Method for remotely exciting micrometer-scale micro-cantilever probe to resonate by using laser

A technology of micro-cantilever and remote excitation, which is applied in the direction of material analysis, instruments, and measuring devices through optical means. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

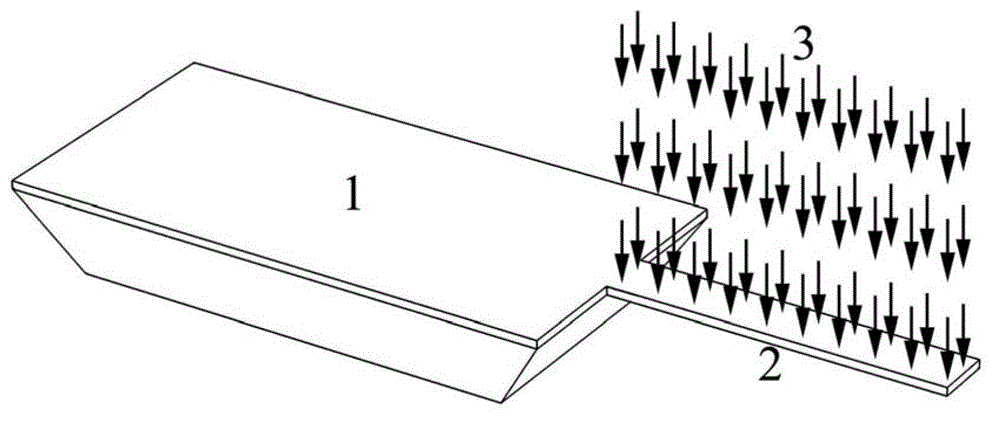

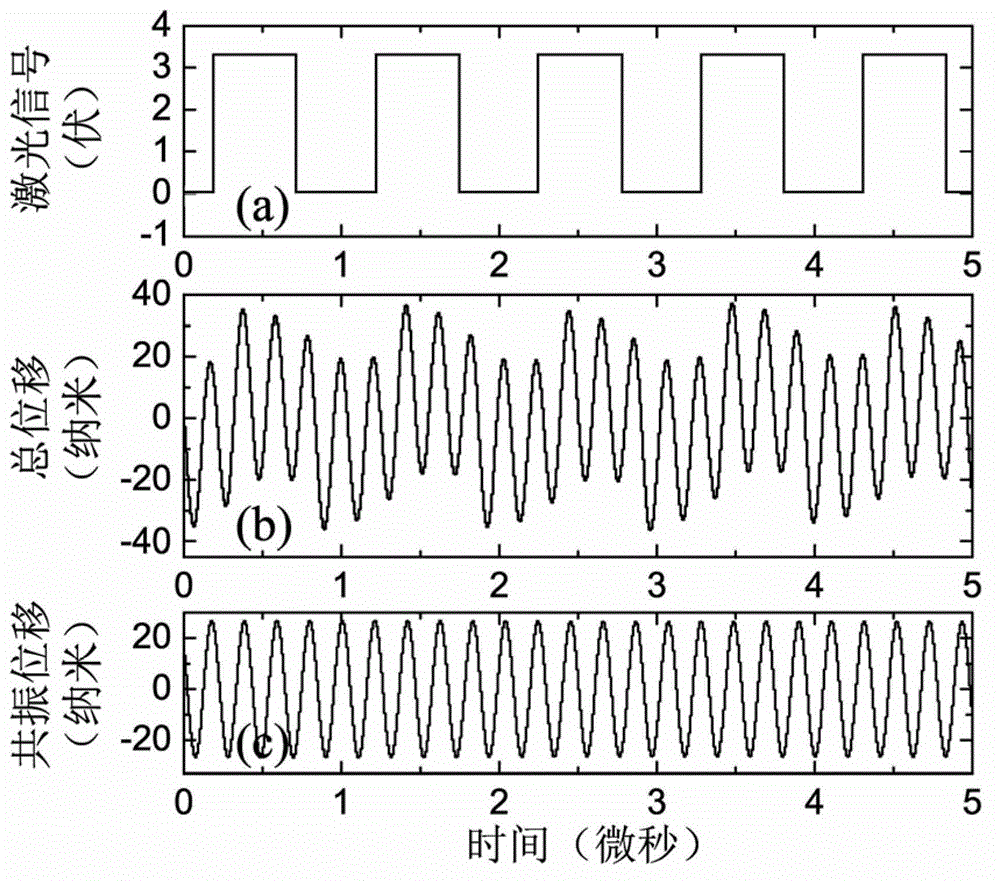

[0025] Such as figure 1 shown. According to claim 1, a method for remotely exciting the resonance of a micron-scale micro-cantilever probe using a laser, using a Zhousi pulse laser 3 to focus on the surface of the micro-cantilever probe 2, through the thermal effect of the laser on the micro-cantilever probe 2 The thermal stress generated in the cantilever probe 2 realizes the resonant excitation of the micro-scale micro-cantilever probe.

[0026] The length of the micro-scale micro-cantilever probe 2 is 100 μm; the width is 10 μm; the thickness is 1 μm. The wavelength of the pulsed laser 3 is 405 nm, and the frequency of the pulsed laser 3 is the 1 / 7 of the resonant frequency.

Embodiment 2

[0028] According to claim 1, a method for remotely exciting the resonance of a micron-scale micro-cantilever beam probe using a laser, its structure and excitation method are the same as those in Example 1, except that:

