Method for testing laser damage threshold of optical thin film

A laser damage threshold, optical thin film technology, applied in the field of optical detection, can solve the problems of urgent optical thin film, time-consuming, complicated operation steps, etc., and achieve the effect of saving the number of test samples and test time, and high applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment implements a laser damage threshold testing system for an optical thin film.

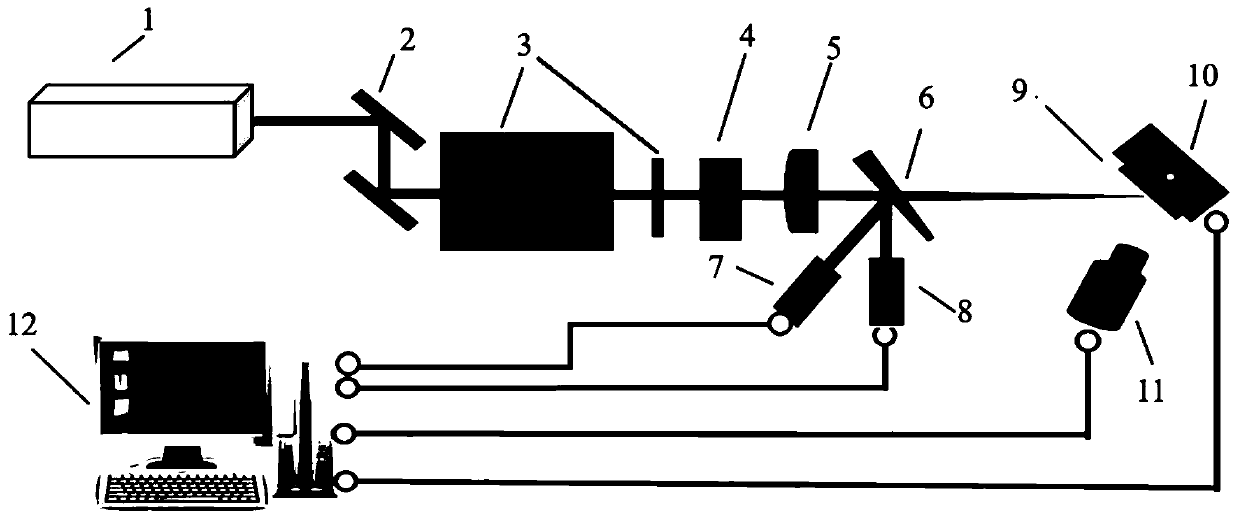

[0039] figure 1 A schematic structural diagram of a laser damage threshold testing system for optical thin films is shown.

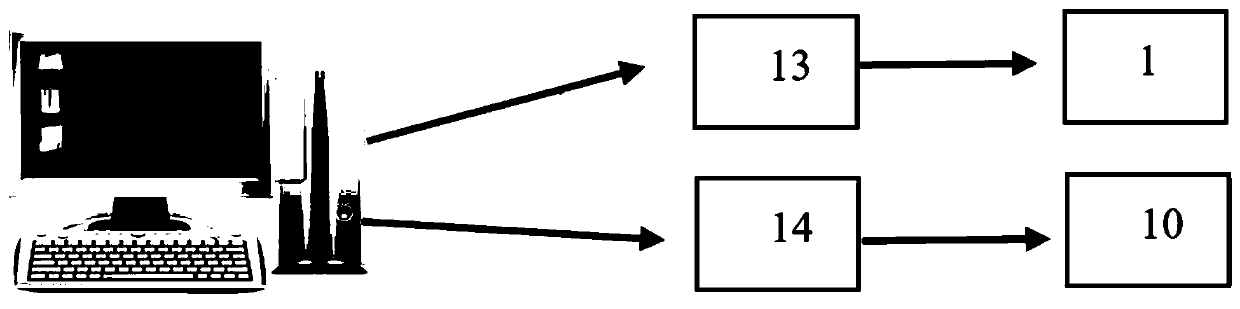

[0040] figure 2 A computer structure schematic diagram of a laser damage threshold testing system for an optical thin film is shown.

[0041] Such as figure 1 , figure 2Shown is a laser damage threshold test system for optical thin films, the test system includes a femtosecond laser 1, two mirrors 2, an energy attenuation system 3, a mechanical shutter 4, a focusing lens 5, a wedge 6, a beam quality analyzer 7, Energy meter 8, two-dimensional mobile platform 10 for optical film placement, CCD camera 11, computer 12, above-mentioned computer 12 is provided with data output card 13, motion control card 14; Above-mentioned femtosecond laser 1 is connected to data output card 13, above-mentioned The two-dimensional mobile platform 10 is connected to t...

Embodiment 2

[0043] This embodiment implements a method for testing the laser damage threshold of an optical thin film.

