Method for regulating and controlling oxygen defects of cerium dioxide nano material by pulse laser irradiation in liquid phase

A technology of pulsed laser and cerium oxide, which is applied in the fields of cerium oxide/cerium hydroxide, chemical instruments and methods, rare earth metal oxides/hydroxides, etc., can solve problems such as unfavorable, high energy consumption and high risk, and achieve Mild conditions, improved catalytic performance, and pure product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

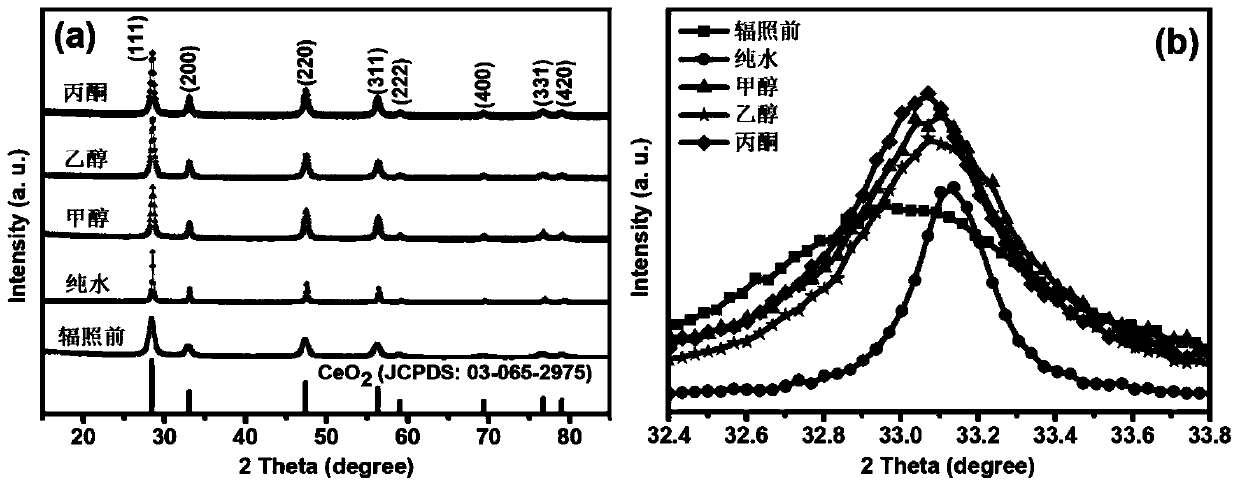

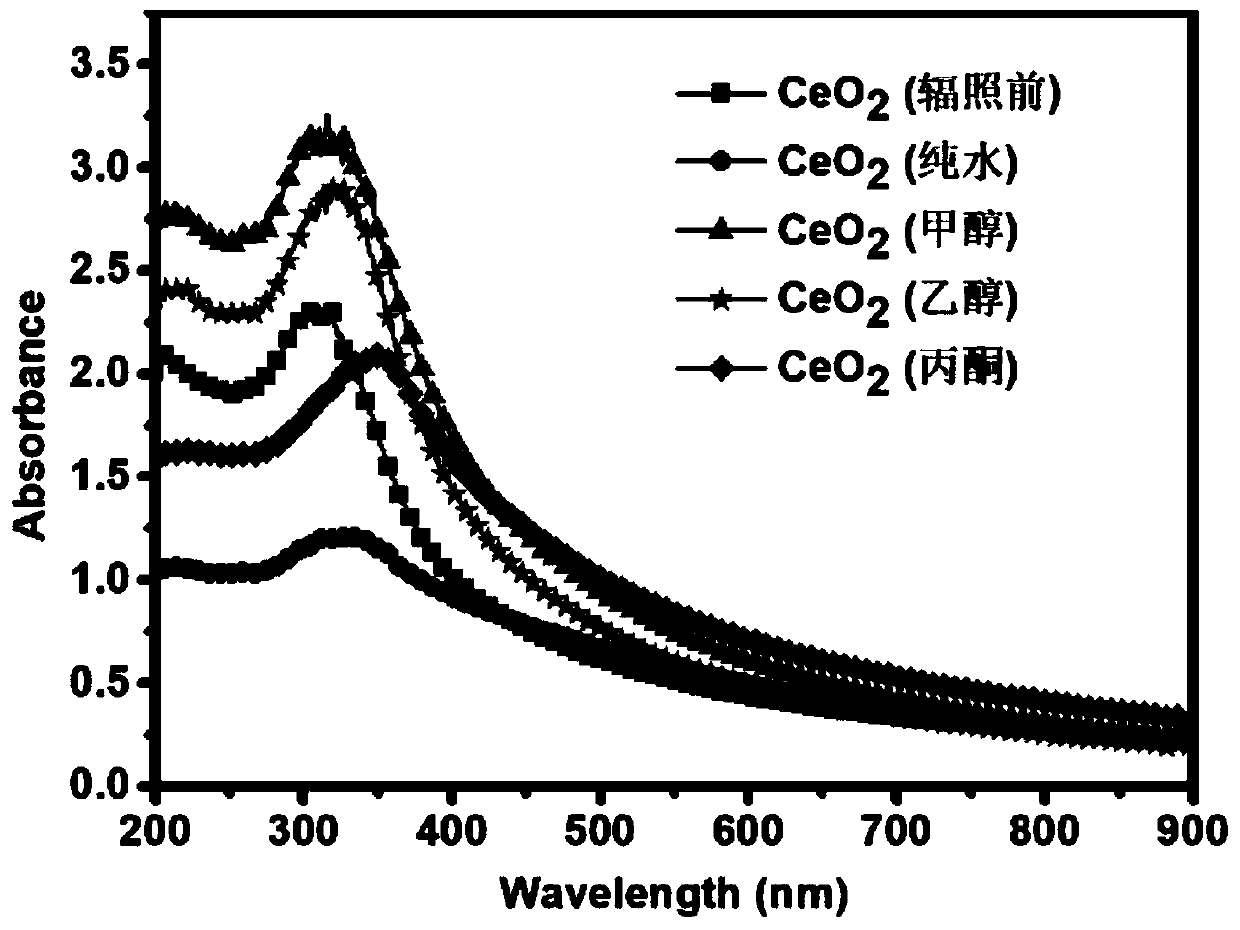

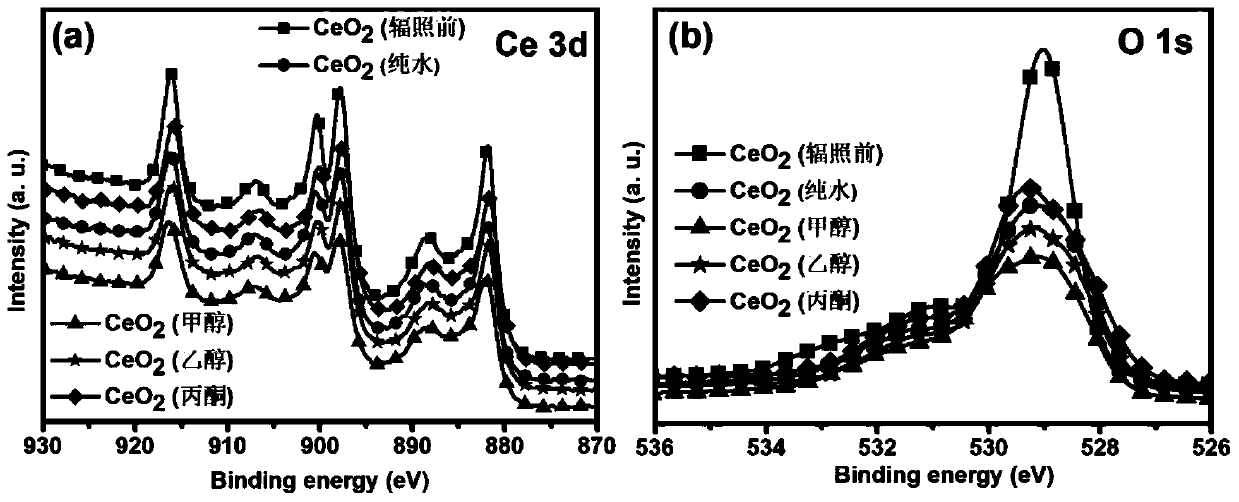

[0027] (1) The solvent is at least one of water, methanol, ethanol or acetone. By adding CeO 2 Nanosheet powder dispersed in different solvents and pulsed laser irradiation can prepare CeO with different sizes and concentrations of oxygen defects 2-x nanomaterials.

[0028] (2) In order to prevent CeO 2 Sedimentation occurs and it is ensured that it is uniformly irradiated by pulsed laser light. During the irradiation process, it is necessary to supplement the suspension with continuous magnetic stirring.

[0029] (3) The pulse laser is a nanosecond parallel pulse laser emitted by a Nd:YAG nanosecond pulse laser.

[0030] (4) By adjusting the laser parameters such as the wavelength, pulse frequency, single pulse energy, and irradiation time of the pulse laser, CeO with different sizes and different concentrations of oxygen defects can be prepared.2-x nanomaterials.

[0031] (5) Oxygen defects in the ceria nanomaterials prepared by the present invention mainly exist in the ...

Embodiment 1

[0036] A method for regulating oxygen defects in ceria nanomaterials by pulsed laser irradiation in a liquid phase, comprising the following steps:

