Non-stick metal surface and preparation method thereof

A metal surface and low surface energy coating technology, which is applied to metal processing equipment, special surfaces, and devices for coating liquids on surfaces, etc., can solve problems affecting food safety, increase equipment cleaning and maintenance costs, and achieve non-stick performance Long-lasting, increased firmness, anti-wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

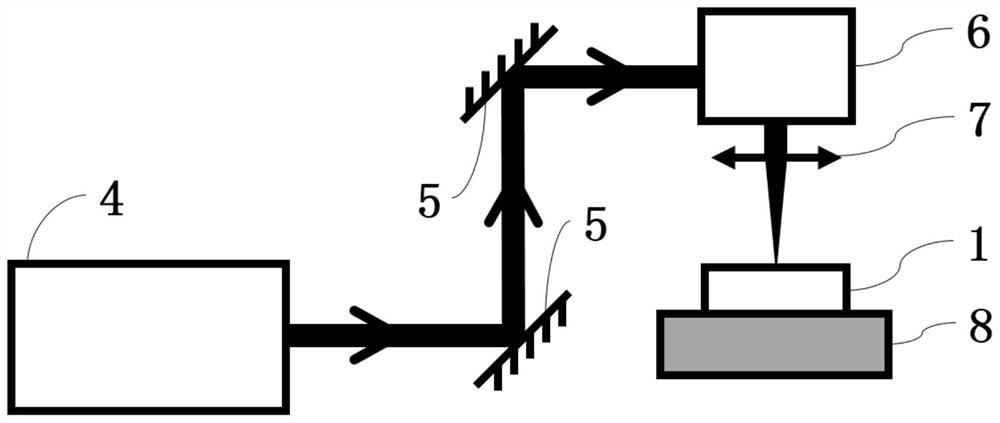

[0060] The non-stick metal surface preparation device can also include cleaning and atomization spraying equipment, and the cleaning equipment can be a commonly used ultrasonic cleaning equipment, which is used to ultrasonically clean the metal surface with ablated micro-nano structure, which will not be repeated in the present invention. , the spraying equipment can fully atomize the low surface energy coating and evenly spray it on the surface of the metal 1, and the details of the spraying equipment will not be repeated in the present invention.

[0061] In a specific example of the present invention, the working parameters of the pulsed laser 4 are: laser wavelength 315nm-1060nm, pulse width 140fs-800fs, repetition frequency 1kHz-1MHz, laser power 50mW-20W.

[0062] In a specific example of the present invention, the scanning vibrating mirror 6 can be controlled by a computer to etch points, lines, grids and various irregular patterns on the surface of the metal 1 .

[006...

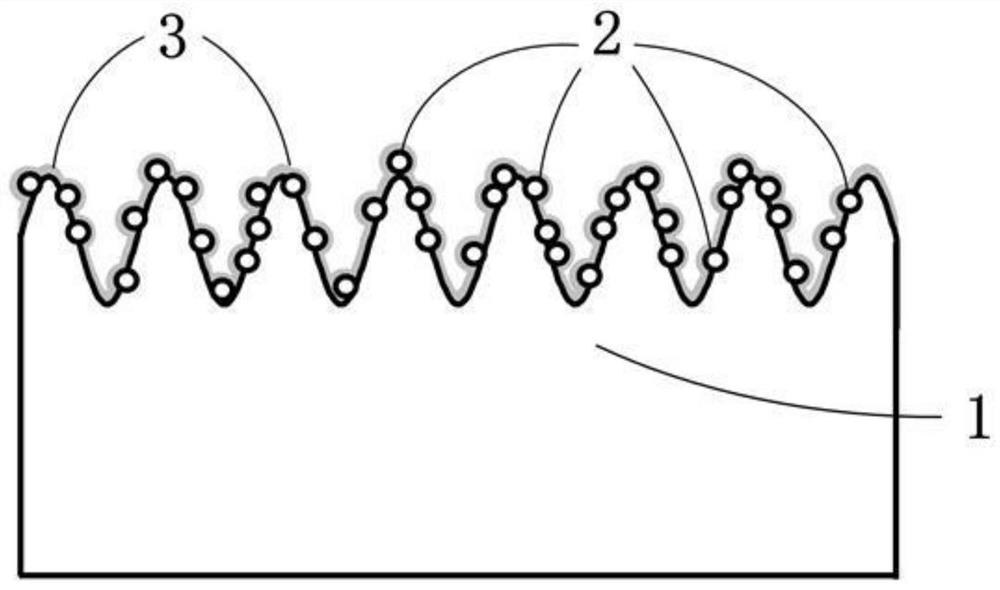

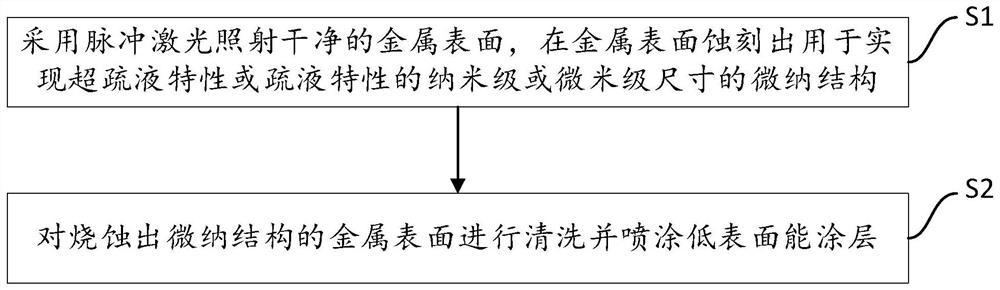

Embodiment 1

[0085] Place the cleaned 316 stainless steel on the three-dimensional mobile platform, and adjust the working parameters of the pulse laser: the wavelength is 1060nm, the pulse width is 800fs, and the power is 10w. Moving at a speed of 10mm / s, the laser irradiates the surface of 316 stainless steel, and scans the surface of 316 stainless steel in the form of a 50μm grid. After laser ablation, a large number of micron or nanoscale granular structures are produced on the surface of 316 stainless steel. The earth increases the roughness of the 316 stainless steel surface.

[0086] Then put the 316 stainless steel into deionized water for ultrasonic cleaning for 5 minutes to remove the unstable granular structure on the surface, and then dry the 316 stainless steel. After drying, use Sysmec's super-hydrophobic and super-oleophobic nano-coating (CCP003-Sysmyk) for spraying. After the coating is dried, the measured contact angle is greater than 160°, and the rolling angle is less th...

Embodiment 2

[0093] Similar to Example 1, place the cleaned 304 stainless steel on the three-dimensional mobile platform, and adjust the working parameters of the pulse laser: the wavelength is 315nm, the pulse width is 140fs, and the power is 10w. The scanning mirror used is SCANcube III, so that the focus on The spot on the surface of 304 stainless steel moves at a speed of 10mm / s. The laser irradiates the surface of 304 stainless steel and scans the surface of 304 stainless steel in the form of 50μm line scanning. The granular structure greatly increases the roughness of the surface of 304 stainless steel.

[0094] Then put the 304 stainless steel into deionized water for ultrasonic cleaning for 5 minutes to remove the unstable granular structure on the surface, and then dry the 304 stainless steel.

[0095] After drying, use Sysmec's super-hydrophobic and super-oleophobic nano-coating (CCP003-Sysmyk) for spraying. After the coating is dried, the measured contact angle is greater than 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com