Method for producing indium phosphide back hole

A manufacturing method and technology of indium phosphide, which are applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., can solve the problems of InP back-hole fabrication and other problems, and achieve good consistency and repeatability. Simple process, simple and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

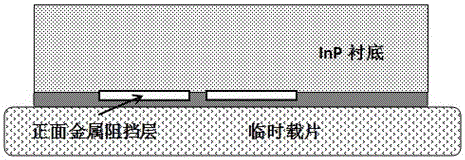

[0033] The method for making an indium phosphide back hole includes the following steps:

[0034] (1) Make a layer of 300nm TiPtAu metal barrier layer on the front of the indium phosphide wafer. After the front process is completed, stick the front of the indium phosphide wafer to the sapphire with high-temperature wax, and then use a grinder to grind the indium phosphide substrate The thickness is reduced to 100um;

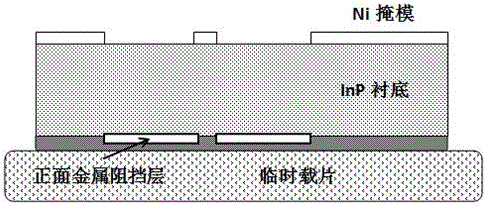

[0035] (2) Use photoresist to lithography the back hole pattern, and then evaporate Ni metal as an etching mask;

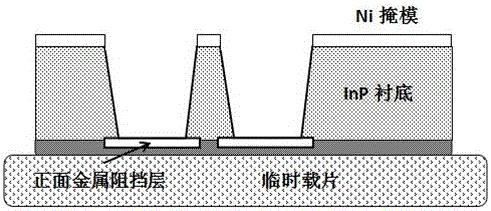

[0036] (3) Use the back helium of the STS ICP dry etching machine to raise the temperature of the wafer to 190 degrees, and use chlorine gas (Cl 2 ) and argon (Ar) to etch indium phosphide at an etching rate of about 1um / min;

[0037] (4) Remove the Ni etching mask with dilute hydrochloric acid;

[0038] (5) Sputter the seed layer Ti / Au / Ti on the back of the indium phosphide wafer, and then electroplate about 5um of Au, so that the bottom of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com