Single-point fluorescent temperature measurement device and method

A temperature measurement device and fluorescence technology, applied in the field of measurement and control, can solve the problems of measurement results that cannot be correlated with time, low measurement accuracy, and low sampling rate, and achieve the effects of enhancing temperature dependence characteristics, improving temperature measurement accuracy, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

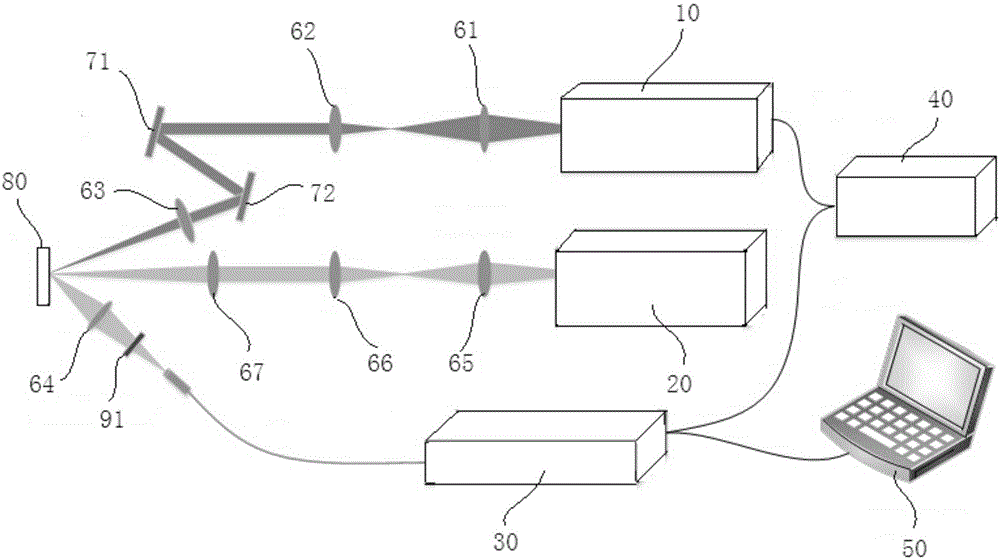

[0033] Example 1 : like figure 1 As shown, this embodiment provides a single-point fluorescence temperature measurement device, including,

[0034] A temperature probe, the temperature probe is YAG:Ce (Y 3 Al 5 o 12 :Ce) powder, which is used for mixing into the system under test or coating on the surface of the object under test 80;

[0035] The heat source laser 20 is used to emit laser pulses to the system under test or the object under test 80 to generate a transient temperature field;

[0036] A fluorescence excitation source 10, configured to emit excitation light to the measured object 80, so that the temperature probe in the transient temperature field is excited to emit anti-Stokes fluorescence and Stokes fluorescence;

[0037] The spectrum detection device 30 is used to collect the anti-Stokes fluorescence and the Stokes fluorescence emitted by the receiving temperature probe after being excited; specifically, the spectrum detection device 30 can be realized...

Embodiment 2

[0041] Example 2 : This embodiment provides a non-contact single-point fluorescence temperature measurement method with high measurement accuracy and high sampling rate, which includes the following steps:

[0042] comprising a step of calibrating the intensity ratio of anti-Stokes fluorescence and Stokes fluorescence to temperature for a specific temperature probe;

[0043] Contains the steps of incorporating the temperature probe into the system under test or painting it on the surface of the object under test 80; (the above two steps are not distinguished before and after)

[0044] Including the step of emitting laser pulses to the system under test or the object under test 80 to generate a transient temperature field;

[0045] Including emitting excitation light to the system under test or the object under test 80, so that the temperature probe in the transient temperature field is excited to emit anti-Stokes fluorescence and Stokes fluorescence;

[0046] comprising the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com