Patents

Literature

57results about How to "Control lift height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent anti-collision guardrail structure

ActiveCN107165092AWith impact resistanceImprove the protective effectRoad vehicles traffic controlAlarmsHydraulic motorRadar

The invention relates to an intelligent anti-collision guardrail structure. The intelligent anti-collision guardrail structure consists of a power system, an anti-collision system, a car preventing system, a violation and evidence obtaining system, an intelligent system, an alarming and reminding display system and a control system. The power system consists of a solar cell panel, a storage battery, a motor, a speed changing box, a hydraulic motor and a hydraulic pump. The anti-collision system consists of a lifting subsystem, a flexible protection subsystem, a semi-rigidity protection subsystem, a rigidity protection subsystem, an air cushion protection subsystem and a magnetic protection subsystem. The violation and evidence obtaining system consists of a camera, a video camera, a radar tachymeter, a wifi device, a GPS device and a data rod. The intelligent anti-collision guardrail structure has the advantages of being high in intellectualization, capable of adjusting a collision angle, high in construction speed, convenient to maintain and long in service life.

Owner:ZHENGZHOU MUNICIPAL MAINTENANCE ENG CO LTD

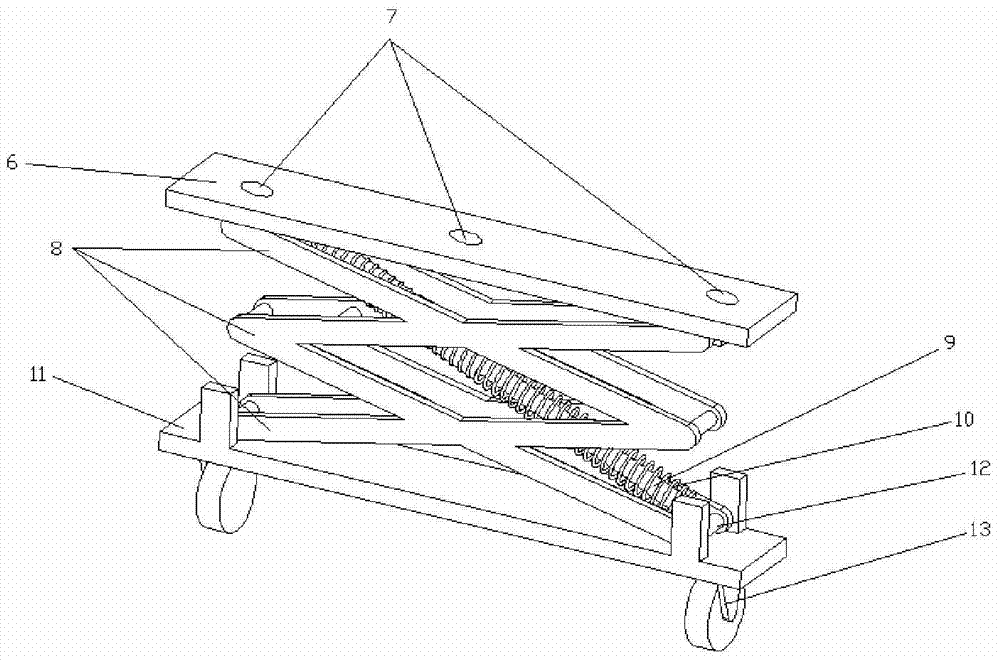

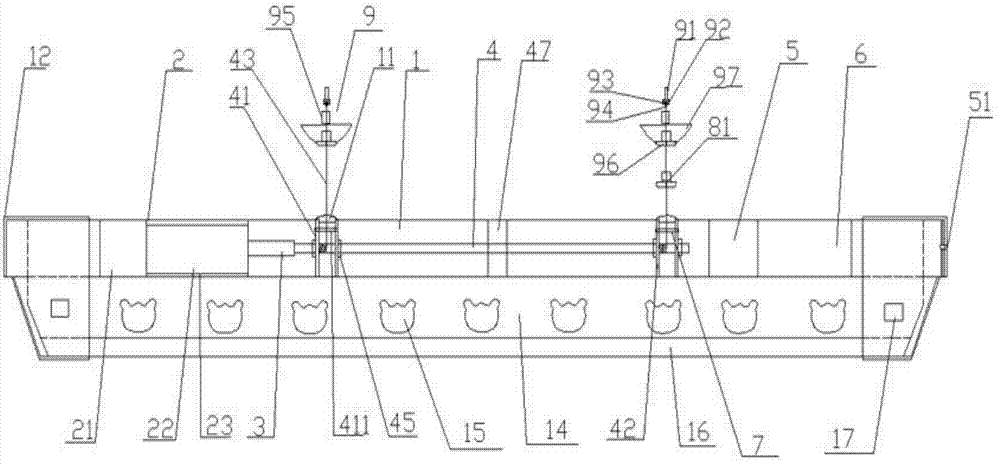

Cart with extension-type wheels

InactiveCN104843038AGuaranteed lateral stabilityUniform supportHand carts with multiple axesHand cart accessoriesHydraulic cylinderAgricultural engineering

The invention discloses a cart with extension-type wheels. Extension-type wheel sets are mounted in the front and in the back of the bottom of a cart carriage. Each extension-type wheel set comprises a wheel, a connecting-rod extension mechanism and a hydraulic cylinder. Each pair of extension-type wheel sets can be adjusted to ascend and descend within a certain range according to needs, so that when the cart needs to pass two ground surfaces different in height, the height of the extension-type wheel sets can be adjusted sequentially, and the cart can cross an obstacle caused by the ground surfaces different in height stably. The trouble of inconvenience in passing can be omitted particularly when the cart carries a plenty of goods; since the extension-type wheel sets are adjusted to ascend and descend in pairs, the goods carried in the cart can be kept horizontal as far as possible during passing, and side tilt is reduced.

