Pulse laser irradiation treatment method for healing fatigue damage of copper thin film part

A technology of fatigue damage and pulsed laser, which is applied in the field of mechanical manufacturing and laser processing, can solve the problems of fatigue damage healing of copper thin film materials, achieve the effect of improving surface quality, enhancing reliability and safety, and achieving remarkable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

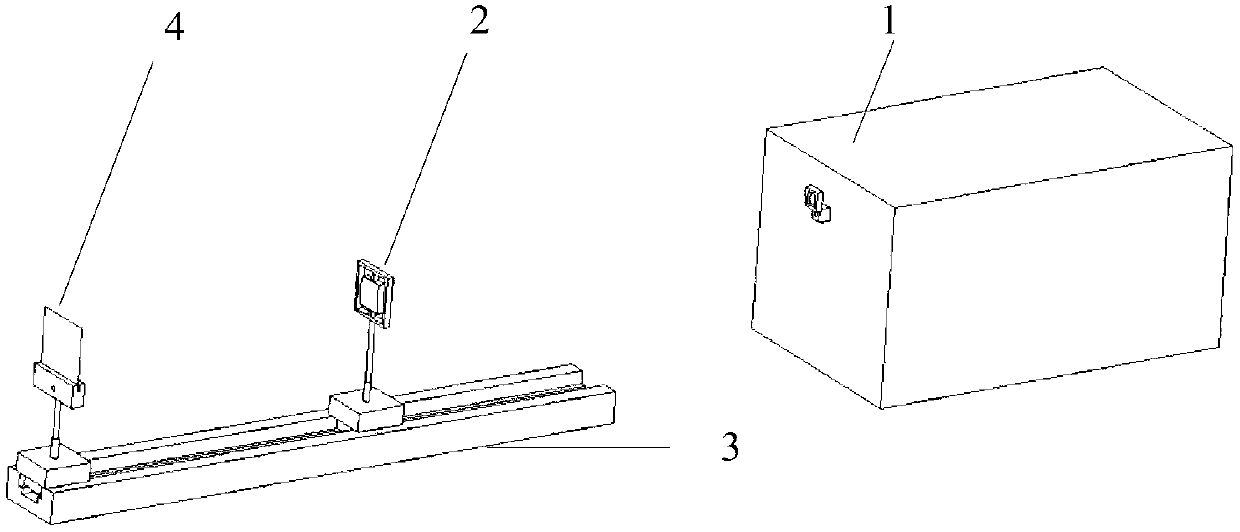

[0026] Below in conjunction with accompanying drawing, the method of the present invention is further elaborated, please refer to Figure 1 to Figure 5 , a pulse laser irradiation treatment method for healing copper film fatigue damage, the steps are:

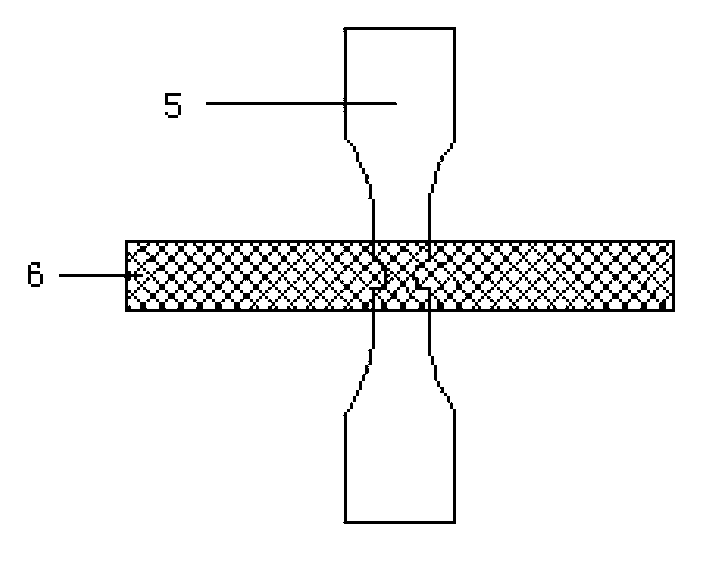

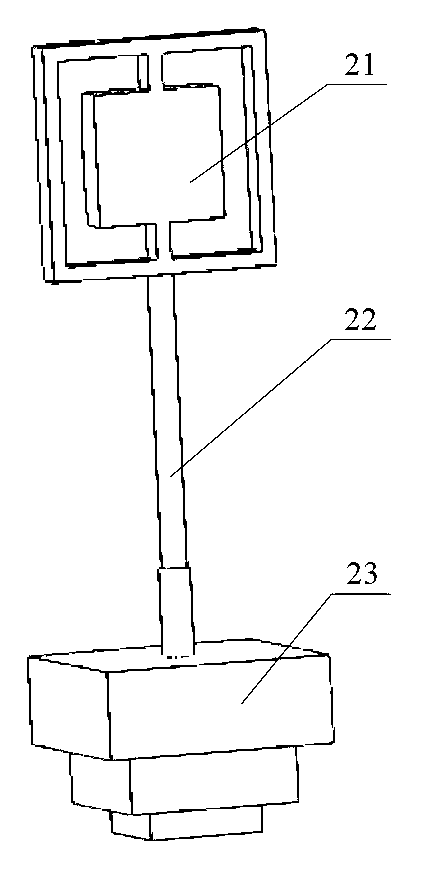

[0027] A) laser radiation healing device is provided, and described laser radiation healing device comprises pulsed laser 1, optical path device 2, guide rail 3 and specimen fixing device 4; Because copper thin film specimen 5 has higher absorption rate to short-wavelength laser, so Described laser selects ultraviolet excimer pulse laser for use; Described optical path device 2 comprises convex lens 21, convex lens support 22, convex lens support 23; Described specimen fixture 4 comprises metal plate 41, magnet 42, metal plate support 43, metal plate support Seat 44 and bolt 45;

[0028] B) Place the copper film test piece 5 with fatigue damage at the center of the metal plate 41, place a magnet 42 at both ends of the test pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com