Patents

Literature

99 results about "Pulsed laser irradiation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser spot control in maldi mass spectrometers

ActiveUS20130056628A1Improve overall utilizationImprove utilityTime-of-flight spectrometersIsotope separationDesorptionLight beam

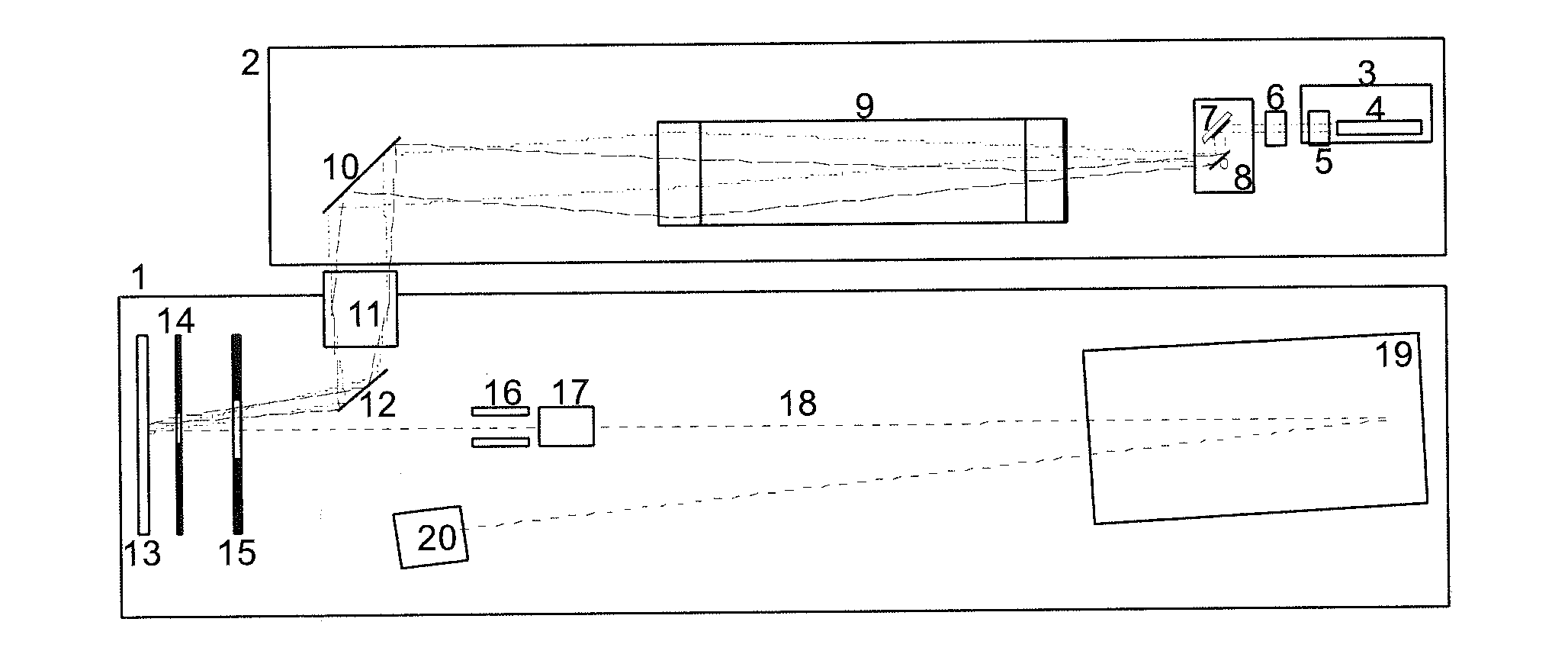

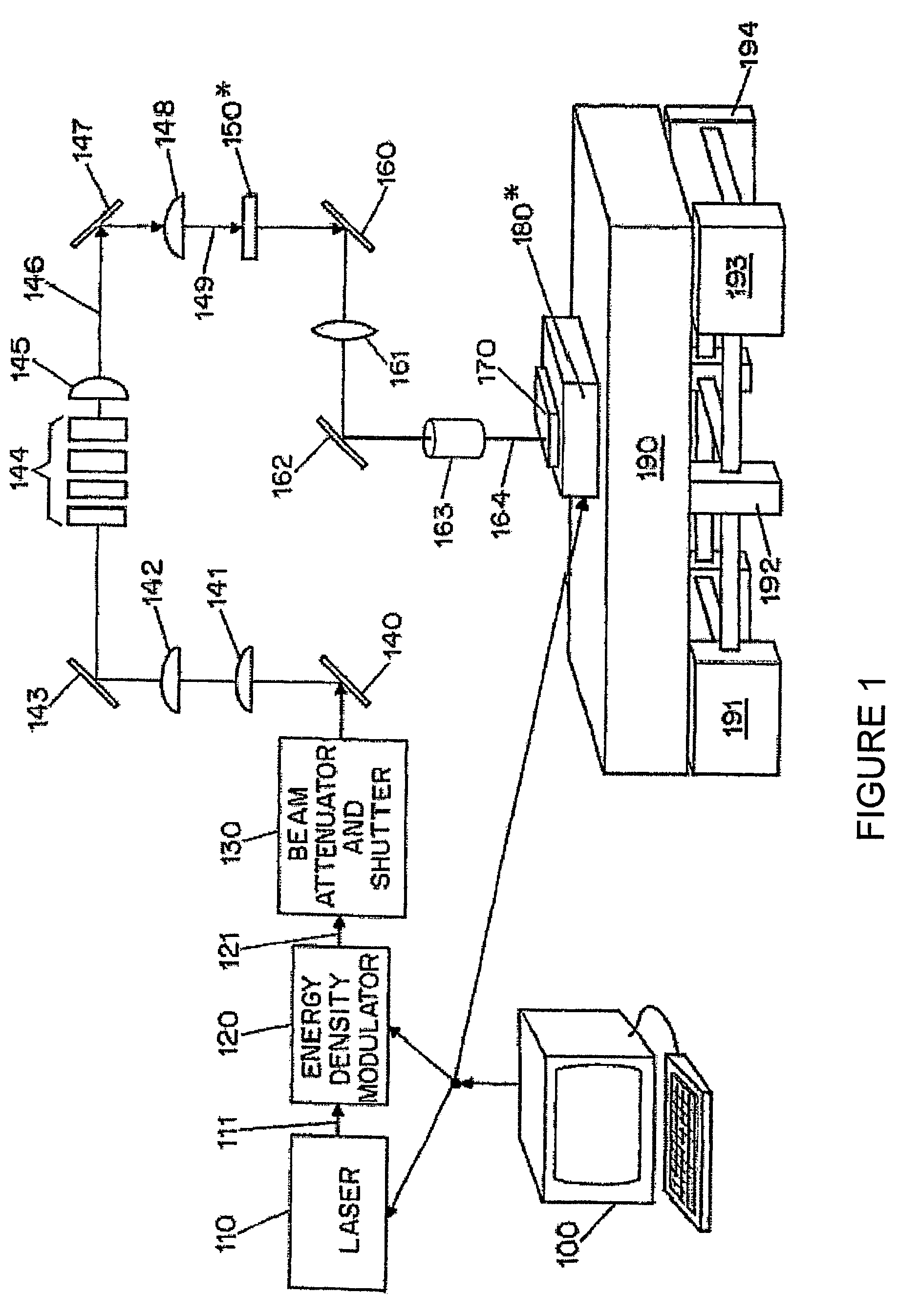

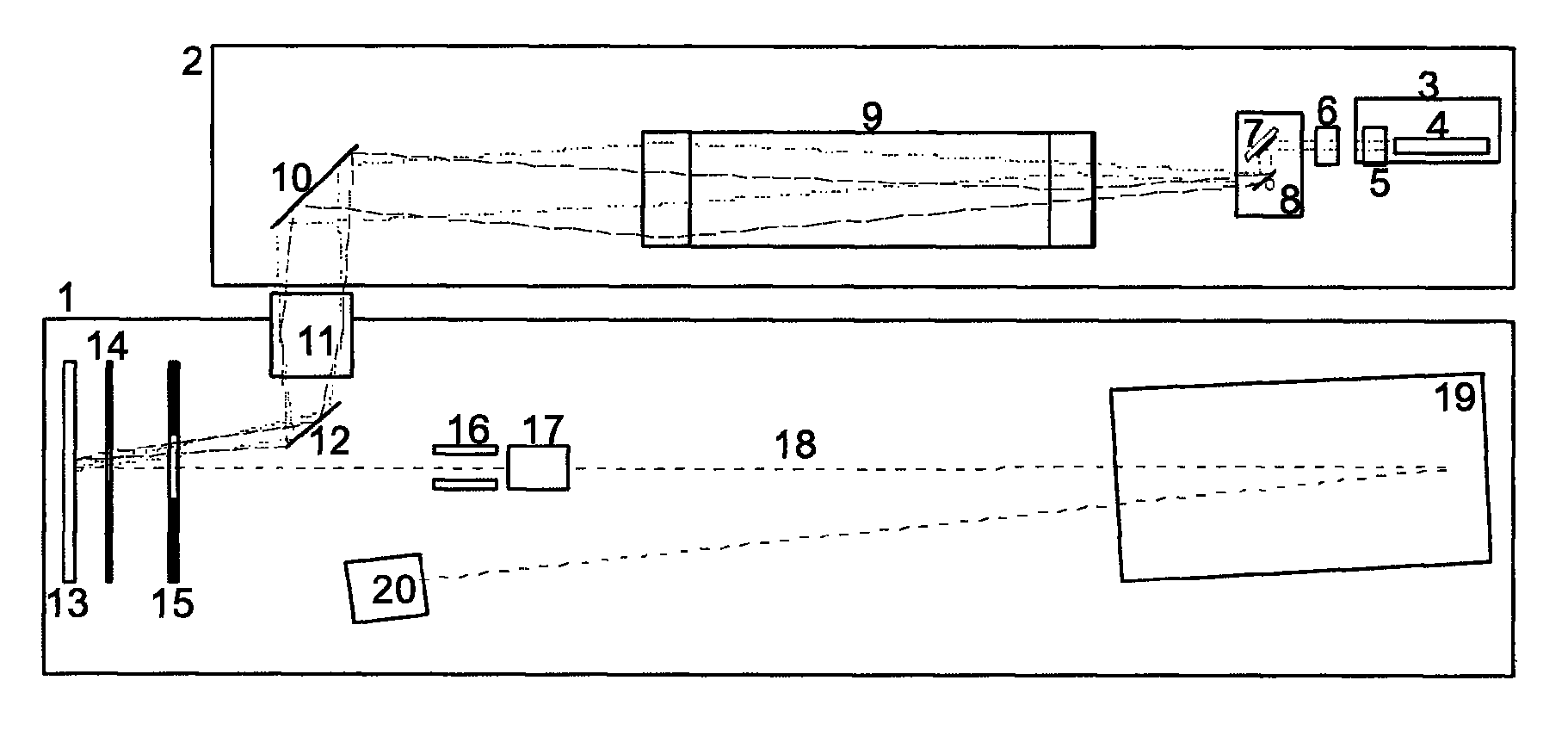

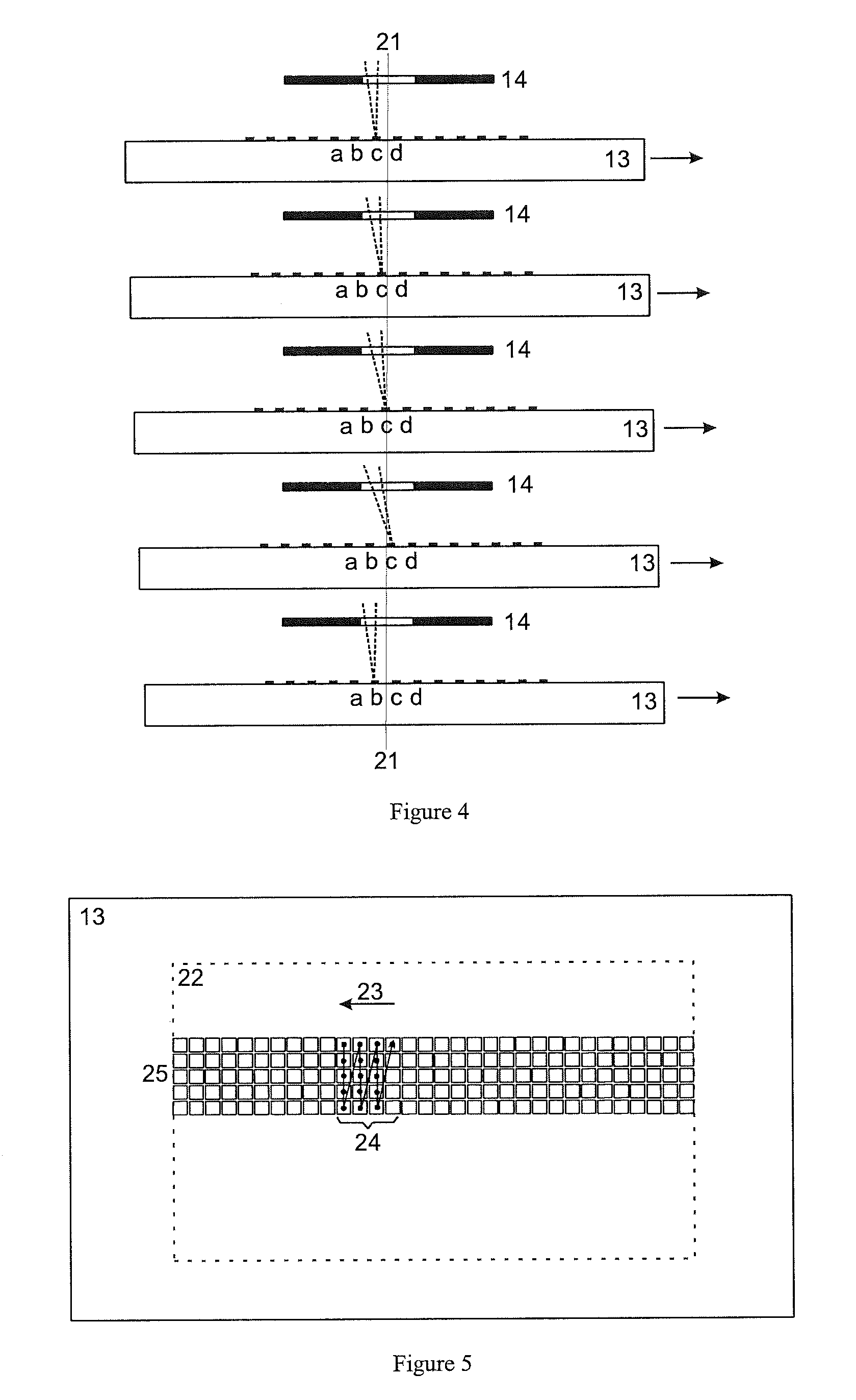

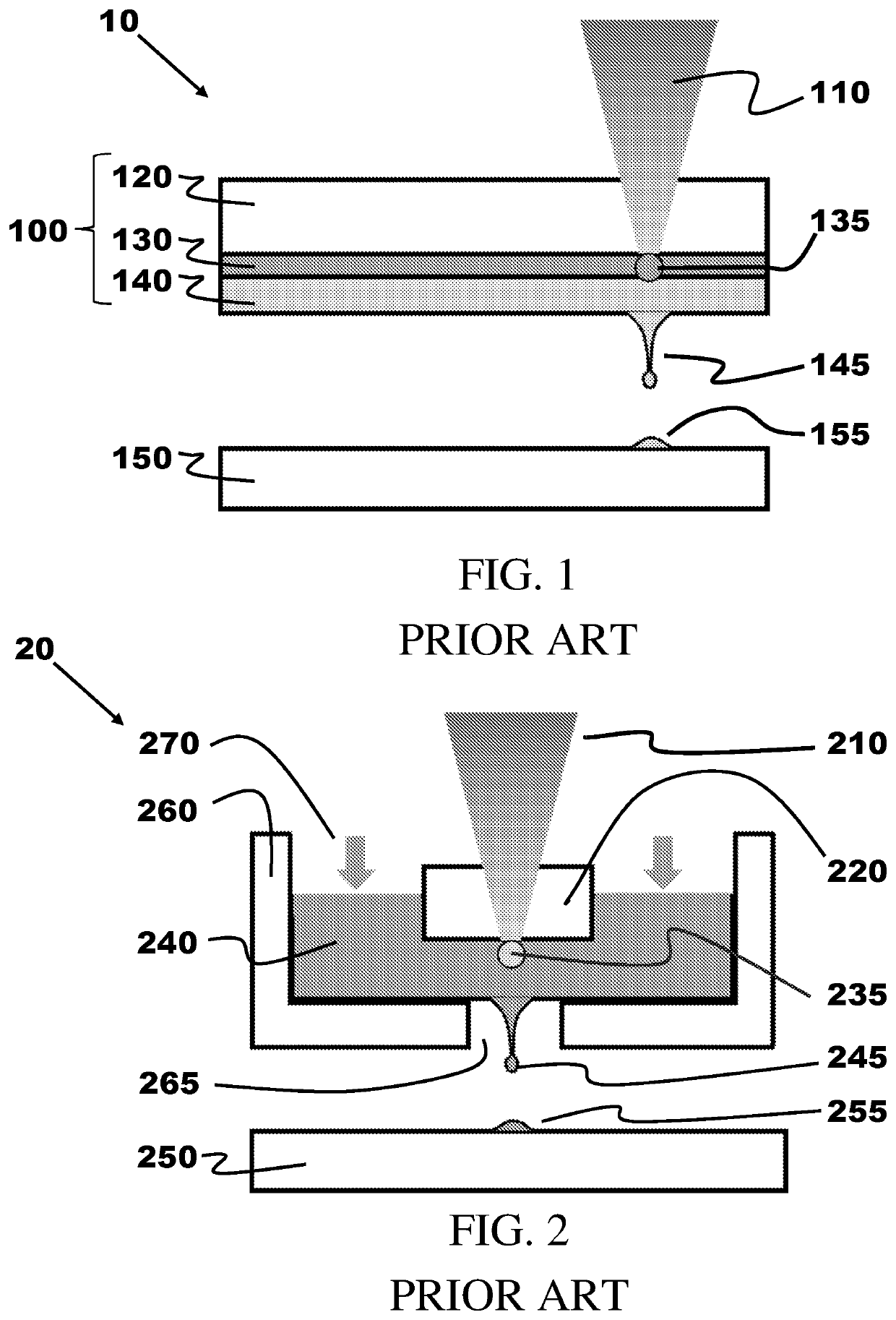

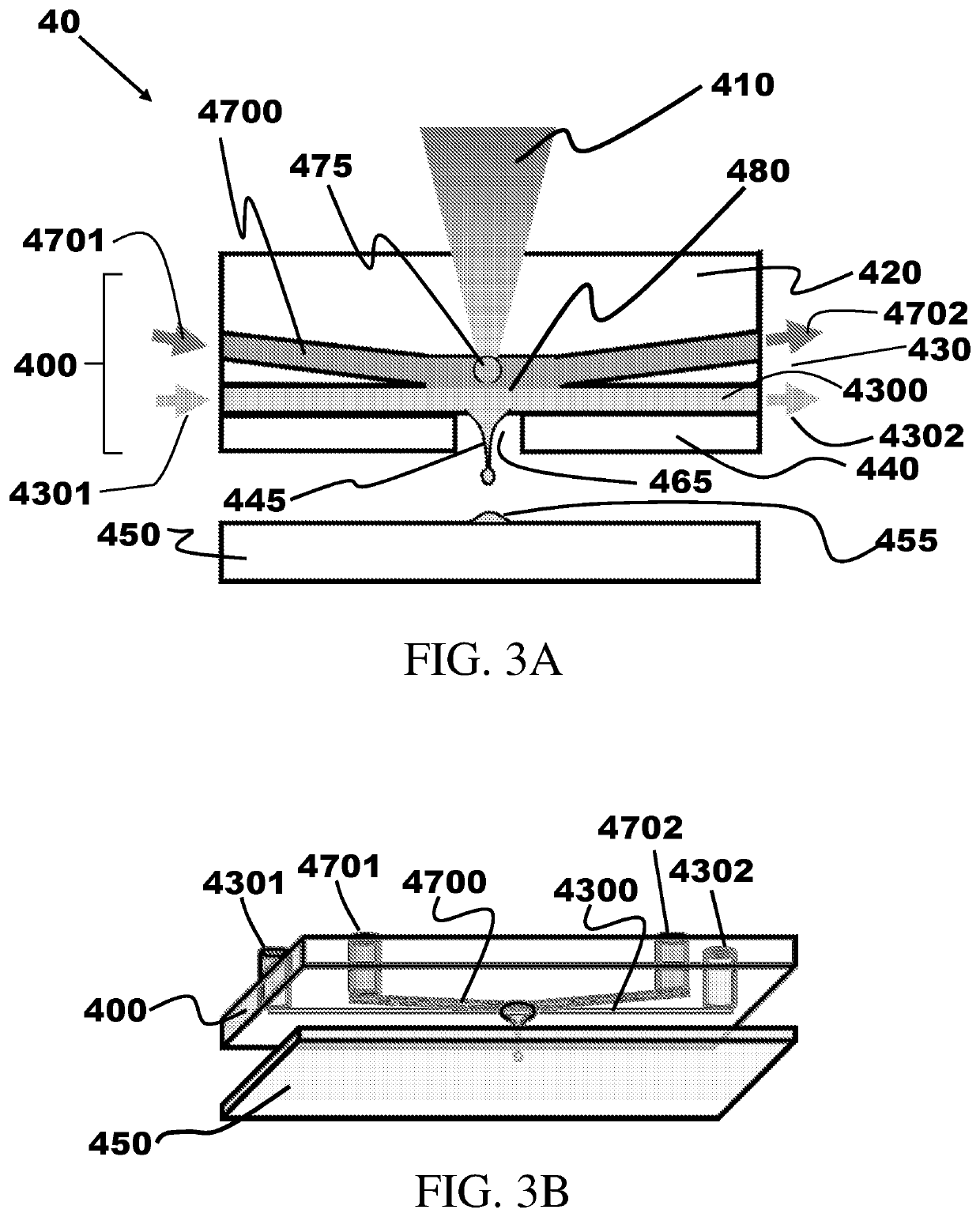

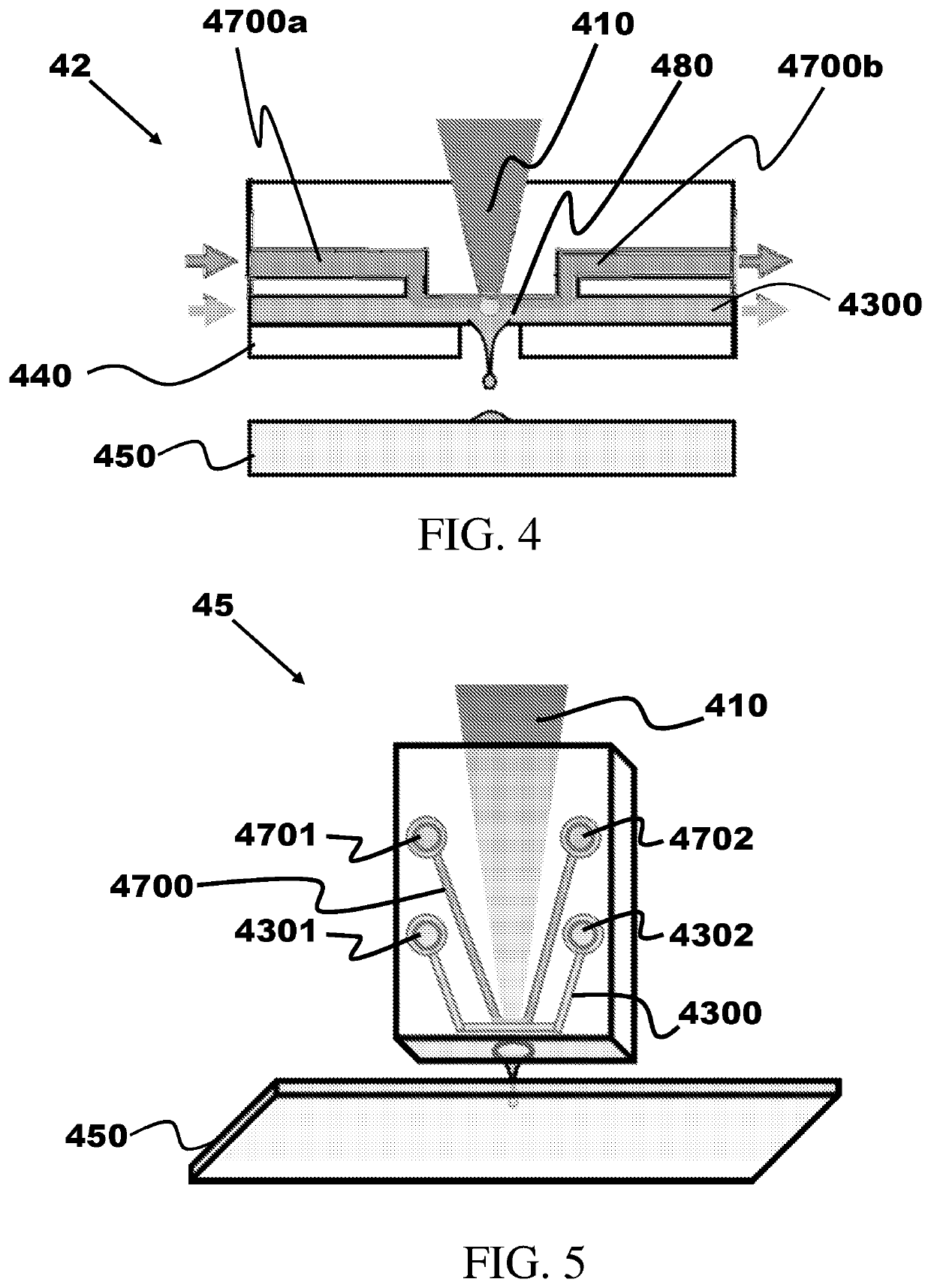

Mass spectrometers ionize samples by matrix-assisted laser desorption (MALDI). The samples are located on a moveable support plate, and irradiated by a pulsed laser. A fast positional control of laser spots is provided via a system of rotatable mirrors to relieve strain on a support plate motion drive. If the spot position is finely adjusted by the mirror system and follows the movement of the sample support plate, the intermittent movement of the sample support can be replaced with a continuous uniform motion. The fast positional control allows more uniform ablation of a sample area. Galvo mirrors with low inertia may be used between the beam generation and a Kepler telescope in the housing of the laser. The positional control can also provide a fully automatic adjustment of MALDI time-of-flight mass spectrometers, at least if the ion-optical elements are equipped with movement devices.