Owner:GUANGXI UNIV

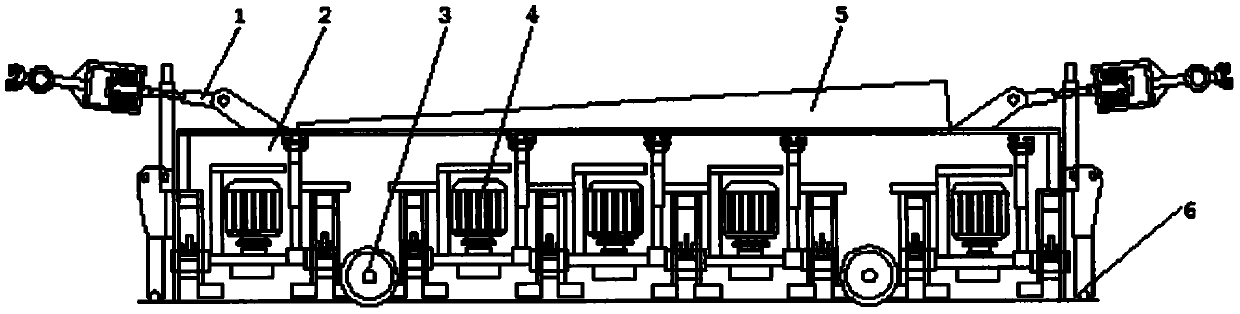

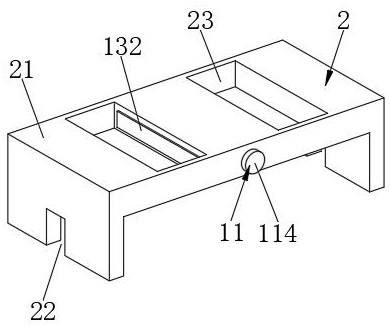

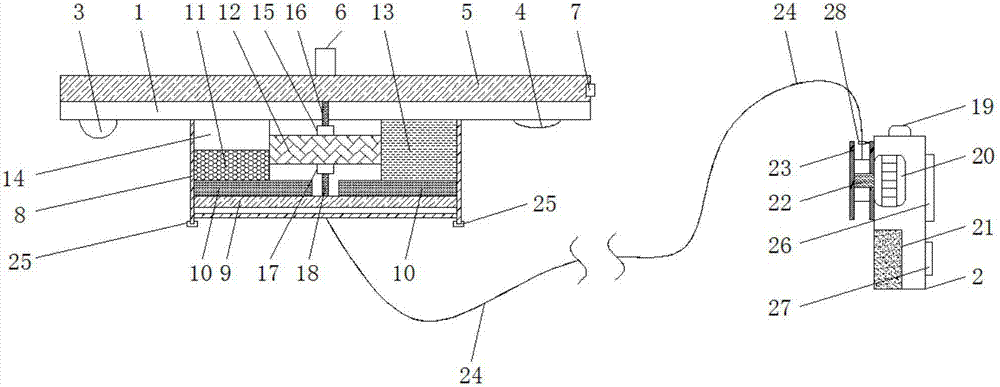

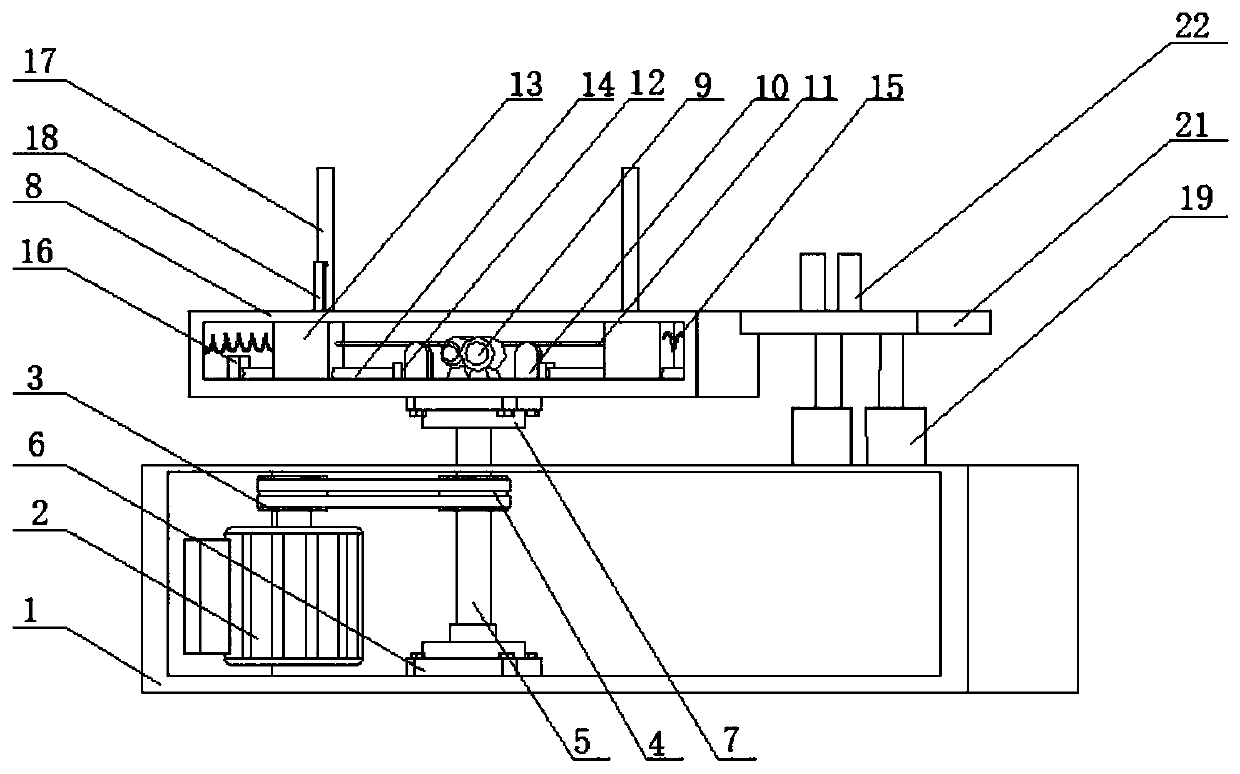

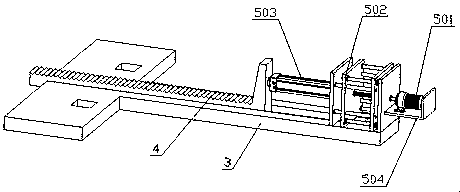

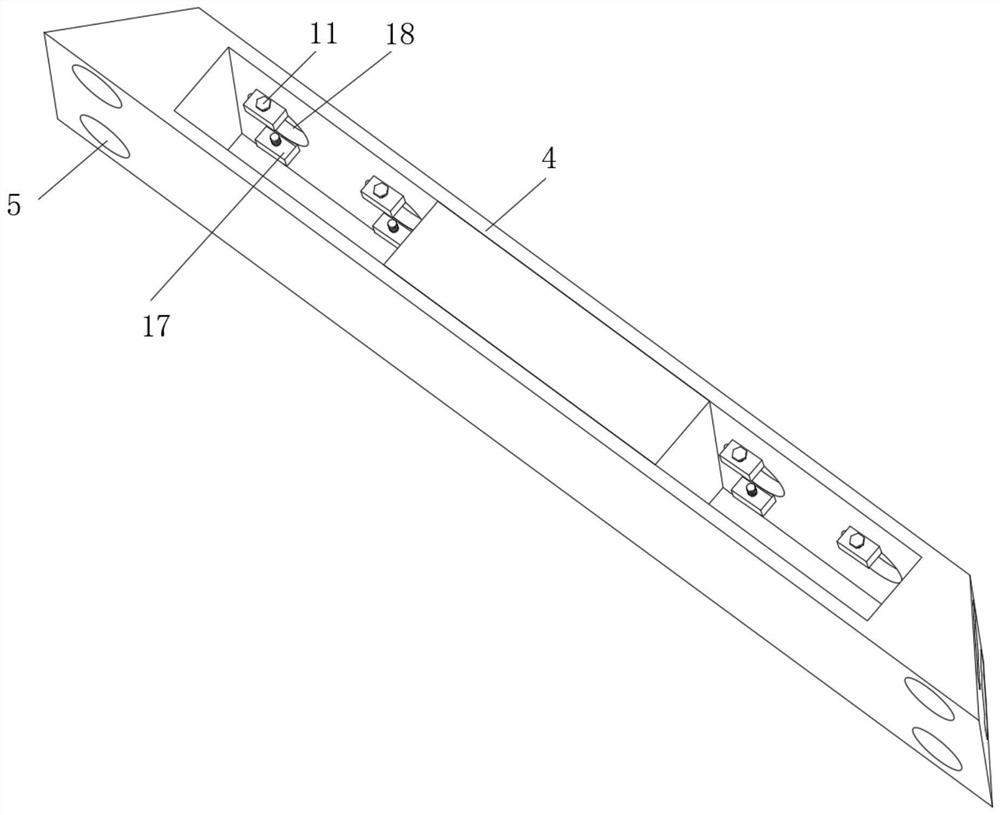

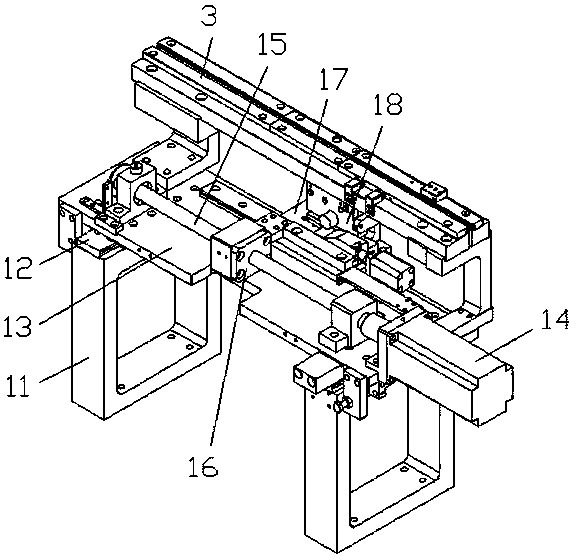

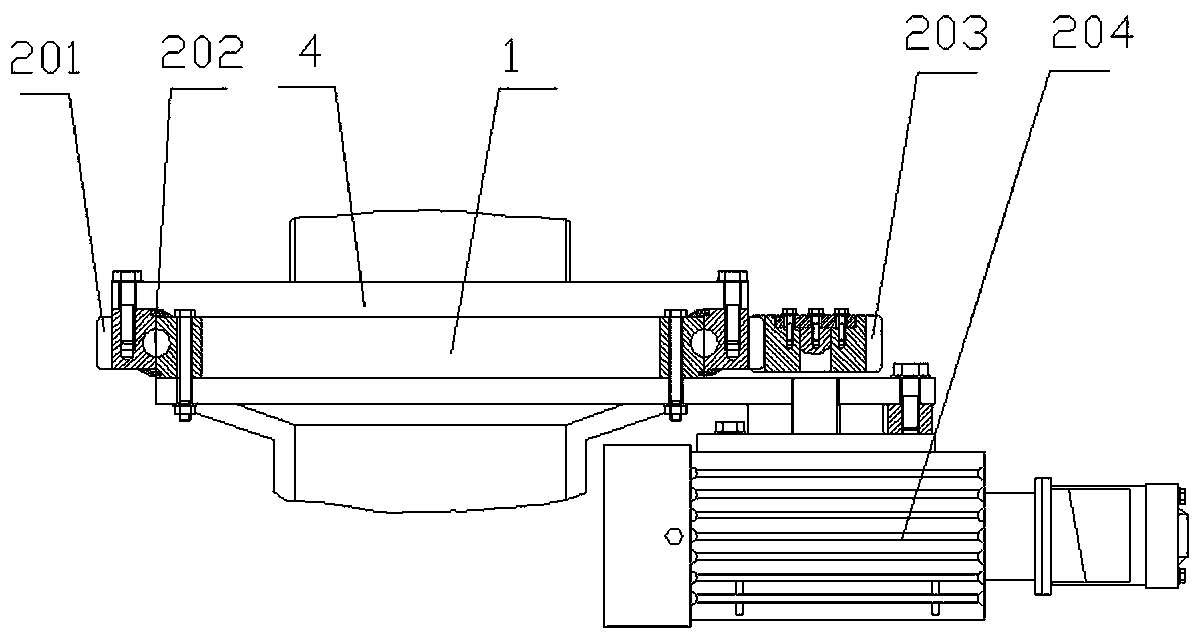

Rail grinding trolley

PendingCN109750566AEasy to panTraversing for easy panningRailway track constructionVehicle frameDerailment

The invention discloses a rail grinding trolley. The rail grinding trolley comprises a frame, a grinding unit and derailment protection devices, wherein traction rods are separately arranged on the upper two sides of the frame, walking wheels are fixed to the lower part of the frame, the grinding unit is arranged in the frame, a dust collection channel is arranged on the upper part of the frame, the derailment protection devices are fixed to the left side and right side of the frame, lifting devices are arranged on the two sides of the inner part of the frame, deflection electric cylinders arearranged below the lifting devices, guide rods are arranged on the lower parts of the deflection electric cylinders, guide seats are arranged on the outer sides of the guide rods, and electric cylinders are fixed to one side of the guide seats. The rail grinding trolley is provided with a transverse moving structure capable of moving horizontally conveniently, and the guide seats can move on theguide rods under the driving action of the electric cylinders, so that the transverse moving of the grinding unit is realized, obstacles on both sides of a rail are conveniently avoided during grinding, and the operation range is expanded.

