A simulation method for heat transfer process of cold helium cylinder deflation

A simulation method, thermal process technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as poor universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

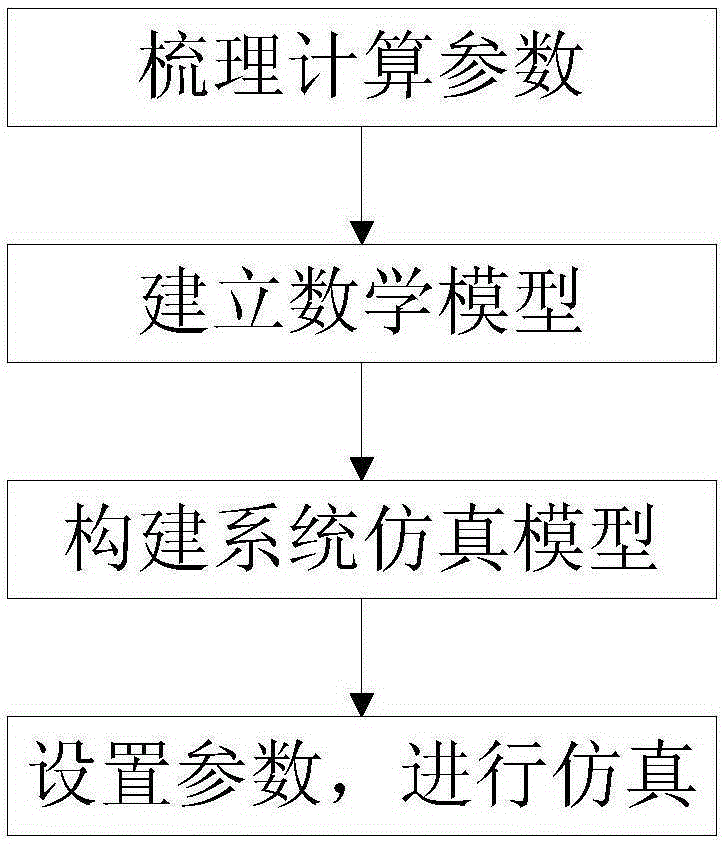

[0039] Such as figure 1 As shown, the present invention provides a simulation method for the process of deflation and heat exchange of cold helium cylinders, the steps are as follows:

[0040] (1) According to the working sequence of the launch vehicle, determine the time when the cold helium cylinder is exposed to the air pillow of the storage tank and the deflation sequence of the cold helium cylinder;

[0041] (2) Establish the mathematical model of convective heat transfer inside the cold helium cylinder, the mathematical model of convective heat transfer outside and the mathematical model of heat conduction on the metal bottle wall according to the lumped parameter method;

[0042] The three models are:

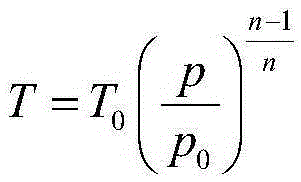

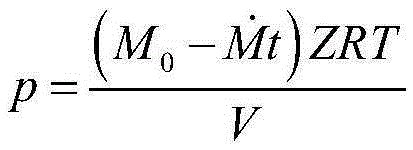

[0043] The mathematical model for calculating the pressure and temperature of cold helium gas is specifically:

[0044] V · ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com