Owner:BRUKER DALTONIK GMBH & CO KG

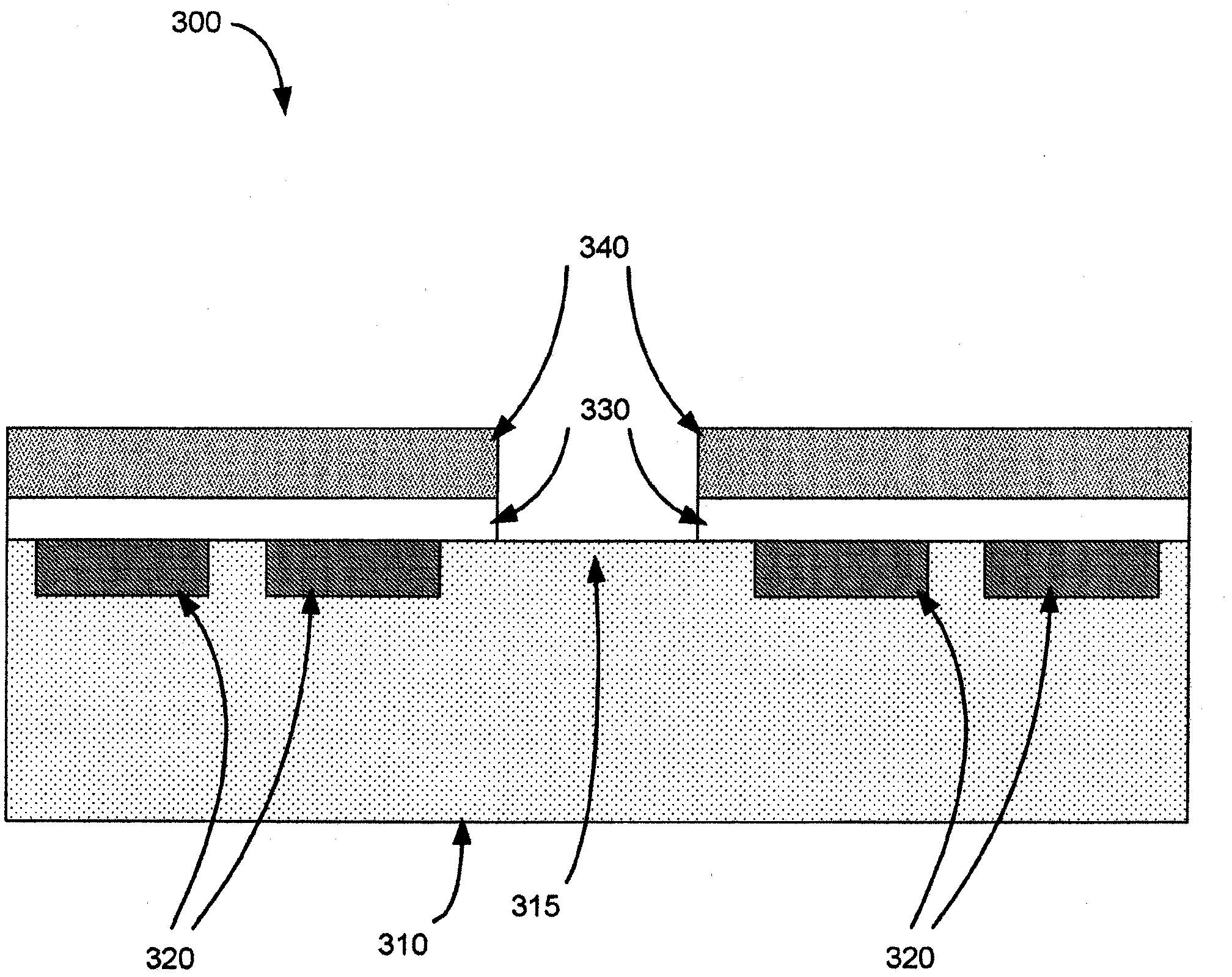

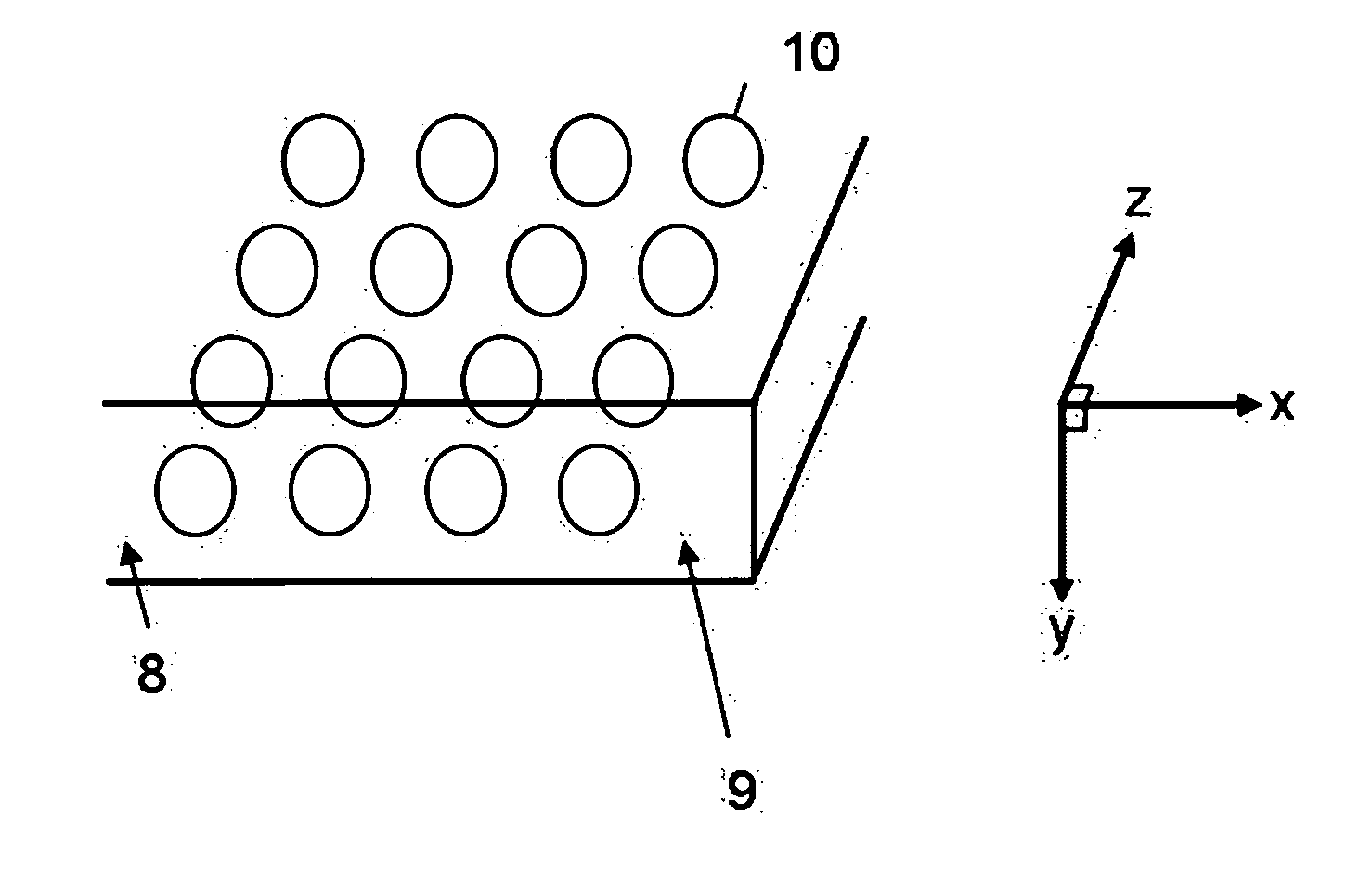

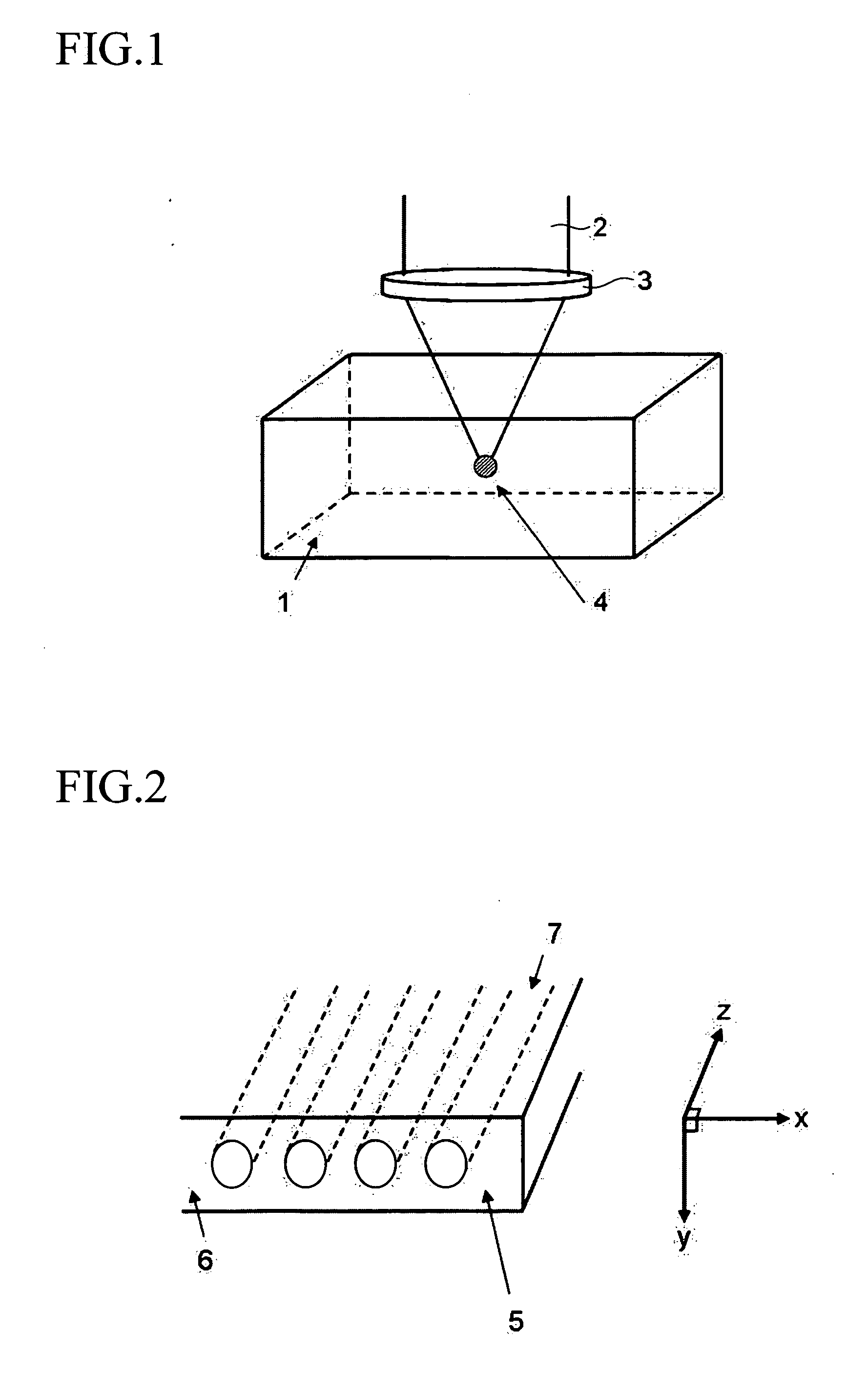

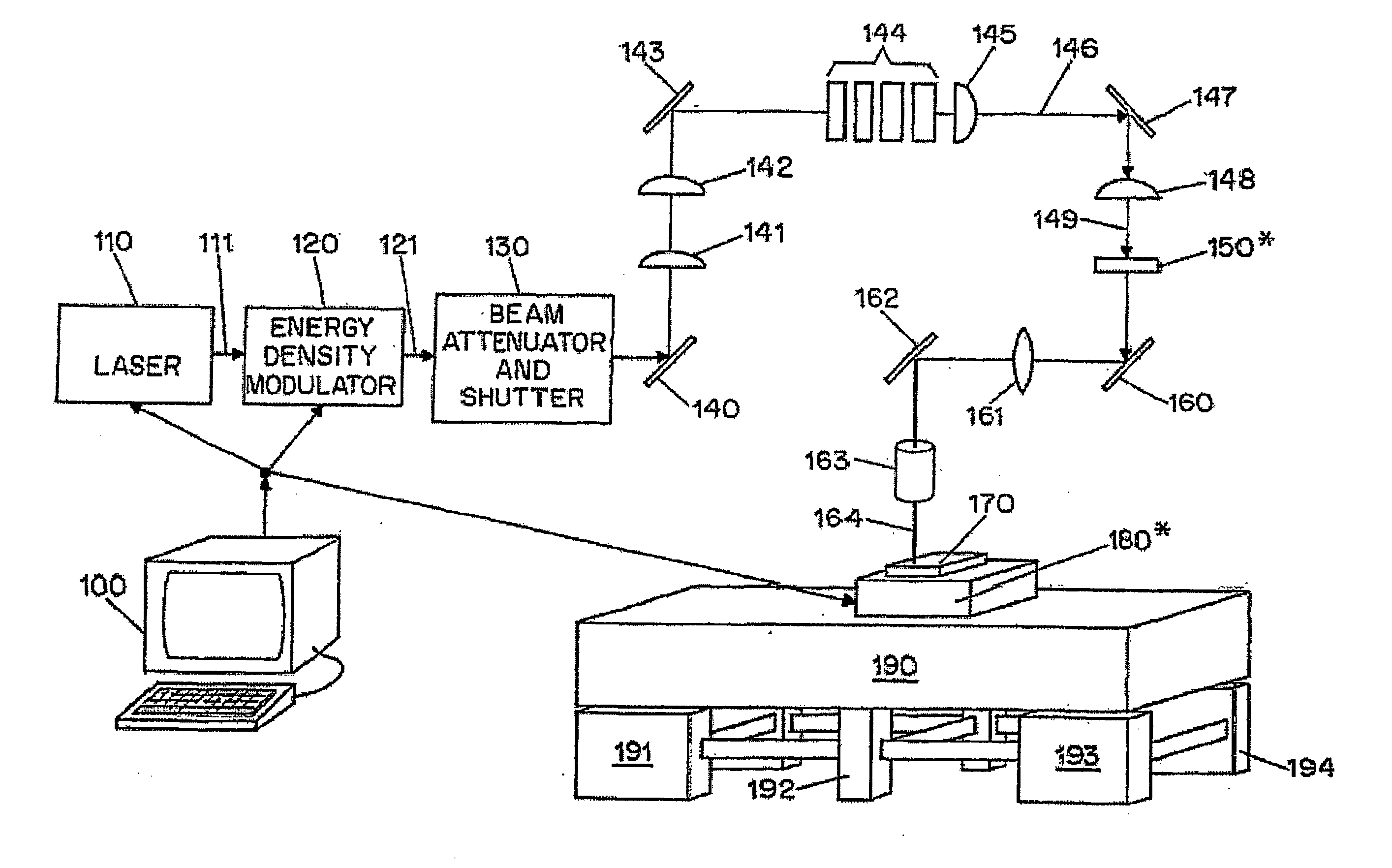

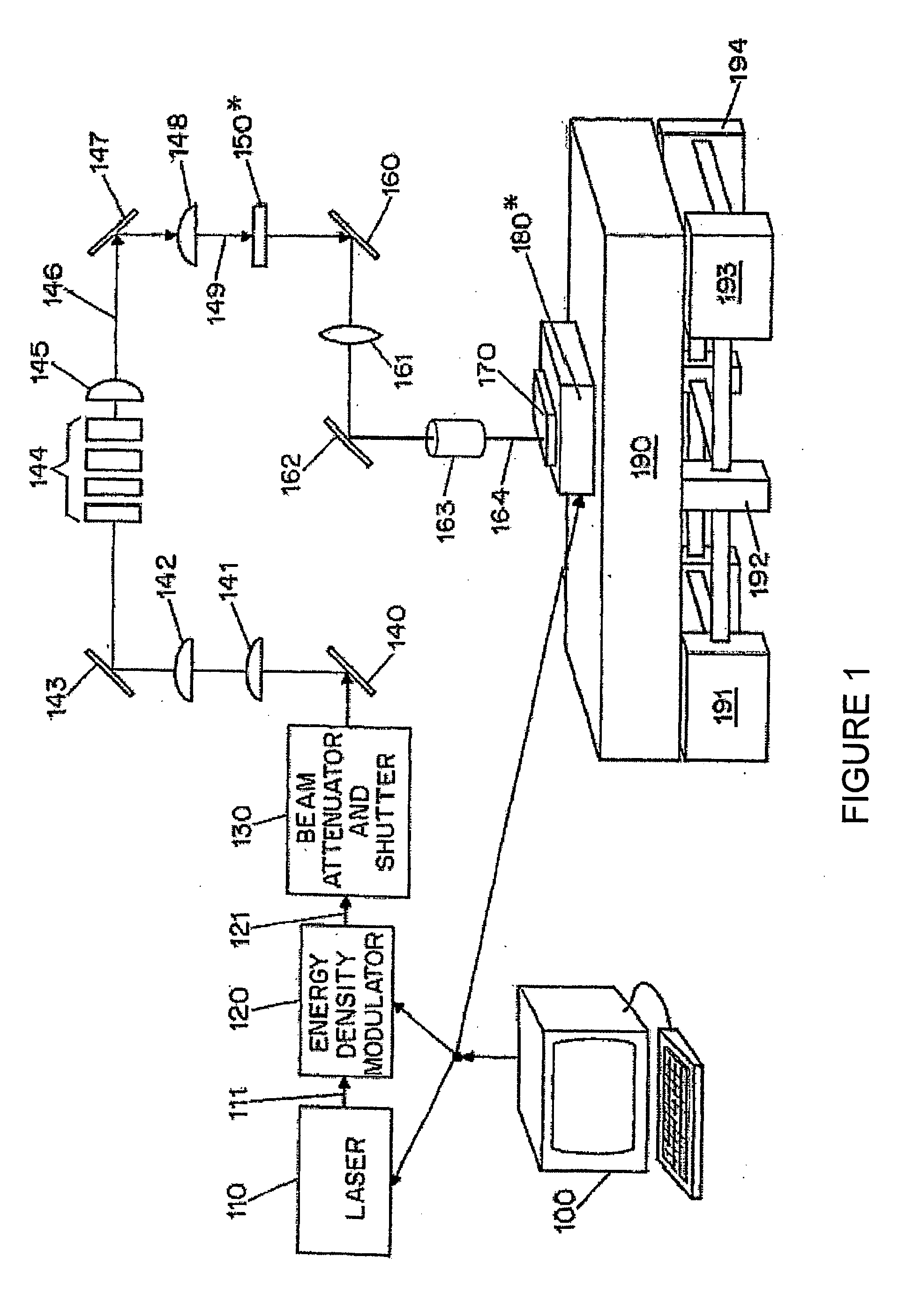

Method and system for providing a thin film with a controlled crystal orientation using pulsed laser induced melting and nucleation-initiated crystallization

InactiveUS7399359B2Liquid crystal compositionsPolycrystalline material growthCrystal orientationThin membrane

