Automatic accurate weighing device for powdery material

A powdery material and material weighing technology is applied in the field of powdery material automatic weighing device, which can solve the problems of inconsistent batching amount, insufficient detection accuracy, inaccurate measurement, etc., to improve production quality, improve operating environment, and achieve good benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

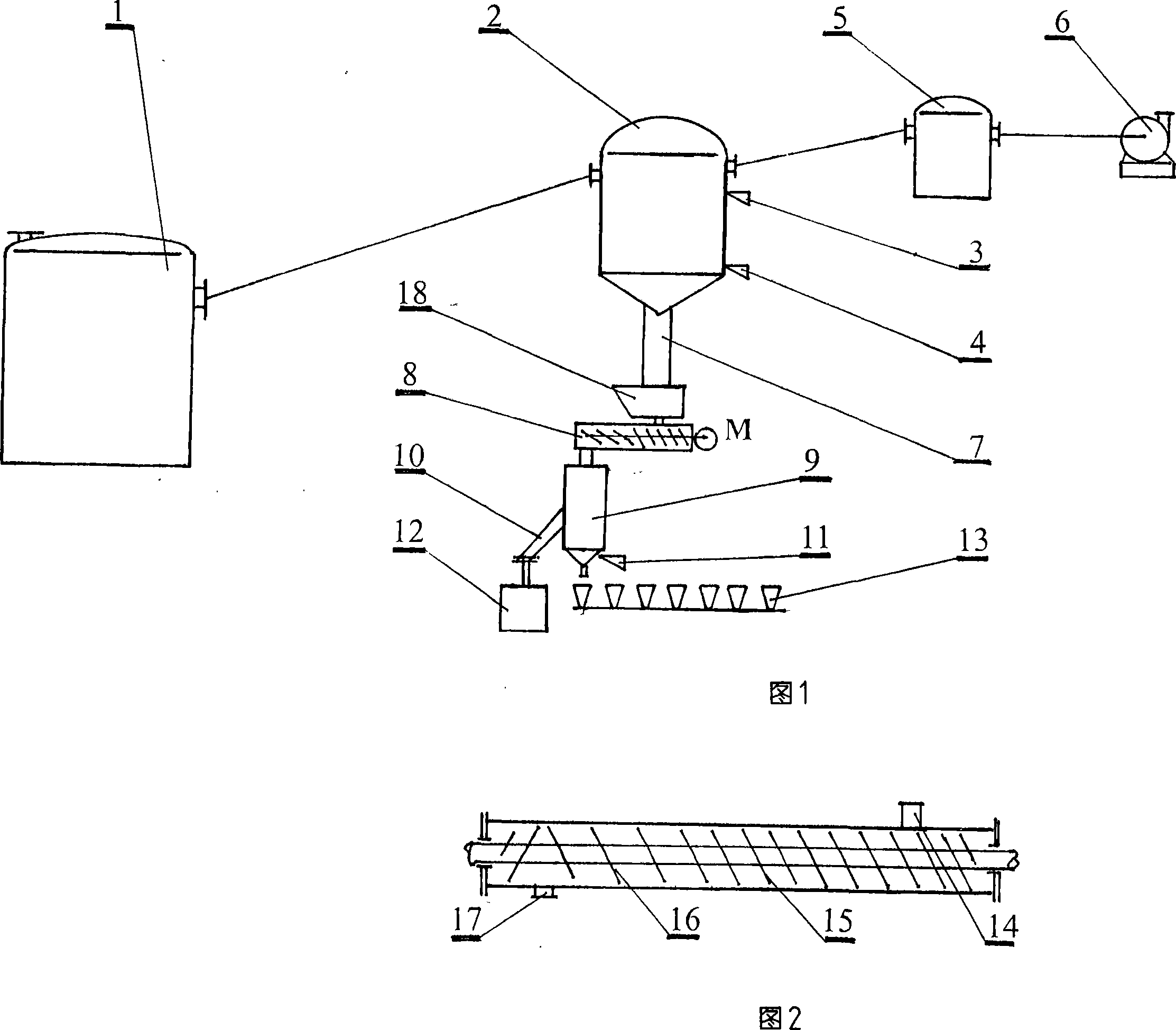

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0010] The powdery material can be a single material or a mixture of various materials. Taking the friction material in the production of brake pads as an example, the automobile friction material prepared according to the specified ratio is put into the raw material box 1. The existing device adopts the method of adding The pressure method uses compressed air to blow the powdery material in the raw material box 1 into the metering equipment, causing dust and toxic substances to leak out, affecting the operation of the device, seriously polluting the environment, and is not conducive to people's physical and mental health. The present invention is provided with a vacuum pump 6 to vacuum Tank 5 is operated under negative pressure, which effectively prevents dust from leaking out; vacuum suction tank 2 is provided with a high-level switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com