Thermal hydraulic characteristic testing device and method for tritium blowing helium of breeding blanket pebble bed of fusion reactor

A technology of multiplication cladding and thermal hydraulics, which is applied in the direction of measuring devices, fluid dynamics tests, and testing of machine/structural components, etc., can solve the problem of limited power density, difficulty in obtaining high power density nuclear heat, and the impact of blowing tritium and helium flow and heat transfer issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

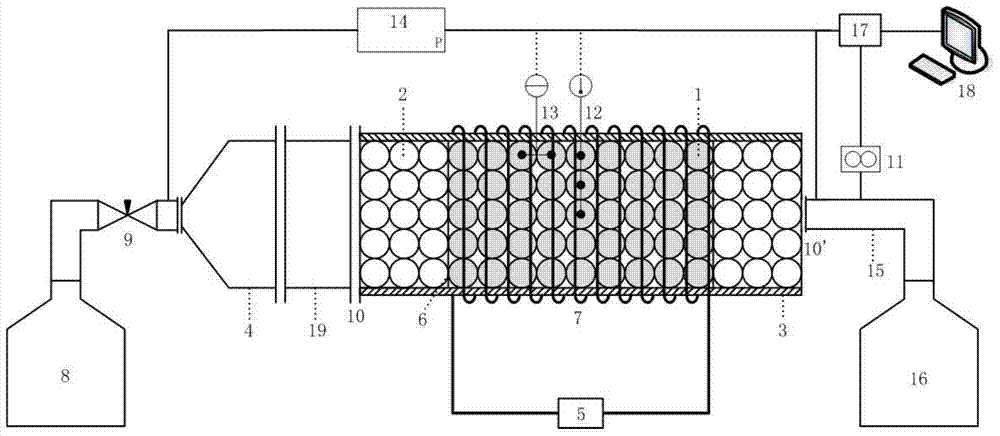

[0020] Specific embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0021] The specific embodiment of the invention is to adopt the attached figure 1 Schematic diagram of a fusion reactor breeding cladding pebble bed blowing tritium and helium gas thermal hydraulic characteristics experimental device schematic diagram shown.

[0022] The present invention adopts a fusion reactor breeding cladding pebble bed blowing tritium helium gas thermal hydraulic characteristics experimental device, which consists of a pseudo-breeding agent metal pellet 1, a high temperature resistant glass pellet 2, a rectangular transparent quartz glass pellet bed experiment section 3, Inlet transition section 4, non-contact high-frequency induction power supply 5, wire mesh 6, spiral heating coil 7, high-pressure helium cylinder 8, needle valve 9, inlet flange 10, outlet flange 10', d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com