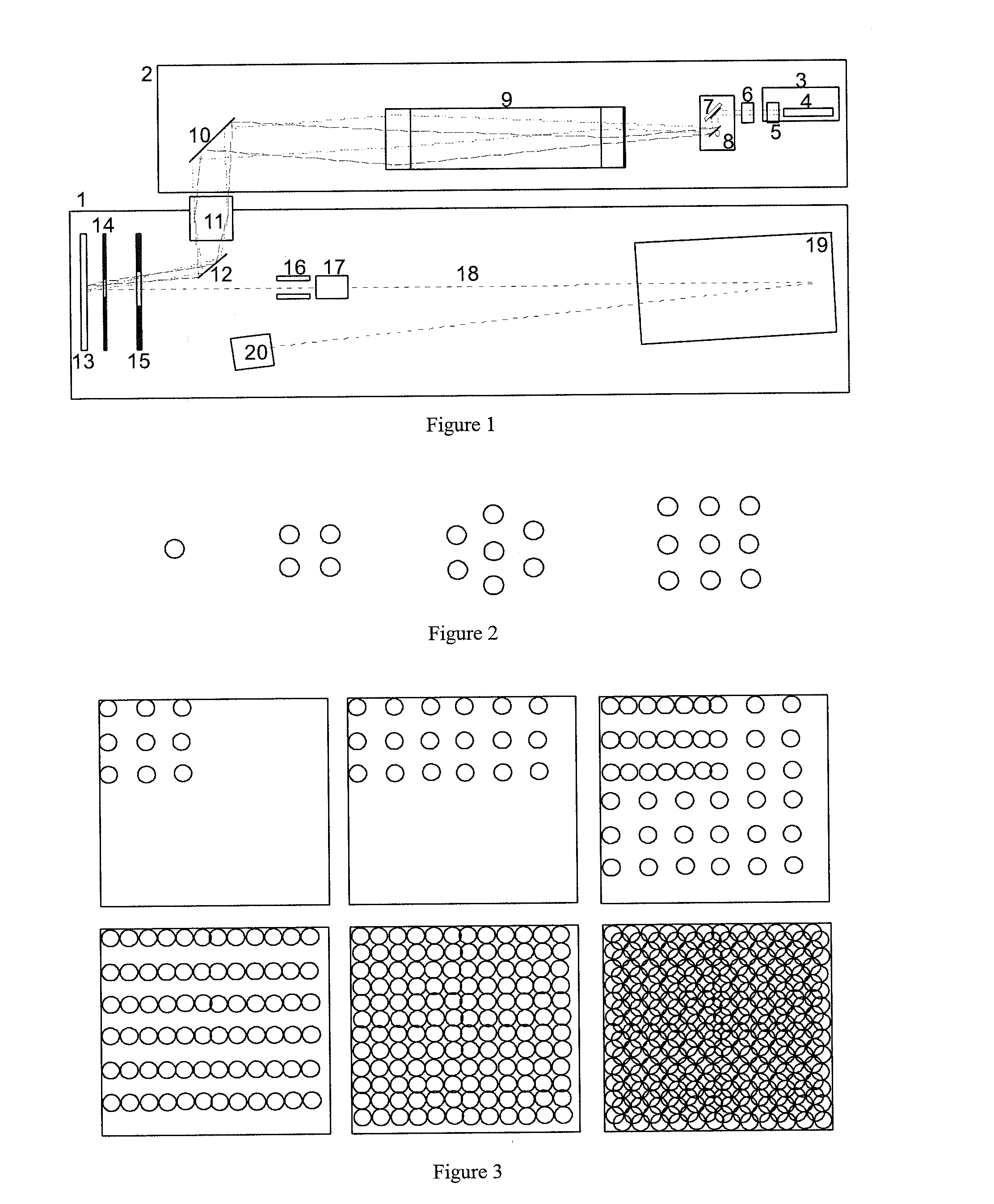

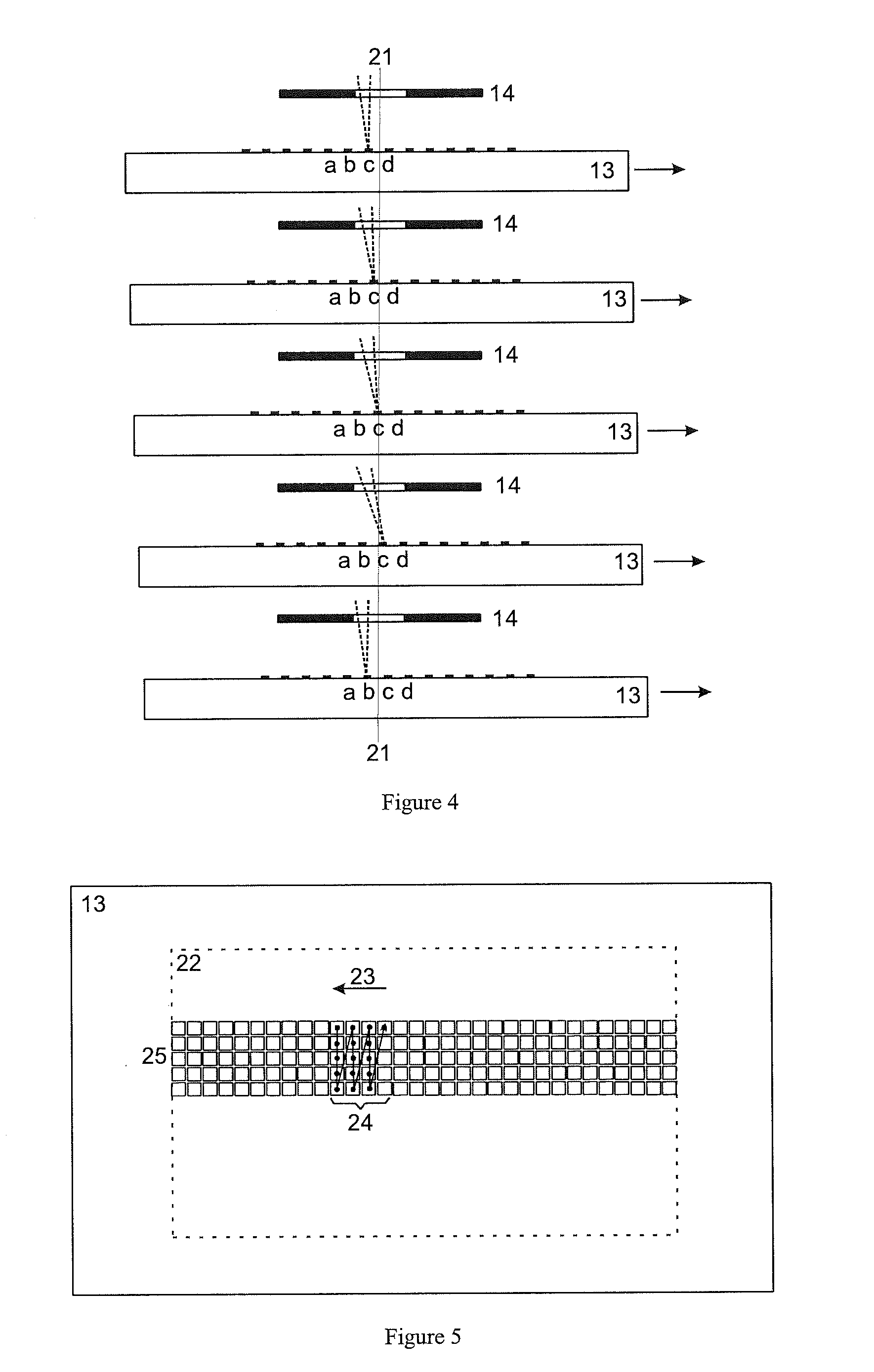

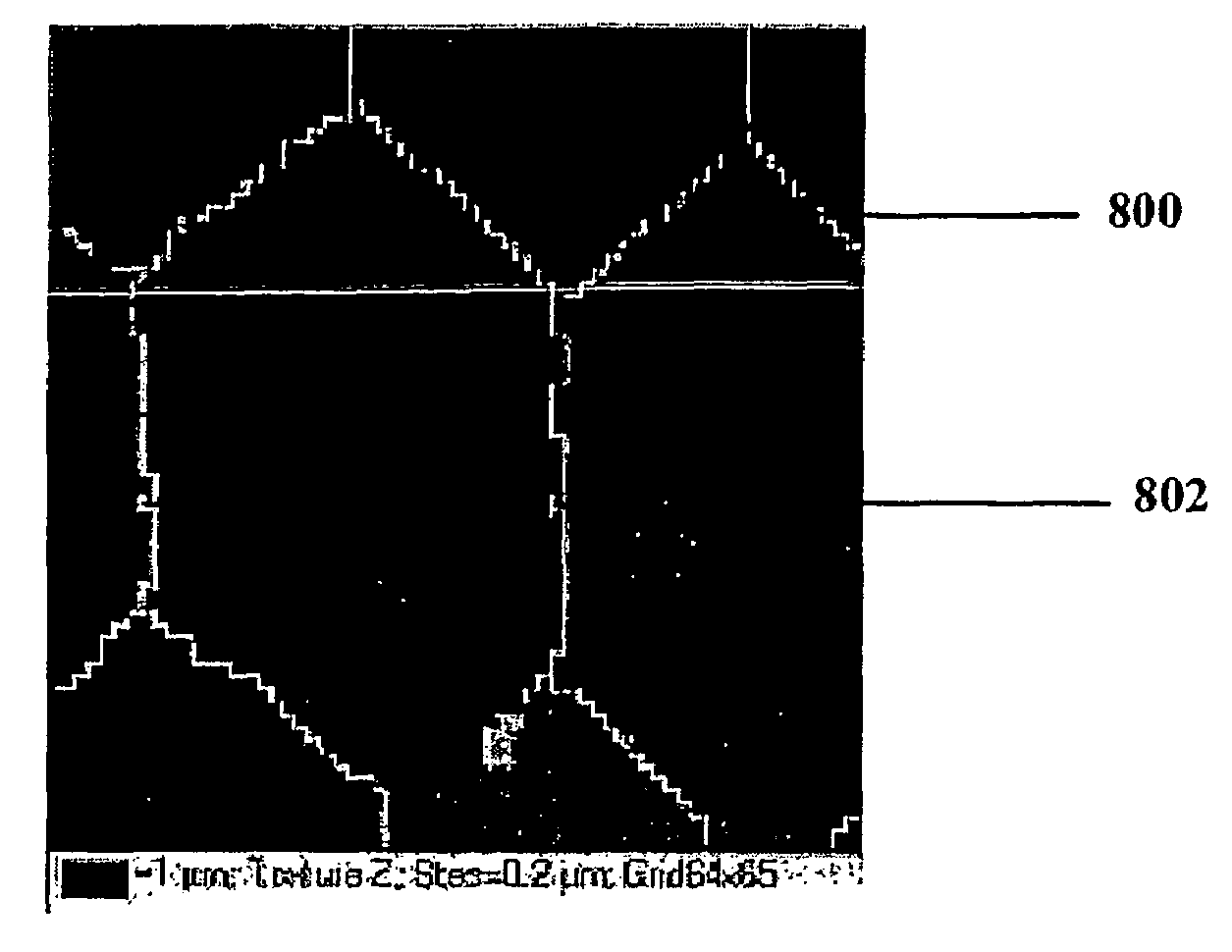

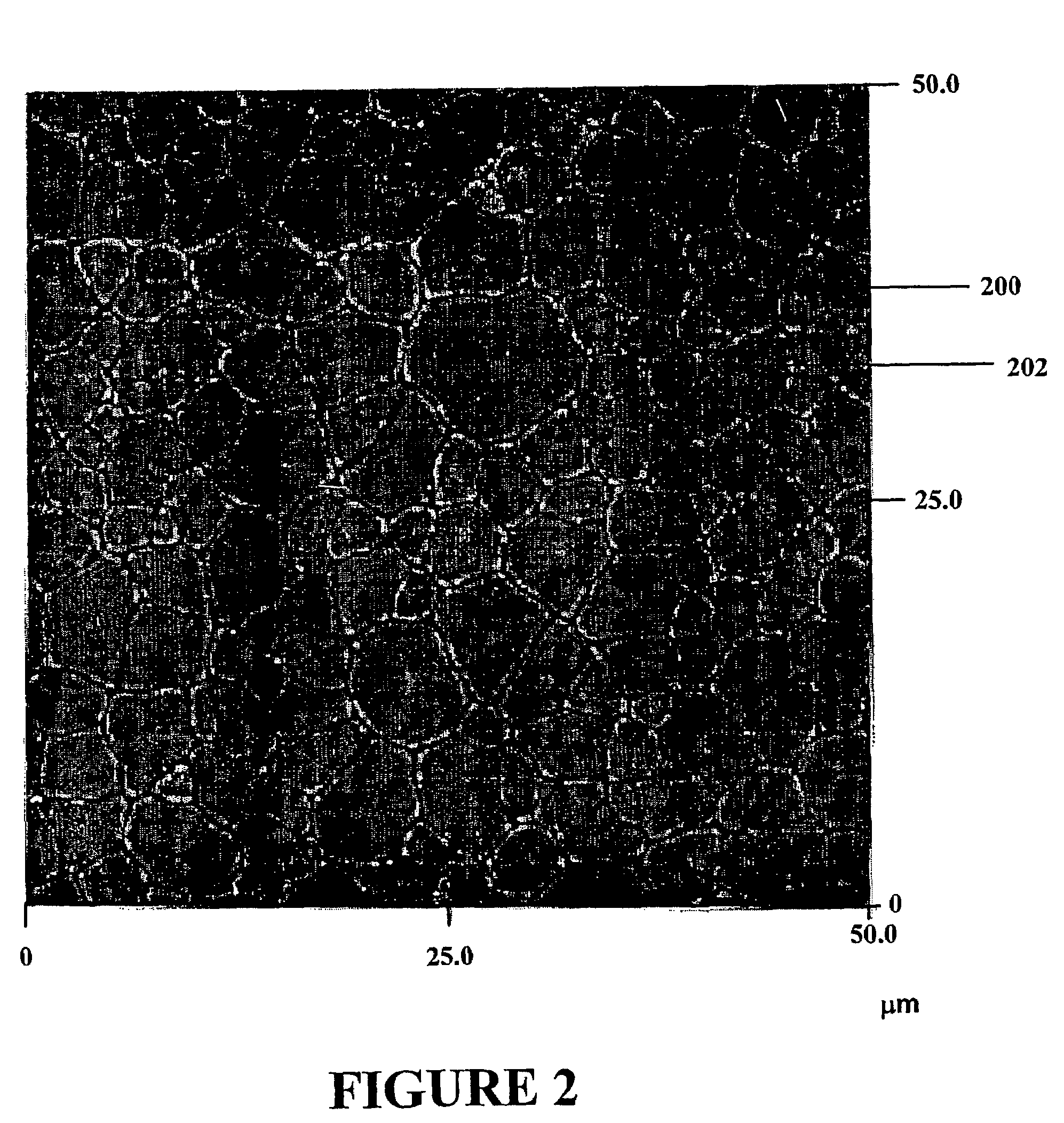

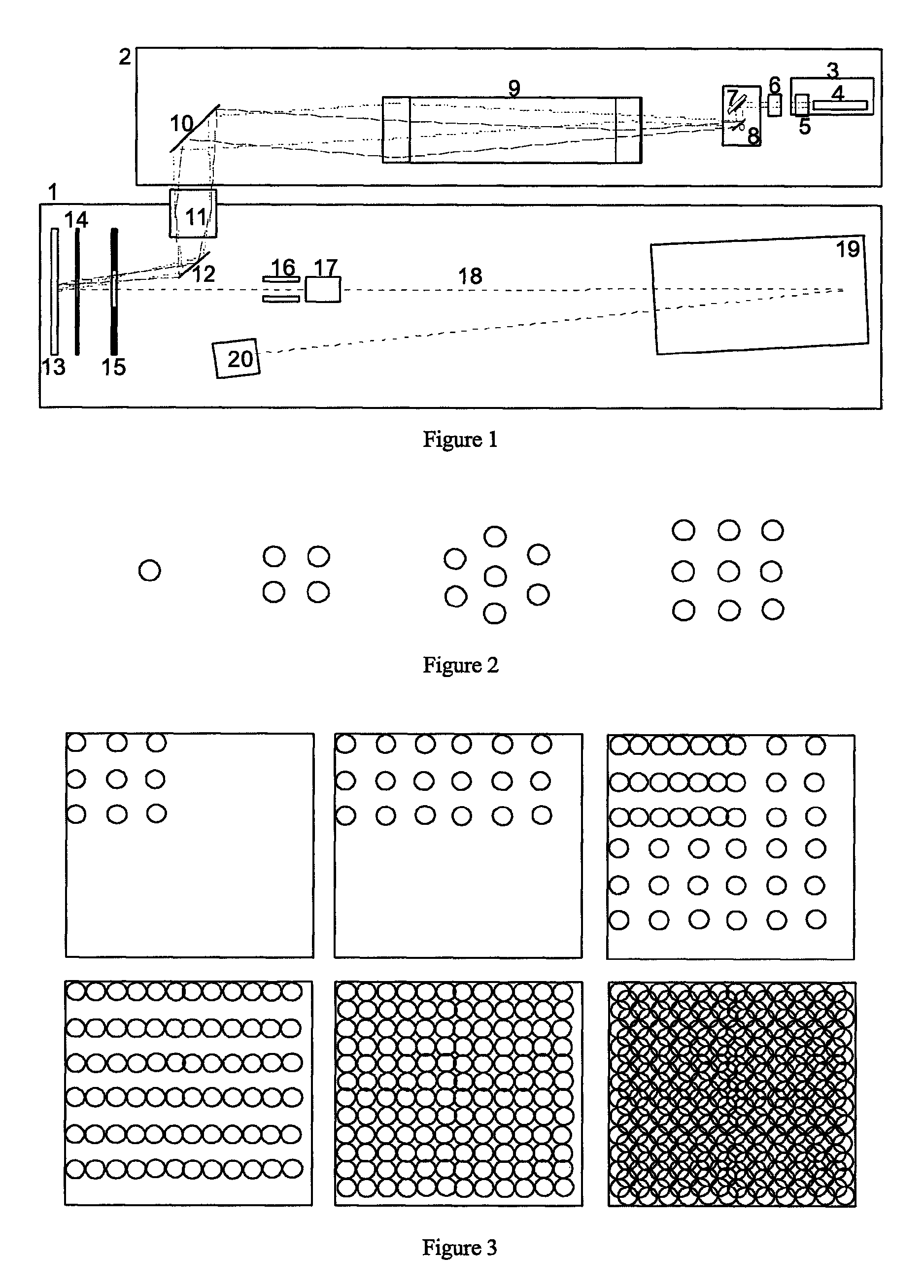

Method and system for generating a metal thin film with a uniform crystalline orientation and a controlled crystalline microstructure are provided. For example, a metal layer is irradicated with a pulsed laser to completely melt the film throughout its entire thickness. The metal layer can then resolidify to form grains with a substantially uniform orientation. The resolidified metal layer can be irradiated with a sequential lateral solidification technique to modify the crystalline microstructure (e.g., create larger grains, single-crystal regions, grain boundary controlled microstructures, etc.) The metal layer can be irradiated by patterning a beam using a mask which includes a first region capable of attenuating the pulsed laser and a second region allowing complete irradiation of sections of the thin film being impinged by the masked laser beam. An inverse dot-patterned mask can be used, the microstructure that may have substantially the same as the geometric pattern as that of the dots of the mask.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

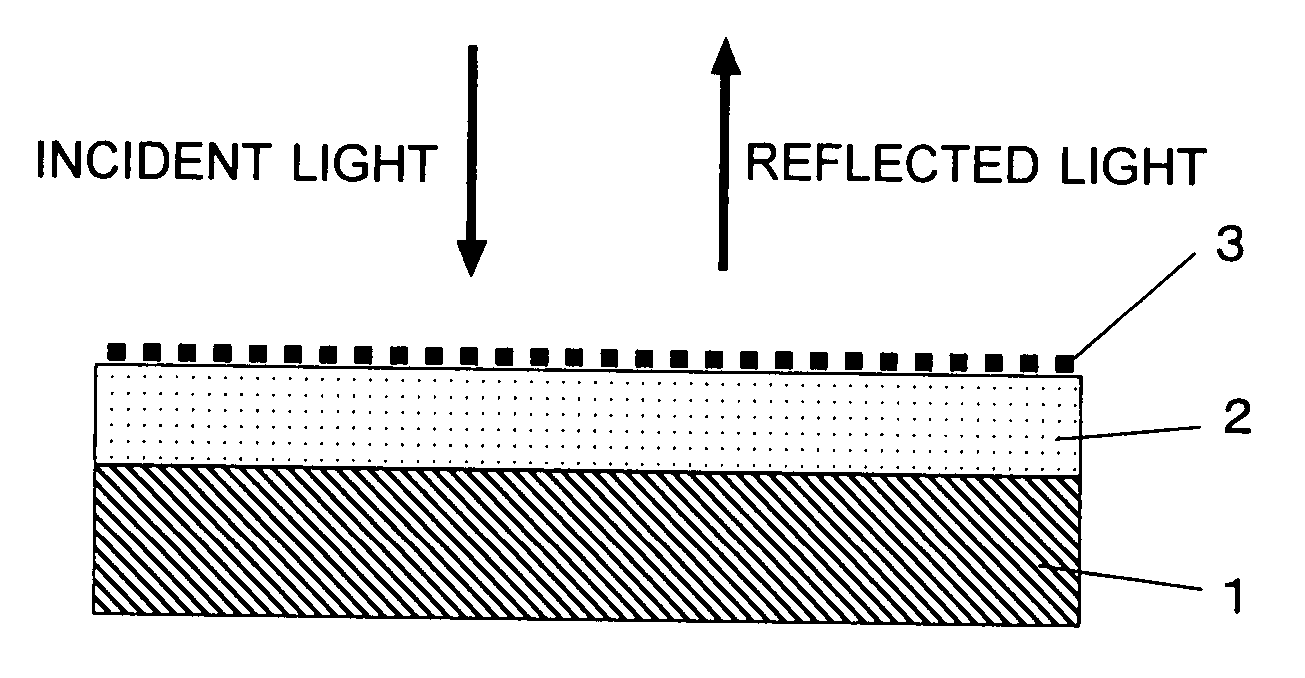

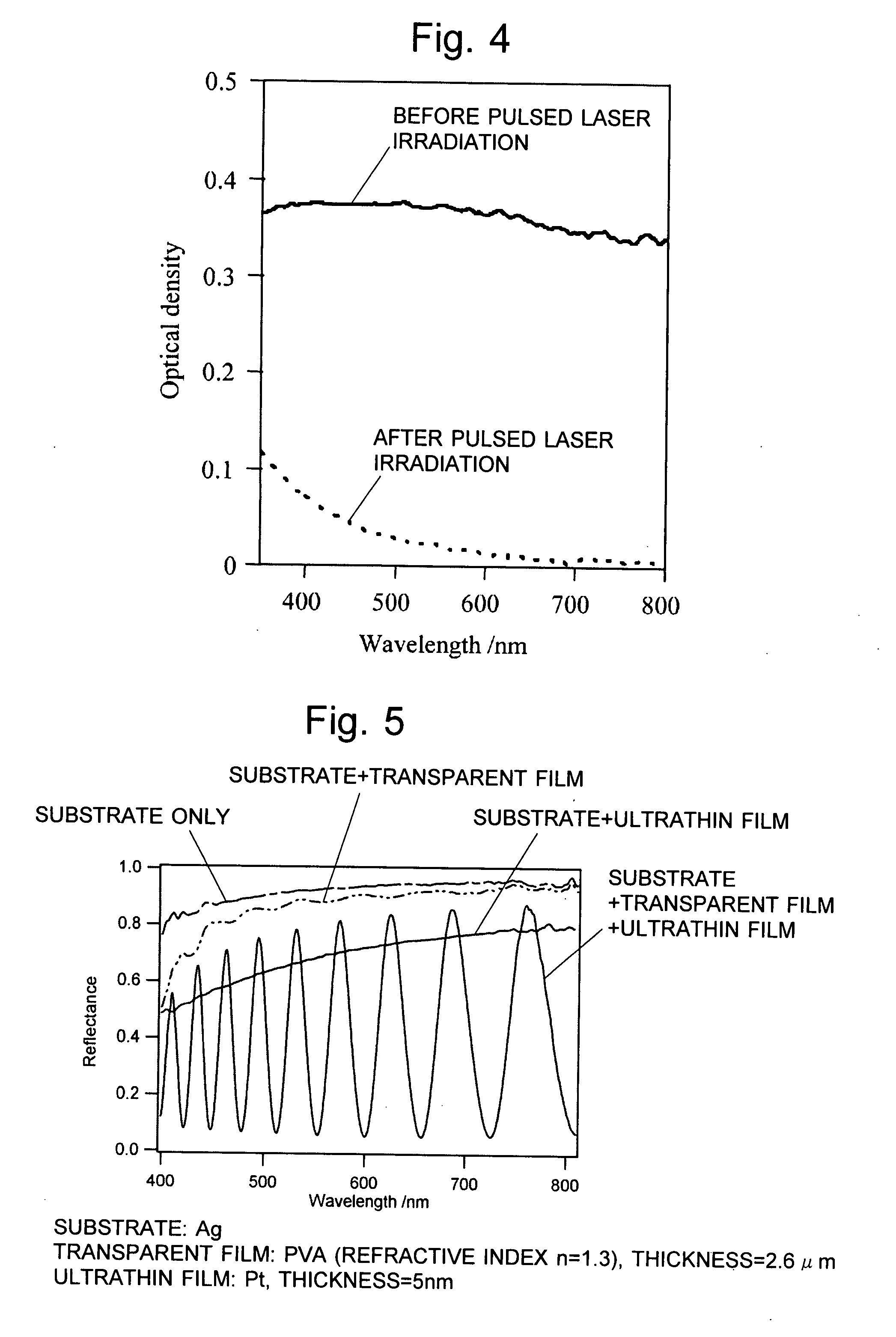

Reflectance Control Optical Element and Ultrathin Film Light Absorption Enhancing Element

InactiveUS20080007852A1Increase credibilityEasy to controlMirrorsRadiation applicationsRefractive indexAlloy

Owner:KYOTO UNIV

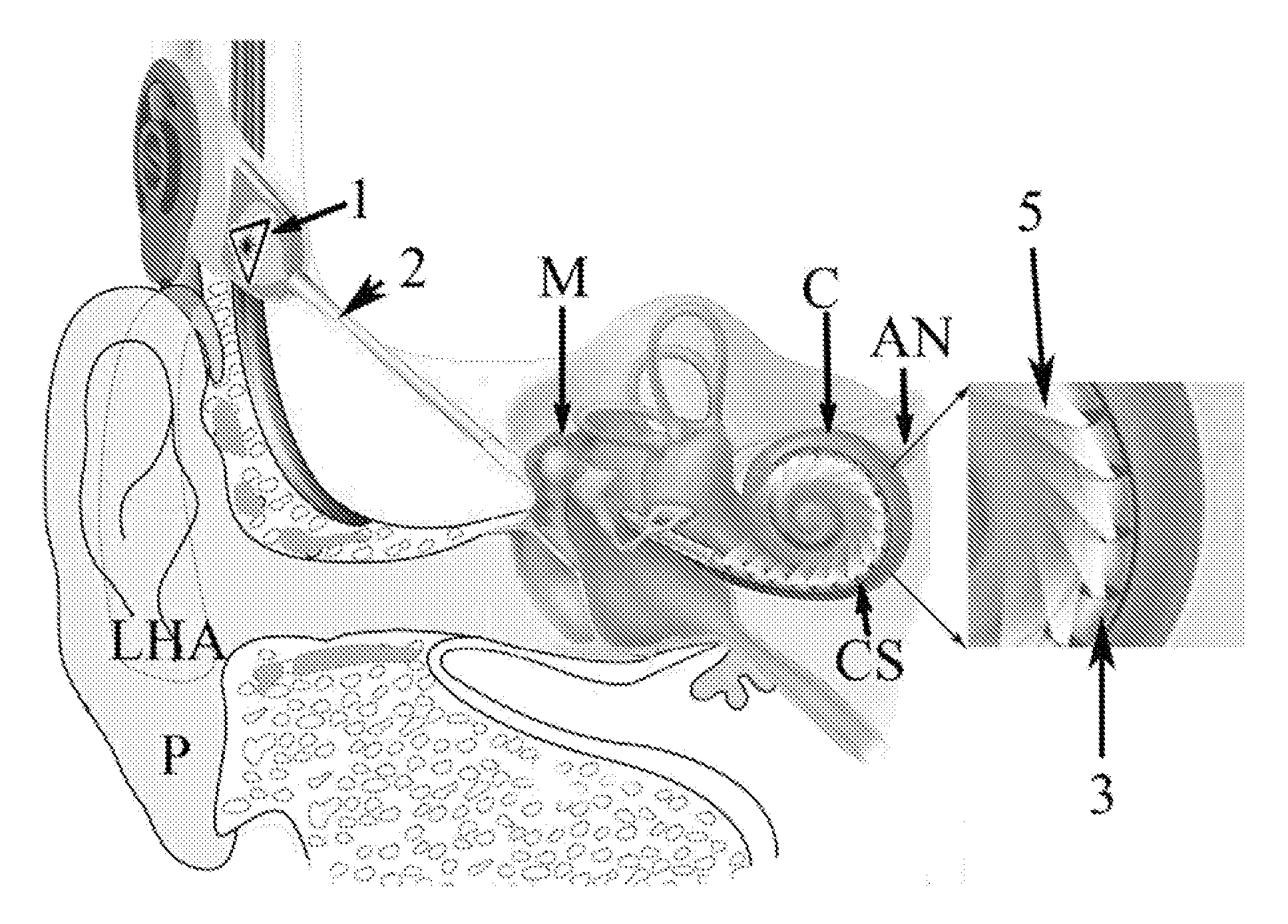

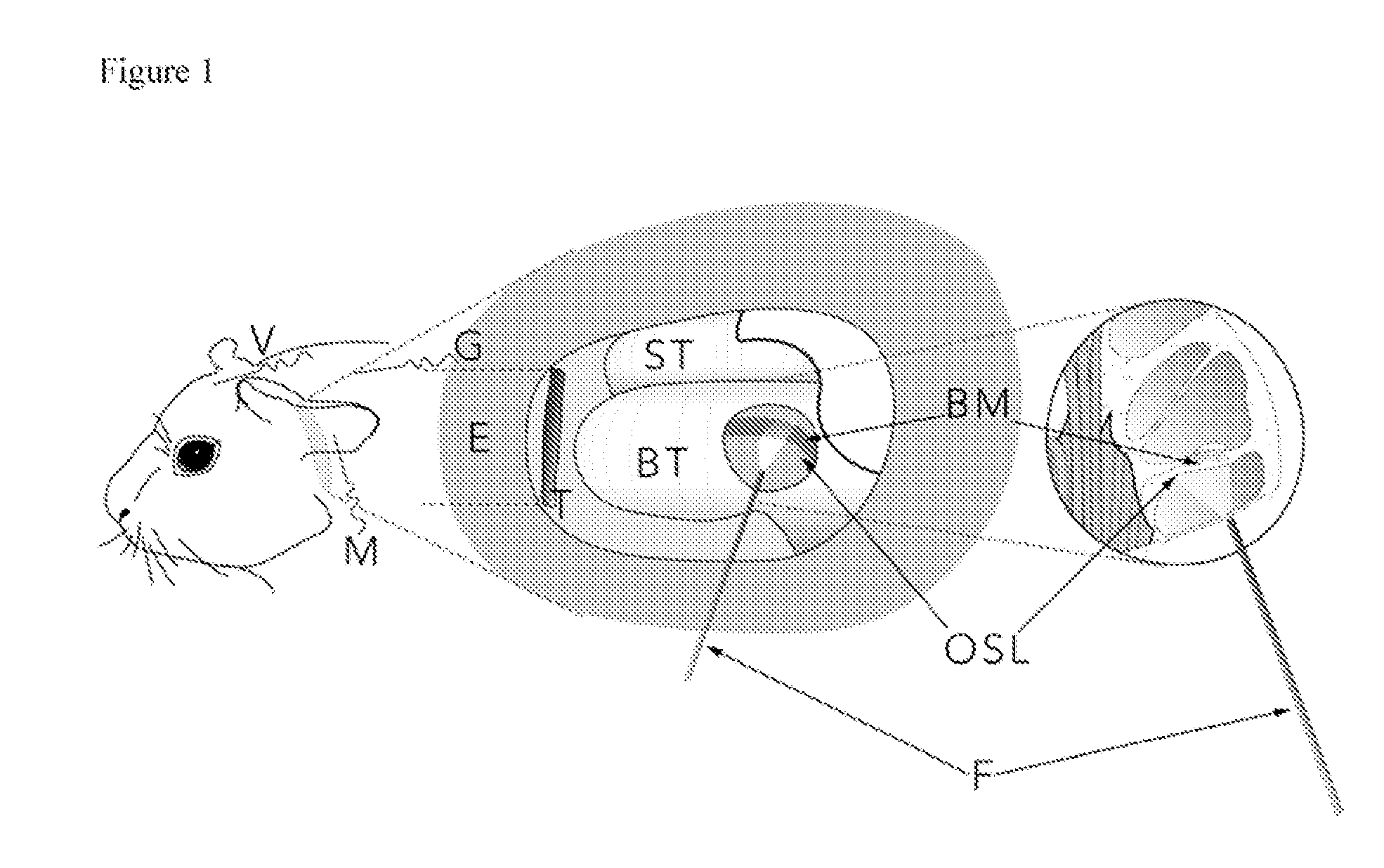

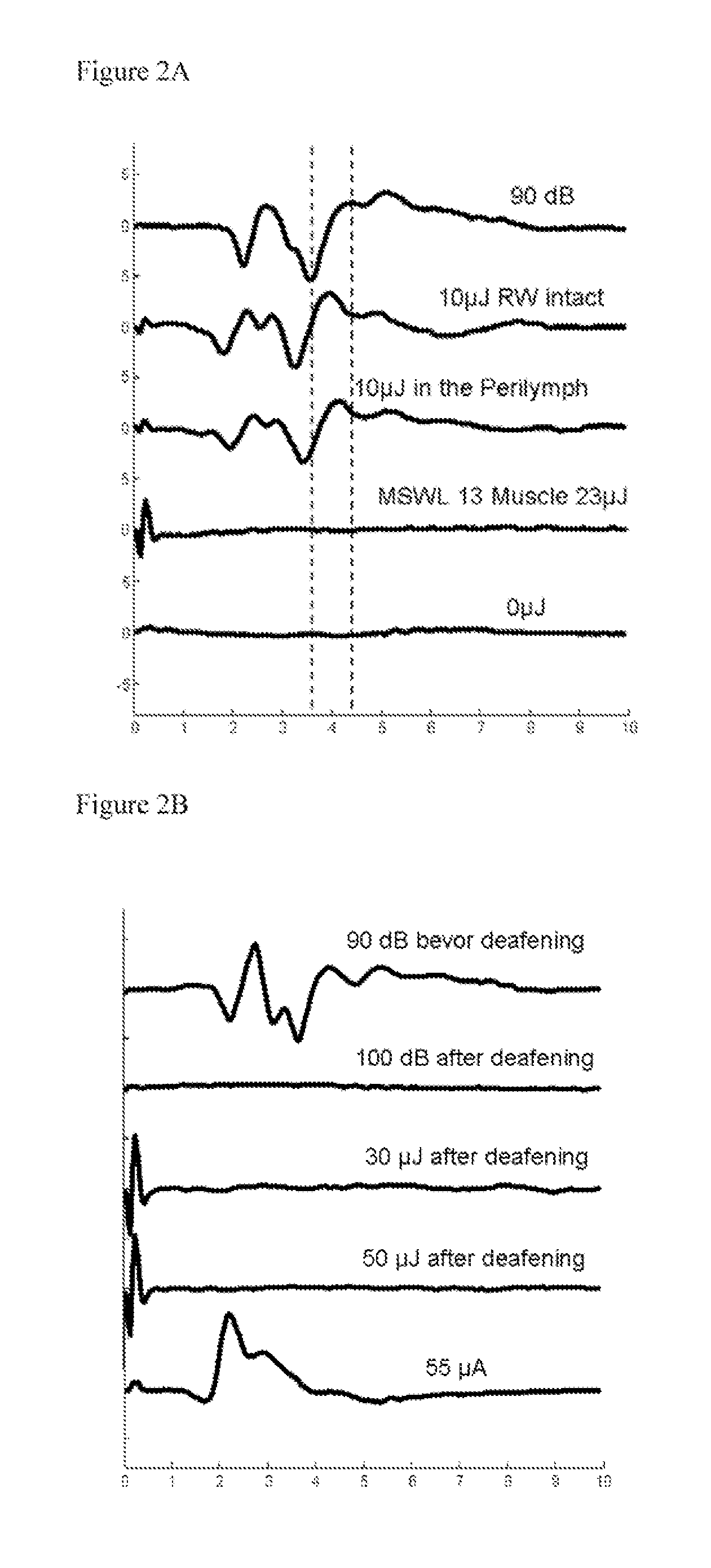

Cochlea stimulator

ActiveUS20100198317A1Improve spatial resolutionHigh frequency resolutionEar treatmentTubular organ implantsSpeech perceptionBiological activation

The invention provides a cochlea stimulator for implantation comprising optical fibres of which are coupled to an irradiation source that is controlled by a modulator to generate irradiation specific for a pre-determined range of sound-frequencies. The cochlea stimulator effects a frequency-specific activation of the organ of Corti needed for speech perception especially in noisy environment and more complex sounds. For imparting excitation signals which are generated by modulated pulsed laser irradiation conducted within an optical fibre in order to elicit nervous signals in residual functional organ of Corti sections, the auditory prosthesis preferably contains optical fibres which are dimensioned to terminate in end sections within the cochlea at different sites or sections of the organ of Corti. e.g. having different lengths for locating their end sections at different internal parts of the cochlea.

Owner:MEDIZINISCHE HOCHSCHULE HANNOVER +1

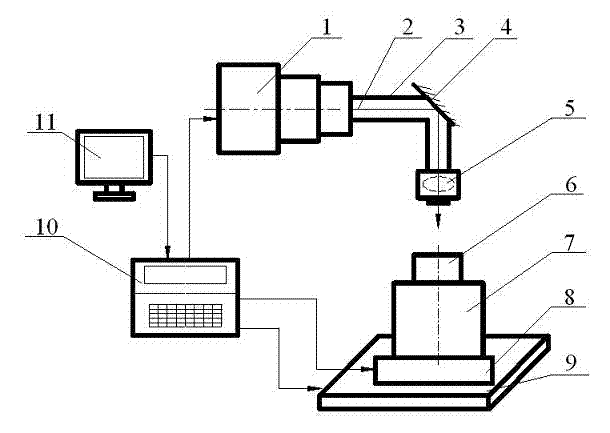

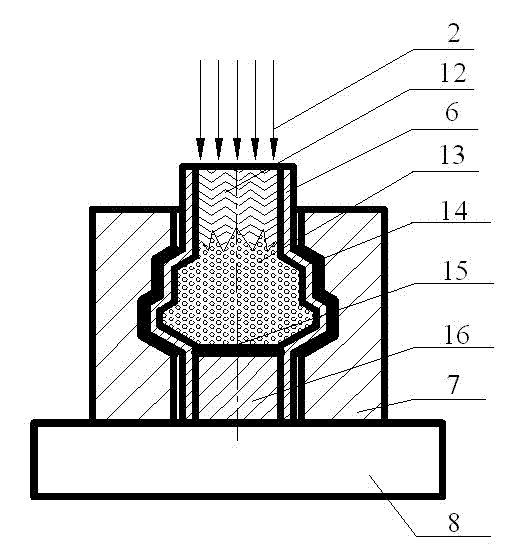

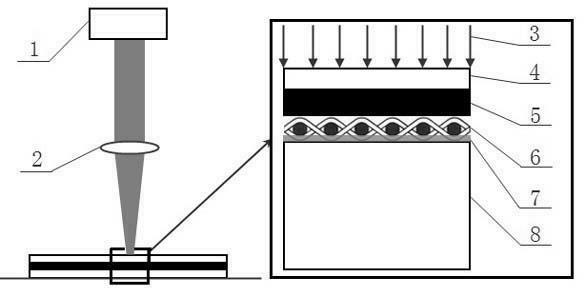

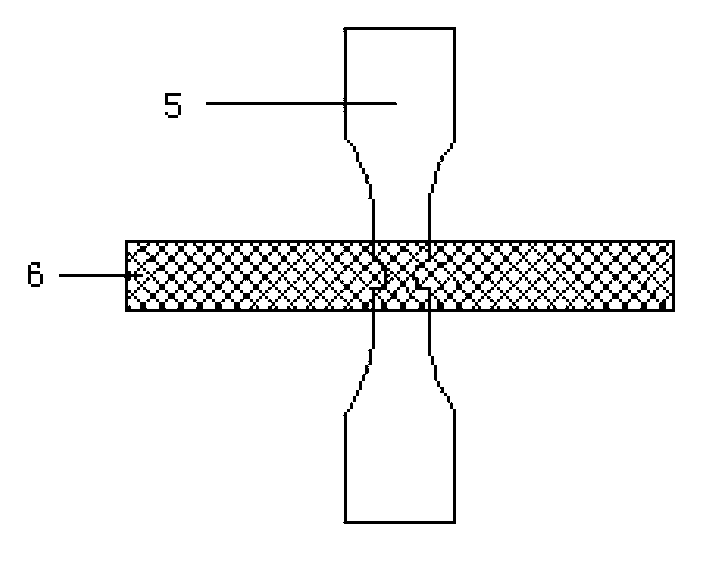

Method and device for forming metal reducer pipe based on laser shock wave technology

ActiveCN102225491AImprove flexibilityHigh value for high flexibilityLaser beam welding apparatusShock waveLaser processing

The invention discloses a method and device for forming a metal reducer pipe based on a laser shock wave technology and belongs to the technical field of laser processing. In the invention, the upper end part, separated from a pipe fitting, of a plugging rod is coated with a laser energy absorption layer; a laser beam enters the interior of a pipe billet to be formed along the axis of the pipe billet, thereby irradiating on the absorption layer on the upper end part of the plugging rod; the absorption layer absorbs laser energy so as to be gasified and ionized, thus forming high-voltage plasmas; and the high-voltage plasmas quickly expand to form a high-amplitude shock wave, thereby promoting the expansion of the pipe billet until the pipe billet is jointed with the profile of a mould, therefore the deformed shape of the pipe billet is in accordance with the profile of the mould. In the invention, the laser shock wave controlled in parameter is utilized as a power source for internal high pressure forming of the pipe billet, and good safety is provided; and the method and device provided by the invention are suitable for not only forming the pipe billet of a material extremely low in yield limit, but also forming the pipe billet with high yield strength; besides, continuous multi-pulse laser irradiation can be performed and uninterrupted multi-impact can be carried out; and high production efficiency is ensured.

Owner:马鞍山市安工大智能装备技术研究院有限公司

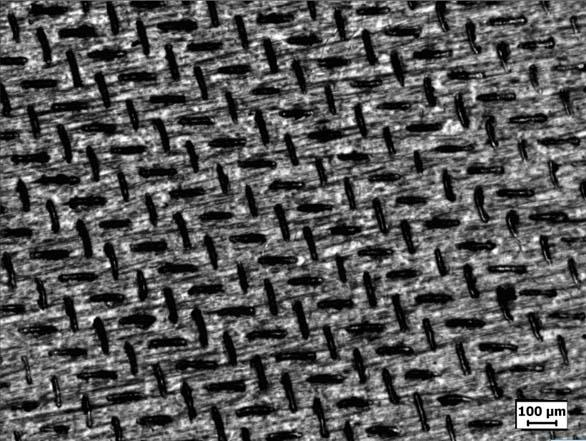

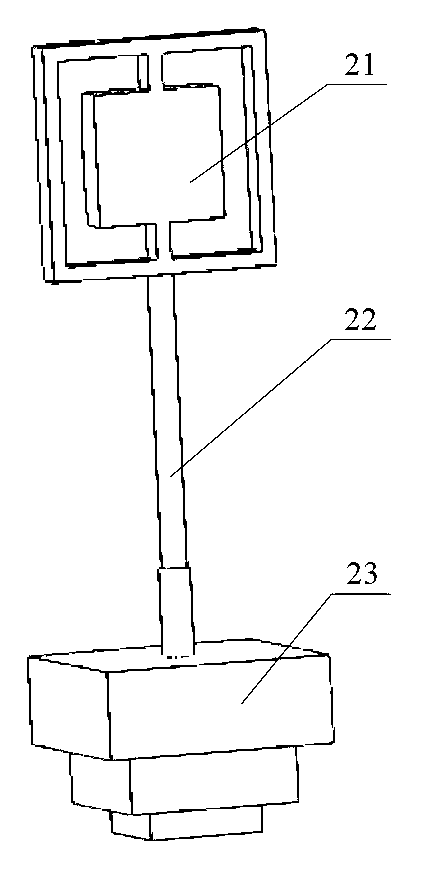

High efficiency apparatus and method based on laser shock wave for manufacturing micro grooves

InactiveCN102626826AImprove fatigue lifeFully automatedLaser beam welding apparatusShock waveHigh energy

The invention provides high efficiency apparatus and method based on laser shock wave for manufacturing micro grooves.The shock wave is generated by an absorbed layer in high energy pulse laser irradiation. The shock wave induced by the laser generates huge pressure, a metal mesh is embedded in a metal material by utilizing the pressure and a micro groove is formed on a surface of the metal material.