[0037] Step 1, the CeO 2 The nanosheet powder was dispersed in methanol and prepared into 0.3mg / mL, 0.5mg / mL, 1mg / mL and 2mg / mL white suspensions respectively.

[0038] Step 2. Carry out magnetic stirring to the four kinds of suspensions respectively, the magnetic stirring speed is 500r / min, and while carrying out magnetic stirring to the suspension, use a wavelength of 355nm, a pulse width of 7ns, a pulse frequency of 20Hz, a single pulse Pulsed laser with an energy of 50mJ irradiated the four kinds of suspensions for 10 minutes respectively, and then centrifuged, and the precipitate obtained from the centrifuged treatment was repeatedly washed with deionized water for 3 to 4 times, and then freeze-dried to obtain yellow-green Ceria nanomaterials with reduced oxygen defects.

[0039] Specifically, at the same time, a portion o...

Embodiment 2

[0041] A method for regulating oxygen defects in ceria nanomaterials by pulsed laser irradiation in a liquid phase, comprising the following steps:

[0042] Step 1, the CeO 2 The nanosheet powder was dispersed in ethanol to prepare a 1 mg / mL white suspension.

[0043] Step 2. Magnetically stir the suspension with stirring speeds of 100r / min, 500r / min and 1500r / min respectively, and while magnetically stirring the suspension, use a wavelength of 355nm and a pulse width of 7ns, pulse frequency of 20Hz, single pulse energy of 50mJ pulsed laser irradiates the suspension, and it is easy to cause CeO 2 The precipitation of the sample makes the irradiation inhomogeneous, and it is easy to cause the suspension to splash out at a high stirring rate, so the optimal stirring rate in the embodiment of the present invention is 500r / min; The suspension was irradiated for 10 minutes, then centrifuged, and the precipitate obtained by the centrifuged treatment was repeatedly washed 3 to 4 ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com