Owner:长沙瀚鹏电子技术有限公司

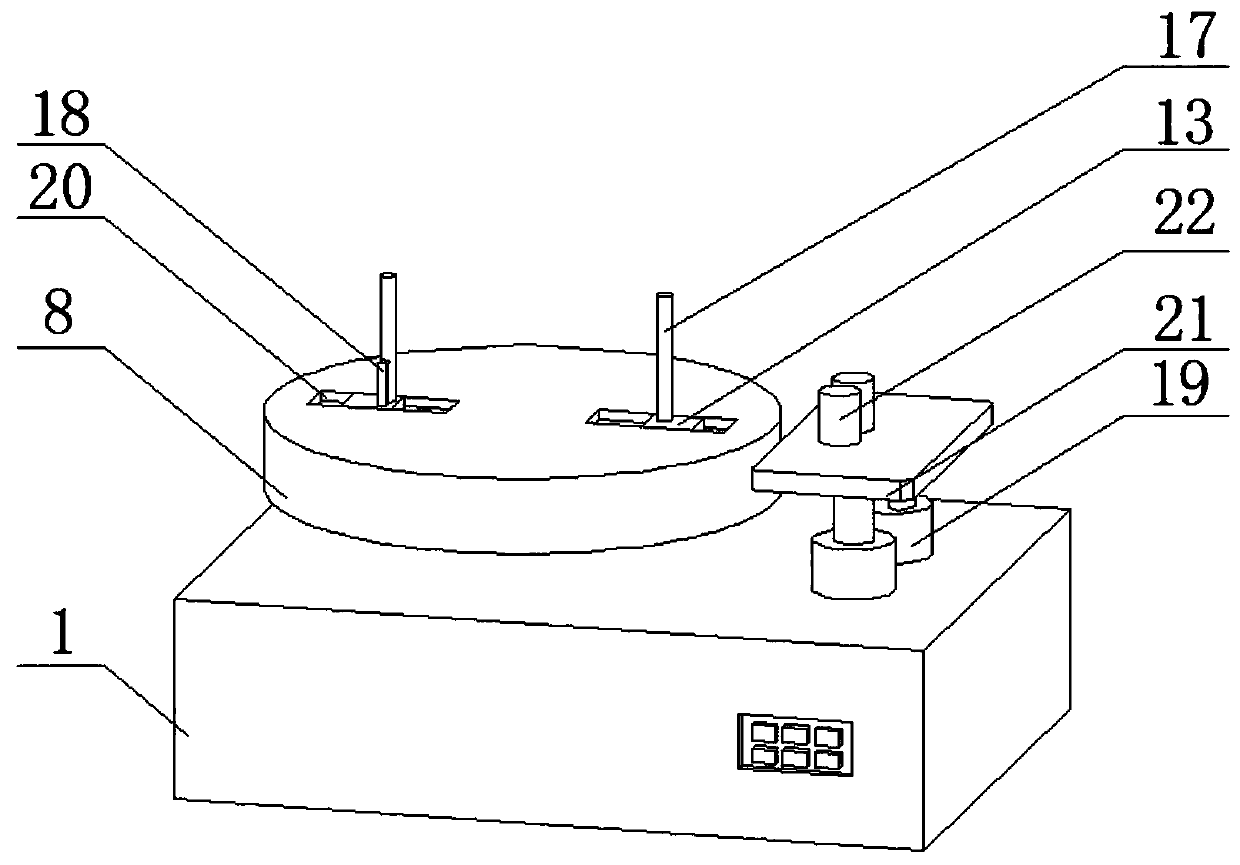

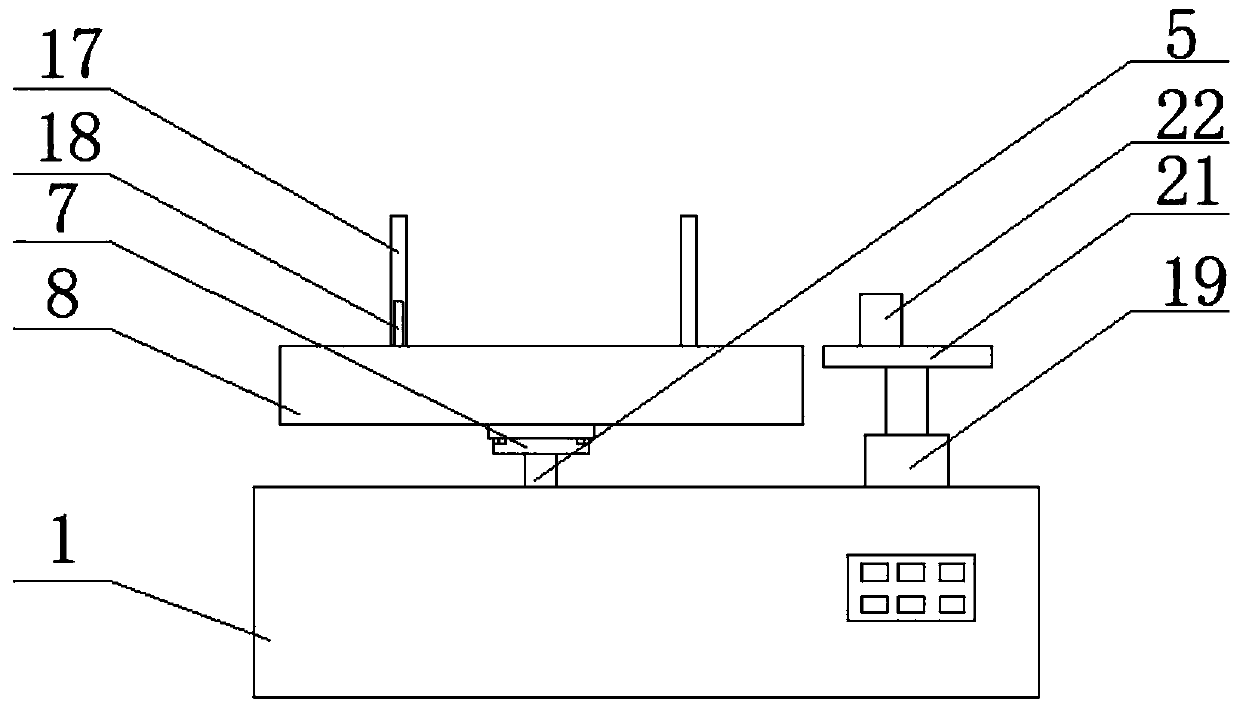

Laser welding device

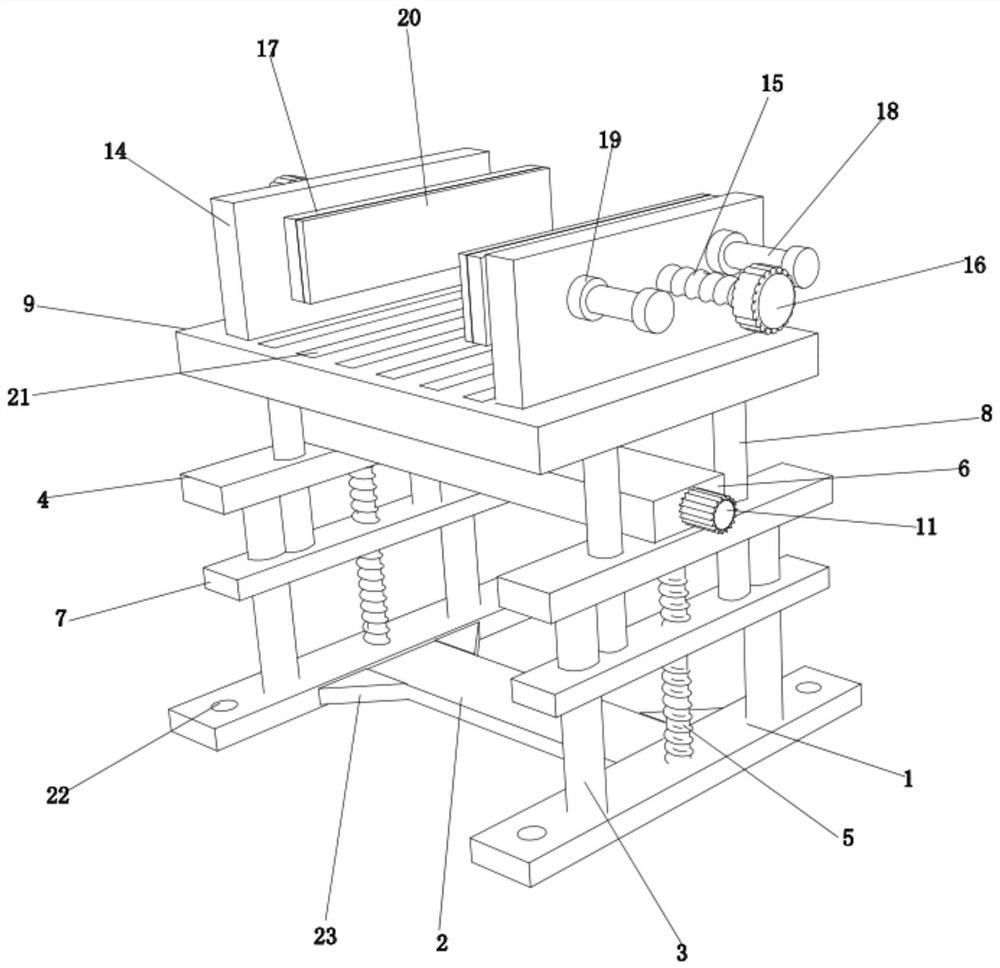

ActiveCN103170745APrecise angle of rotationEffectively control the rotation angleWelding/cutting auxillary devicesAuxillary welding devicesLinear motionSpot welding

The invention relates to a laser welding device comprising a worktable, a weld fixing device and a control device, wherein the weld fixing device comprises a fixing plate, a vertical plate, a connecting plate, a first motor, a rotating shaft, a workpiece fixing structure, a second motor and a lead screw; the rotation motion of the workpiece fixing structure is controlled through the first motor; and the rotating speed of the workpiece fixing structure is determined by the rotating speed of an output shaft of the first motor. According to the invention, the rotating speed of the first motor can be set to a preset value, so that the accurate rotation angle of the workpiece fixing structure is guaranteed; in addition, the lifting motion of the workpiece fixing structure is realized through driving the lead screw by using the second motor and cooperating with a lead screw nut; the circular motion of the second motor can be transformed into accurate linear motion through the cooperation of the lead screw and the lead screw nut, so that the control of the lifting height can be realized through controlling the rotating speed of the second motor; and therefore, the weld fixing device is capable of effectively controlling the rotation angle and the lifting height of the workpiece fixing structure and welding spots are uniformly distributed during multiple-spot welding.