Owner:阜宁县科技创业园有限公司

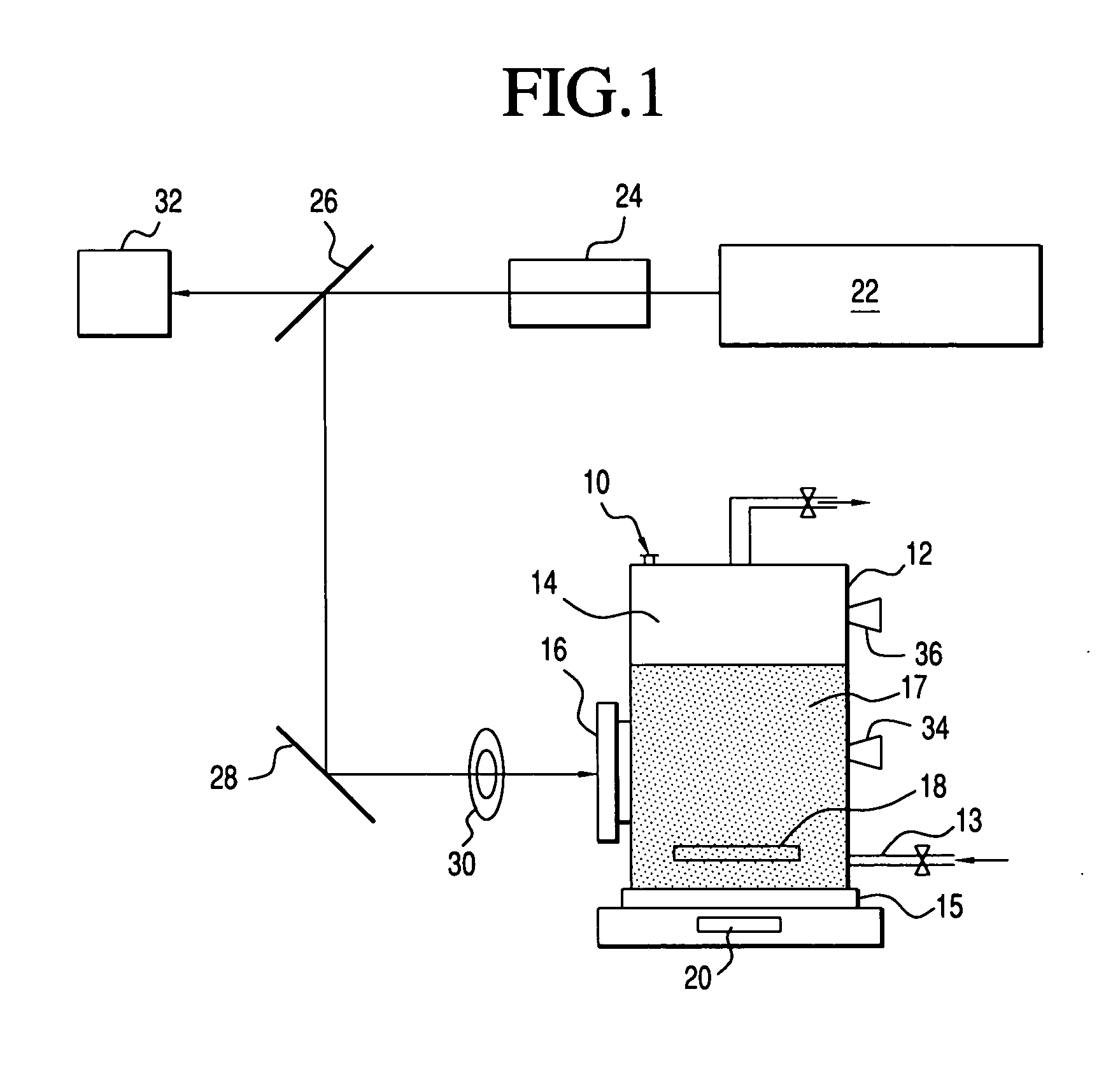

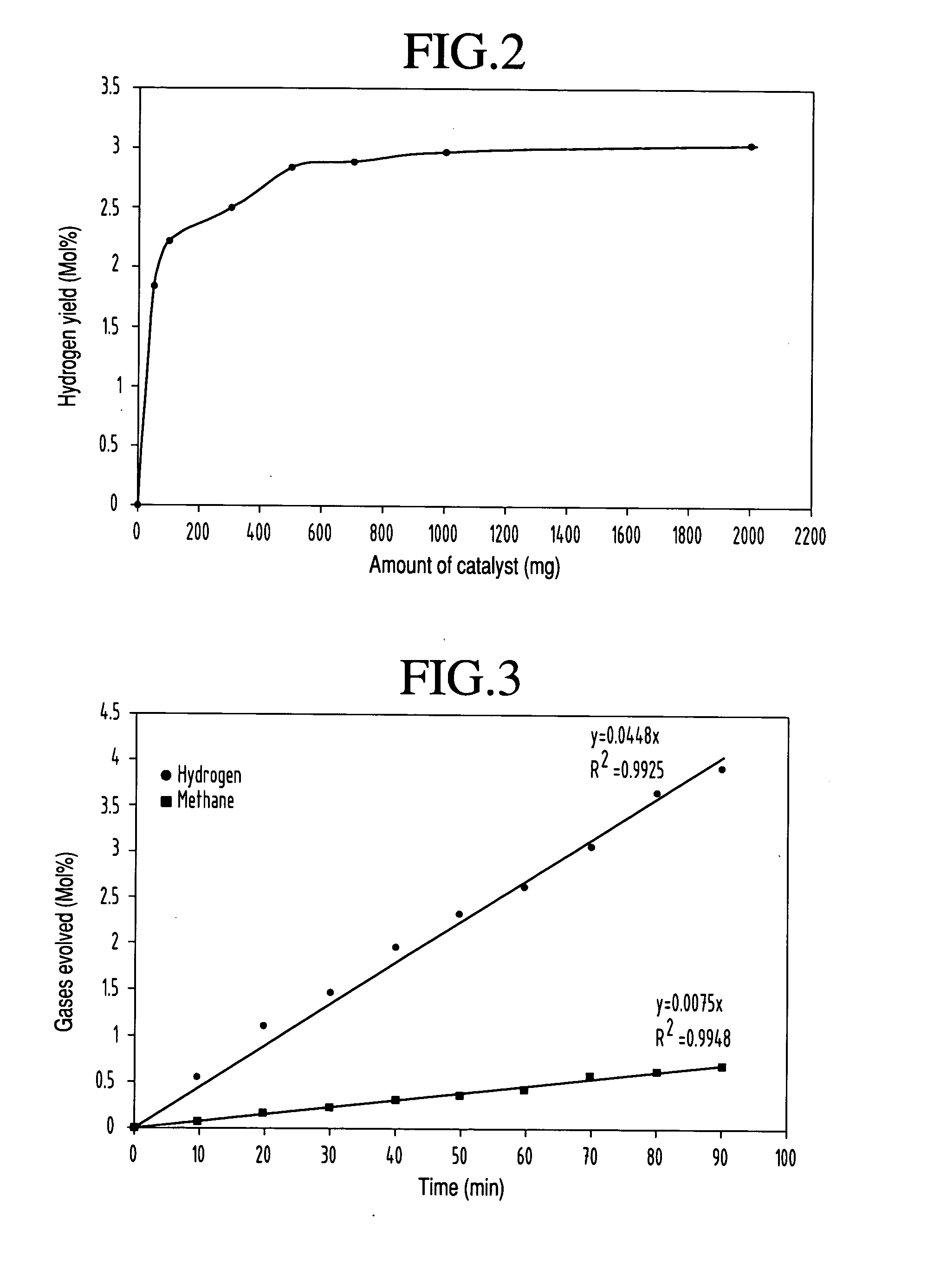

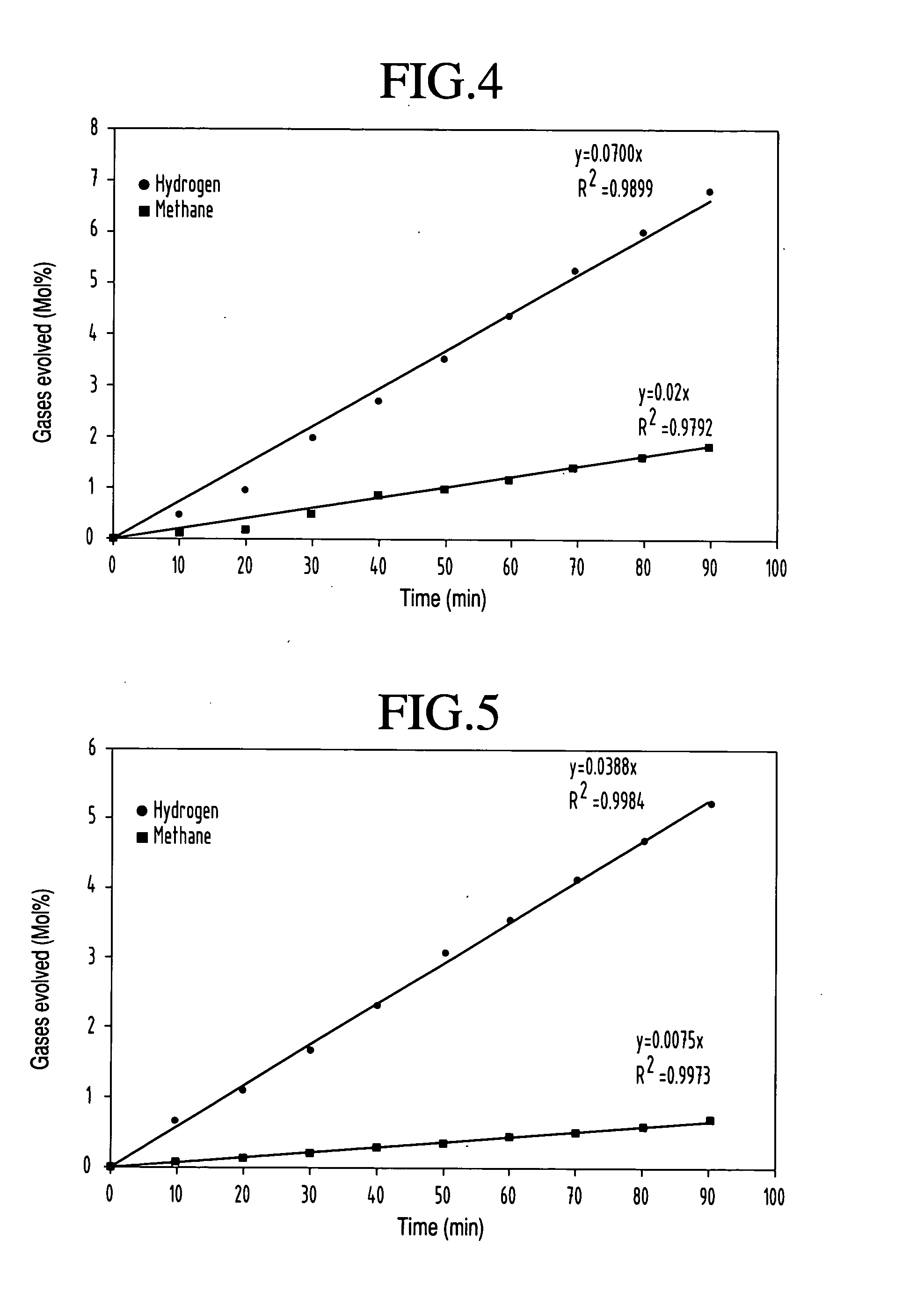

Laser photo-catalytic process for the production of hydrogen

InactiveUS20050226808A1High yieldHydrogen productionChemical/physical/physico-chemical stationary reactorsPhoto catalyticHydrogen

A method for the photocatalytic conversion of an oxygenated hydrocarbon such as methanol includes the step of forming a colloidal suspension of a metal oxide catalyst in an oxygenated hydrocarbon. The method also includes the step of irradiating the colloidal suspension with pulsed laser irradiation in the range of about 180 nm to 520 nm wavelength at about 150 mJ per pulse at a temperature at about 16° C. to 60° C. for a period of about 30 minutes or more.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

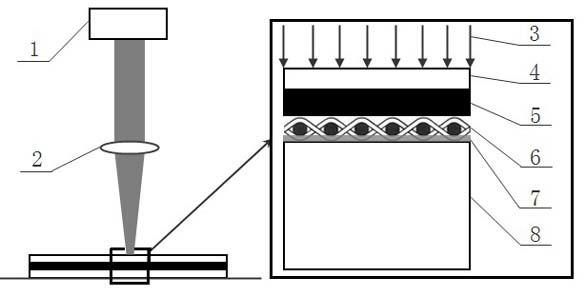

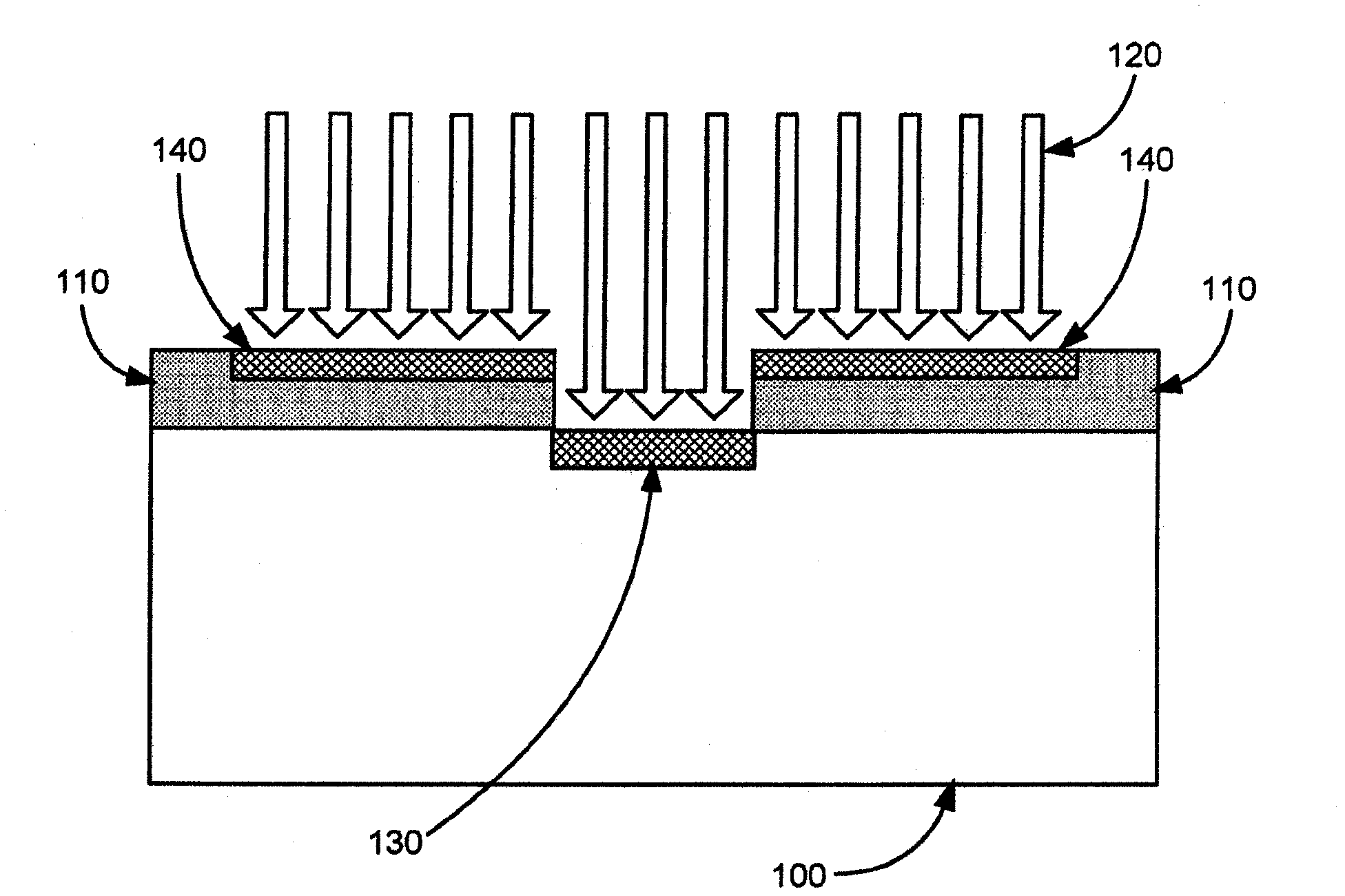

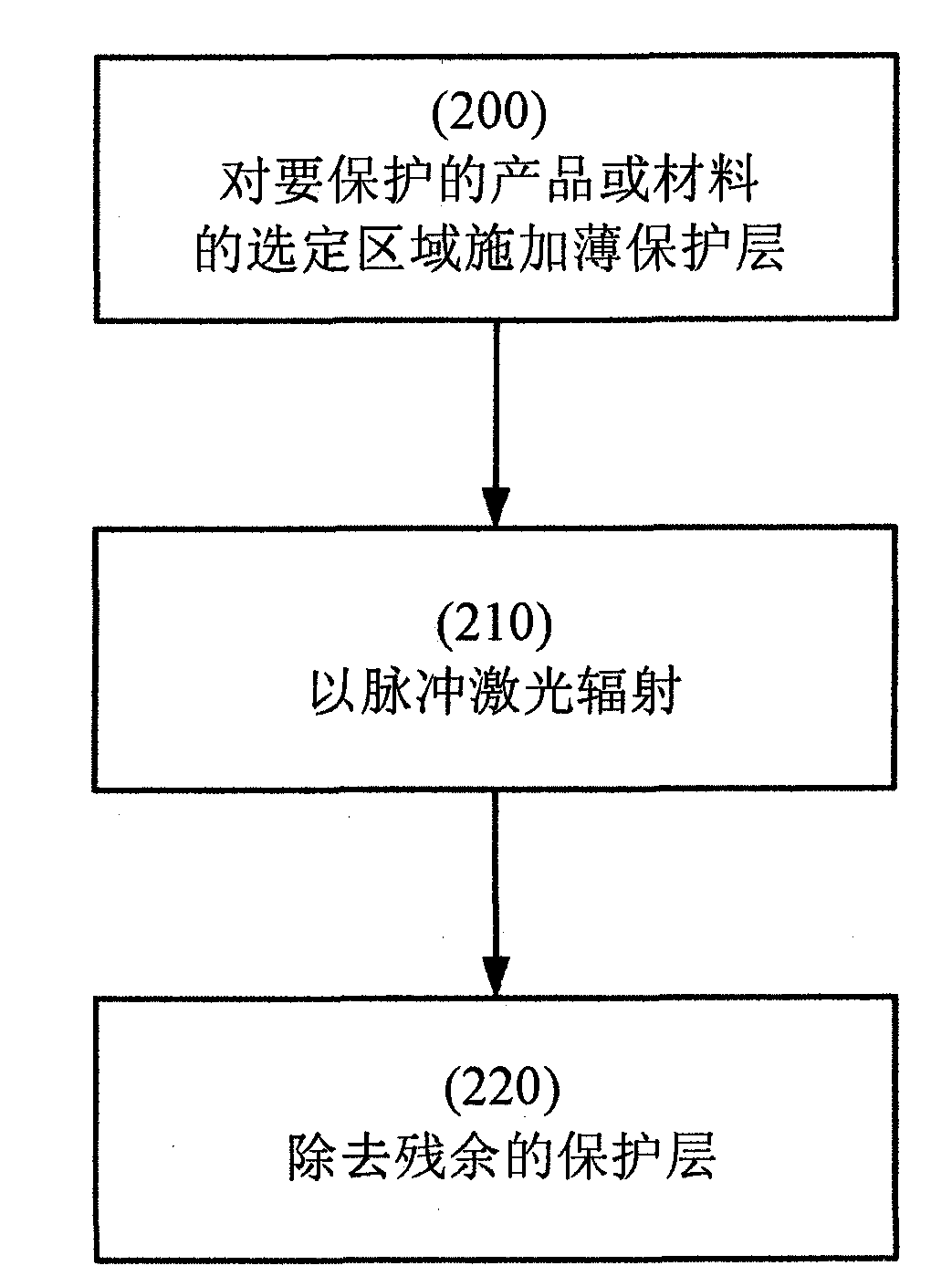

Thin sacrificial masking films for protecting semiconductors from pulsed laser process

InactiveCN102099898ASolid-state devicesSemiconductor/solid-state device manufacturingLaser processingPulsed laser radiation

The present disclosure is directed to systems and methods for protecting a semiconductor product or material from harmful effects of pulsed laser irradiation. In some embodiments, a thin sacrificial protective mask layer that expires after one laser processing operation is applied to the surface of the product or material to be laser-treated. The thin protective mask layer reflects, absorbs, or otherwise protects the underlying product or material from the energy of the laser.

Owner:SIONYX

Single-point fluorescent temperature measurement device and method

ActiveCN106017722AEnhanced temperature dependent propertiesImprove temperature measurement accuracyThermometers using physical/chemical changesFluorescenceAbsorbed energy

The invention relates to the field of measurement and control, in particular to a single-point fluorescent temperature measurement device and method. YAG:Ce powder is doped into a measured system or smeared to the surface of a measured object to serve as a fluorescent temperature probe, pulse lasers serving as a heat source irradiate the measured system or the measured object to generate a transient temperature field, and meanwhile multiphonon-assisted excitation of the fluorescent temperature probe is achieved through a fluorescent excitation light source. Different from conventional excitation in an absorption band, the fluorescent temperature probe absorbs energy of one incident photon and multiple phonons at the same time to achieve excitation, and therefore fluorescence emitted by the excited fluorescent temperature probe generates anti-Stokes fluorescence. According to the scheme, the temperature dependency character of the anti-Stokes fluorescence can be enhanced, and the temperature measurement precision under high temperature can be improved.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