[0029] The length of the micro-cantilever probe on the micrometer scale is 300 μm; the width is 35 μm; the thickness is 1 μm, the wavelength of the pulsed laser is 532 nm, and the frequency of the pulsed laser is the resonant frequency of the micro-cantilever probe 1 / 5.

Embodiment 3

[0031] According to claim 1, a method for remotely exciting the resonance of a micron-scale micro-cantilever beam probe using a laser, its structure and excitation method are the same as those in Example 1, except that:

[0032] The length of the micro-cantilever probe on the micrometer scale is 500 μm; the width is 50 μm; the thickness is 2 μm, the wavelength of the pulsed laser is 650 nm, and the frequency of the pulsed laser is the resonant frequency of the micro-cantilever probe 1 / 3.

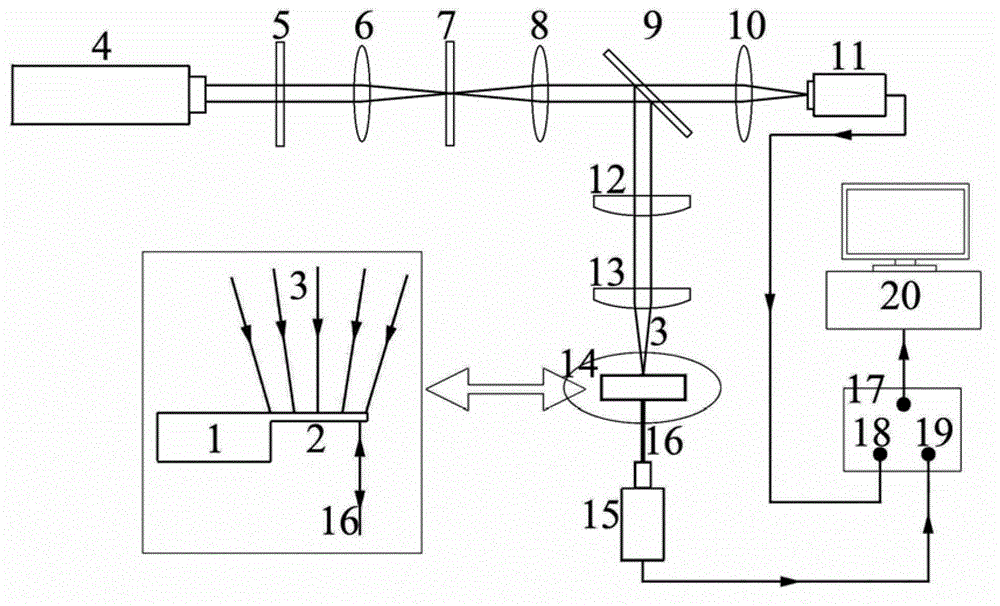

[0033] Such as figure 2 shown. In order to achieve the above-mentioned remote excitation of the micro-cantilever beam probe resonance with laser, the following excitation device is used:

[0034] The excitation device includes a laser emitting device and a micro-cantilever, and the micro-cantilever includes a micro-cantilever base 1 and a micro-cantilever probe 2 of the same material as one with the micro-cantilever base 1;

[0035]Described laser emitting device comprises continuous las...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com