Owner:HANS LASER TECH IND GRP CO LTD

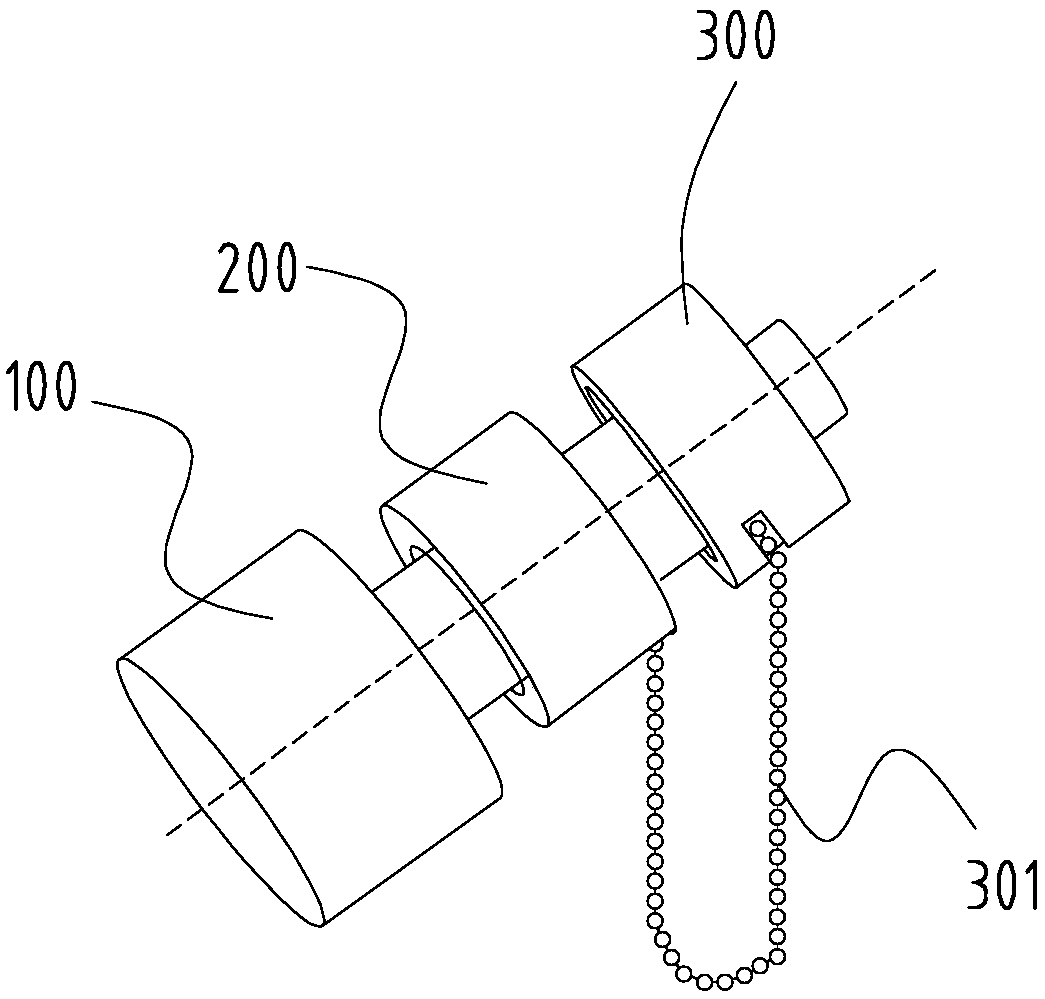

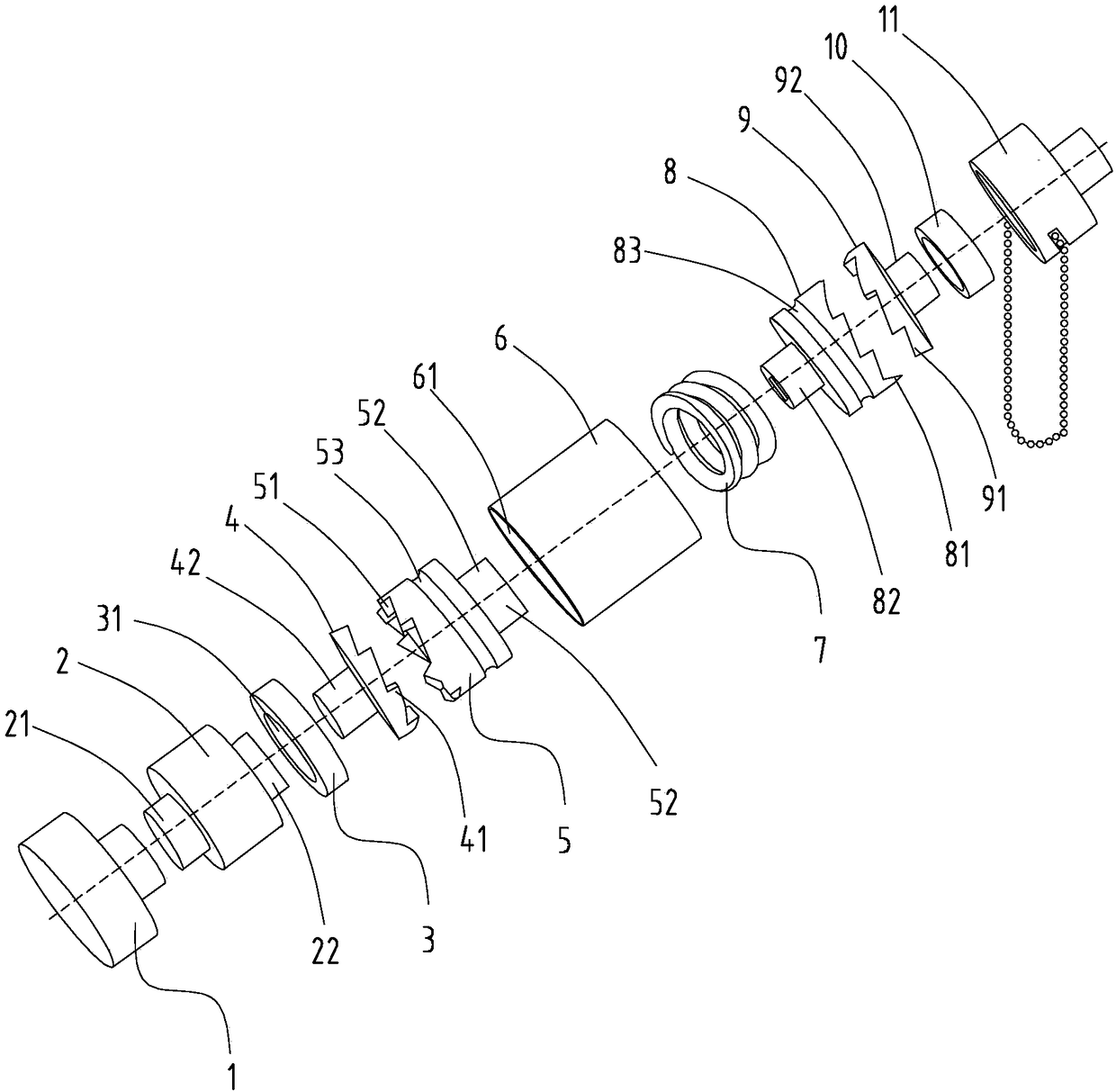

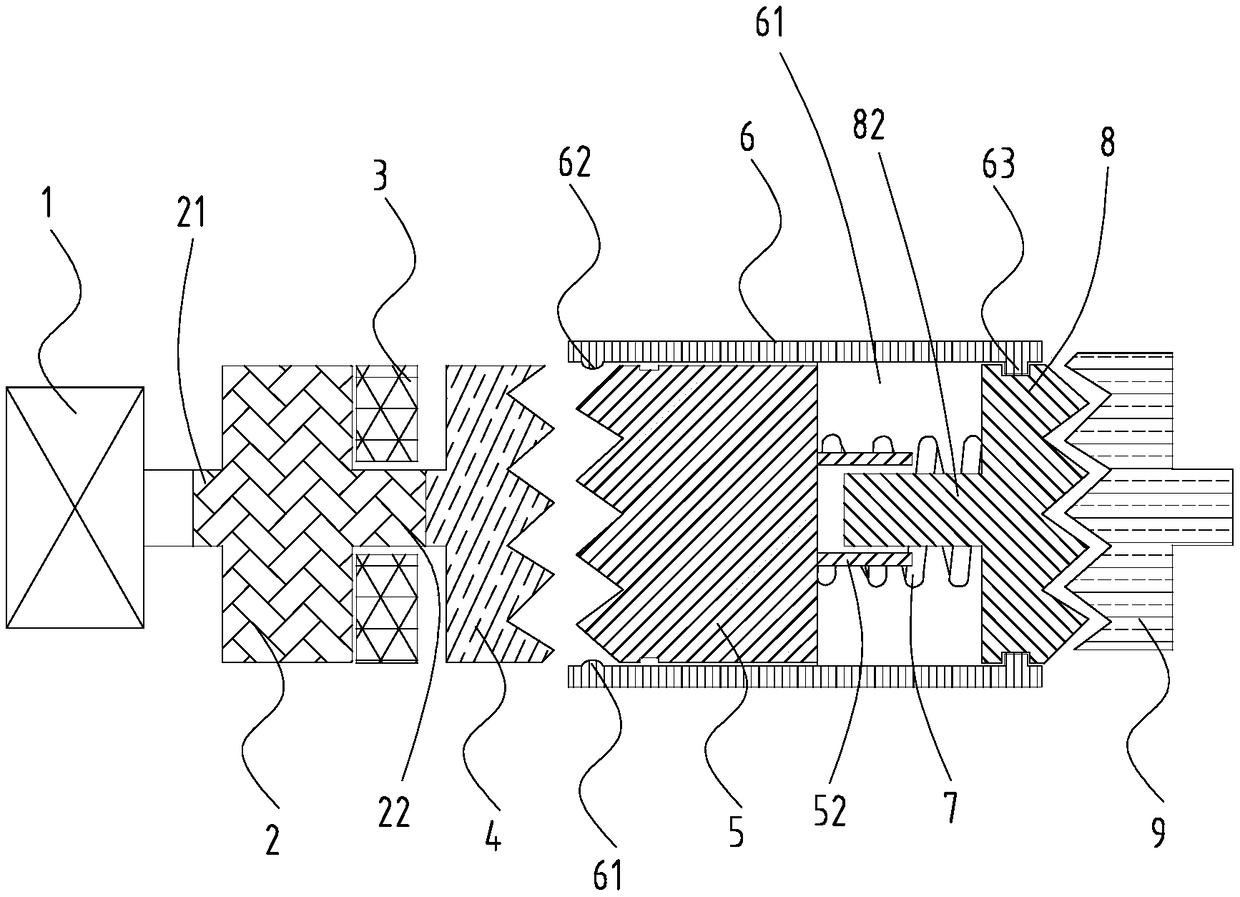

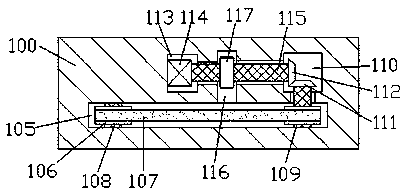

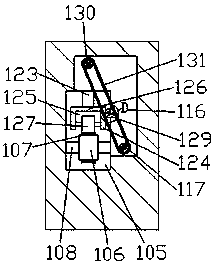

Automatic curtain control apparatus

ActiveCN108577475AControl lift heightAccurately calculate the number of turnsCurtain accessoriesReducerEngineering

The invention relates to an automatic curtain control apparatus. The automatic curtain control apparatus comprises a motor, a planetary gear speed reducer, a sucker electromagnet, a first end surfacefluted disc, a sliding block apparatus, a second end surface fluted disc and a bead curtain brake head. The motor is connected with the first end surface fluted disc by virtue of the planetary gear speed reducer, and the sucker electromagnet is arranged on the planetary gear speed reducer. The sliding block apparatus comprises a shell, a third end surface fluted disc with magnetism, a spring and afourth end surface fluted disc, the middle part of the shell is provided with a shell through hole, the third end surface fluted disc and the fourth end surface fluted disc are respectively arrangedin the shell through hole in a rotating manner, the third end surface fluted disc and the fourth end surface fluted disc are connected by virtue of a spline, and two ends of the spring are respectively connected with the third end surface fluted disc and the fourth end surface fluted disc. Teeth of the second end surface fluted disc are engaged with the teeth of the fourth end surface fluted disc,and the second end surface fluted disc is connected with the bead curtain brake head. By adopting the automatic curtain control apparatus, the problems of the existing automatic curtain control apparatus that when in power failure, labor is wasted when a bead chain is manually pulled and the bead chain is easy to break can be solved.