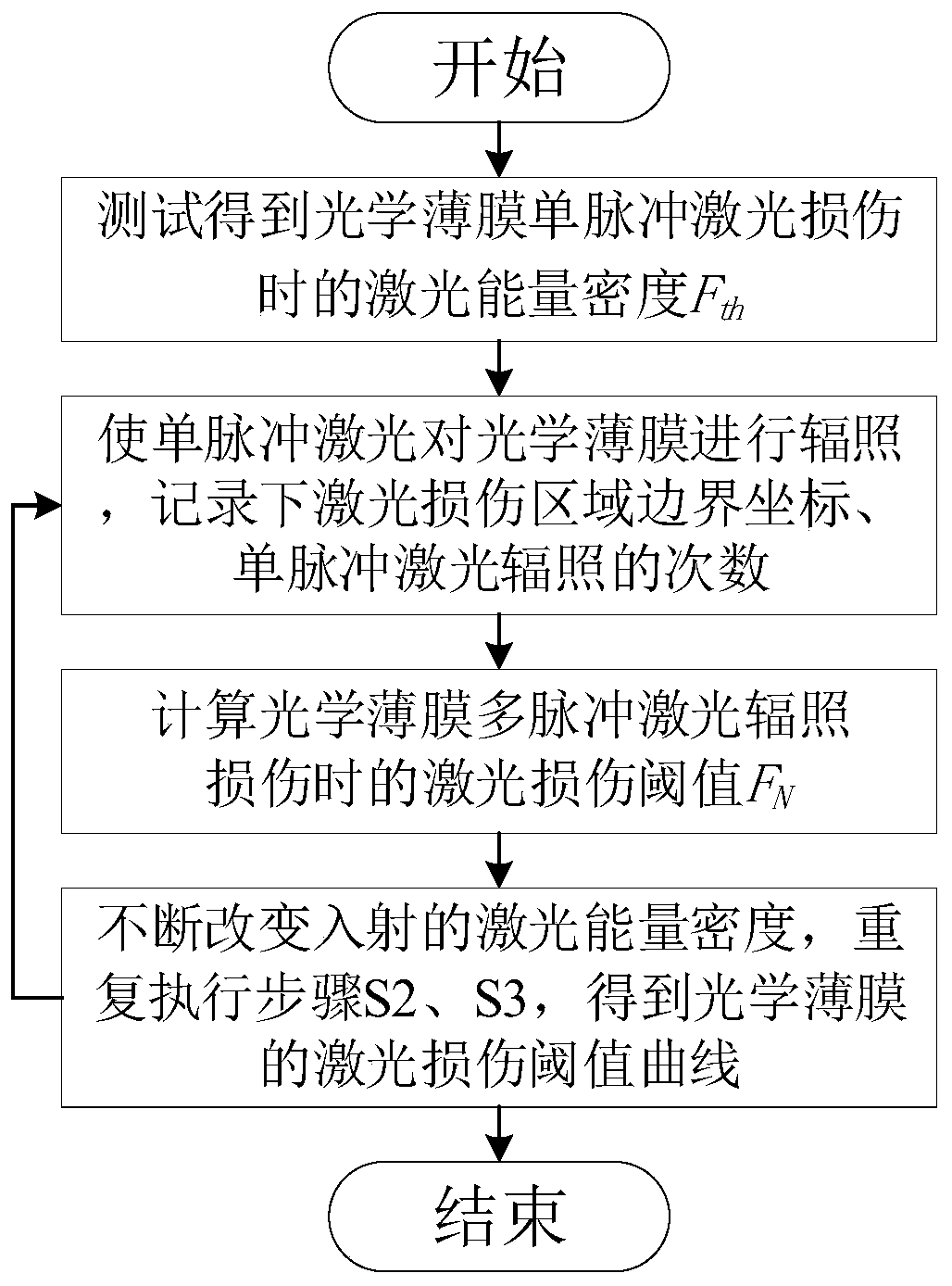

[0044] image 3 A step diagram of a method for testing the laser damage threshold of an optical thin film is shown.

[0045] Such as image 3 As shown, a method for testing the laser damage threshold of an optical thin film, the above-mentioned test method runs on the above-mentioned test system, and includes the following steps:

[0046] S1. Adjust the incident laser to a single pulse laser, move the optical film 9 to the position of the laser spot, adjust the peak laser energy density of the incident single pulse laser from high to low, and use the 1-on-1 mode to test to obtain a single pulse of the optical film 9 Laser energy density F during laser damage th ;

[0047] S2. Adjust the laser energy density of the incident single pulse laser to be lower than F th a certain value of F 0 , adjust the mechanical shutter 4 to be in a normally open state, so that the s...

Embodiment 3

[0064] This embodiment is a method for testing the laser damage threshold of an optical thin film under multi-pulse irradiation of a femtosecond laser. This embodiment is a specific application of Embodiment 1 and Embodiment 2.

[0065] A method for testing the laser damage threshold of an optical thin film under multi-pulse irradiation of a femtosecond laser, the method comprising the following steps:

[0066] Step 1, the computer 12 controls the laser output of the femtosecond laser 1 through the data output card 13, and the laser beam output by the laser 1 reaches the energy attenuation system 3 after passing through two reflectors 2, and the described laser can be transferred by controlling the energy attenuation system 3 1 The output Gaussian laser energy density is adjusted to 0.2J / cm 2 ~0.5J / cm 2 , and then set the number of pulses output by the laser 1 through the mechanical shutter 4 as a single shot, the laser pulse reaches the wedge plate 6 after passing through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com