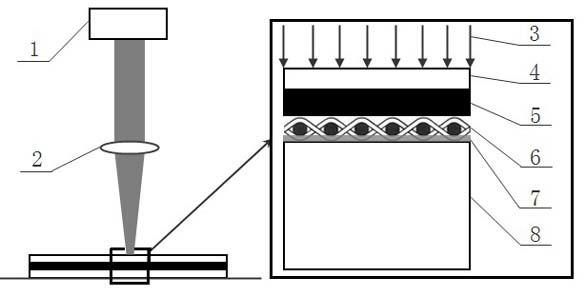

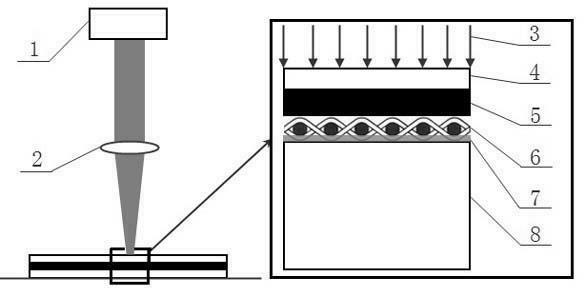

High efficiency apparatus and method based on laser shock wave for manufacturing micro grooves

A shock wave and micro-groove technology, applied in the field of high-efficiency micro-groove manufacturing based on laser shock wave, can solve the problems of low processing efficiency, complex tool manufacturing, easy environmental pollution, etc., and achieve the effect of improving workpiece fatigue life and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

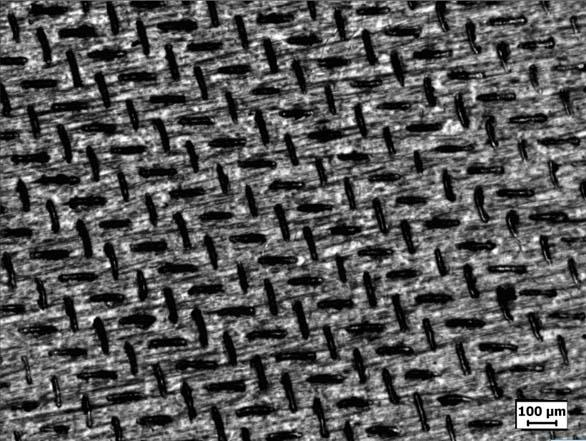

[0026] Specific embodiment 1: the workpiece is pure titanium, and the surface of pure titanium is polished and cleaned with acetone and alcohol; 300-mesh stainless steel square mesh is bonded to the surface of pure titanium through an organic adhesive; an aluminum foil with a thickness of 240 μm is covered on the The surface of the stainless steel square mesh; the water film with a thickness of about 1mm will be covered on the surface of the aluminum foil; the repetition frequency of the laser used in the present invention is 5HZ, and the laser emits energy of 12.5J and pulsed laser with a pulse width of 10ns. After focusing through the focusing lens, An irradiation area with a diameter of about 4.5cm is formed on the surface of the aluminum foil. The aluminum foil absorbs the laser energy and explodes to form a high-intensity shock wave. Under the strong thrust generated by the shock wave, the lower end of the 300-mesh stainless steel square mesh is embedded in the pure titaniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com