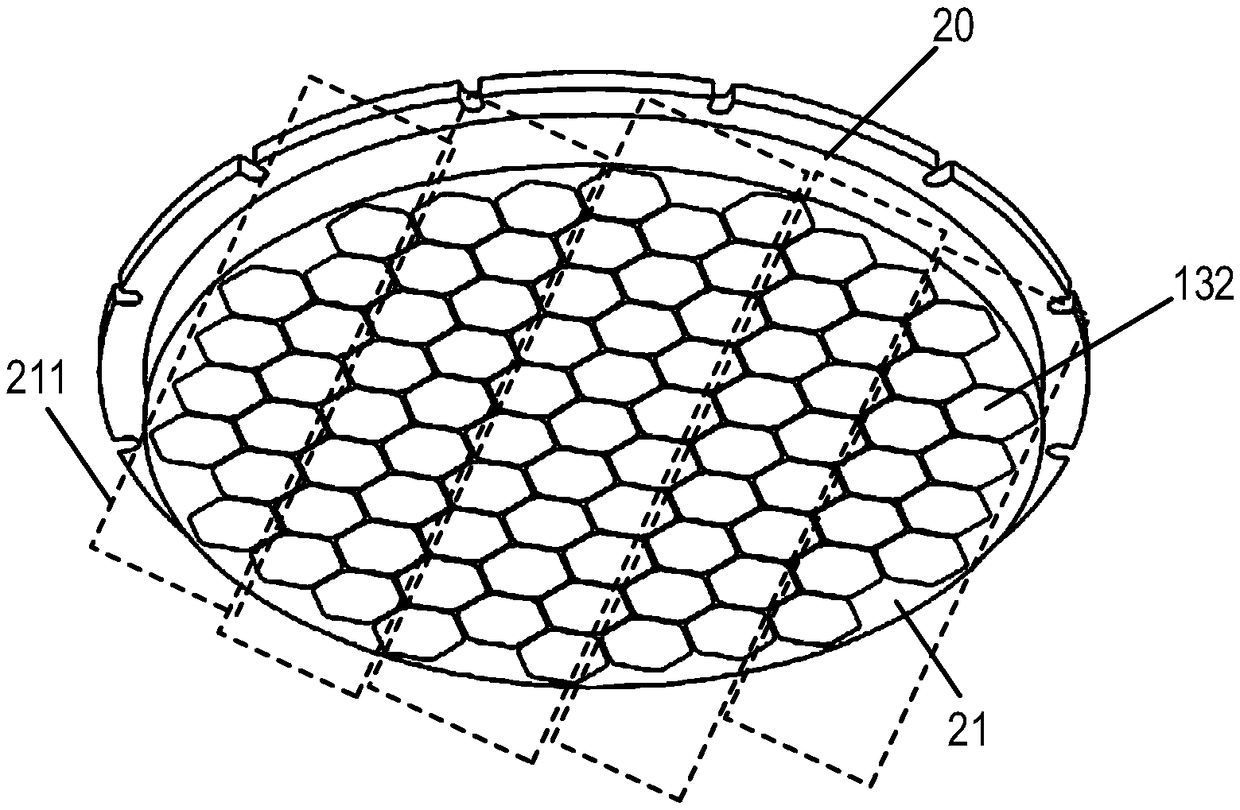

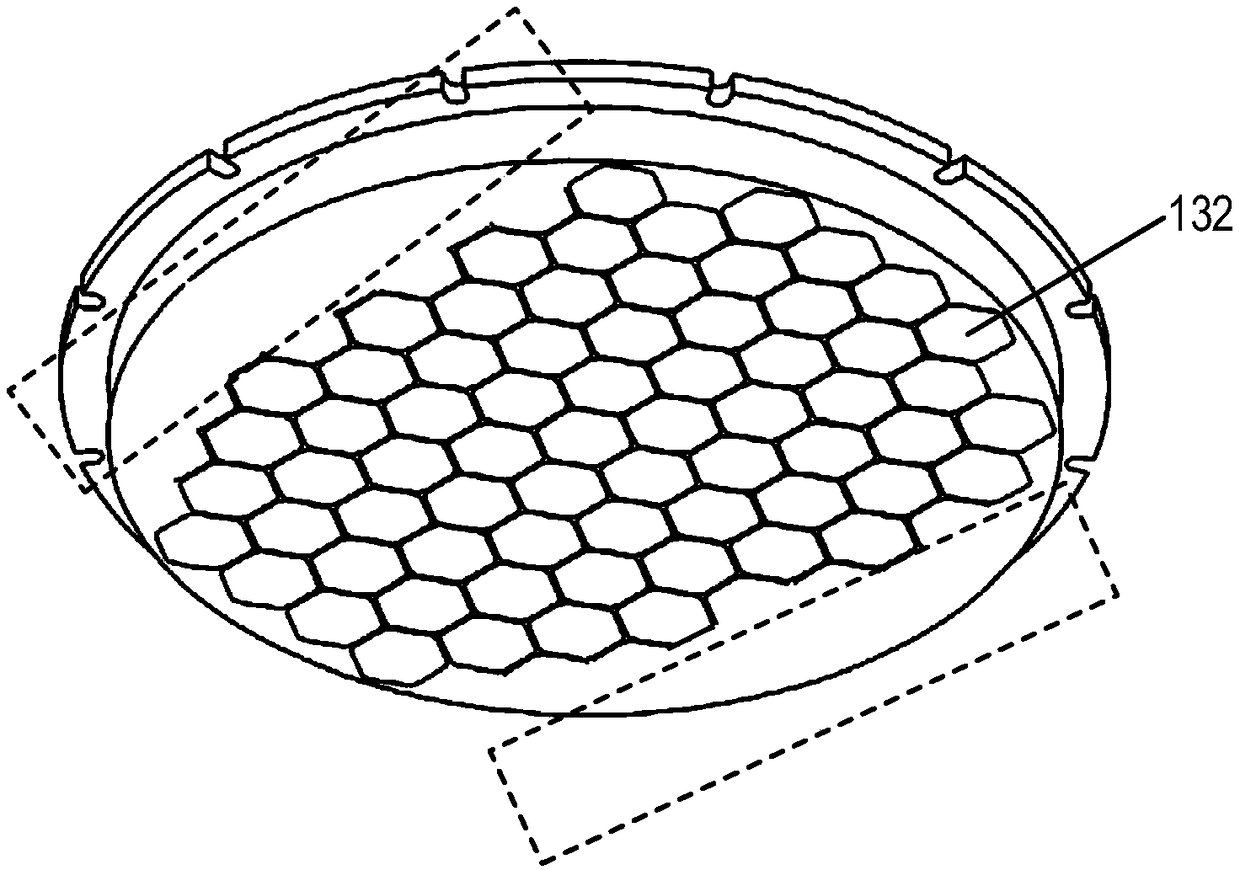

[0029] The specific implementation of the film deposition device provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0030] During the manufacturing process of the wafer and the subsequent process of manufacturing electronic components on the surface of the wafer, the curvature distribution of the wafer may be unbalanced, resulting in warping of the wafer. The occurrence of wafer warpage will cause many problems, such as the peeling off of the laminated film on the wafer surface, wafer cracking, unstable layout alignment performance, and the sucker of the subsequent process cannot hold the wafer, etc., and the subsequent process cannot be completed, which will eventually lead to Instable performance of wafer products, and reduced yield and yield of wafer products.

[0031] Bowl-shaped wafers are a common unbalanced state of wafer bow distribution. For bowl-shaped wafers, the way to balance the curvature distributi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com