Owner:泉州市巨将防盗设备有限公司

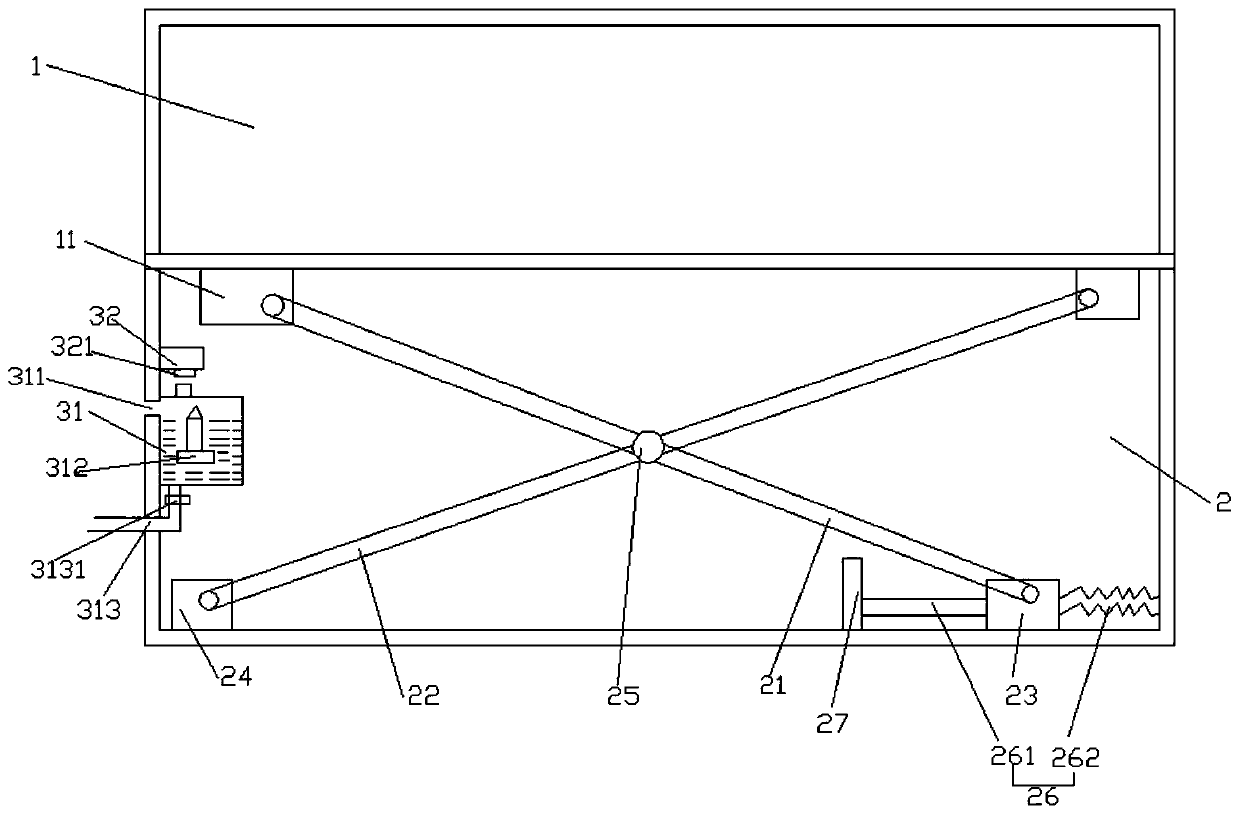

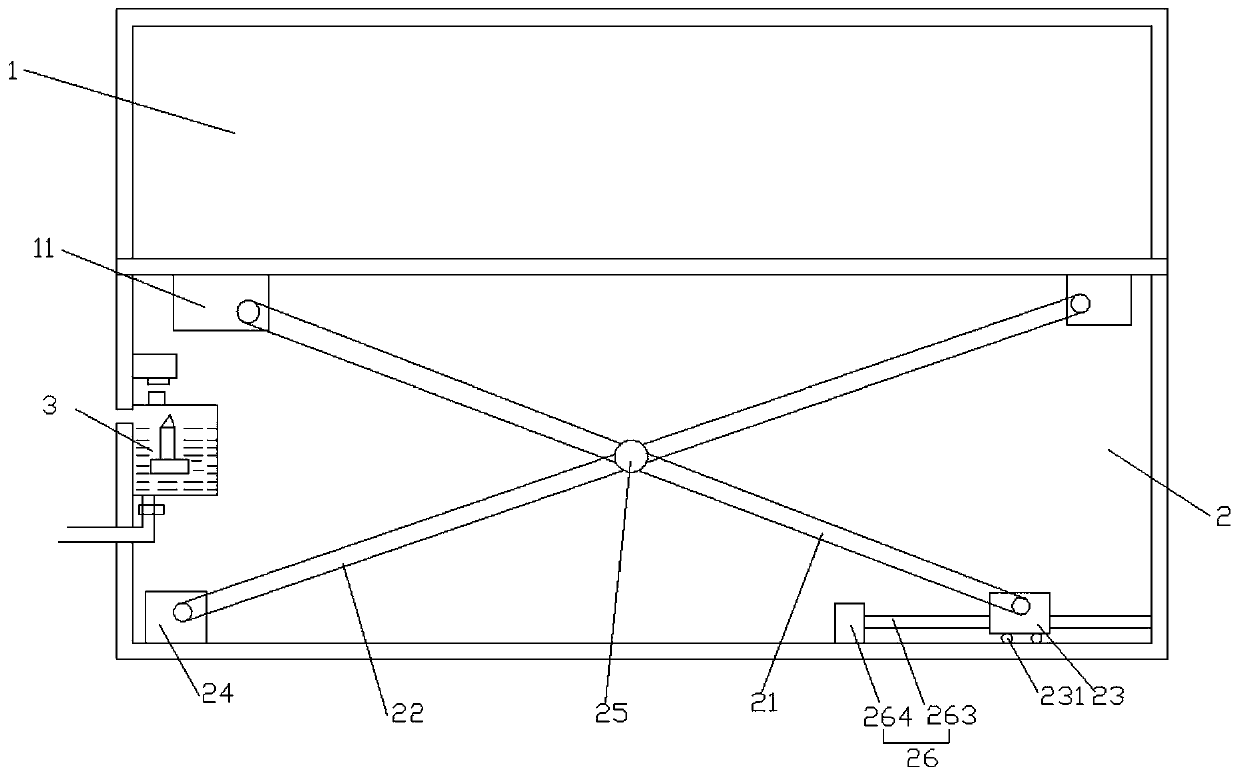

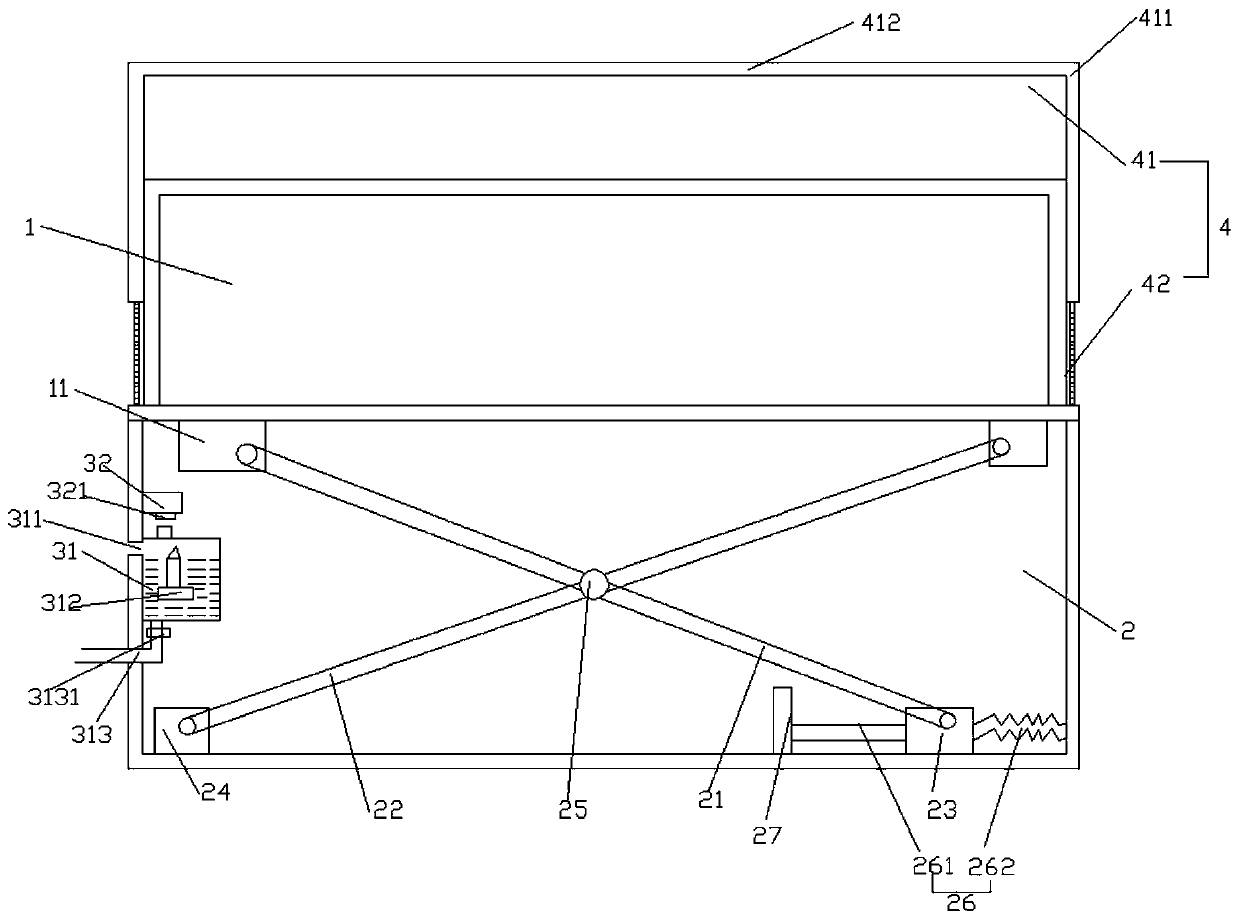

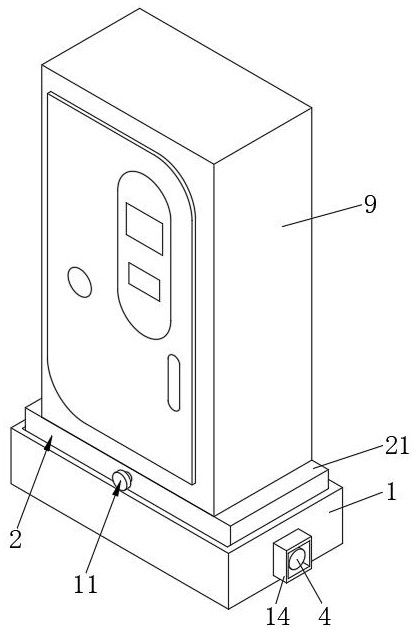

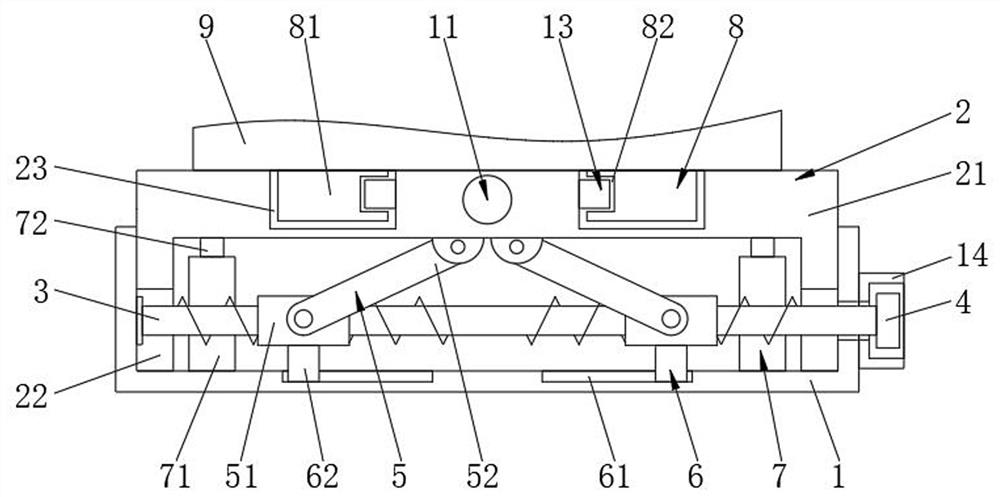

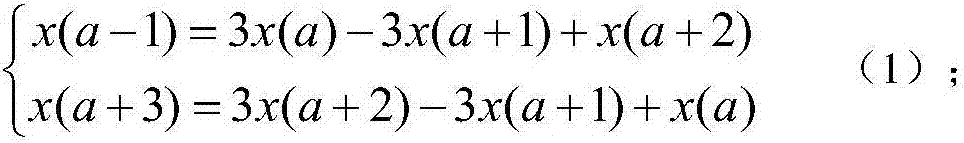

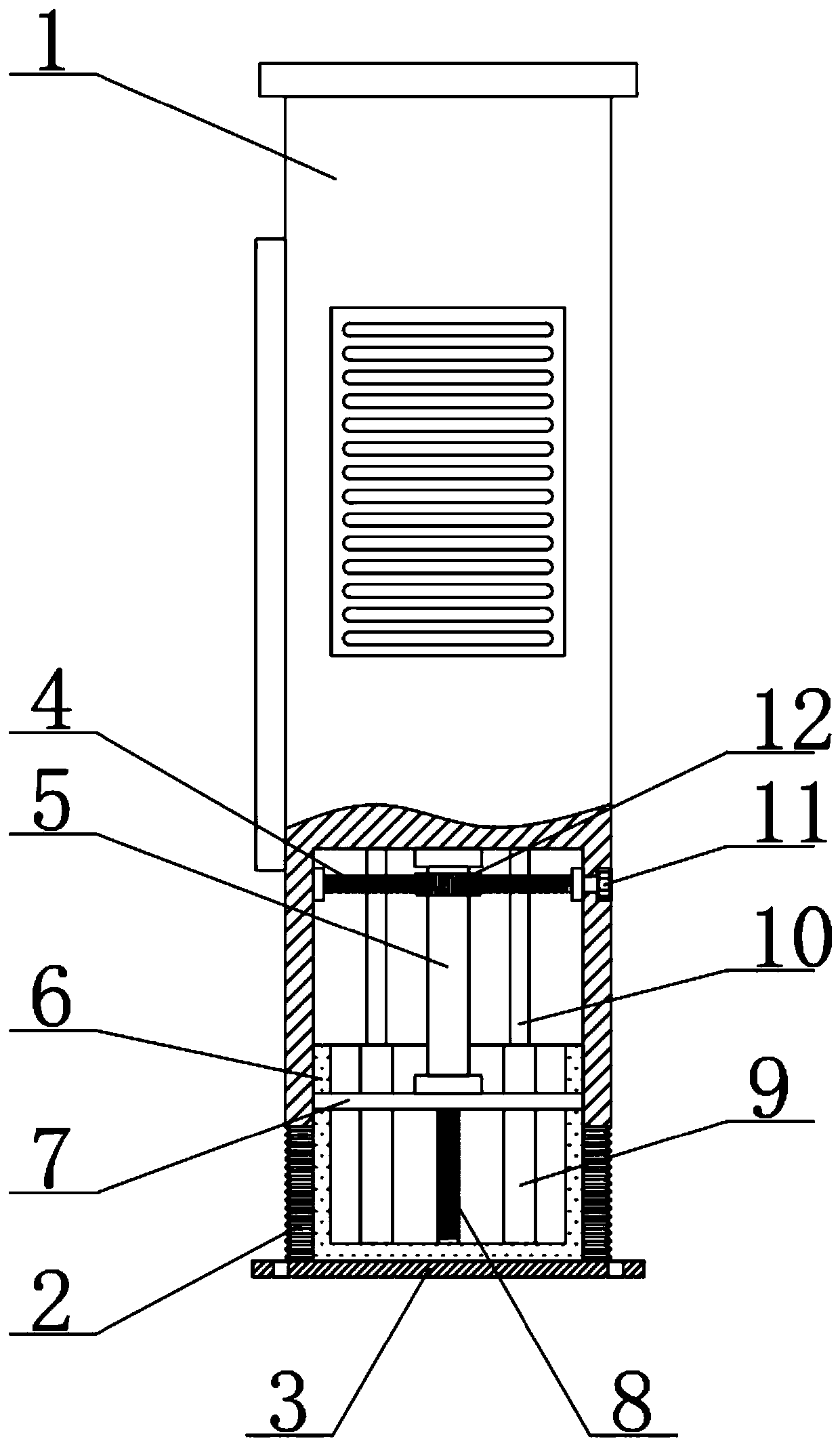

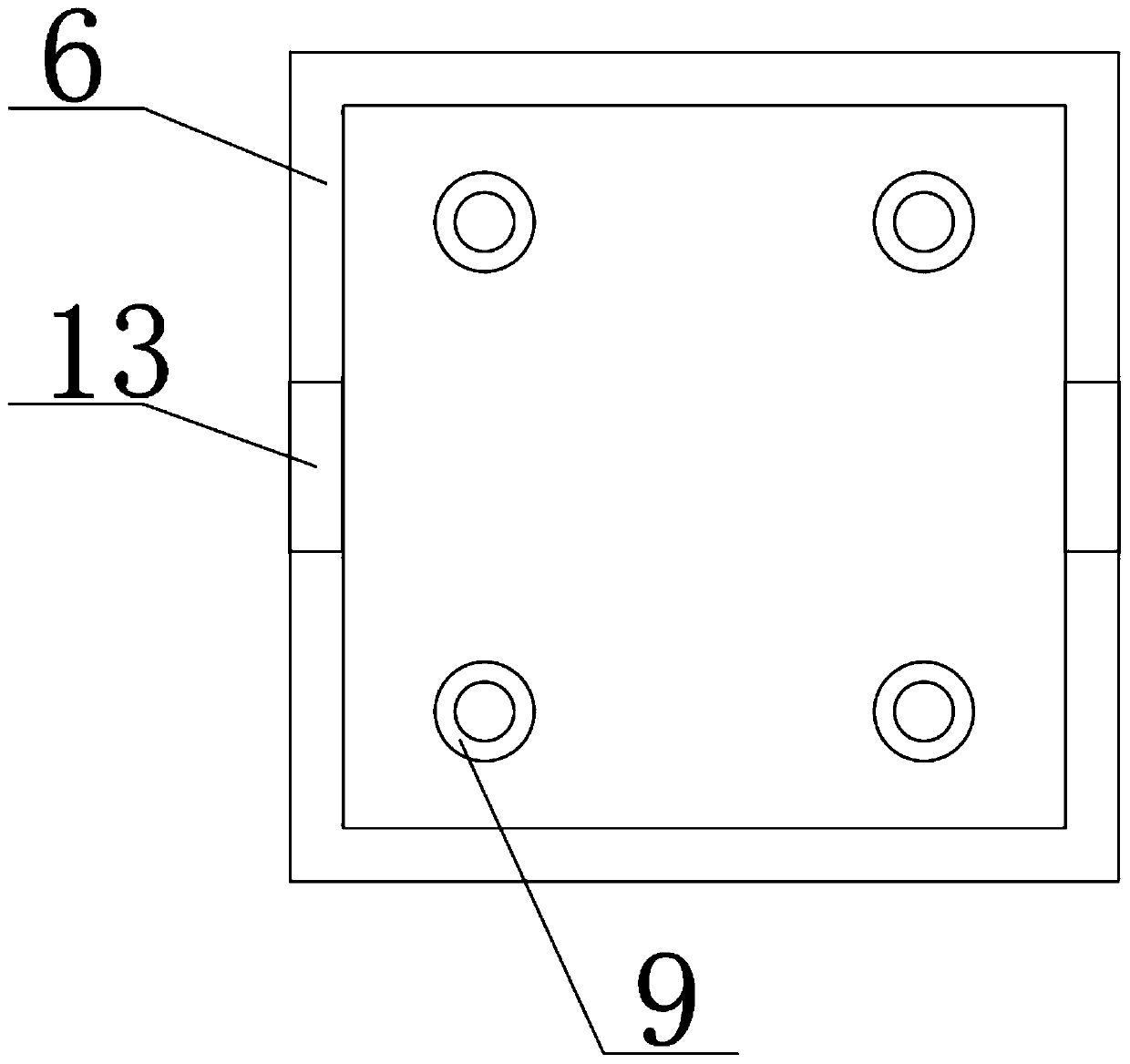

Lifting intelligent vehicle charging pile

InactiveCN109747463AIncrease profitEasy to useCharging stationsElectric vehicle charging technologyEngineeringCross point

The invention discloses a lifting intelligent vehicle charging pile, and relates to the field of charging piles. The lifting intelligent vehicle charging pile comprises a pile body and a lifting basearranged on the upper part of the pile body; the two side walls of the lifting base are retractable, and a first supporting rod and a second supporting rod are arranged in an inner cavity of the lifting base; first mounting seats are oppositely arranged on the two sides of the bottom of the pile body, and a sliding mounting seat is arranged on one side of the inner bottom of the lifting base; oneend of the first supporting rod is connected to one of the first mounting seat, and the other end of the first supporting rod is connected to the sliding mounting seat; a second mounting seat is correspondingly arranged on the other side in the lifting base, one end of the second supporting rod is connected to the other first mounting seat, and the other end of the second supporting rod is movablyconnected to the second mounting seat; the first supporting rod and the second supporting rod are mounted in a crossed mode, and the cross point is provided with a movable shaft; and the movable shaft penetrates through the first supporting rod and the second supporting rod, and a driving device is arranged on the sliding mounting seat. According to the charging pile, through cooperation of the driving device and the sliding mounting seat, the pile body can ascend or descend, and the utilization rate of the charging pile is effectively increased.