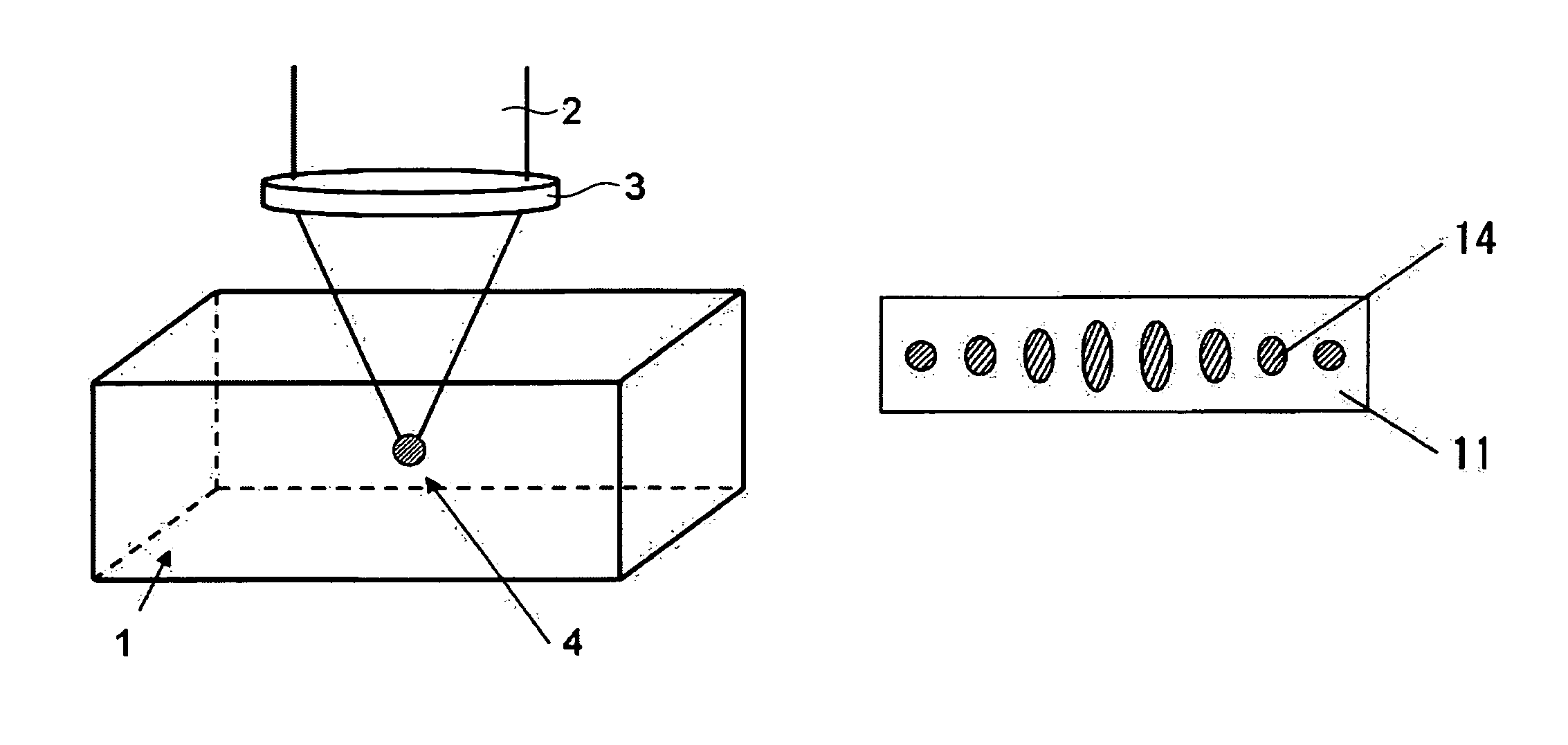

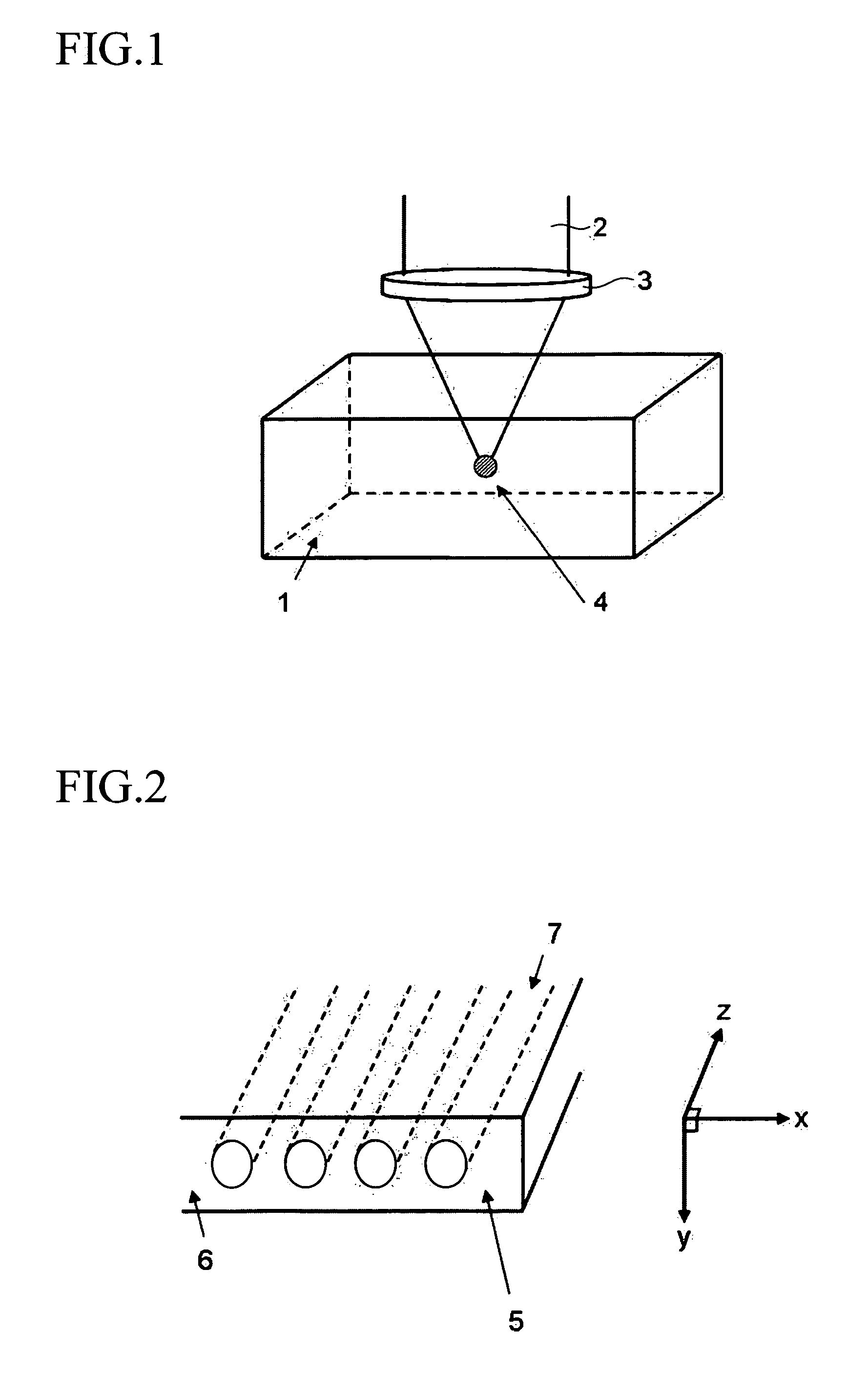

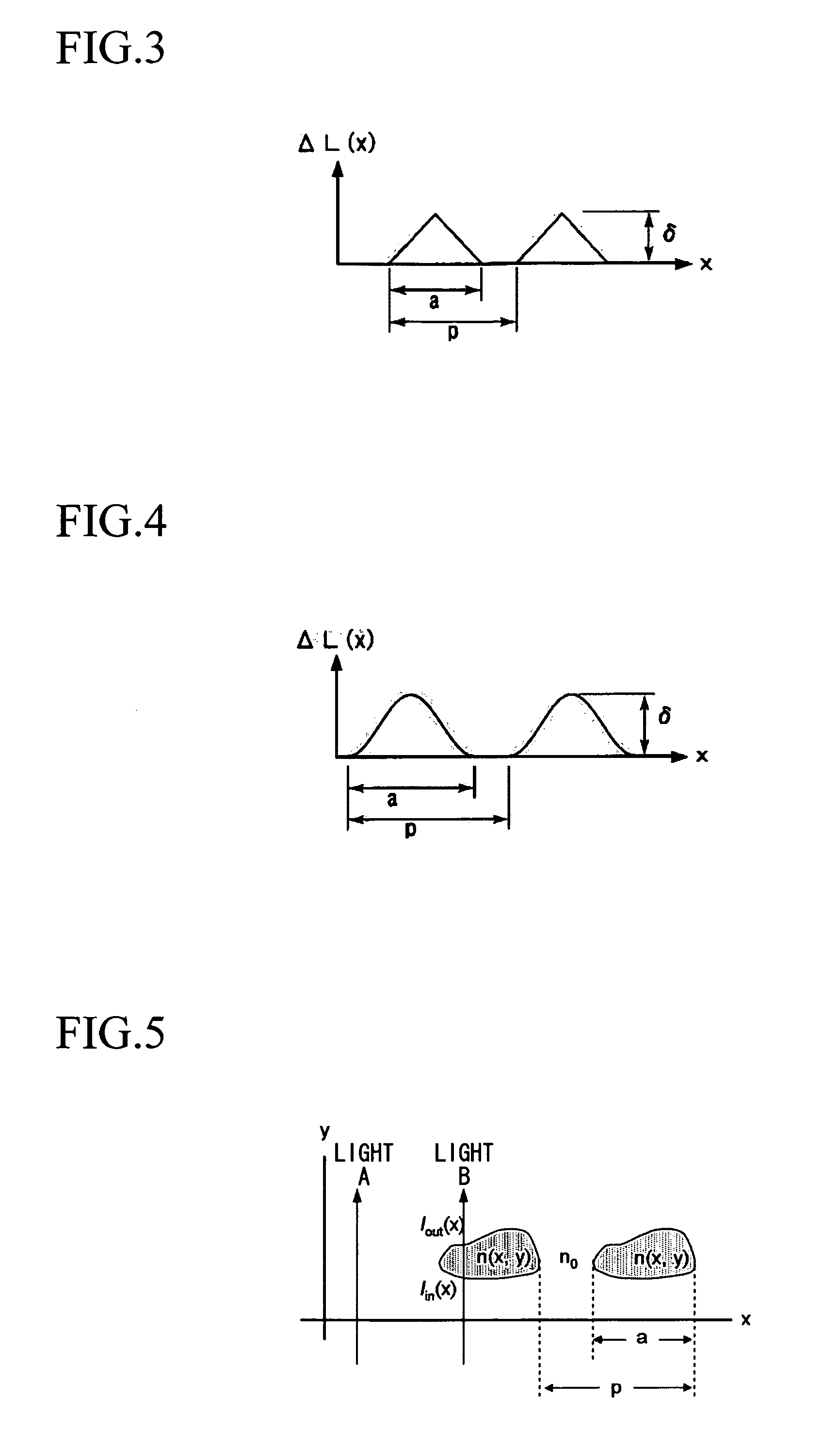

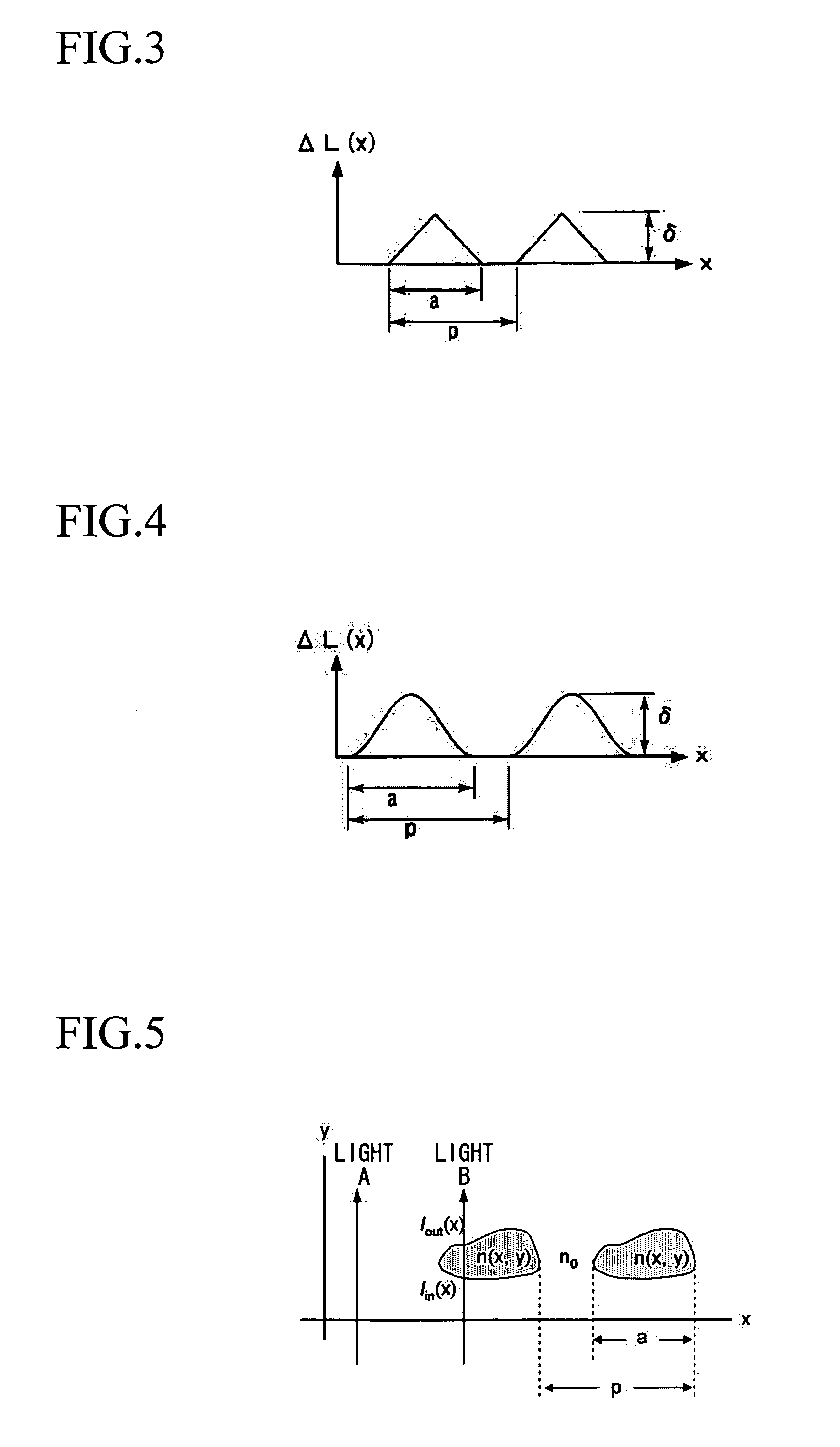

Optical component and method of manufacture of optical component

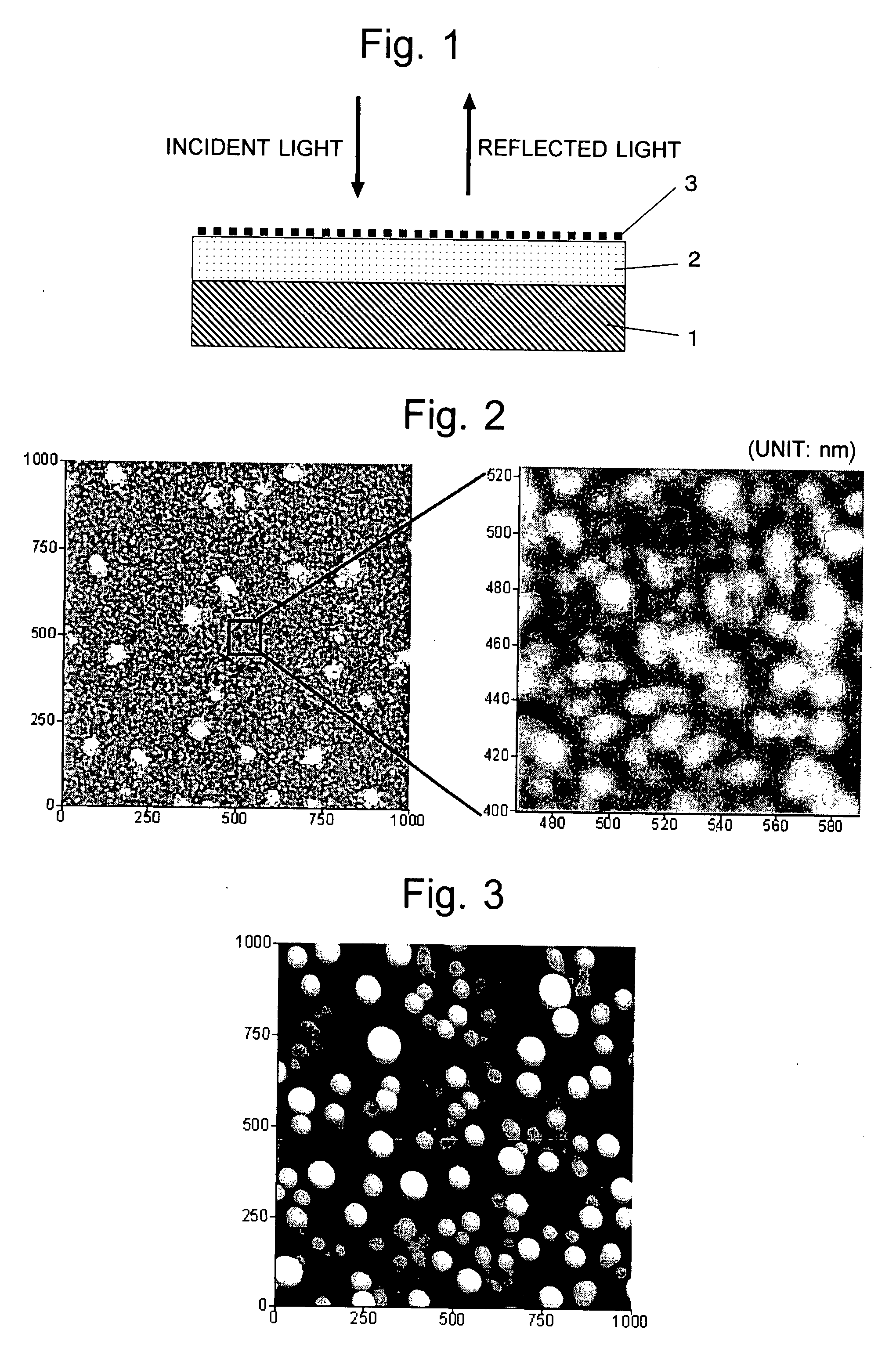

InactiveUS7405883B2Easy to manufactureIncrease freedomOptical fibre with graded refractive index core/claddingDiffusing elementsLow-pass filterRefractive index

An optical component or optical low-pass filter has two or more regions demarcated by differences in refractive indexes, in which a region having a refractive index different from the refractive index of the continuous region with the largest volume among the two or more regions is formed in the interior of a transparent material. This optical component or optical low-pass filter has regions with different refractive indexes formed in the interior by pulsed laser irradiation or focused irradiation of the transparent material.

Owner:OHARA

Laser spot control in maldi mass spectrometers

ActiveUS8872103B2Improve overall utilizationImprove utilityTime-of-flight spectrometersIon sources/gunsEngineeringMass analyzer

Mass spectrometers ionize samples by matrix-assisted laser desorption (MALDI). The samples are located on a moveable support plate, and irradiated by a pulsed laser. A fast positional control of laser spots is provided via a system of rotatable mirrors to relieve strain on a support plate motion drive. If the spot position is finely adjusted by the mirror system and follows the movement of the sample support plate, the intermittent movement of the sample support can be replaced with a continuous uniform motion. The fast positional control allows more uniform ablation of a sample area. Galvo mirrors with low inertia may be used between the beam generation and a Kepler telescope in the housing of the laser. The positional control can also provide a fully automatic adjustment of MALDI time-of-flight mass spectrometers, at least if the ion-optical elements are equipped with movement devices.

Owner:BRUKER DALTONIK GMBH & CO KG

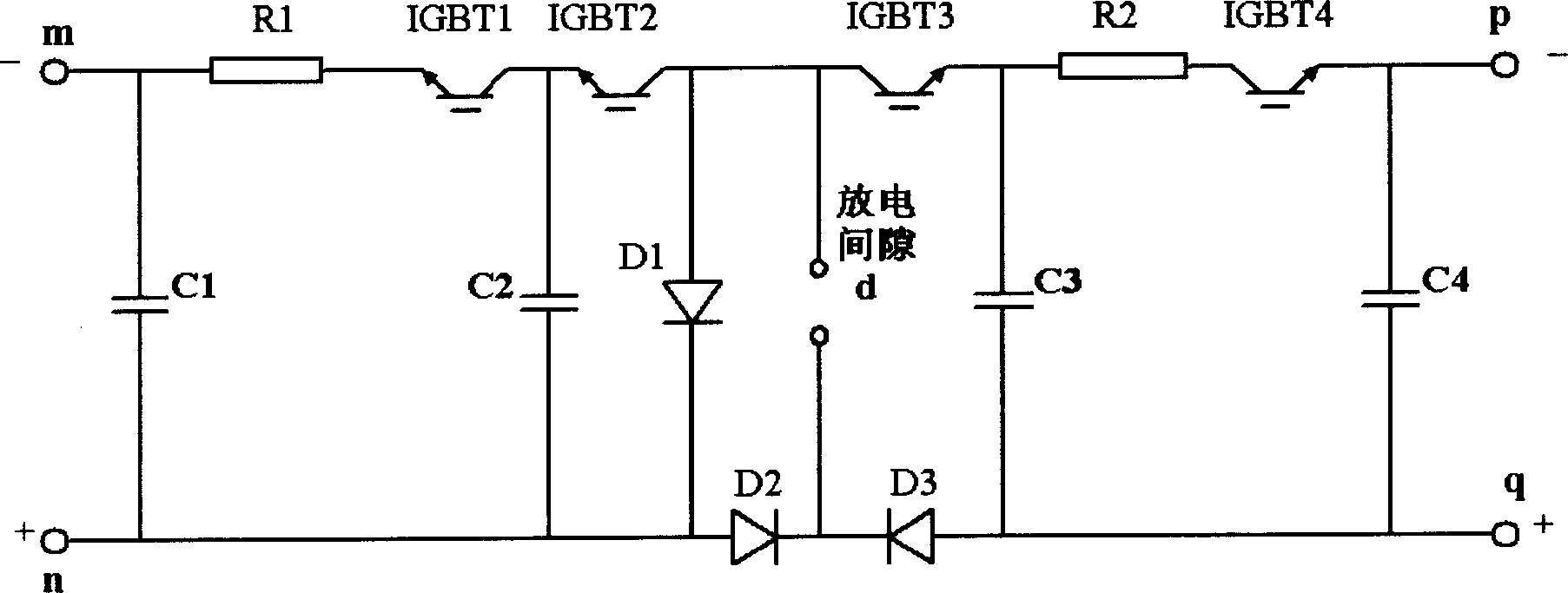

Method of high recurrent frequency pulse laser induction electrode directional discharge and application of said method

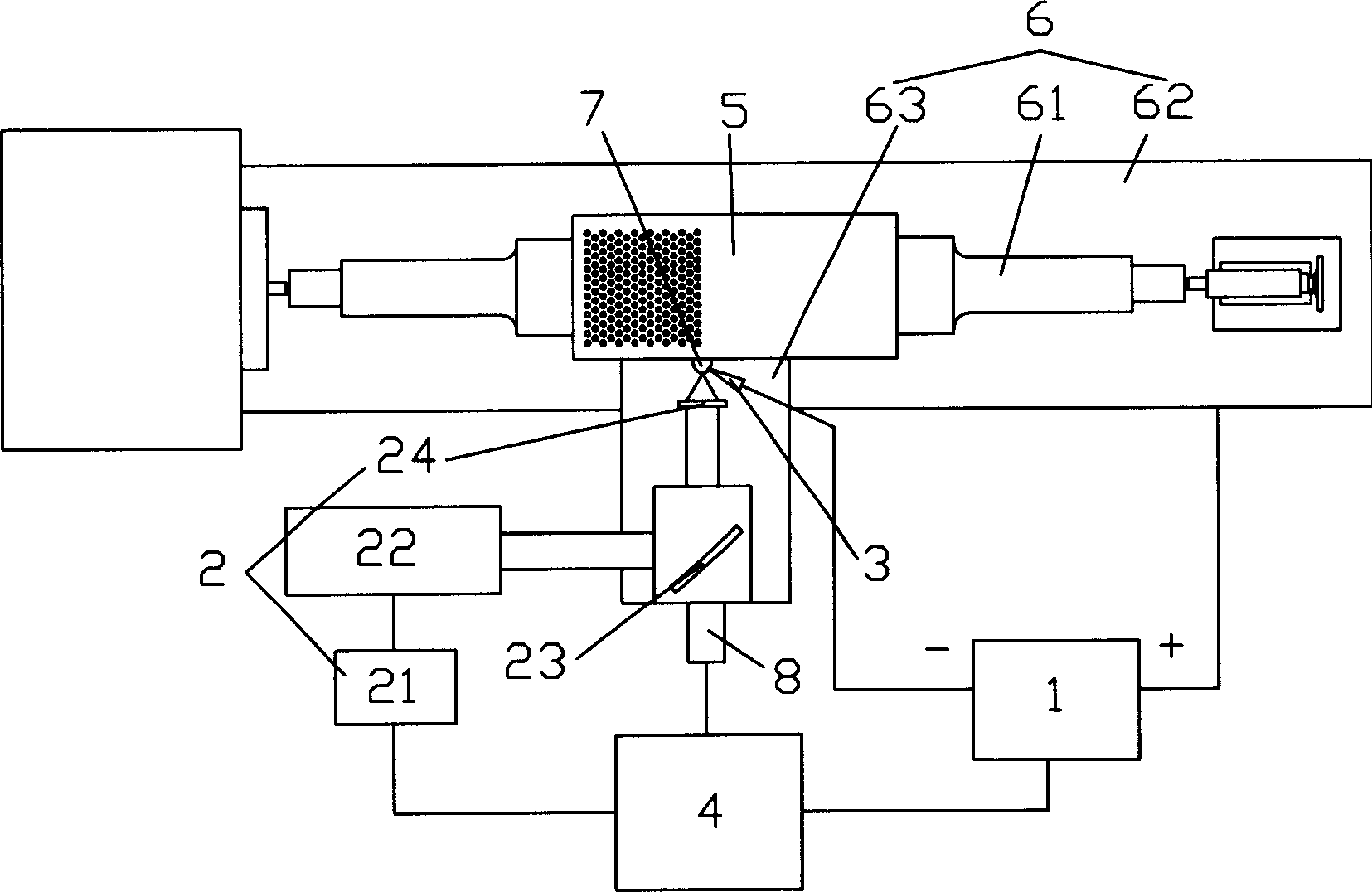

A method for inducing the directional discharge of electrode by the pulse laser at high repeat frequency features that after the workpiece to be machined and the discharging electrode are connected respectively to two poles of pulse power supply, the high-repeat-frequency pulse laser generated by laser generator is used to radiate on the surface of said workpiece and the plasma plume is generated at the radiated dot, which can induce the electrode to discharge toward the dot at high frequency. Its application is also disclosed.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

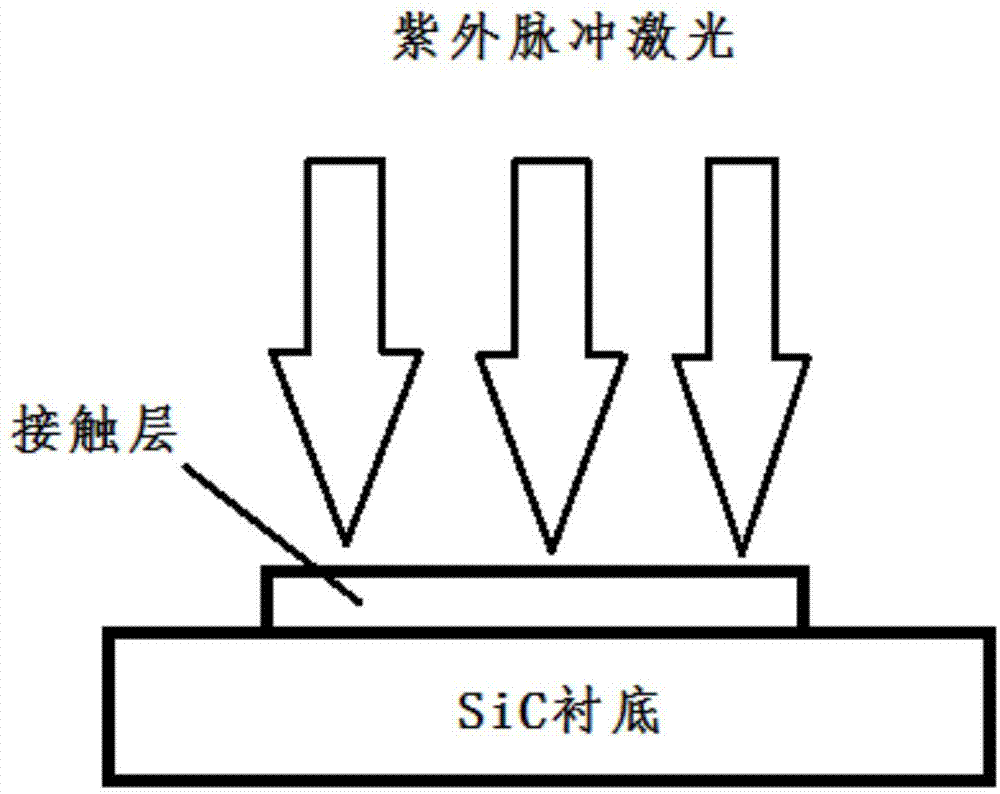

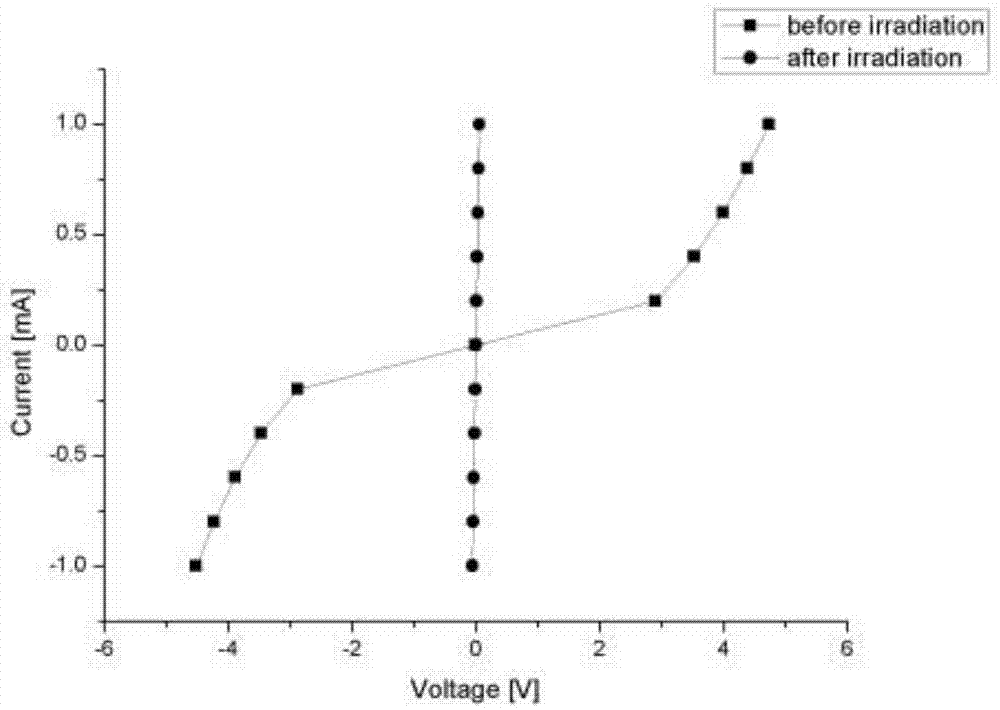

Method for preparing SiC ohmic contact by ultraviolet pulse laser irradiation device

InactiveCN103700580AShort processing timeRaise the reaction temperatureSemiconductor/solid-state device manufacturingSemiconductor devicesOhmic contactUltraviolet

The invention discloses a method for preparing a SiC ohmic contact by an ultraviolet pulse laser irradiation device, and relates to the technical field of semiconductor device preparation. The method comprises the following steps of cleaning the surface of a SiC substrate; preparing a contact layer on the SiC surface; after ultraviolet pulse lasers are focused, irradiating the front of the material under the condition of high vacuum or under the protection of inert gas to obtain the ohmic contact. The ultraviolet pulse laser irradiation replaces the traditional thermal annealing, and the SiC ohmic contact with high performance can be obtained. Compared with the traditional thermal annealing, the method has the advantages of short processing time and high reaction temperature, and the range of a processing area can be accurately controlled.

Owner:SHANGHAI NORMAL UNIVERSITY

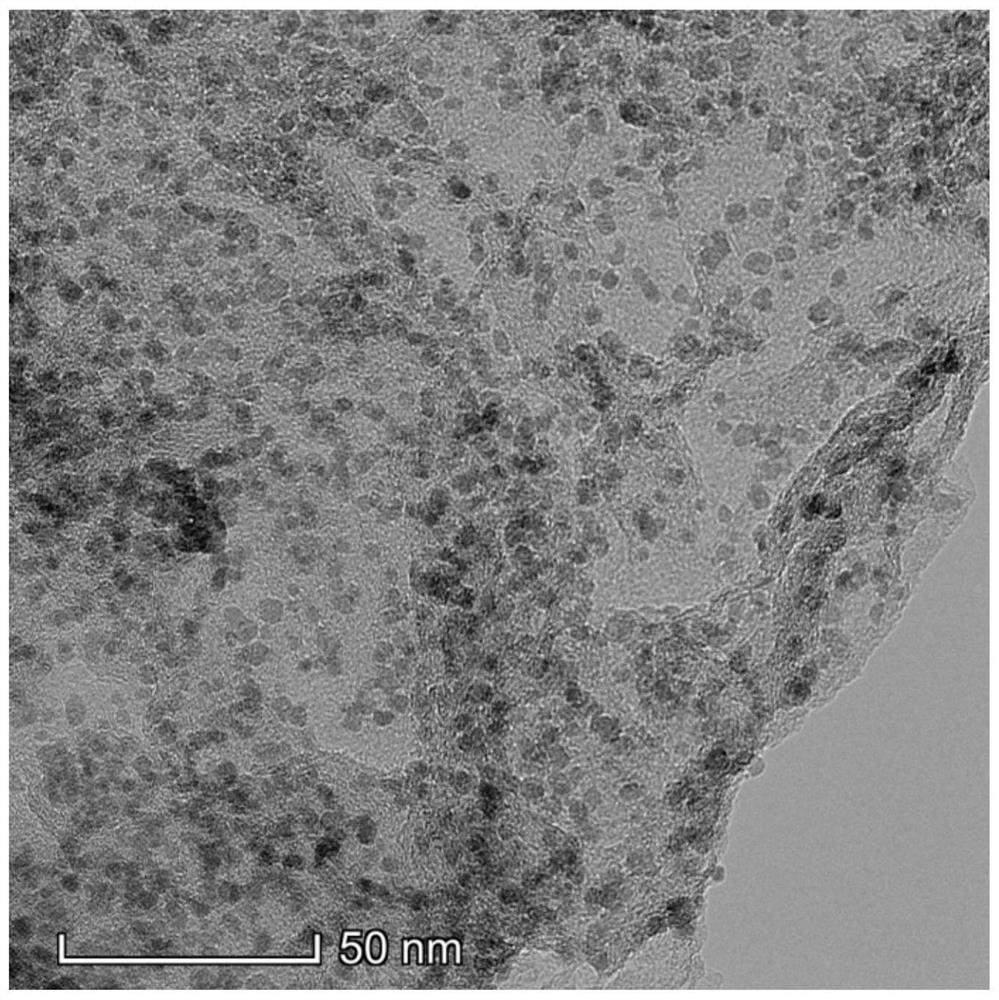

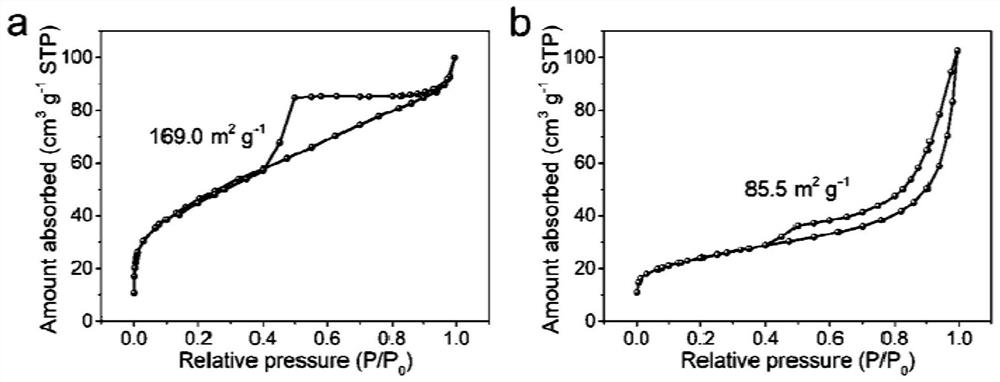

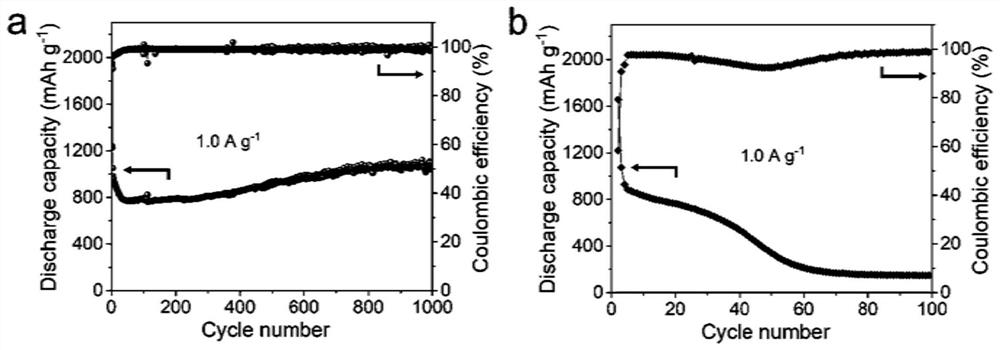

SnO2/graphene composite material as well as preparation method and application thereof

