Self-cleaning metal surface as well as preparation method and preparation device thereof

A metal surface, self-cleaning technology, applied to the surface coating liquid device, metal processing equipment, special surface, etc., can solve the problems of long time consumption and environmental protection, and achieve long-lasting performance, high efficiency, green environmental protection and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

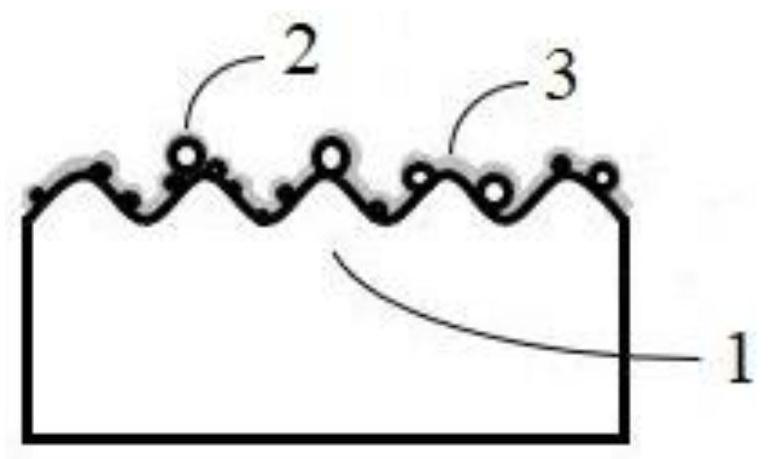

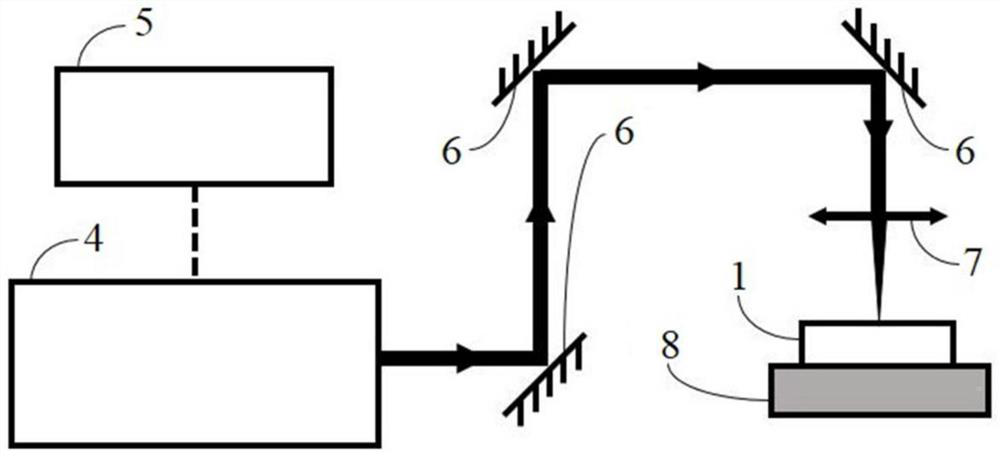

[0061] The preparation device for the self-cleaning metal surface can also include heating equipment, which can be a drying oven, etc., for heating the surface of the metal 1 after laser treatment, so as to speed up the adsorption of organic matter on the surface of the metal 1 and increase the adsorption amount of organic matter .

[0062] In a specific example of the present invention, the working parameters of the pulsed laser 4 are: the laser wavelength is 800nm, the pulse width is 40fs, the repetition frequency is 1k-1MHz, and the laser power is 50mW-20W.

[0063] In some preferred embodiments of the present invention, the repetition frequency of the femtosecond pulsed laser is preferably 1 kHz, and the laser power is preferably 200 mW, and the contact angles of the surface wetting properties of the prepared metal 1 are all greater than 155°, showing super-lyophobic properties .

[0064] The foregoing describes the self-cleaning metal surface preparation device provided ...

Embodiment 1

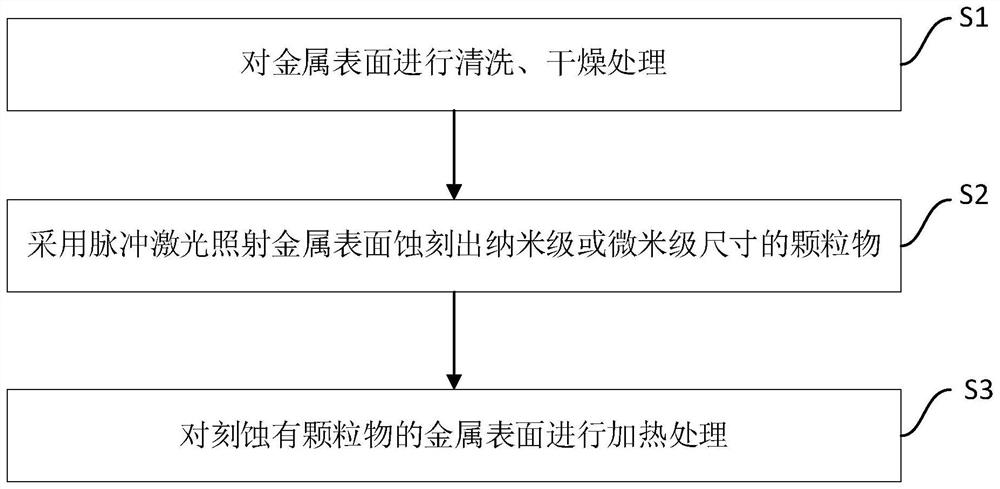

[0094] Put the cleaned aluminum on the three-dimensional mobile platform, adjust the working parameters of the pulsed laser light source: the wavelength is 800nm, the pulse width is 40fs, the power is 200mw, the grid scanning interval is 100 microns, and the three-dimensional mobile platform moves at a speed of 1mm / s , the laser is irradiated onto the aluminum surface, and the aluminum surface is scanned to form a grid-like structure with an interval of 100 microns, and then heat-treated, and then heat-treated at 200° C. for 30 minutes. Titanium, iron, copper, zinc, 1:1 copper-titanium alloy, and 304 stainless steel are treated in the same way. Measurement results such as Figure 6 As shown, it can be seen that aluminum, titanium, iron, copper, zinc, 1:1 copper-titanium alloy, and 304 stainless steel all have a contact angle of about 150°. Except for zinc, they all have a rolling angle of about 10°, which is hydrophobic. / superhydrophobic state.

[0095] Microstructure obse...

Embodiment 2

[0105] Place the cleaned aluminum on the three-dimensional mobile platform, adjust the working parameters of the femtosecond pulsed laser source: the wavelength is 800nm, the pulse width is 40fs, the power is 200mw, the grid scanning interval is 300 microns, and the scanning speed is 1mm / s. to the aluminum surface, and then heat the aluminum surface at 200°C for 30 minutes to obtain a sample with a super-hydrophobic surface after processing, and test the contact angle and rolling angle of the aluminum surface respectively. For the results, see Figure 9 , showing that the contact angle is greater than 150° and the rolling angle is about 10°, showing superhydrophobic properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com