Owner:ANHUI NENGTONG NEW ENERGY TECH CO LTD

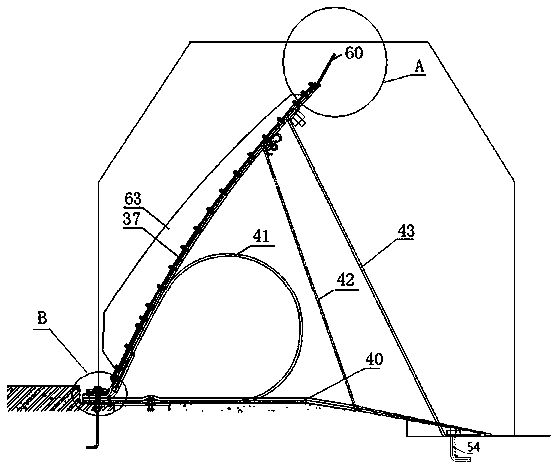

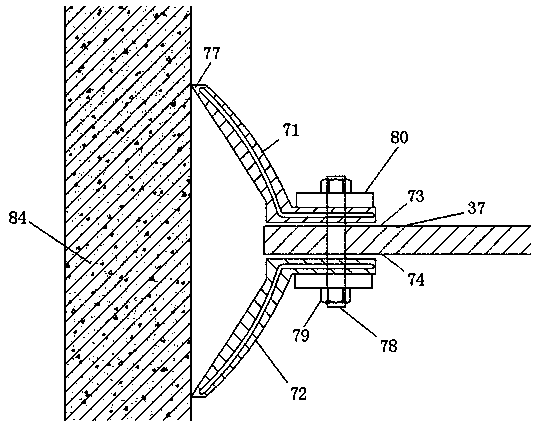

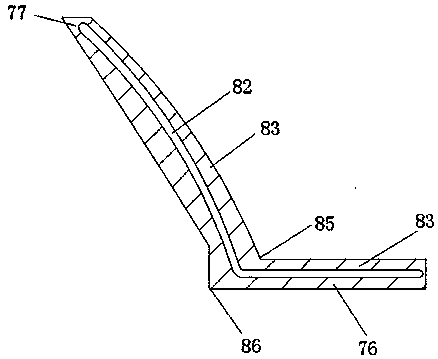

Pneumatic shield gate dam

PendingCN108867567ARealize two-way water stopIngenious structural designBarrages/weirsResonanceEngineering

The invention belongs to the technical field of pneumatic shield gate dams and relates to a pneumatic shield gate dam. The pneumatic shield gate dam comprises a shield plate, the bottom of the shieldplate is fixed to a foundation bottom plate, an air bag and an ornamental curtain for shielding the air bag are sequentially arranged on the back surface of the shield plate from front to back, and the air bag is used for driving the shield plate to move up and down. Wall protecting plates are arranged on left and right sides of the shield plate respectively, bidirectional side wall water-stop body groups are arranged between left and right sides of the shield plate and the corresponding wall protecting plates, the bottom of the shield plate is connected with the foundation bottom plate through a foundation soft connection belt, and a turbulence device is mounted at the top of the shield plate. The pneumatic shield gate dam is high in strength and abrasion resistance, great in water-stop effect and firm in connection with a concrete side wall, and vacuum formed in operation of the pneumatic shield gate dam in water can be prevented. In addition, the pneumatic shield gate dam has a damheight control function and is high in flexibility, less prone to breakage, long in service life and high in stability, the aging speed is reduced, an ornamental effect is achieved, flow breaking andturbulence can be realized while resonance is avoided, and accordingly high safety coefficient is achieved.