InactiveCN111640925AHigh reactivityLarge specific surface areaNegative electrodesSecondary cellsMetallic foilFreeze-drying

The invention discloses a SnO2 / graphene composite material as well as a preparation method and application thereof, and belongs to the technical field of new energy materials. The preparation method comprises the steps of taking a metal Sn foil as a target material and deionized water as a solvent, and preparing a SnOx colloidal solution by adopting a liquid-phase pulse laser irradiation technology; and dropwise adding the SnOx colloidal solution into the graphene oxide solution, uniformly mixing and dispersing, carrying out hydrothermal reaction, and carrying out freeze drying on the productto obtain a SnO2 / graphene composite material. According to the SnO2 / graphene composite material prepared by the invention, SnOx and graphene oxide are subjected to an in-situ oxidation-reduction reaction in a hydrothermal process, so that uniform and tight anchoring of covalent bonding of ultrafine SnO2 quantum dots on a reduced graphene oxide lamellar wall is realized; and the porous structure ofthe reduced graphene oxide can also be maintained when SnO2 quantum dots are highly loaded.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

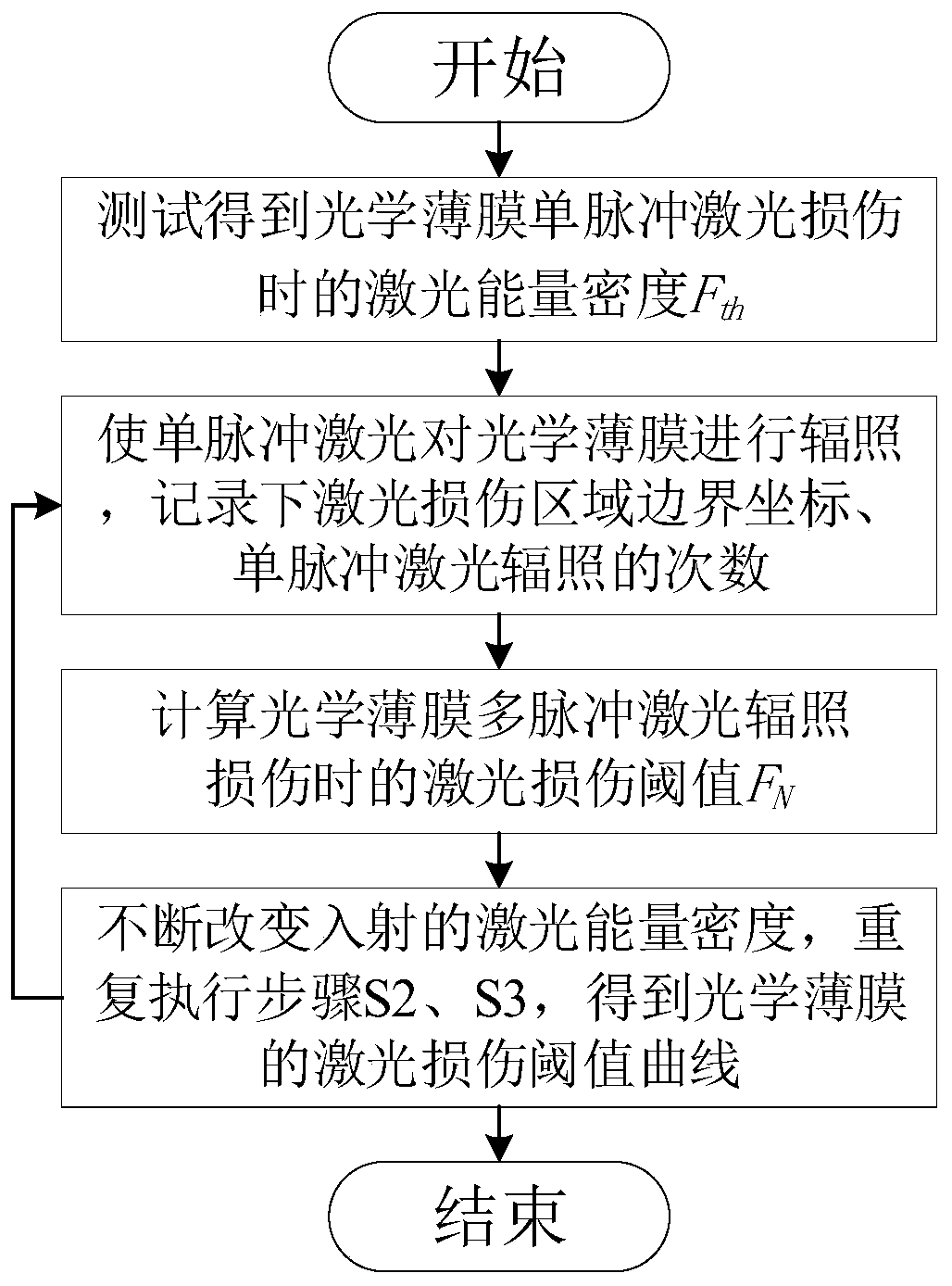

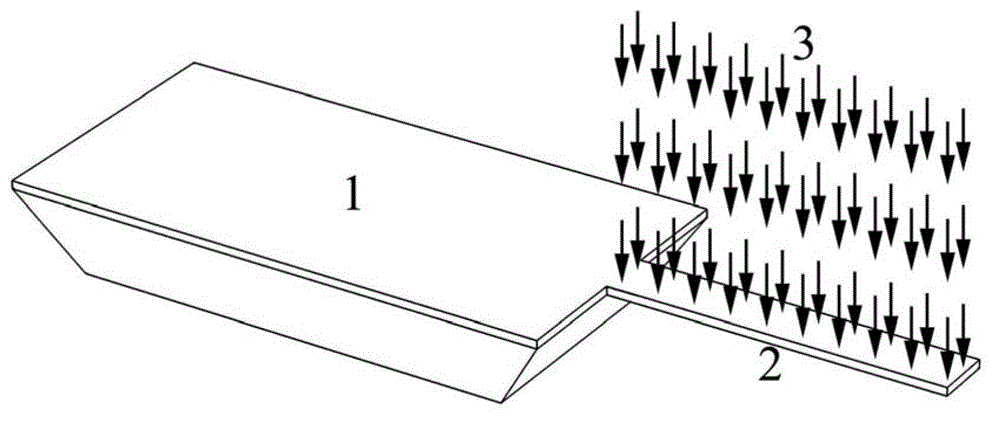

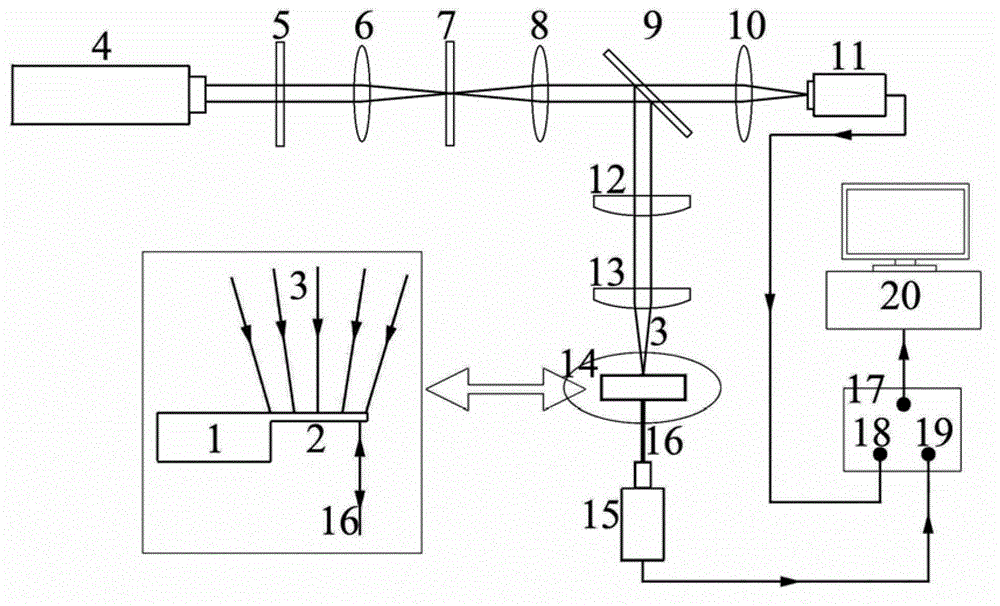

Method for testing laser damage threshold of optical thin film

ActiveCN110542684ADamage Threshold DeterminationEnables damage threshold measurementsMaterial analysis by optical meansOptical apparatus testingTest efficiencyOptical thin film

The invention relates to a method for testing a laser damage threshold of an optical thin film. The method comprises the following steps: S1, obtaining laser energy density Fth of the optical thin film during single-pulse laser damage through test; S2, irradiating the optical thin film by the single-pulse laser, recording laser damage area boundary coordinates (xi, yi) when the laser damage boundary on the surface of the optical thin film is not increased any more, and meanwhile, recording the number n of times of single-pulse laser irradiation; S3, comparing Gaussian distribution of the laserenergy density with laser damage area distribution to obtain a laser damage threshold FN of the optical thin film during multi-pulse laser irradiation damage; and S4, continuously changing the incident laser energy density, and repeatedly executing the steps S2 and S3 to obtain a laser damage threshold curve of the optical thin film under the irradiation of femtosecond laser with different pulsenumbers. The method has the beneficial effects that the measurement accuracy of the laser damage threshold of the optical thin film under multi-pulse laser irradiation is guaranteed, and meanwhile, the test efficiency of the damage threshold of the optical thin film under multi-pulse laser irradiation is greatly improved.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

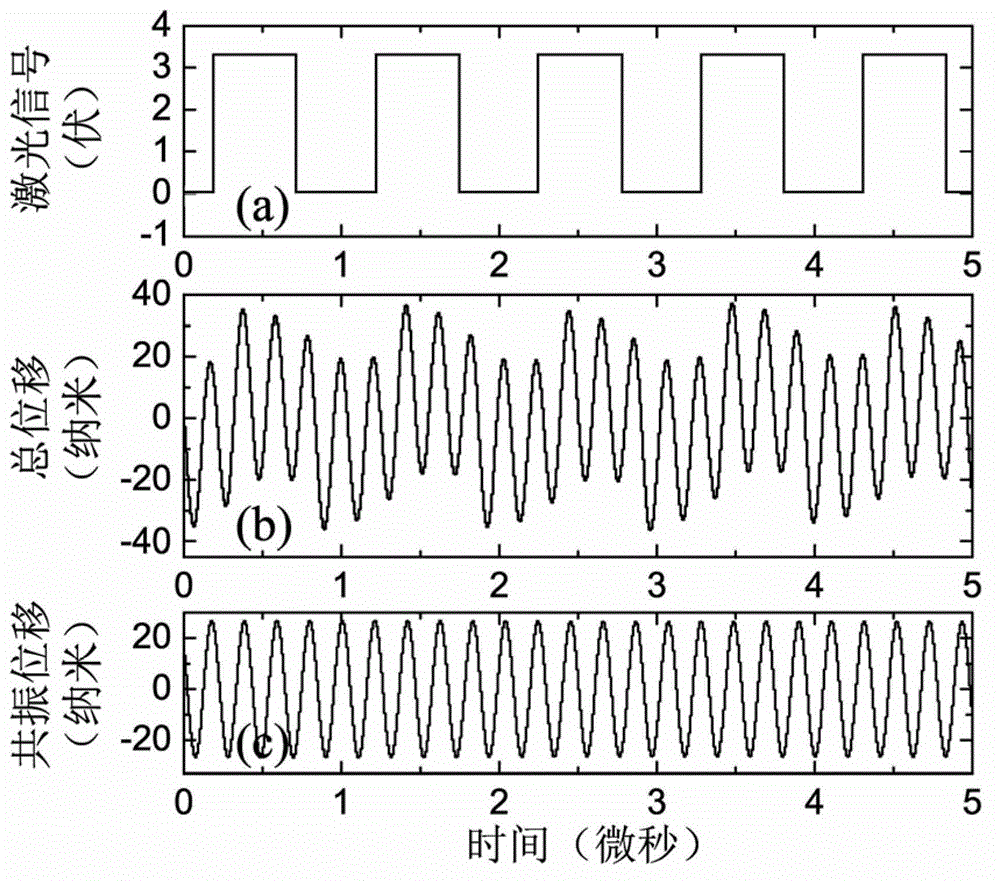

Method for remotely exciting micrometer-scale micro-cantilever probe to resonate by using laser

InactiveCN102944615AReduce the impactImprove working precisionComponent separationMaterial analysis by optical meansHarmonicMicrometer scale

The invention relates to a method for remotely exciting micrometer-scale micro-cantilever probes to resonate by using laser. By applying pulse laser with certain frequency for radiation onto surfaces of the micrometer-scale micro-cantilever probes and producing thermal stress in the micrometer-scale micro-cantilever probes under the thermal effect of the laser, the resonance excitation of the micrometer-scale micro-cantilever probes is realized. The frequency of the pulse laser is 1 / n of the resonance frequency of the micro-cantilever probes, wherein n is a number within 1-10. The micrometer-scale micro-cantilever probes are excited to resonate by using n-order Fourier harmonic waves of the thermal stress produced in the micro-cantilever probes under the thermal effect of the laser.

Owner:SHANDONG UNIV

System and Method for Laser Induced Forward Transfer Comprising a Microfluidic Chip Print Head with a Renewable Intermediate Layer

ActiveUS20200070514A1Lower Reynolds numberSuppressing turbulence within flowInking apparatus3D object support structuresVapor bubblePulsed laser irradiation

Methods and systems for Laser-Induced Forward Transfer are disclosed in which a microfluidic chip is used as the printing head. The head comprises a transparent upper region, a middle region comprising an intermediate layer channel and an ink channel in fluid connection with said intermediate layer channel, and a lower layer with an orifice in fluid contact with the ink channel. When material in the intermediate layer channel is irradiated by an energy source (typically a pulsed laser) at a spot opposite the orifice, the material is partially evaporated, creating a vapor bubble that creates a transient pressure increase when it collapses, thereby forcing ink out of the orifice and onto a receiving substrate.

Owner:PRECISE BIO INC +1

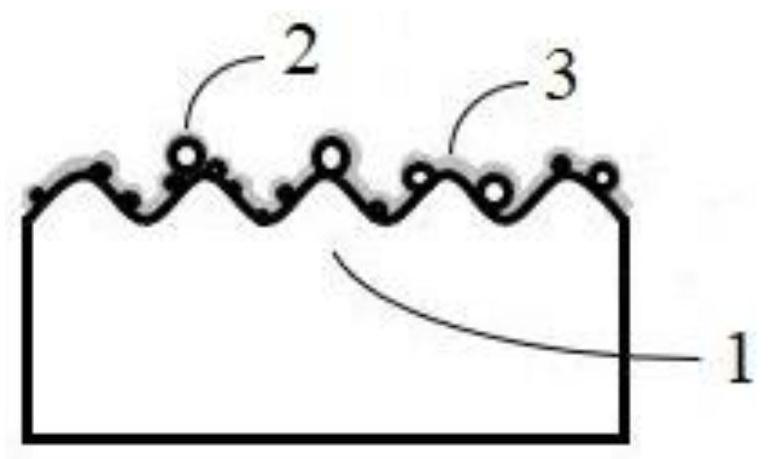

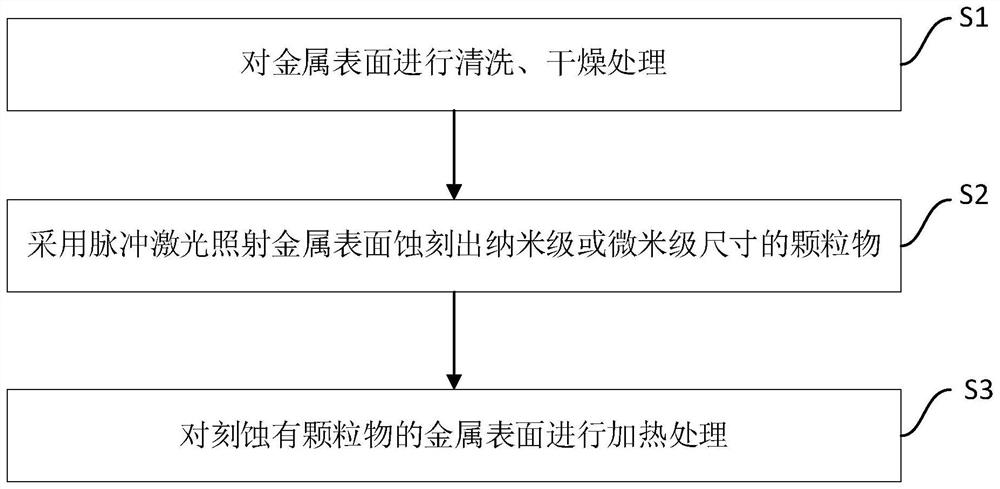

Non-stick metal surface and preparation method thereof

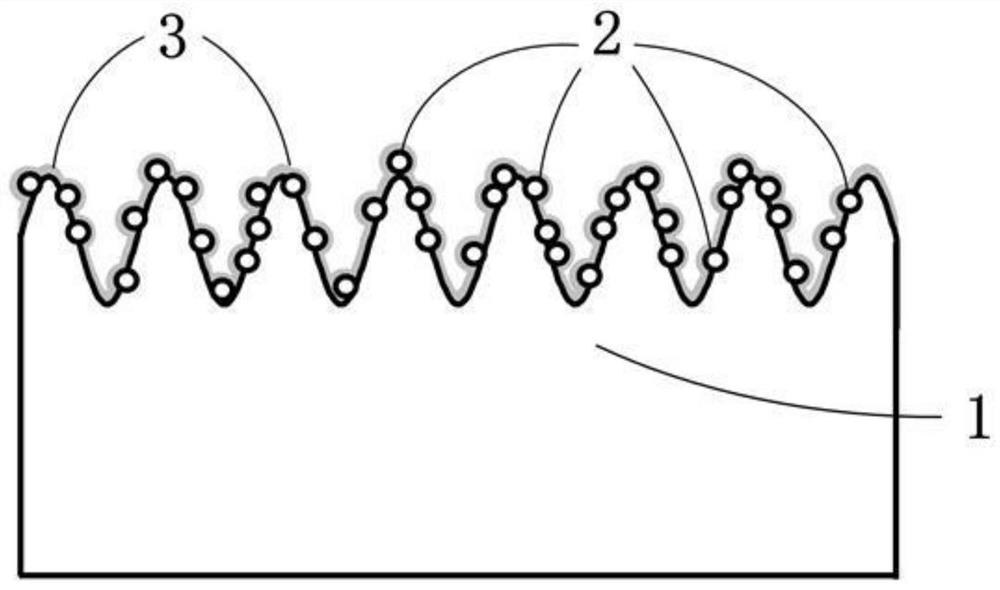

PendingCN113634909AWith characteristicsLong-lasting non-stick performanceCoatingsSpecial surfacesMicron scaleNano structuring

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

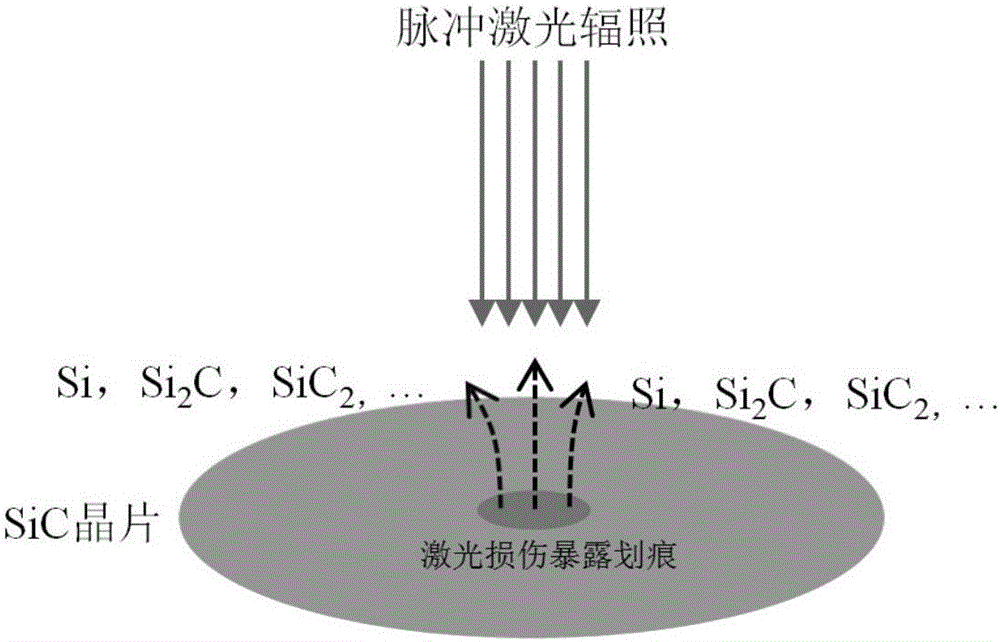

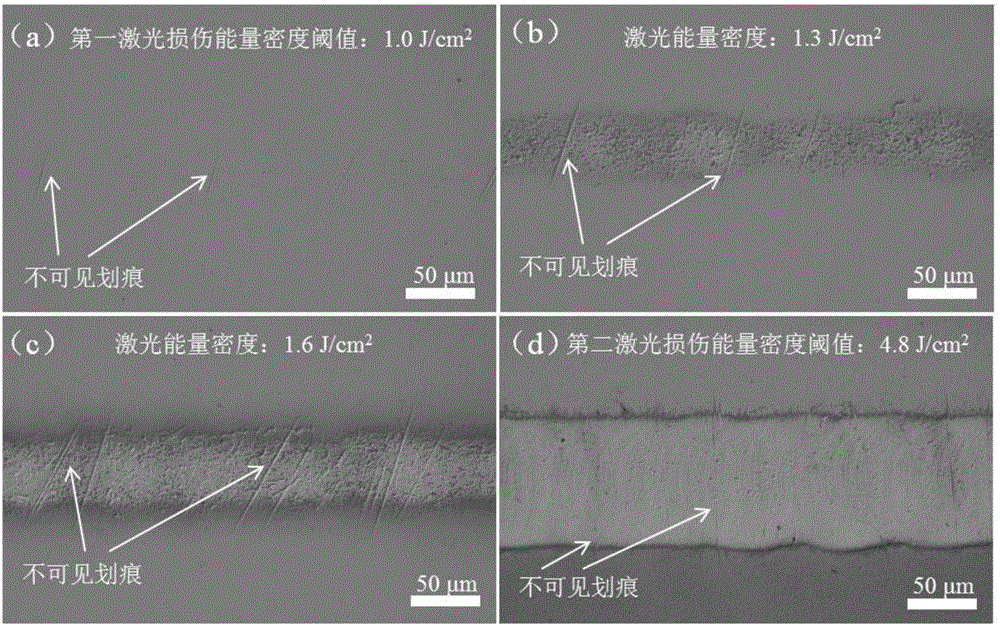

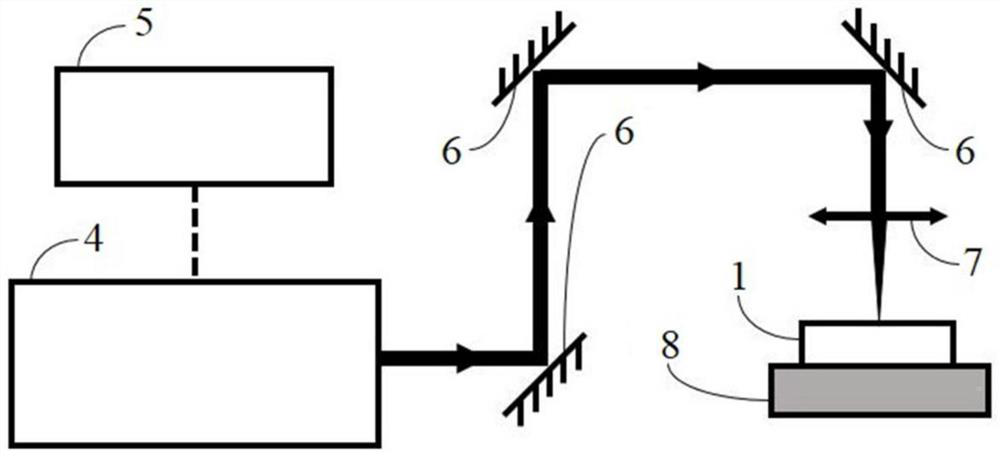

Method for detecting semiconductor polish wafer surface scratches

ActiveCN105870033AQuick checkEfficient detectionSemiconductor/solid-state device testing/measurementMicroscopic observationPulsed laser irradiation

The invention provides a method for detecting semiconductor polish wafer surface scratches. The detection method comprises the following steps that 1, a semiconductor polish wafer is irradiated by means of a pulse laser; 2, the semiconductor polish wafer surface subjected to pulse laser irradiation is observed with a microscope, wherein the total irradiation energy density of the pulse laser is between a first damage energy density threshold value and a second damage energy density threshold value. The detection method is high in speed, low in cost, small in damage to the wafer, free of pollution and capable of being widely applied to rapid detection on the surface scratches of semiconductor polish wafer products.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

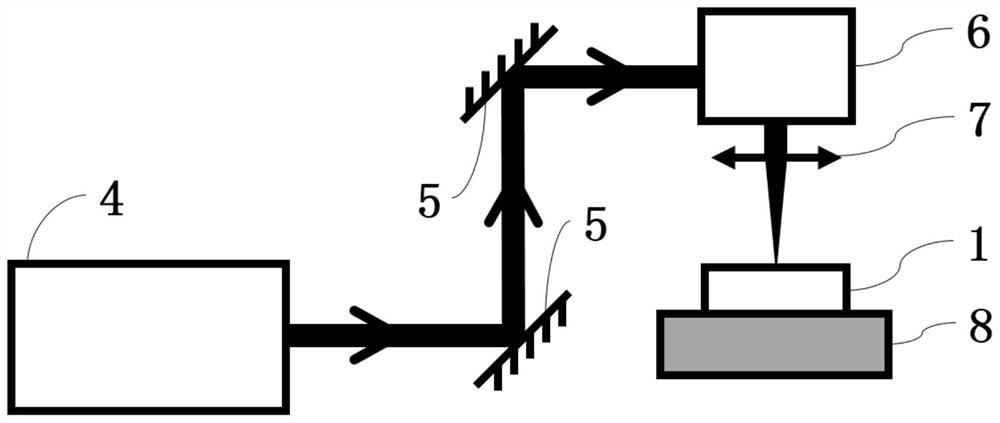

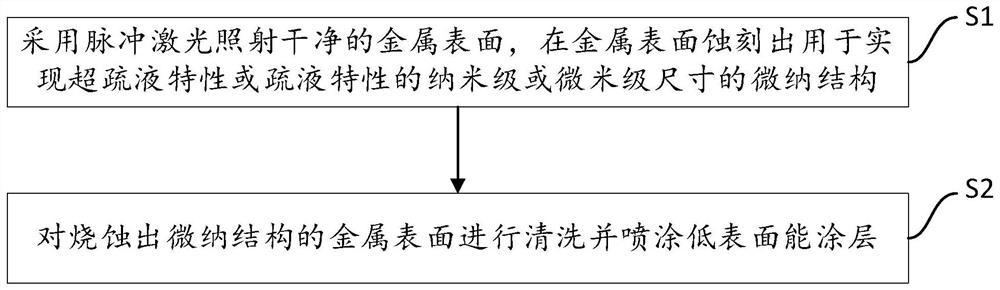

Self-cleaning metal surface as well as preparation method and preparation device thereof

InactiveCN112207010AWith characteristicsSimple processPretreated surfacesCoatingsMicron scaleLaser etching

The invention discloses a self-cleaning metal surface as well as a preparation method and a preparation device thereof. A measurement method comprises the following steps that S1, the metal surface iscleaned and dried; S2, pulse laser is adopted to irradiate the metal surface to etch out nano-scale or micron-scale particles, organic matter is adsorbed to the metal surface obtained after laser etching, and the organic matter has a functional group used for reducing surface energy; and S3, heating treatment is carried out on the metal surface etched with the particles. According to the invention, the self-cleaning metal surface with a super-lyophobic characteristic or lyophobic characteristic can be prepared only through pulse laser and heating treatment, chemical process treatment is not needed, the process is simple, the efficiency is high, environmental protection is achieved, and the performance is lasting.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Optical component and method of manufacture of optical component

InactiveUS20060119956A1Easy to manufactureIncrease freedomOptical fibre with graded refractive index core/claddingDiffusing elementsLow-pass filterRefractive index

An optical component or optical low-pass filter has two or more regions demarcated by differences in refractive indexes, in which a region having a refractive index different from the refractive index of the continuous region with the largest volume among the two or more regions is formed in the interior of a transparent material. This optical component or optical low-pass filter has regions with different refractive indexes formed in the interior by pulsed laser irradiation or focused irradiation of the transparent material.

