SnO2/graphene composite material as well as preparation method and application thereof

A composite material and graphene technology, applied in the direction of active material electrodes, electrical components, electrochemical generators, etc., can solve the problems of destroying the stability of electrode structures, reducing the specific surface area of composite materials, and unfavorable lithium ion transmission, etc., to achieve reversible improvement Capacity and cycle life, increased active sites for lithium storage, clean and ligand-free surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

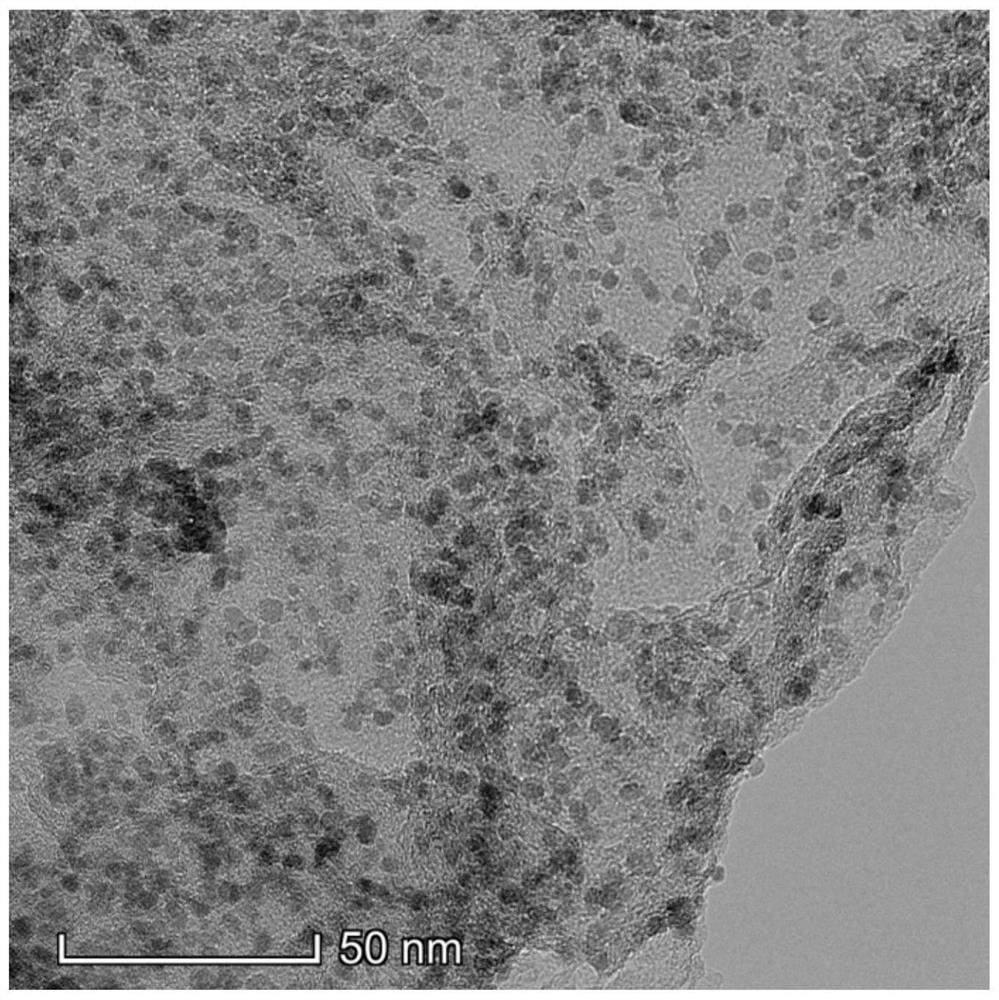

[0033] A kind of SnO 2 / The preparation method of graphene composite material, comprises the following steps:

[0034] (1) The polished metal Sn foil (1cm×1cm, thickness 1mm) was immersed in a glass bottle filled with 10mL deionized water, and the glass bottle was fixed in an ultrasonic instrument filled with circulating water at 0°C. Under ultrasonic conditions, the laser flux is 800mJ pulse -1 cm -2 The nanosecond pulsed laser beam (Nd:YAG) bombarded the metal Sn foil for 60s to prepare SnO x Colloidal solution;

[0035] (2) Disperse 50mg of graphene oxide powder in 50mL of deionized water, sonicate for 1h to obtain 1.0mg mL -1 Graphene oxide solution;

[0036] (3) Measure 300mL SnO x Colloidal solution was added dropwise to 50mL graphene oxide solution under vigorous stirring, followed by ultrasonication at room temperature for 1h to obtain uniformly dispersed SnO x / graphene oxide solution;

[0037] (4) SnO x / The graphene oxide solution is sealed into a high-temp...

Embodiment 2

[0039] A kind of SnO 2 / The preparation method of graphene composite material, comprises the following steps:

[0040] (1) The polished metal Sn foil (1cm×1cm, thickness 1mm) was immersed in a glass bottle filled with 10mL deionized water, and the glass bottle was fixed in an ultrasonic instrument filled with circulating water at 0°C. Under ultrasonic conditions, the laser flux is 1000mJ pulse -1 cm -2 The nanosecond pulsed laser beam (Nd:YAG) bombarded the metal Sn foil for 30s to prepare SnO x Colloidal solution;

[0041] (2) Disperse 50mg of graphene oxide powder in 50mL of deionized water, sonicate for 1h to obtain 1.0mg mL -1 Graphene oxide solution;

[0042] (3) Measure 300mL SnO x Colloidal solution was added dropwise to 50mL graphene oxide solution under vigorous stirring, followed by ultrasonication at room temperature for 1h to obtain uniformly dispersed SnO x / graphene oxide solution;

[0043] (4) SnO x / The graphene oxide solution is sealed into a high-t...

Embodiment 3

[0045] A kind of SnO 2 / The preparation method of graphene composite material, comprises the following steps:

[0046] (1) The polished metal Sn foil (1cm×1cm, thickness 1mm) was immersed in a glass bottle filled with 10mL deionized water, and the glass bottle was fixed in an ultrasonic instrument filled with circulating water at 0°C. Under ultrasonic conditions, the laser flux is 600mJ pulse -1 cm -2 The nanosecond pulsed laser beam (Nd:YAG) bombarded the metal Sn foil for 90s to prepare SnO x Colloidal solution;

[0047] (2) Disperse 50mg of graphene oxide powder in 50mL of deionized water, sonicate for 1h to obtain 1.0mg mL -1 Graphene oxide solution;

[0048] (3) Measure 300mL SnO x Colloidal solution was added dropwise to 50mL graphene oxide solution under vigorous stirring, followed by ultrasonication at room temperature for 1h to obtain uniformly dispersed SnO x / graphene oxide solution;

[0049] (4) SnO x / The graphene oxide solution is sealed into a high-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com