Owner:YANTAI SUNNY RUBBER

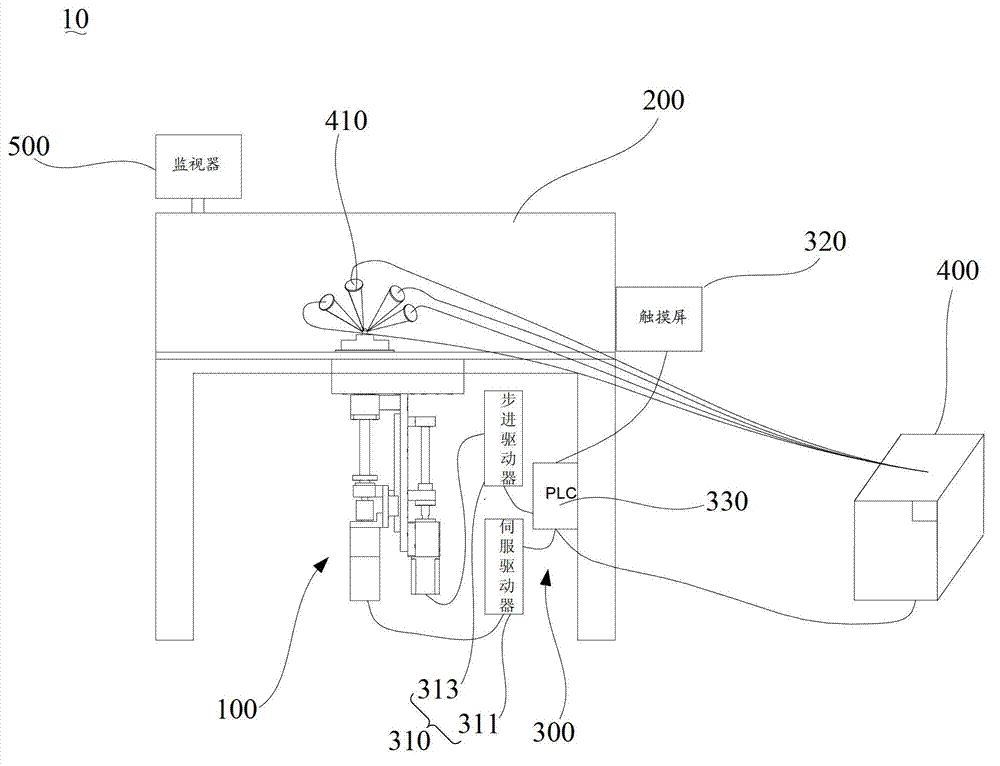

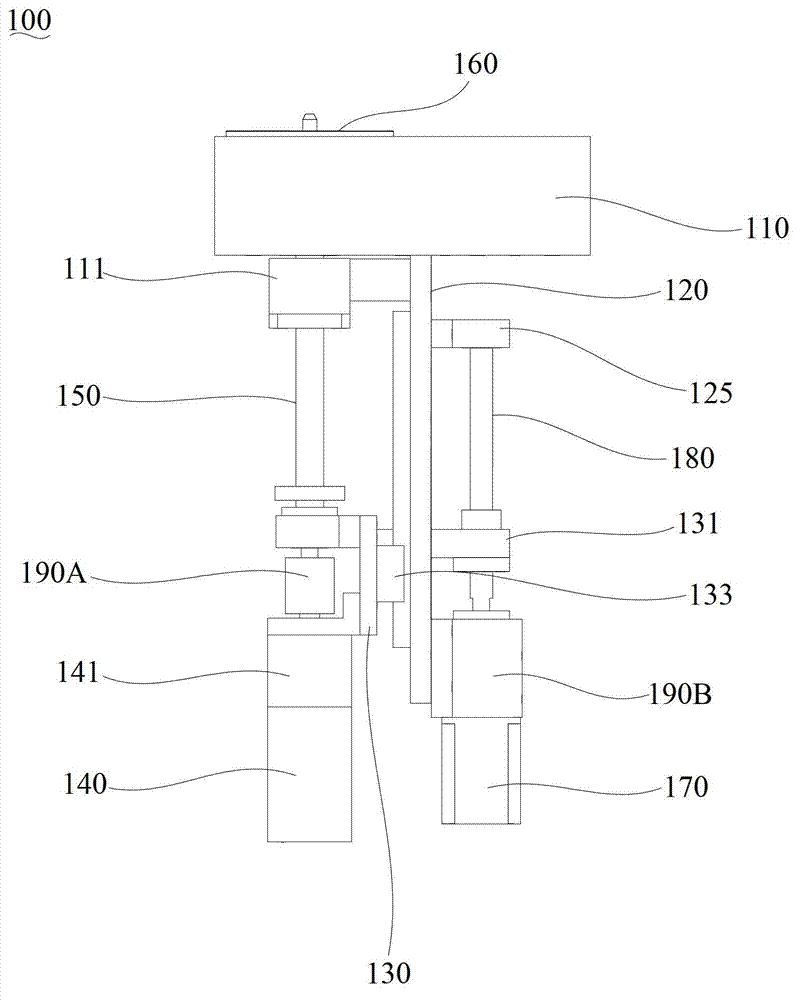

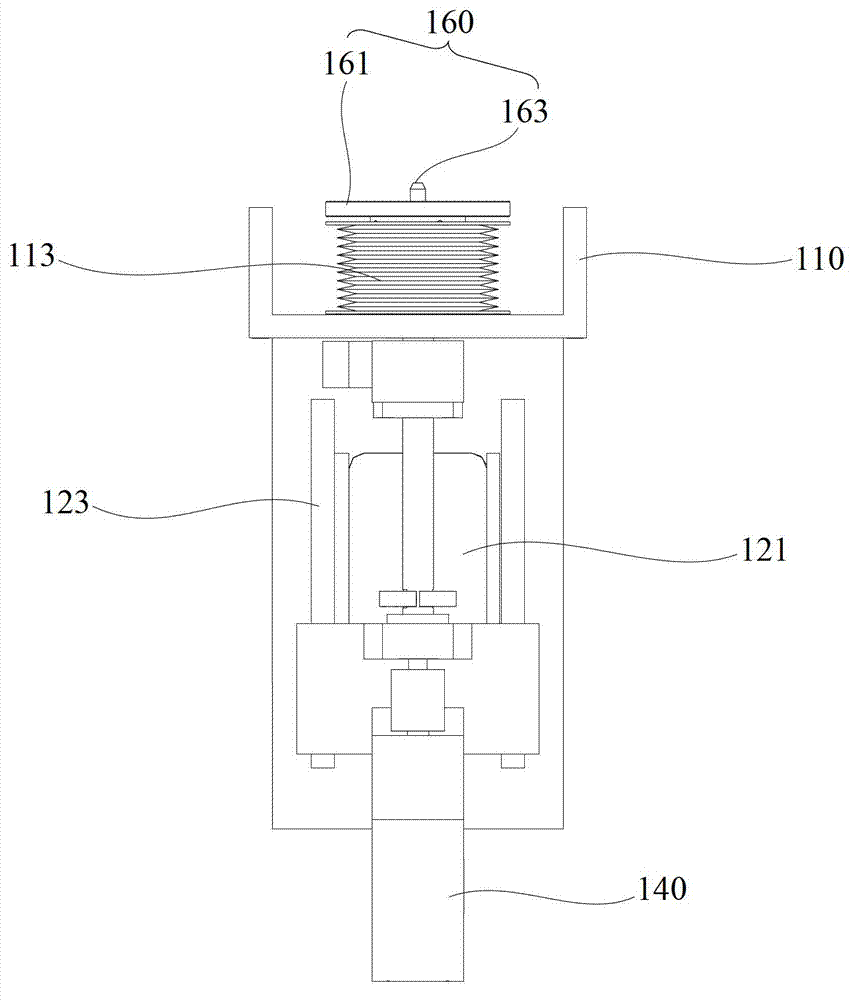

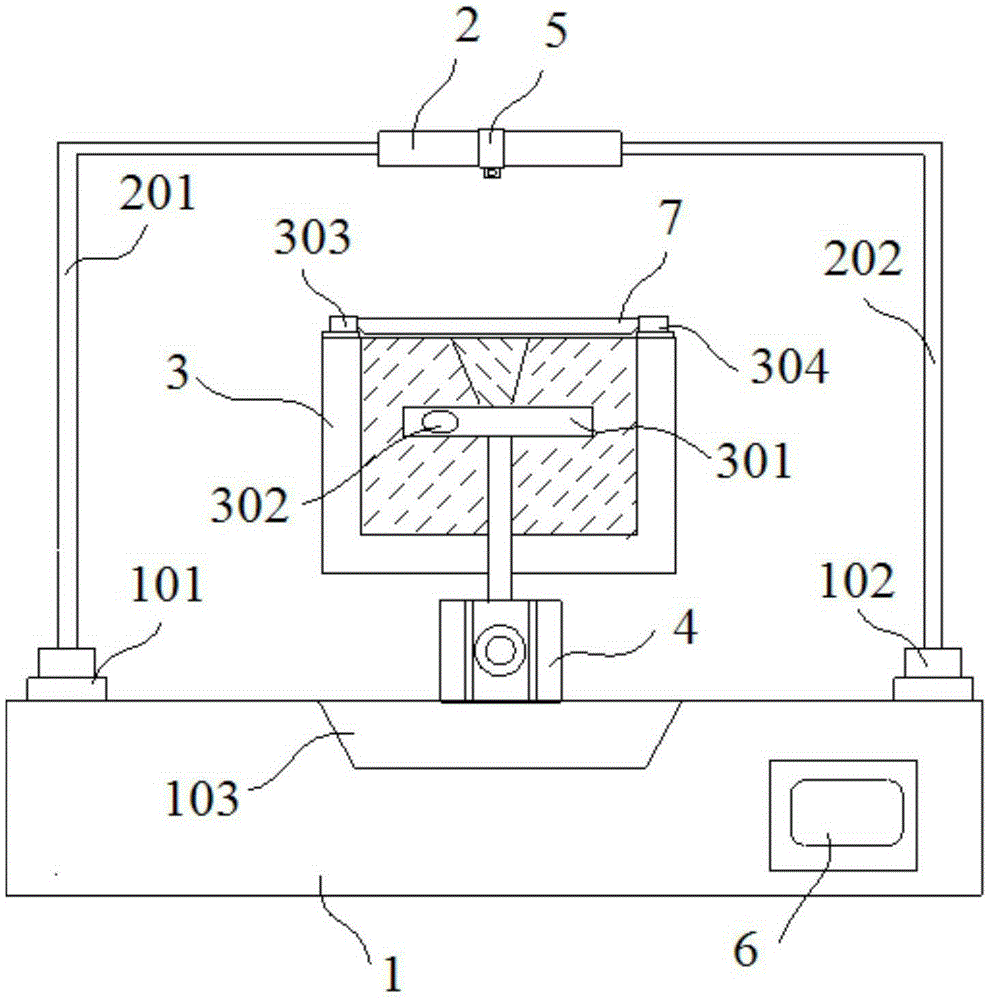

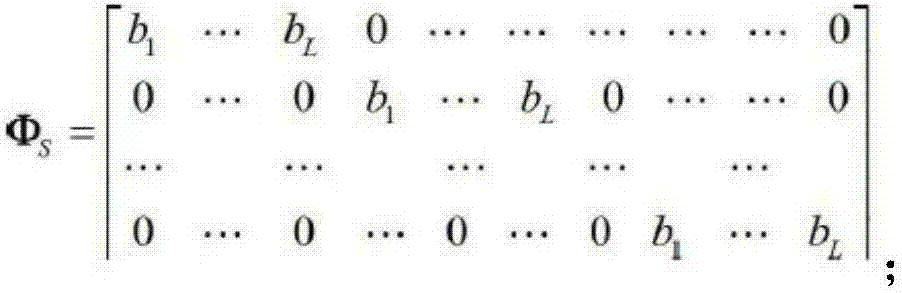

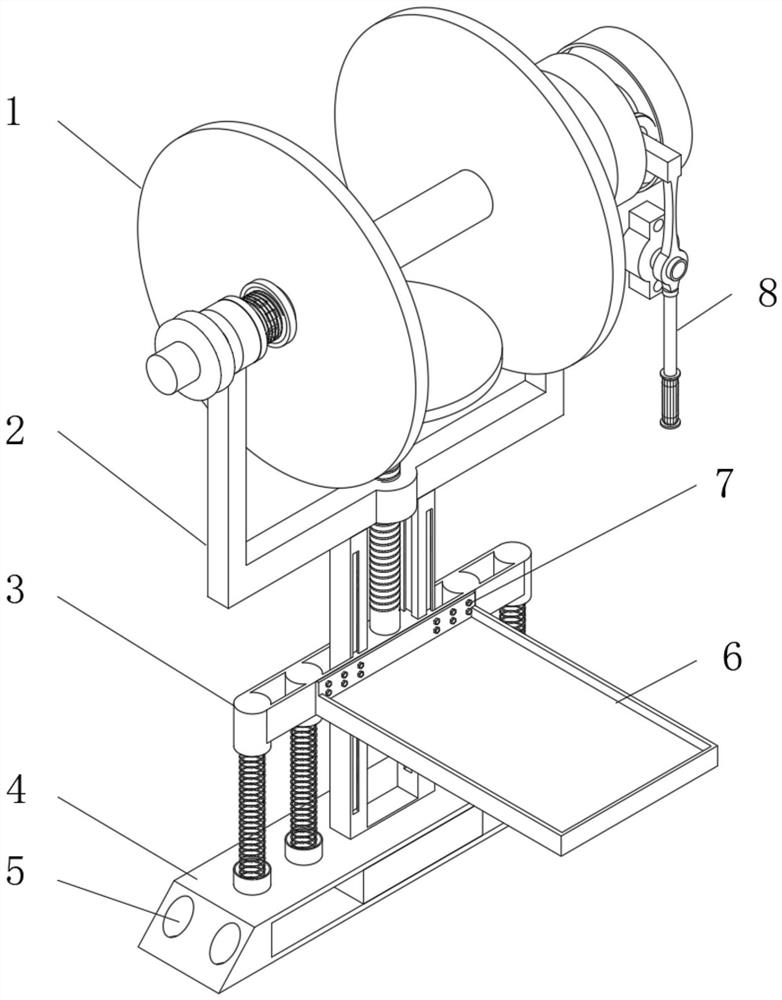

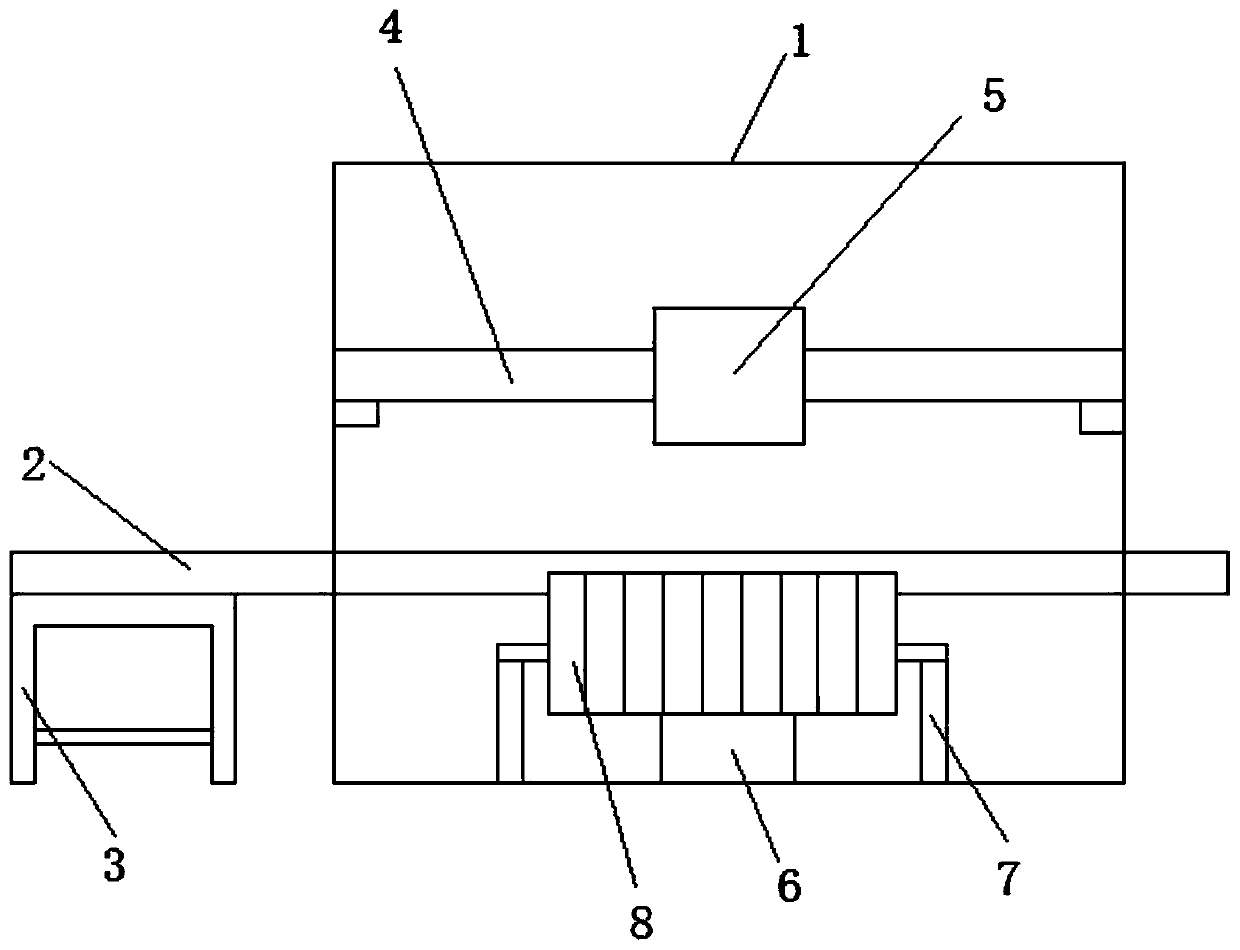

3D printing device and forming method thereof

InactiveCN105346085AImprove molding qualityPrecise control of lifting heightAdditive manufacturing apparatusEngineeringMaterial storage

The invention discloses a 3D printing device and a forming method of the device. The 3D printing device comprises a machine base, a laser radiation device, a material storage device, an air cylinder, an image sensor and a controller. As a sliding device arranged on the machine base drives the laser radiation device to slide, and a plurality of laser diodes are arranged inside the laser radiation device in an array manner, scanning forming from lines to faces can be carried out on workpieces in a large area, the forming speed is high, and the forming efficiency is high; a displacement sensor is arranged in a working platform, position information can be obtained in real time, the lifting height of the working platform can be precisely obtained, and the forming quality of the workpieces can be improved; and the image sensor is arranged so that a formed layer section image can be obtained and sent to a controller, the layer section image can be compared with data of stored layer section, printing correctness of each layer section can be ensured, and the forming quality of the workpieces can be further improved. The device is simple in structure, convenient to operate, good in forming quality, high in forming speed and suitable for large-scale industrial production.

