Method for preparing SiC ohmic contact by ultraviolet pulse laser irradiation device

A technology of pulsed laser and ohmic contact, which is applied in semiconductor/solid-state device manufacturing, electrical components, semiconductor devices, etc., can solve unseen problems and achieve the effects of short processing time, precise processing range, and control processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

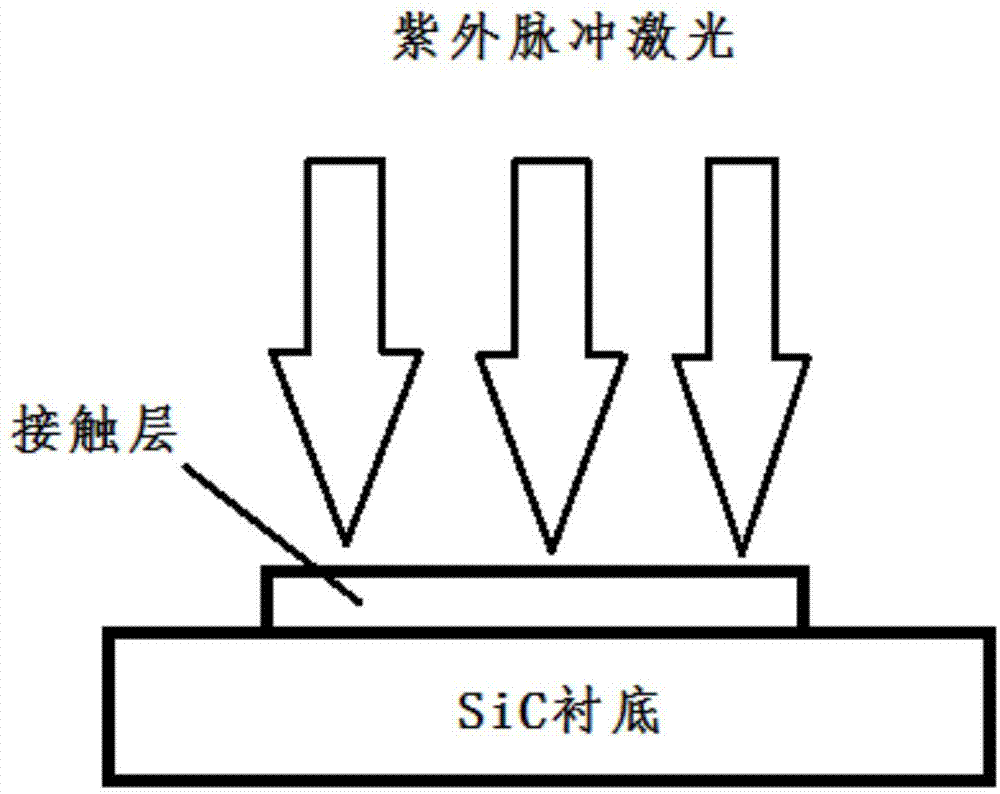

[0015] Embodiment 1 (as attached figure 1 shown)

[0016] The n-type 4H-SiC is used as the substrate, the surface of the substrate is cleaned, and a layer of Ni metal is sputtered by a magnetron sputtering method. Using a focused pulsed laser with a wavelength of 248nm and a single pulse energy of 250mJ, the front side of the above material is irradiated in an argon atmosphere to obtain an ohmic contact.

Embodiment 2

[0018] The n-type 4H-SiC is used as the substrate, the surface of the substrate is cleaned, and a layer of Ti metal is sputtered by magnetron sputtering. Using a focused pulsed laser with a wavelength of 248nm and a single pulse energy of 250mJ, the front side of the above material is irradiated in an argon atmosphere to obtain an ohmic contact.

Embodiment 3

[0020] The n-type 4H-SiC is used as the substrate, the surface of the substrate is cleaned, and a layer of Ni metal is sputtered by a magnetron sputtering method. A pulsed laser with a wavelength of 248nm and a single pulse energy of 300mJ is used to focus and irradiate the front side of the above material in an argon atmosphere to obtain an ohmic contact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com