Control method and system of high temperature gas cooled reactor power

A high-temperature gas-cooled reactor and power control technology, which is applied in the field of nuclear energy science and engineering, can solve problems such as the form and performance of high-temperature gas-cooled reactor power control methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

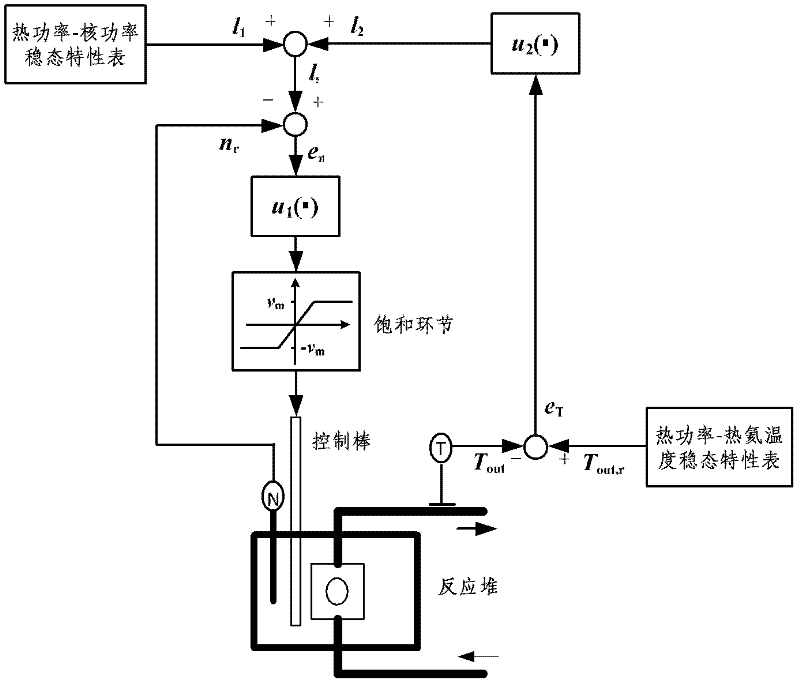

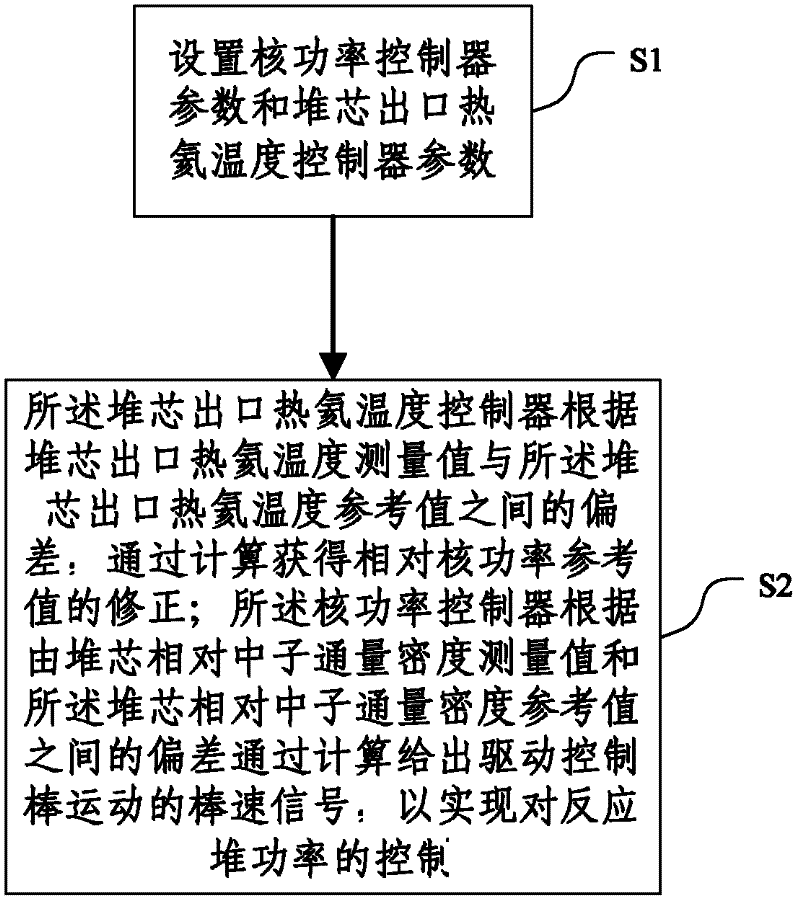

Method used

Image

Examples

Embodiment 1

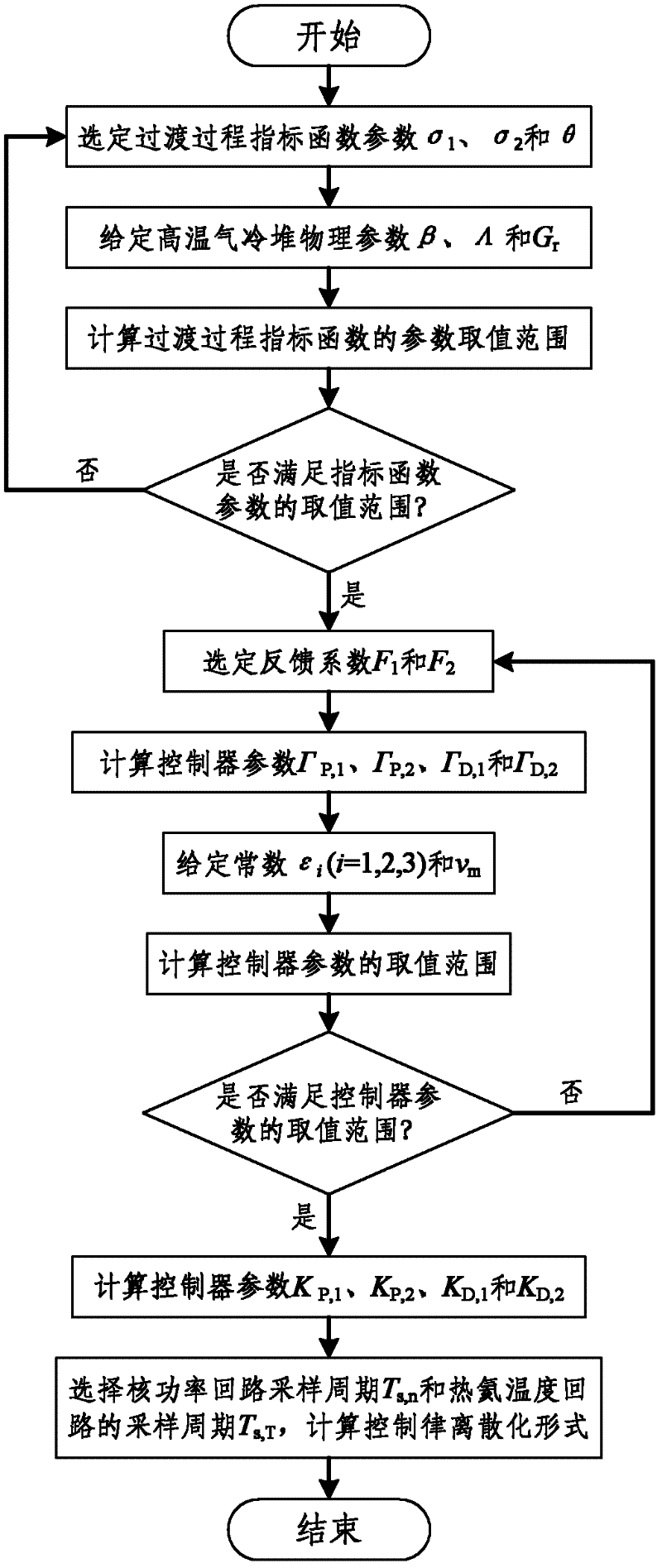

[0134] The specific implementation of the parameter setting in the high temperature gas-cooled reactor power control method proposed by the present invention can refer to image 3 The flow chart is given, and the specific steps are as follows: the first step is to select its parameter σ according to the physical meaning of the transition process index function 1 , σ 2 and θ; in the second step, the physical parameters of the reactor are given, namely the delayed neutron share β, neutron generation time Λ and control rod differential value G r The value of ; the third step is to calculate the index function parameter σ according to the first inequality in equations (15) and (17) 1 and σ 2 The value range of ; the fourth step is to judge the selected σ 1 , σ 2 and θ meet the value range of the index function parameters, if not, reselect σ 1 , σ 2 and θ, otherwise, continue the design process; the fifth step, select the feedback coefficient F 1 and F 2 The value of ; sixth,...

specific example

[0136] The first step is to select the parameters of the transition process index function to satisfy σ 1 =0.2, σ 2 =0.1 and θ=0.1.

[0137] The second step, given the physical parameters of a certain high-temperature gas-cooled reactor: delayed neutron share β=0.005, neutron generation time Λ=0.001 second and control rod differential value G r = 0.001.

[0138] In the third step, according to the first inequality in equations (15) and (17), σ 1 and σ 2 The range of values is

[0139] 0i <10, i=1, 2

[0140] The fourth step, according to the results of the first step and the third step, it can be judged that the parameter value selection of the transition process index function meets the requirements, and the design process continues.

[0141] The fifth step, choose to set the feedback coefficient F 1 =0.004, F 2 = 0.002.

[0142] The sixth step is to calculate the controller parameter Γ P,1 , Γ P,2 , Γ D,1 and Γ D,2 The value is

[0143] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com