Owner:OHARA

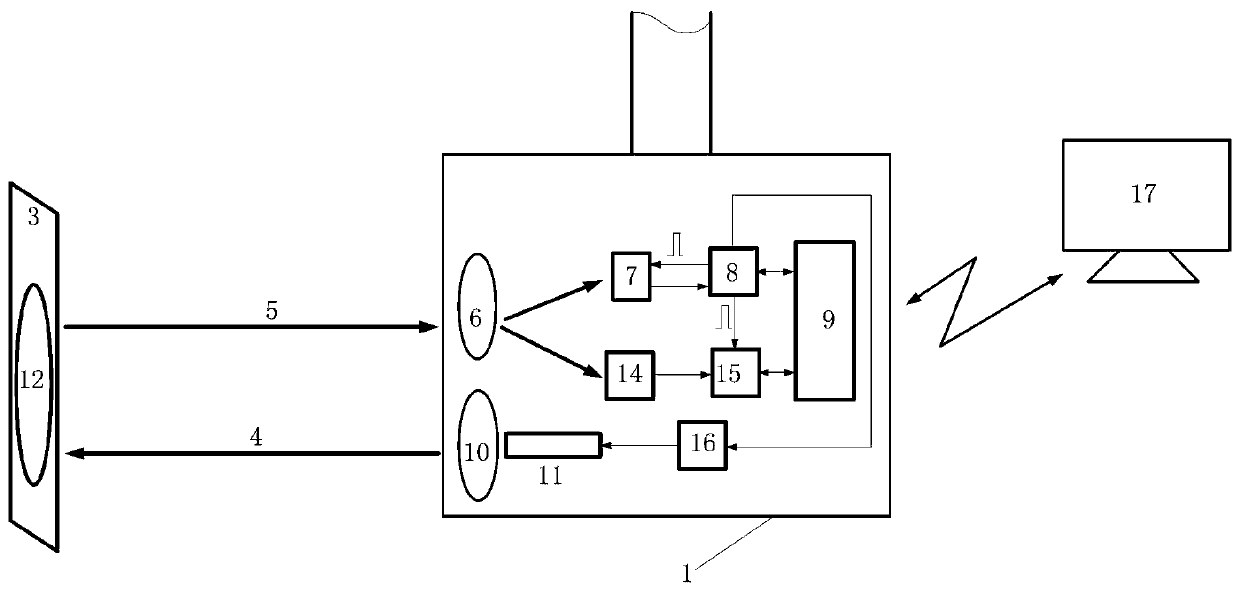

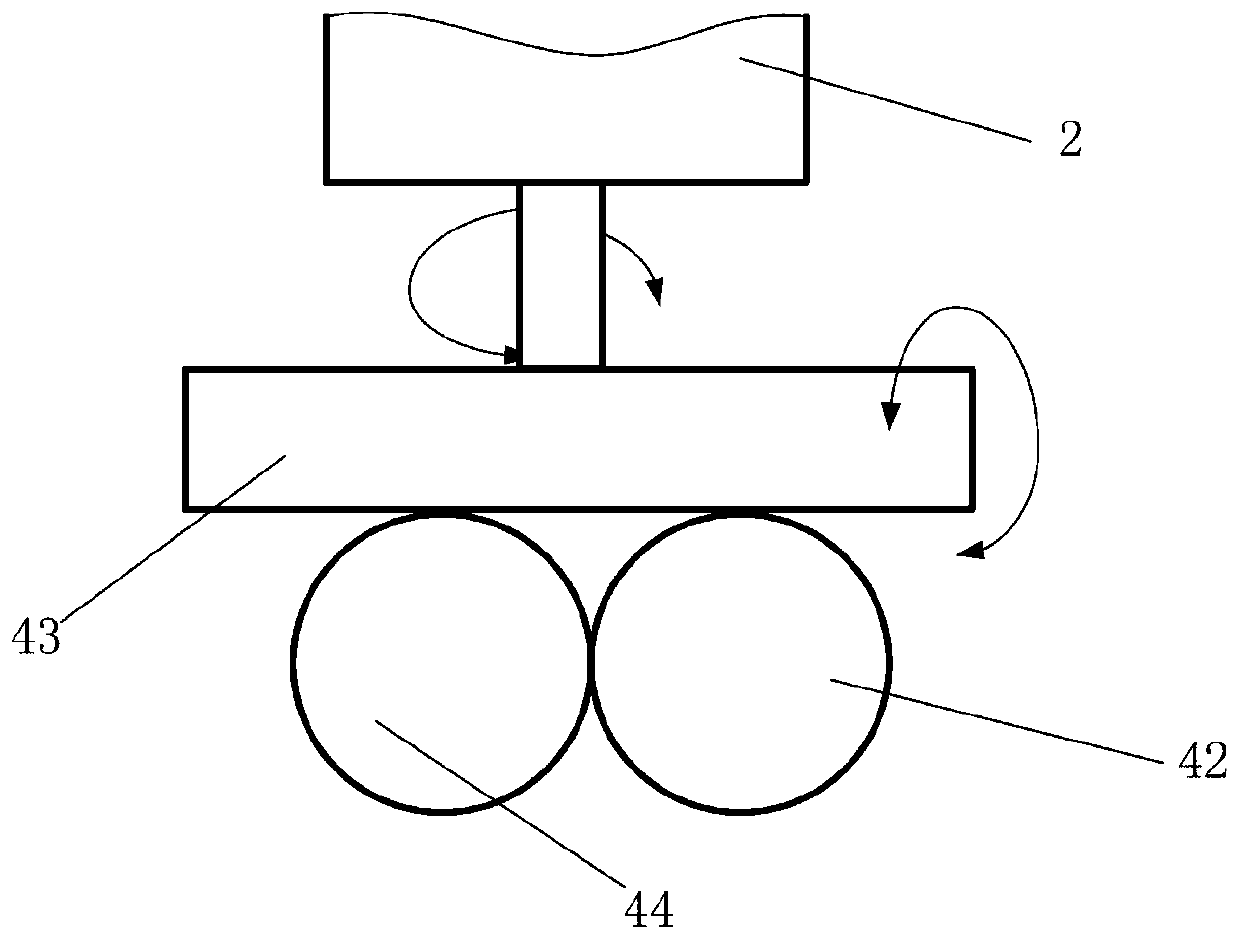

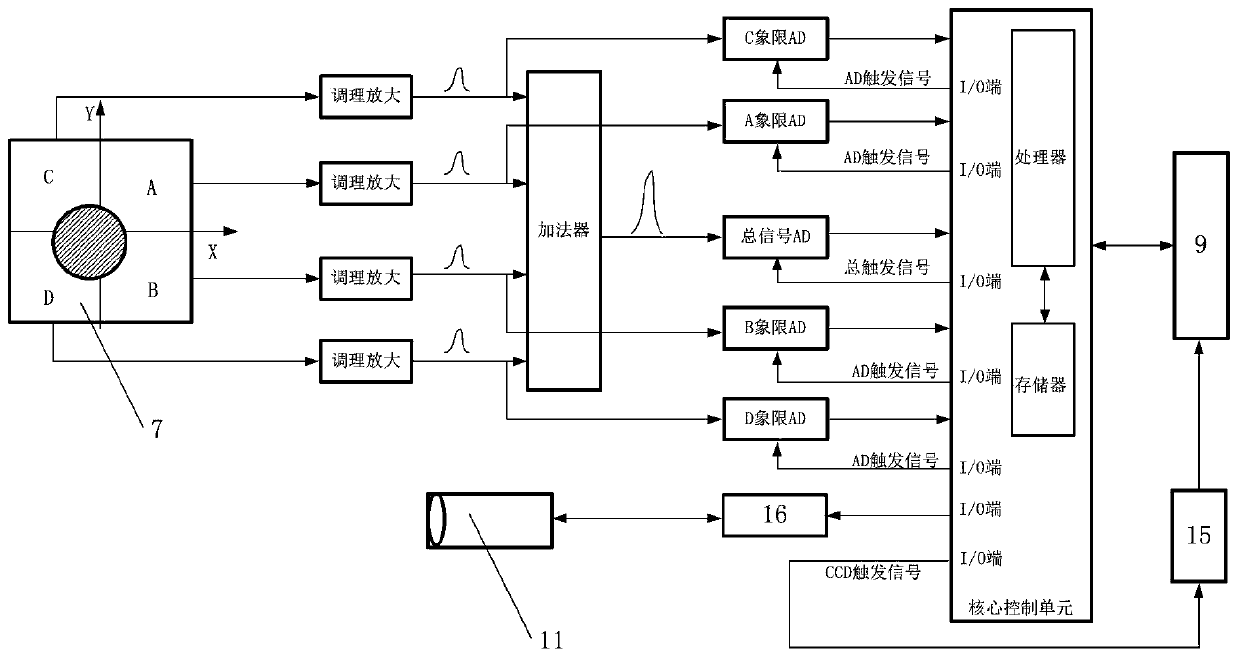

Laser active tracking system and tracking method

ActiveCN111158010AImplement testAchieve goal trackingElectromagnetic wave reradiationLight spotEngineering

The invention discloses a laser active tracking system and tracking method. The system comprises a laser marker, a light spot test unit and a data transmission unit. The light spot test unit comprisesa receiving mirror, a four-quadrant photoelectric detector, a CCD imaging detector and an acquisition processing circuit; after pulse laser emitted by the laser irradiates a target, the CCD processing unit processes the CCD imaging detector to obtain a light spot image; the acquisition processing circuit acquires and processes an output electric signal of the four-quadrant photoelectric detectorto obtain a light spot centroid coordinate; the light spot image and the light spot centroid coordinate are sent to a far-end command and control center through the data transmission unit; according to the invention, the active tracking system integrates the four-quadrant detector, the CCD image sensor and the target indication laser together; the target indication laser emits pulse laser; comprehensive testing and target tracking of laser spots are achieved, and target parameters and decision basis reference are provided for accurate strike of semi-active guided weapons.

Owner:AEROSPACE JINPENG TECH EQUIP (BEIJING) CO LTD

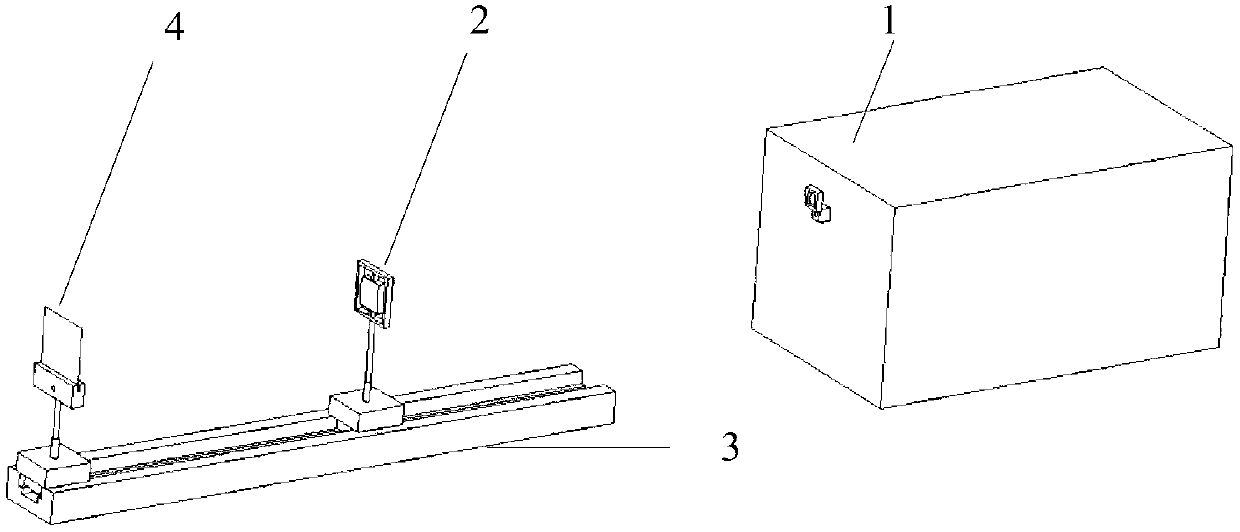

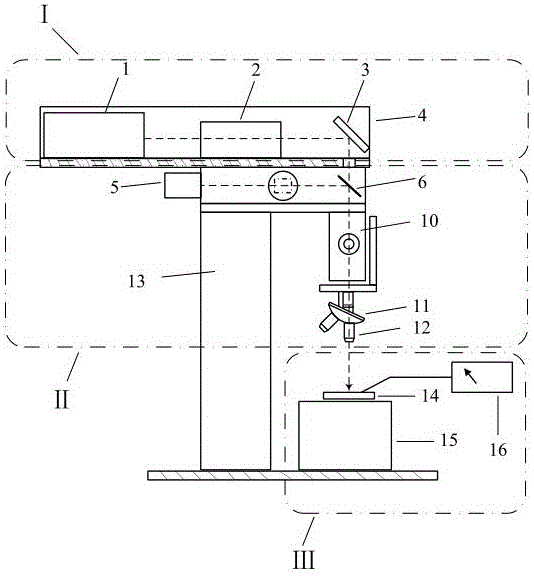

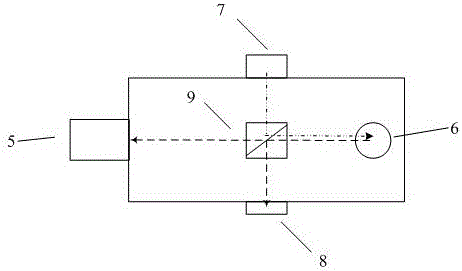

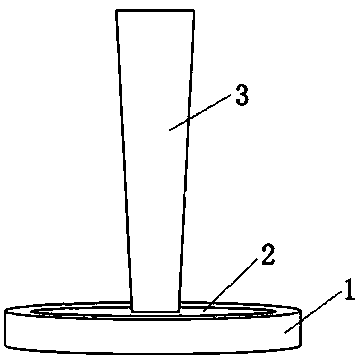

Pulse laser irradiation treatment method for healing fatigue damage of copper thin film part

The invention relates to a pulse laser irradiation treatment method for healing fatigue damage of a copper thin film part. The pulse laser irradiation treatment method comprises the following steps of: A) providing a laser irradiation healing device, wherein the laser irradiation healing device comprises a pulse laser, a light path device, a guide rail and a test piece fixing device; B) fixing a copper thin film test piece at the center of a metal flat plate; C) causing a laser emitting hole, the light path device and the test piece fixing device to be on the same line by virtue of the guide rail; D) controlling size of a laser spot; E) causing the laser spot to accurately irradiate a gap of a test piece; F) adjusting single pulse energy by virtue of a laser control system, so as to change energy density of lasers, wherein the lasers emitted by the pulse laser are irradiated onto the surface of the copper thin film test piece by virtue of a convex lens in the light path device; and G) taking down the copper thin film test piece from the test piece fixing device. By adopting the pulse laser irradiation treatment method, a heat-affected zone is formed on the surface of a material, so that fatigue damage of the copper thin film test piece can be effectively healed, and fatigue life of the copper thin film test piece can be also greatly prolonged.

Owner:BEIJING UNIV OF TECH

Method and system for providing a thin film with a controlled crystal orientation using pulsed laser induced melting and nucleation-initiated crystallization

InactiveUS20060006464A1Unified directionLiquid crystal compositionsPolycrystalline material growthCrystal orientationThin membrane

Method and system for generating a metal thin film with a uniform crystalline orientation and a controlled crystalline microstructure are provided. For example, a metal layer is irradicated with a pulsed laser to completely melt the film throughout its entire thickness. The metal layer can then resolidify to form grains with a substantially uniform orientation. The resolidified metal layer can be irradiated with a sequential lateral solidification technique to modify the crystalline microstructure (e.g., create larger grains, single-crystal regions, grain boundary controlled microstructures, etc.) The metal layer can be irradiated by patterning a beam using a mask which includes a first region capable of attenuating the pulsed laser and a second region allowing complete irradiation of sections of the thin film being impinged by the masked laser beam. An inverse dot-patterned mask can be used, the microstructure that may have substantially the same as the geometric pattern as that of the dots of the mask.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

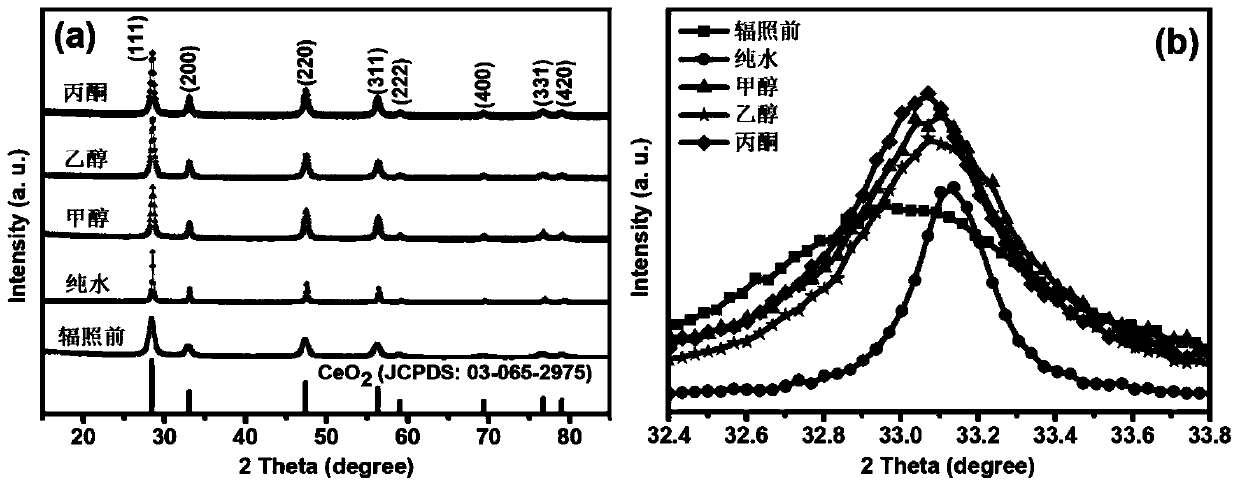

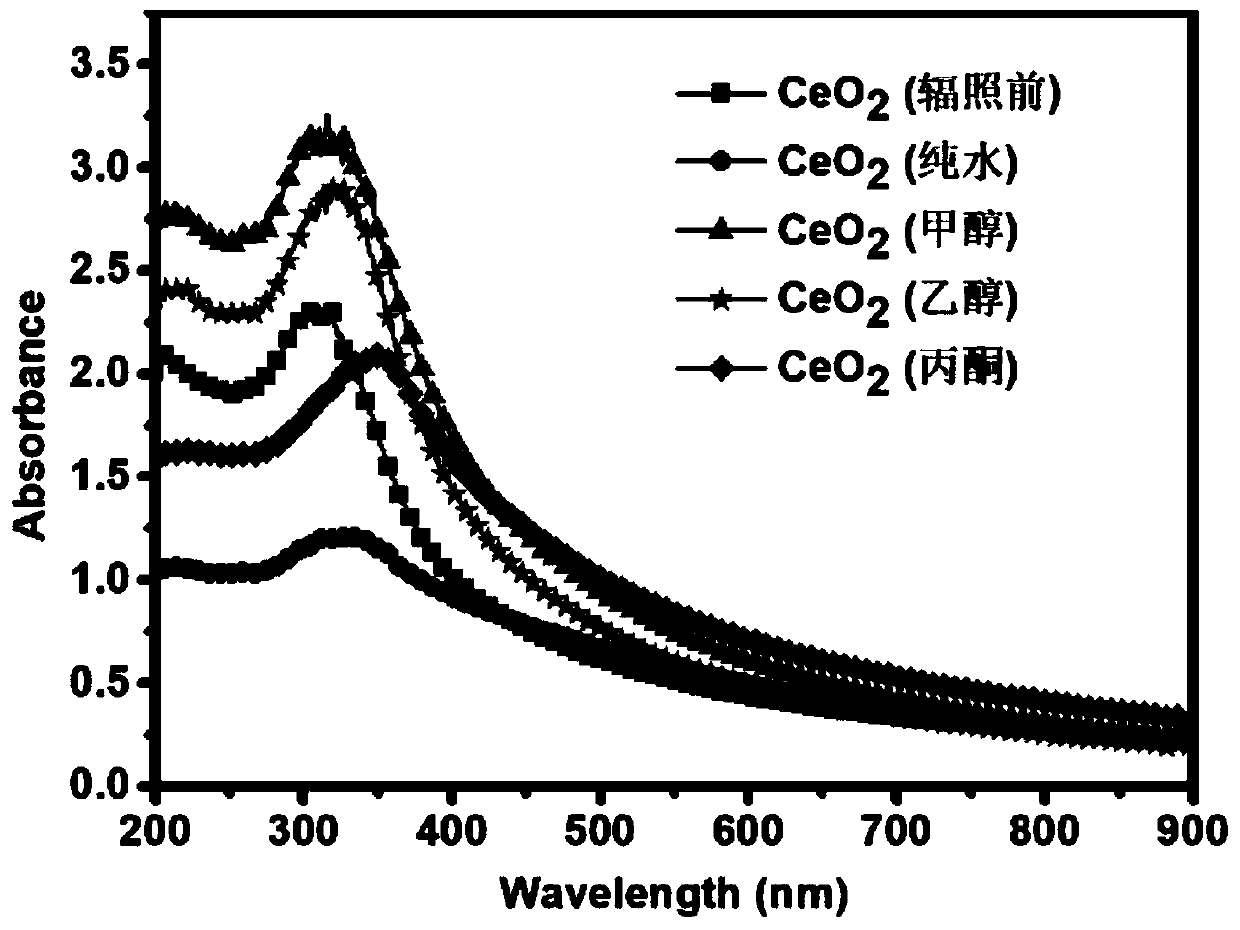

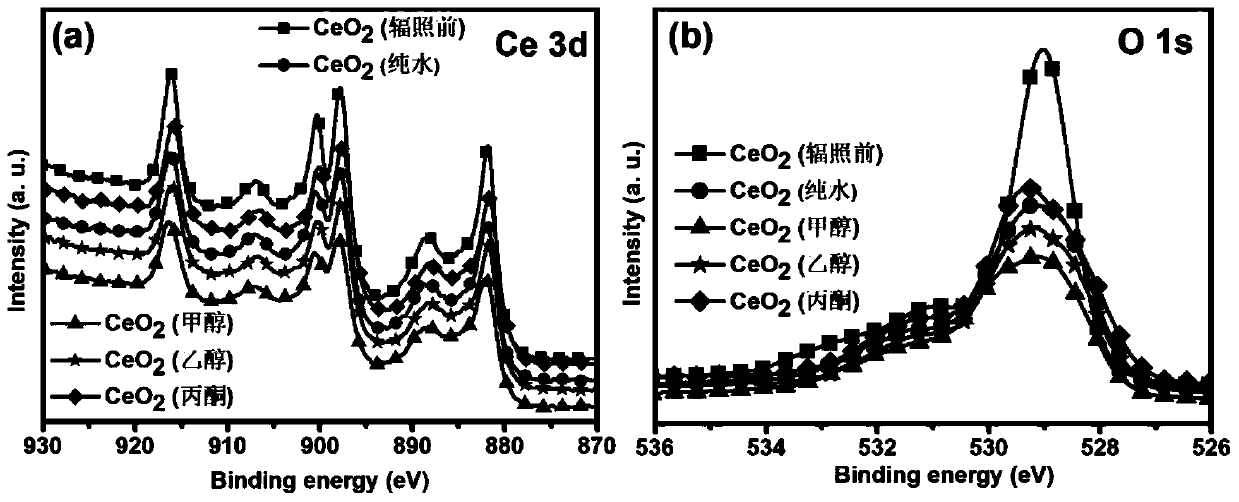

Method for regulating and controlling oxygen defects of cerium dioxide nano material by pulse laser irradiation in liquid phase

ActiveCN111003724AMild conditionsEfficient and fast regulation processMaterial nanotechnologyCerium oxides/hydroxidesFreeze-dryingCerium(IV) oxide

The invention discloses a method for regulating and controlling oxygen defects of a cerium dioxide nano material by pulse laser irradiation in a liquid phase, and the method comprises the following steps: dispersing CeO2 nanosheet powder in a solvent to prepare a 1mg / mL turbid liquid; wherein the solvent is at least one of water, methanol, ethanol or acetone; while stirring the turbid liquid, irradiating the turbid liquid for 5-60 minutes by adopting pulse laser with the wavelength of 355 nm or 532 nm, the pulse frequency of 20 Hz and the monopulse energy of 10-120 mJ; carrying out centrifugaltreatment, cleaning precipitates obtained by the centrifugal treatment by adopting deionized water, and then carrying out freeze drying to obtain the cerium dioxide nano material with reduced oxygendefects. The method is simple, safe, mild in condition, efficient and rapid in regulation and control process and environmentally friendly, other impurities are not introduced, and the pure and high-performance CeO2-x nano material with reduced oxygen defects can be obtained.

Owner:合肥中科纳普新材料有限公司

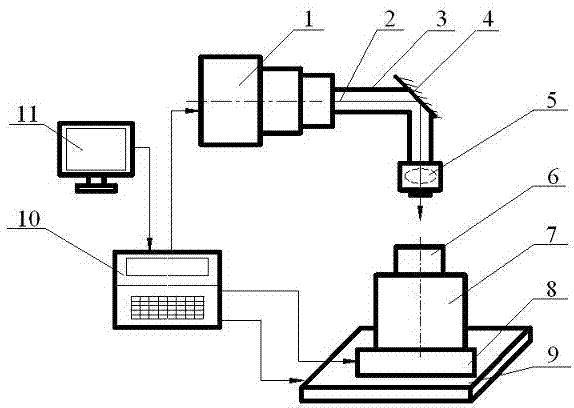

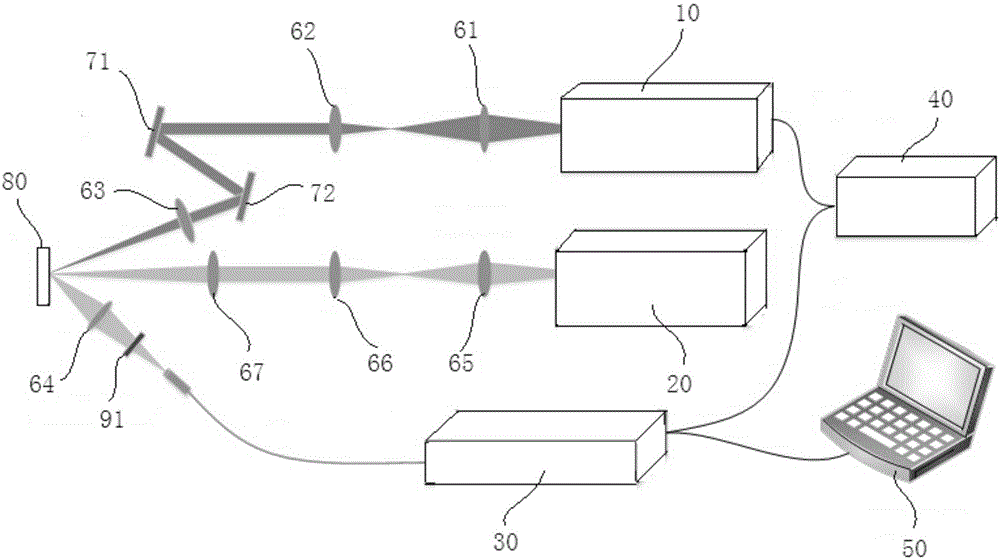

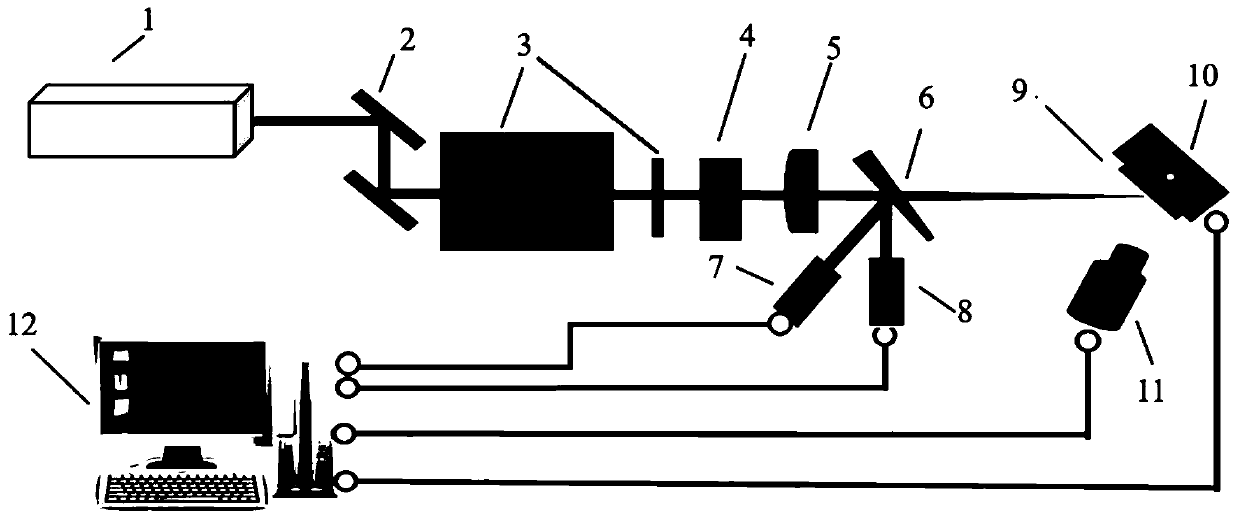

Wide bandgap semiconductor device irradiation effect laser simulation system

ActiveCN106771952AWith miniaturizationIntegratedSemiconductor operation lifetime testingGamma rayPulsed laser irradiation

The invention discloses a wide bandgap semiconductor device irradiation effect laser simulation system. The system comprises a short wavelength pulse laser generation and attenuation system, a microimaging and energy monitoring system and a testing and control system. The short wavelength pulse laser irradiation wide bandgap semiconductor device can be used, an ionization effect is generated in the semiconductor device to simulate gamma ray and other irradiation sources to act on the irradiation ionization effect of the semiconductor device, a gap of the wide bandgap semiconductor device irradiation ionization effect laser simulation system is filled up, the system has the advantages of being compact in structure, high in safety and the like, lowers the testing cost and improves the testing efficiency, and the effective means is provided for performing irradiation resisting reinforcing design on the wide bandgap semiconductor device.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

