Special helium detection method and special helium detection device of sensing element

A sensing element, a special technology, applied in the direction of detecting the appearance of fluid at the leakage point, using liquid/vacuum degree to measure the liquid tightness, etc., can solve the problem of not being able to normally determine whether the product sealing is qualified, the detection efficiency is low, and the operation Complicated procedures and other issues to achieve the effect of avoiding interference, high detection efficiency, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

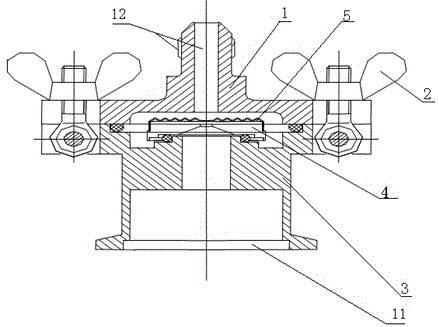

[0018] Example. A device for the special helium detection method of the sensing element, as attached figure 1 And attached figure 2 As shown, the pressurized cover 1 is included, the pressurized cover 1 is provided with a connection interface 12, the pressurized cover 1 is also connected with a frock base 3, and the frock base 3 is connected with a sealing ring 4 for placing a sensing element 5, the The tool base 3 is also provided with a helium detector interface 11 .

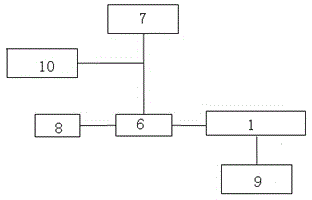

[0019] The connection interface 12 is provided with two, one is connected with the high-pressure air source 9, and the other is connected with the three-way switch 6, and the three-way switch 6 is connected with the pressure relief valve 8 and the helium gas source 7 respectively.

[0020] The pressurized cover 1 is connected with the tooling base 3 through a butterfly nut 2 .

[0021] A pressure gauge 10 is connected between the three-way switch 6 and the helium source 7 .

[0022] Working principle: as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com