High-temperature gas cooled reactor helium flow control system and method with incremental adjusting function

A high-temperature gas-cooled reactor and gas flow technology, which is applied in the direction of flow control, control/regulation system, flow control of electrical devices, etc., can solve the problem of non-linear control characteristics, difficulty in precise control, and the need for improvement in dynamic adjustment performance, etc. problem, achieve the effect of overcoming power overshoot or oscillation, improving robustness, improving stability and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

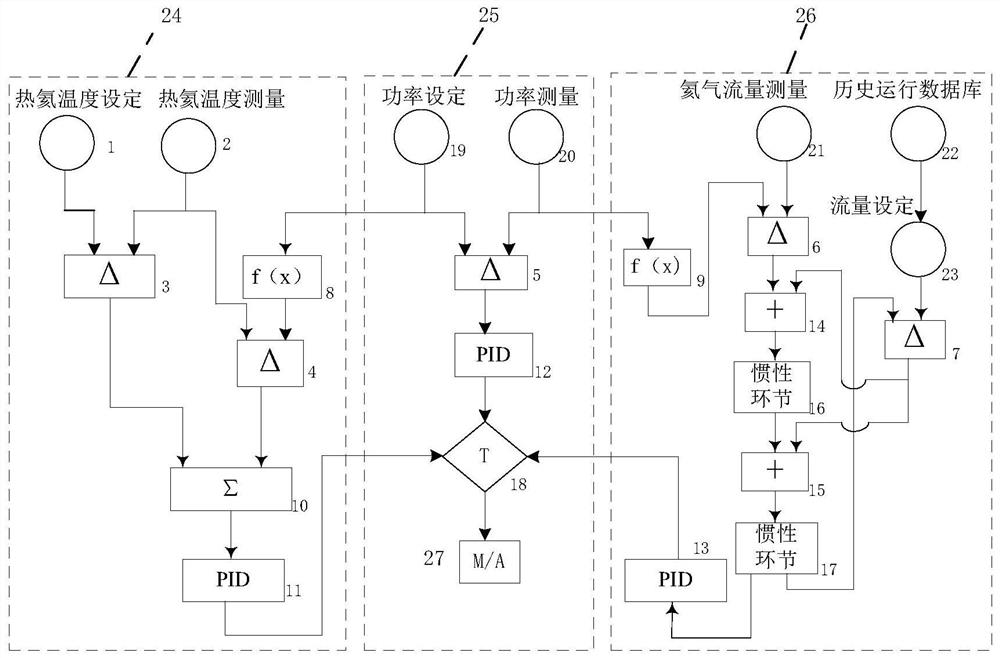

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

[0023] refer to figure 1 , the high temperature gas-cooled reactor helium flow control method with incremental adjustment function described in the present invention comprises the following steps:

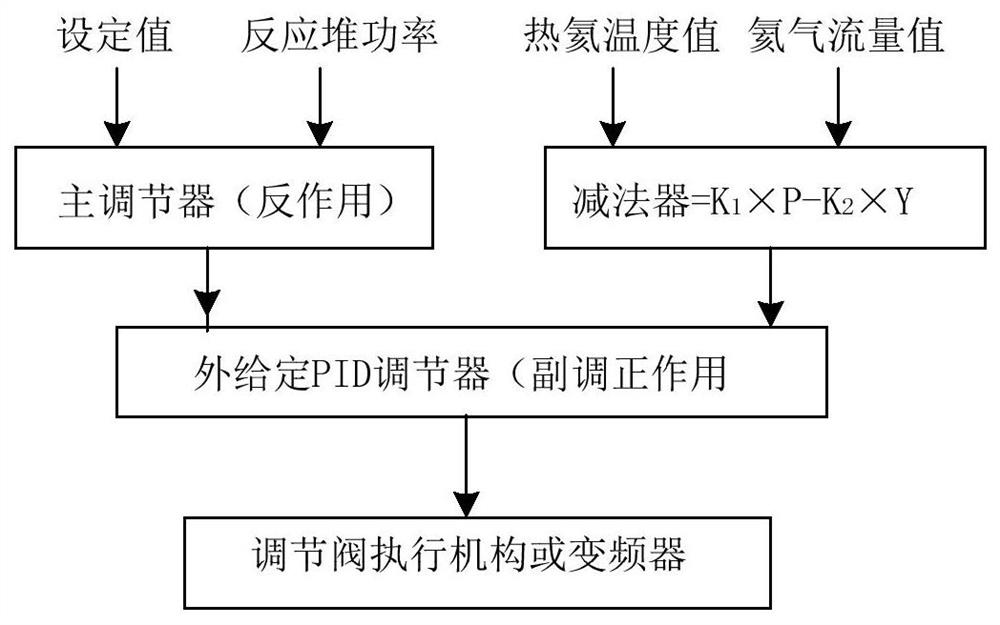

[0024] 1) Obtain the measured value of the helium temperature, and then calculate the deviation between the set value of the heated helium temperature and the measured value of the heated helium temperature to obtain the first thermal helium temperature deviation value, calculate the calculated value of the heated helium temperature according to the power set value, and convert the heated helium temperature Calculate the deviation between the calculated value of the helium temperature and the measured value of the thermal helium temperature to obtain the second thermal helium temperature deviation value, and perform weighted calculations on the first thermal helium temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com