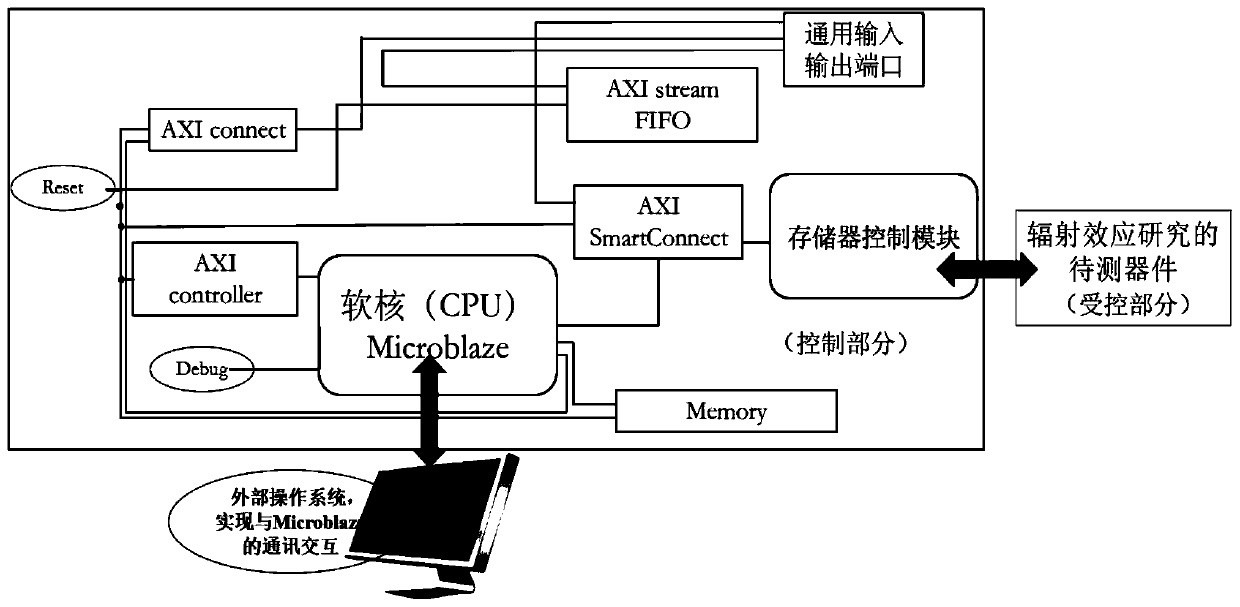

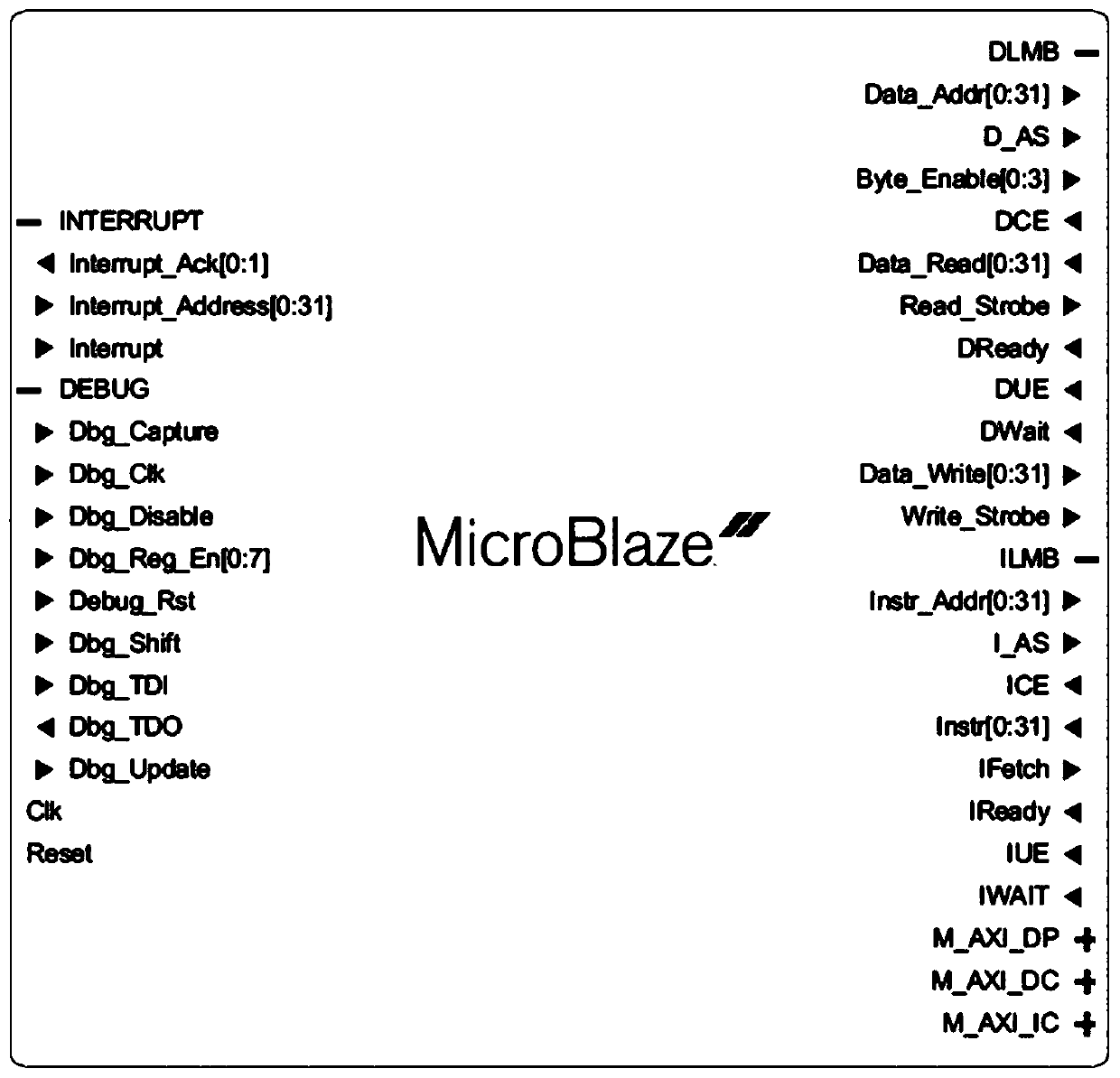

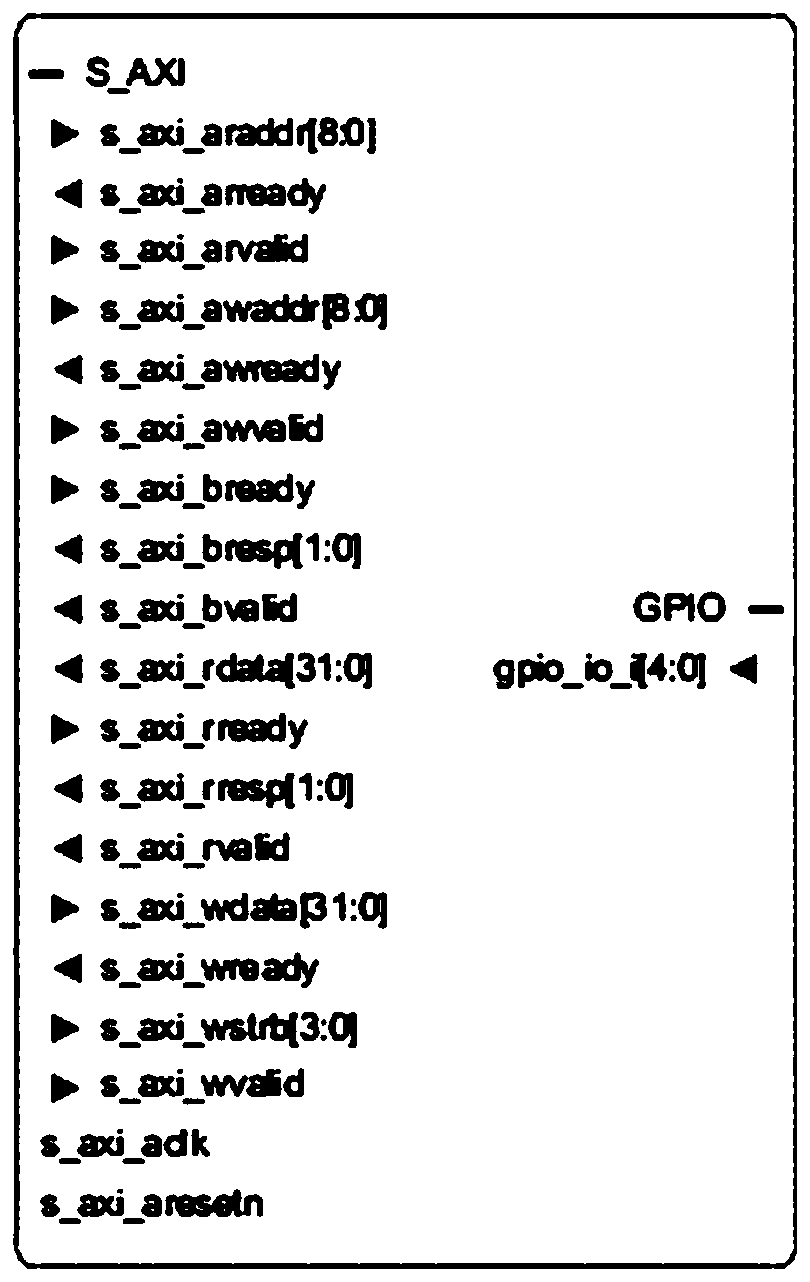

High-speed DDR single event effect evaluation system and method based on FPGA

PendingCN111444662AValid testEfficient StatisticsCAD circuit designComputer hardwarePulse laser irradiation

The invention relates to a high-speed DDR4 single event effect evaluation system and method based on an FPGA. The high-speed DDR4 single event effect evaluation system comprises a DDR4 to be tested, ahigh-energy irradiation experiment terminal or pulse laser irradiation platform and a single event test system. A DDR4 active region to be tested is located in the center of the high-energy irradiation experiment terminal or the pulse laser irradiation platform, and the DDR4 to be tested is in real-time communication with the single-particle test system; the lower computer system of the single particle test system is used for performing read-write operation on the DDR4 to be tested according to an instruction sent by the upper computer system and sending read-back data of the DDR4 to be tested to the upper computer system; and the upper computer system is used for issuing an instruction, carrying out read-write operation on the to-be-tested DRR4 in real time, carrying out read-back verification on written data, and discriminating single-particle soft errors, thereby realizing testing of the single-particle effect of the to-be-tested DRR4. The method can be widely applied to the fieldof single event effect testing.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

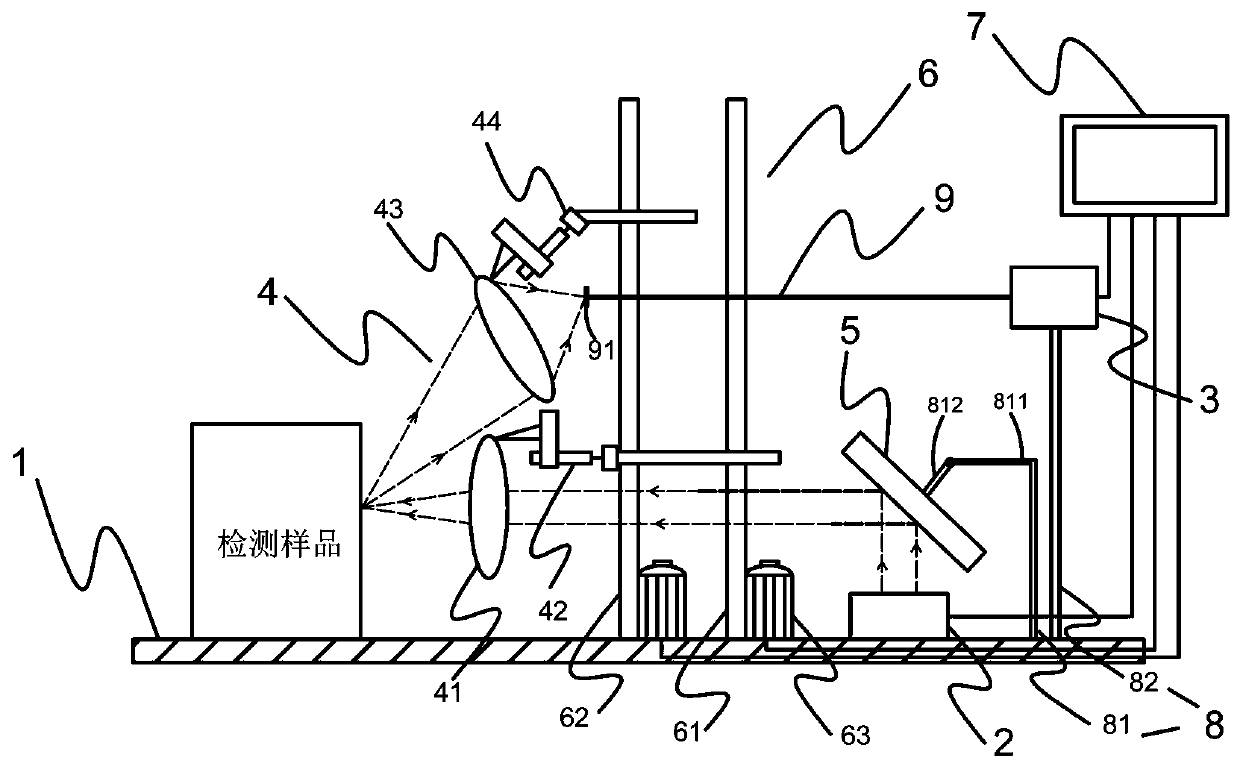

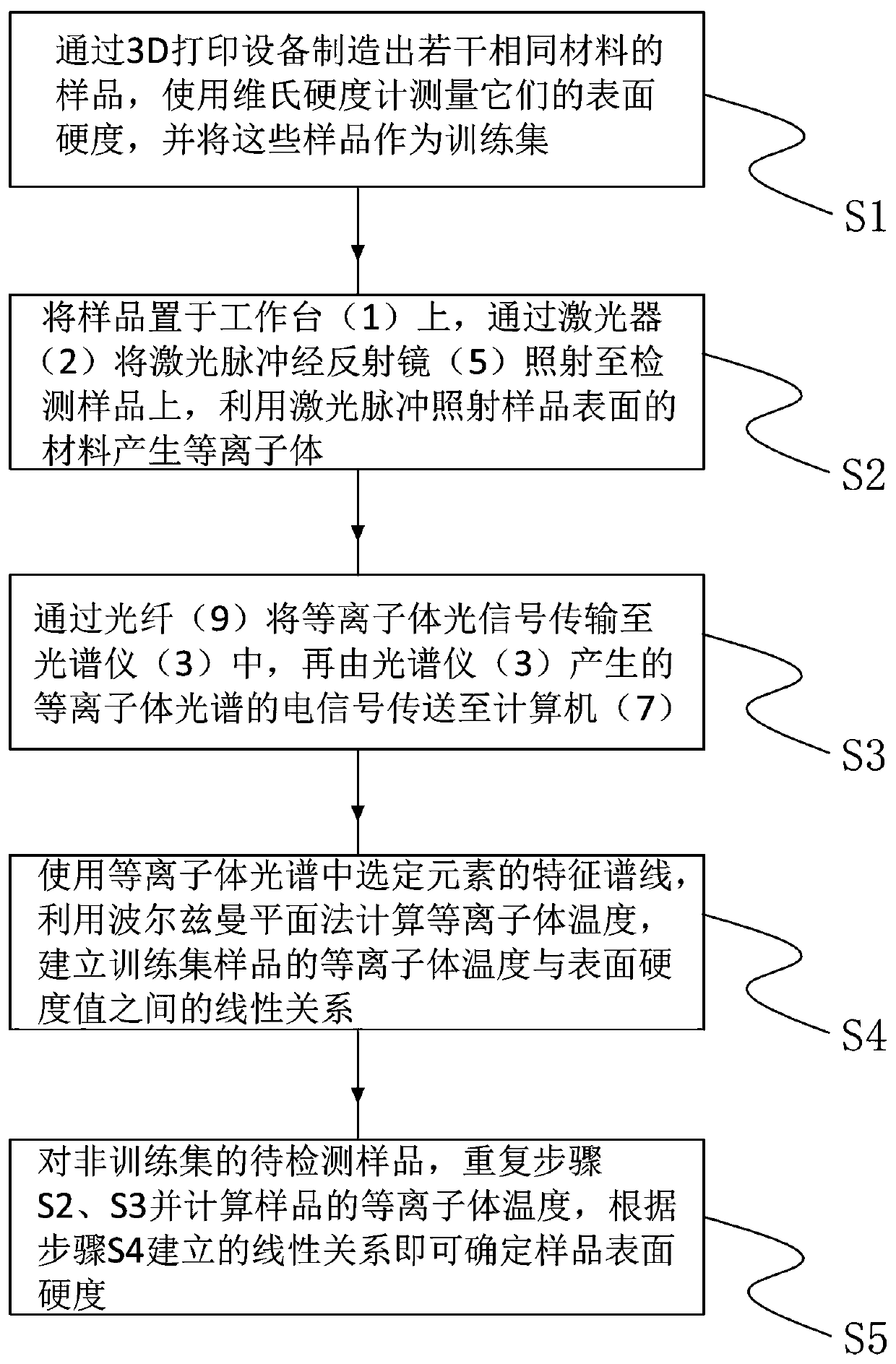

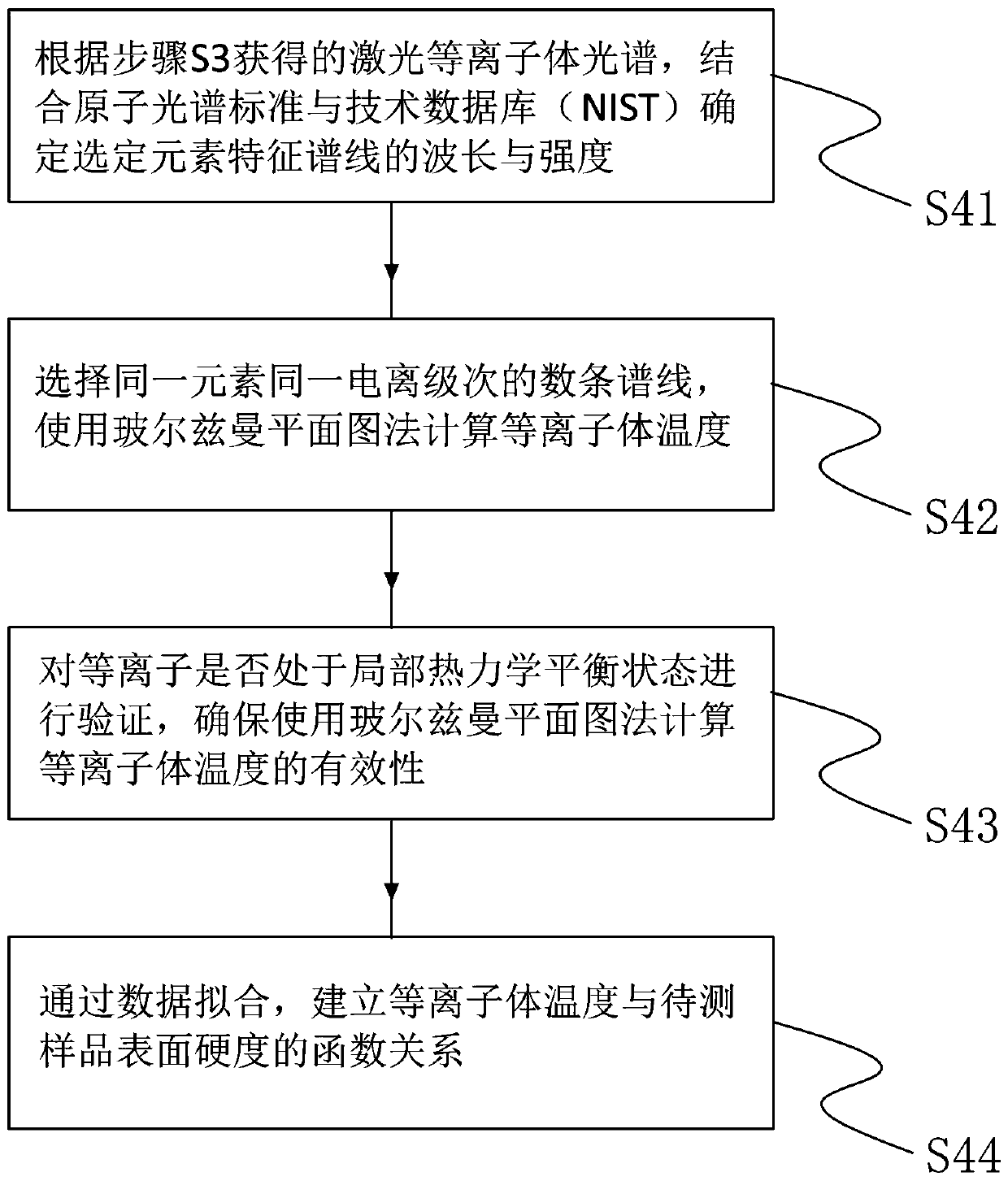

Online monitoring device for surface hardness of 3D printing part in forming process and method

PendingCN110763715AGuaranteed validityAvoid the phenomenon that the hardness does not meet the standardMaterial analysis using wave/particle radiation3d printOptical spectrometer

The invention belongs to the technical field of 3D printing equipment detection and discloses an online monitoring device for the surface hardness of a 3D printing part in a forming process. The device comprises a workbench, a laser, a spectrograph, a light path device, a reflector, an electric control displacement device, a computer and a support. The electric control displacement device, the laser and the support are sequentially arranged on the workbench, the laser is arranged below the reflector, the light path device is arranged on one side of the electric control displacement device, andthe computer is arranged above the workbench. The invention further discloses a detection method. The device is mounted in a forming chamber of 3D printing equipment, the pulse laser irradiation canbe performed on a formed part of the part in real time to generate plasma, plasma spectrum data are collected to evaluate the surface hardness of the formed part, a condition that the overall surfacehardness of the 3D printing part meets a design requirement is ensured through online real-time hardness detection, and the phenomenon that the hardness does not reach a standard due to unpredictablefactors in the forming process is avoided.

Owner:FUJIAN UNIV OF TECH

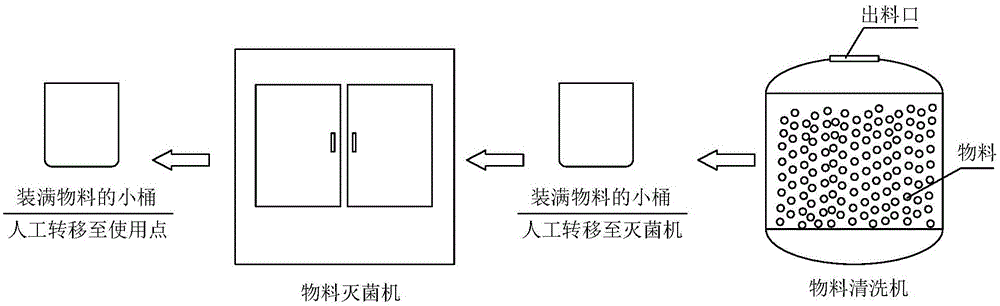

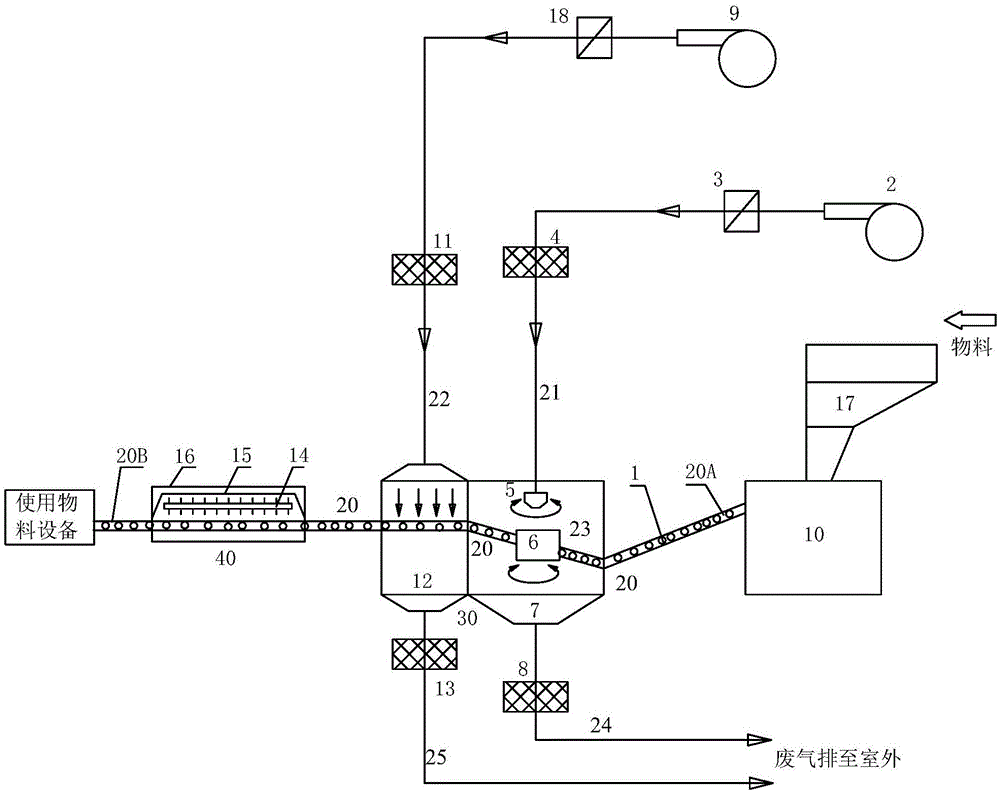

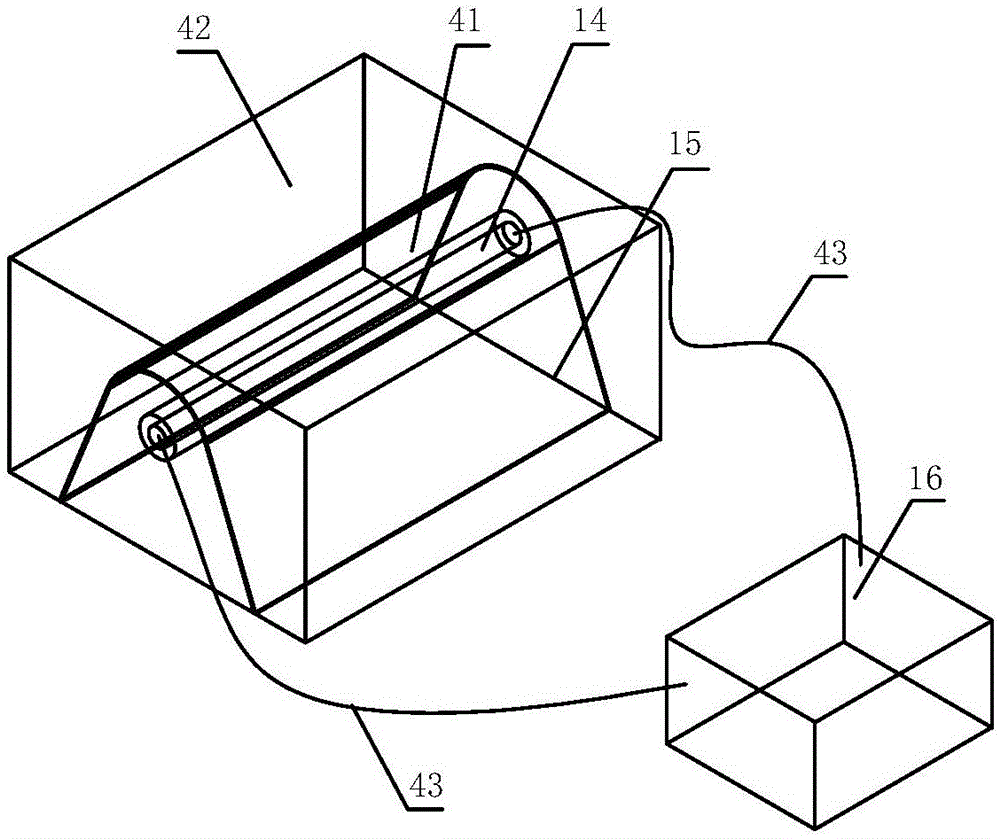

Dry-cleaning sterilizer and method thereof

InactiveCN105148295AAvoid corrosion and other damageShort sterilization timePackage sterilisationCleaning using gasesForeign matterLight energy

The invention discloses a dry-cleaning sterilizer. The dry-cleaning sterilizer comprises an arranging mechanism, a conveying belt, a dry-cleaning device and a sterilization device, wherein a jet nozzle is arranged at the top end of the dry-cleaning device; the conveying belt is used for conveying a material to a material use point through the dry-cleaning device and the sterilization device from the collection opening end of the conveying belt; the sterilization device comprises an inert gas lamp, a pulse laser generator and reflectors on two sides of the sterilization device; the conveying belt positioned in the sterilization device passes through the space between the reflectors on two sides of the sterilization device; and high-intensity pulse laser generated by the pulse laser generator is used for completely illuminating all light energy to a to-be-processed material on the conveying belt by virtue of the reflectors. According to the dry-cleaning sterilizer, pre-treatment and cleaning operation before foreign material cleaning and sterilization of a material surface can be completed by adopting a mode of cleaning, boosting, high-temperature air local dry-cleaning and integral wiping; the material surface is sterilized by adopting a harmless pulse laser irradiation mode; and the material is continuously conveyed by adopting the transmission mechanism, and the effective effect of cleaning and sterilizing can be guaranteed.

Owner:王世庆 +1

A surface treatment method of a gallium arsenide substrate

InactiveCN109148259AHigh interface contact qualityGuarantee the quality of interface contactSemiconductor/solid-state device manufacturingSemiconductor devicesNitrogenOrganic matter

A surface treatment method of a gallium arsenide (GaAs) substrate comprises the following steps: (1) thinning the GaAs substrate; 2) uniformly applying pulsed laser to the surface of the GaAs substrate; (3) cleaning the GaAs substrate after pulsed laser irradiation with deionized water; (4) drying the deionized water washed GaAs substrate with hot nitrogen to obtain a clean GaAs substrate. This method is simple, high proces efficiency, without the introduction of irritant chemicals, with the aid of a pulsed laser, deionized water and hot nitrogen can clean the surface of GaAs substrate, The surface of the treated GaAs substrate is free of organic matter and impurity particles, which ensures the quality of interface contact after subsequent metal evaporation, prevents electrode dropping anddevice voltage abnormality, improves product yield and device performance, ensures surface cleanliness to the maximum extent, and improves production efficiency.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com