Owner:SUZHOU SUNSHINE LASER & ELECTRONICS TECH CO LTD

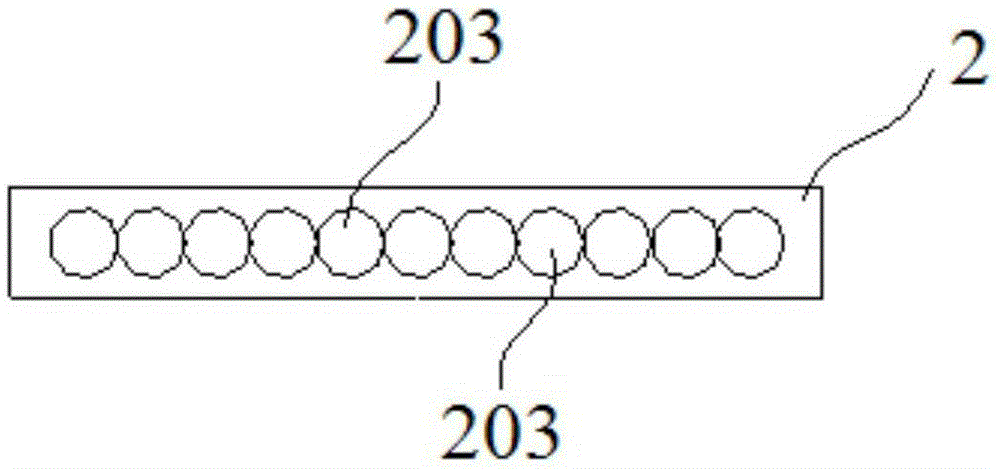

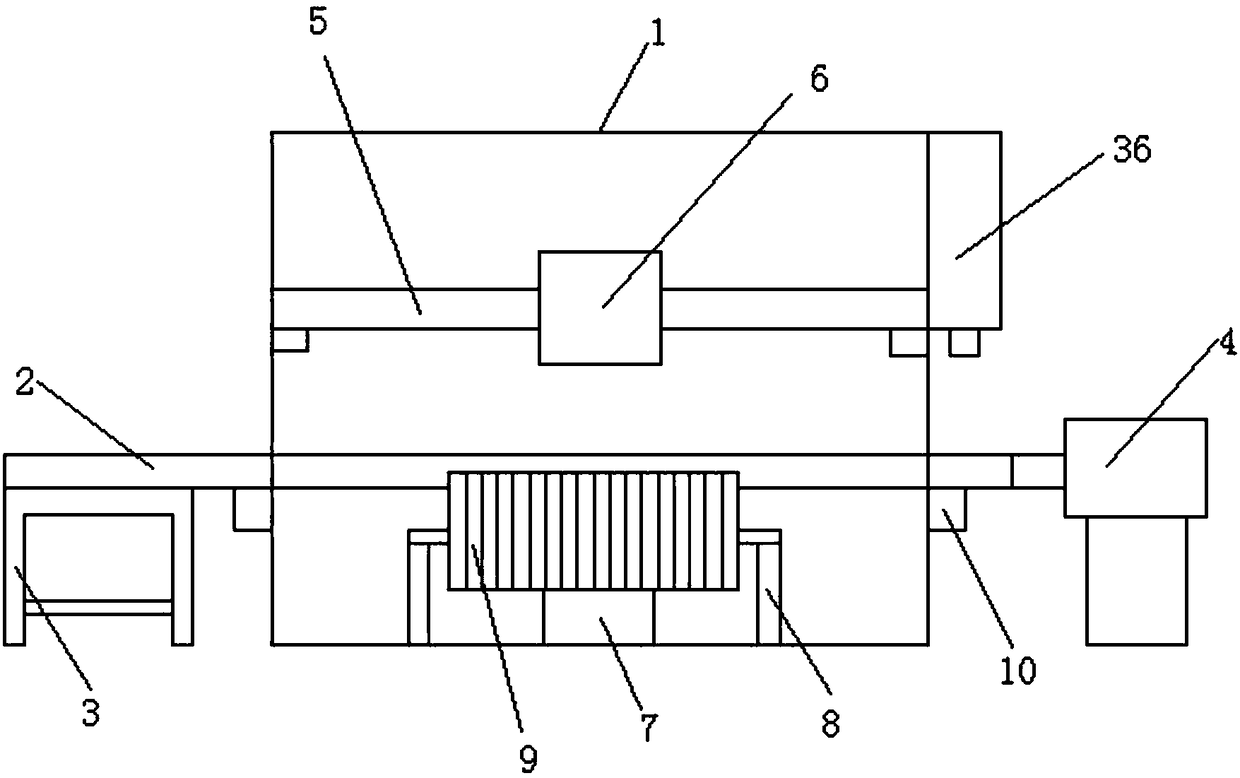

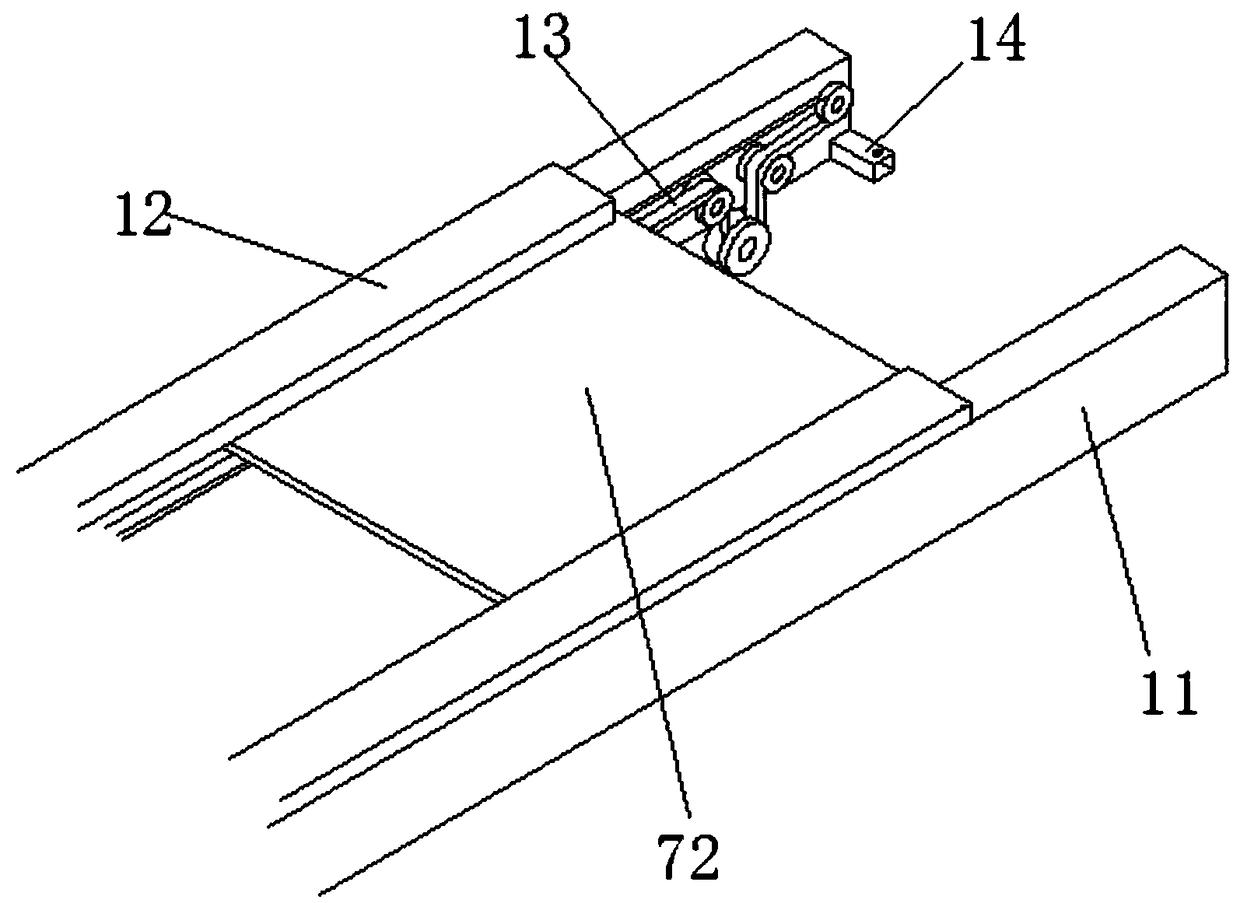

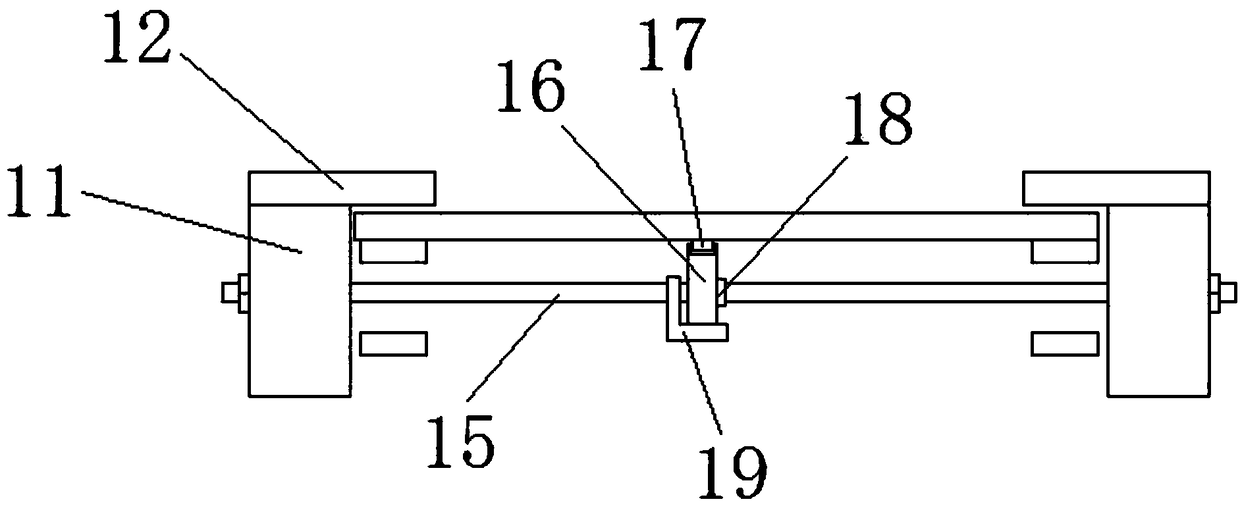

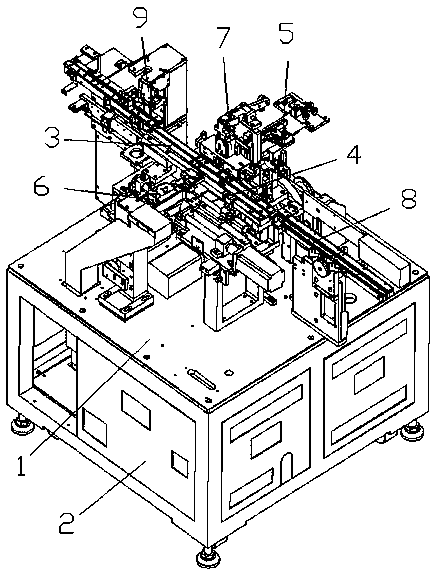

An LED chip mounter

ActiveCN108538753AControl lift heightReduce damage ratePrinted circuit assemblingSemiconductor/solid-state device manufacturingDrive wheelEngineering

The invention provides an LED chip mounter and belongs to the technical field of LED chip mounting processing. The LED chip mounter comprises a shell, a conveying mechanism, width adjusting mechanisms, a moving mechanism, a supporting mechanism and a part picking and placing head. The conveying mechanism is located at the middle position of the shell; a feeding machine base is arranged at the leftside of the lower portion of the conveying mechanism; a supporting rack is arranged at the front side of the shell and a plurality of chip fetching supports are arranged on the supporting rack; the conveying mechanism comprises two side plates which are arranged in parallel; the upper portions of the side plates are connected with clamping plates; the inner sides of the side plates are provided with conveying belts each of which comprises a conveying belt unit and a plurality of driving wheels driving the conveying belt unit to rotate. The LED chip mounter can finish chip mounting work stablywith high speed, can reduce production cost and has the advantages of compact structure, high speed and stability.

Owner:绍兴舜宇照明工程有限公司

Woven bag making device

InactiveCN108724810AUnified specificationsControl lift heightBag making operationsPaper-makingEngineeringBilateral symmetry

The invention discloses a woven bag making device. The device comprises a fixing machine body. An installation chamber is arranged in the interior of the left end wall of the fixing machine body. Arcblocks are fixed on front and back walls of the installation chamber. A detachable rotary shaft is rotatably arranged on the upper end surfaces of the arc blocks. The rotary shaft is connected with athin film material drum in a sleeved manner. A working space is arranged in the interior on the right end wall of the installation chamber. Rolling drums are arranged on the lower side in the interiorof the working space in the manner of bilateral symmetry. A sliding cavity is arranged in the interior of the back end wall of a driving cavity. A sliding board is arranged in the interior of the sliding cavity in a sliding manner. The back end of a first rack penetrates through the back end wall of the driving cavity to be fixedly connected with the front end surface of the sliding board. A pneumatic space is arranged in the interior of the back end wall of the sliding cavity. A pneumatic pump is fixedly arranged in the interior of the pneumatic space. The back end surface of the pneumatic space is equipped with an air suction pipeline in a communicating manner. The back end of the air suction pipeline penetrates through the back end wall of the pneumatic space and stretches into an external space.

Owner:绍兴初汇纺织有限公司

New energy automobile charging pile mounting structure

InactiveCN112319285AEasy to installEasy to prevent standing waterCharging stationsElectric vehicle charging technologyElectrical and Electronics engineeringNew energy

The invention discloses a new energy automobile charging pile mounting structure, and the structure comprises a mounting base and a charging pile body; a placement mechanism is arranged in an inner cavity of the mounting base, a bidirectional threaded rod is movably connected to the left side of the inner cavity of the mounting base through a bearing, and opposite threads are arranged on the surface of the bidirectional threaded rod. The two mounting blocks are placed in the inner cavities of the two mounting grooves correspondingly, the second knob is rotated, the second knob finally drives the second wedge block to enter the inner cavity of the strip-shaped groove to lock the two mounting blocks, and the first knob and the first knob are rotated to finally drive the mounting frame and the charging pile body to ascend, so that the purposes of convenient mounting and water accumulation prevention are achieved; the new energy automobile charging pile installation structure has the advantages of being convenient to install and capable of preventing water accumulation, cement does not need to be adopted for pouring, the function of rapid disassembly and assembly is achieved, the lifting height of the charging pile can be conveniently controlled according to the installation position, and the charging pile is not prone to being soaked by accumulated water.

Owner:郭连坤

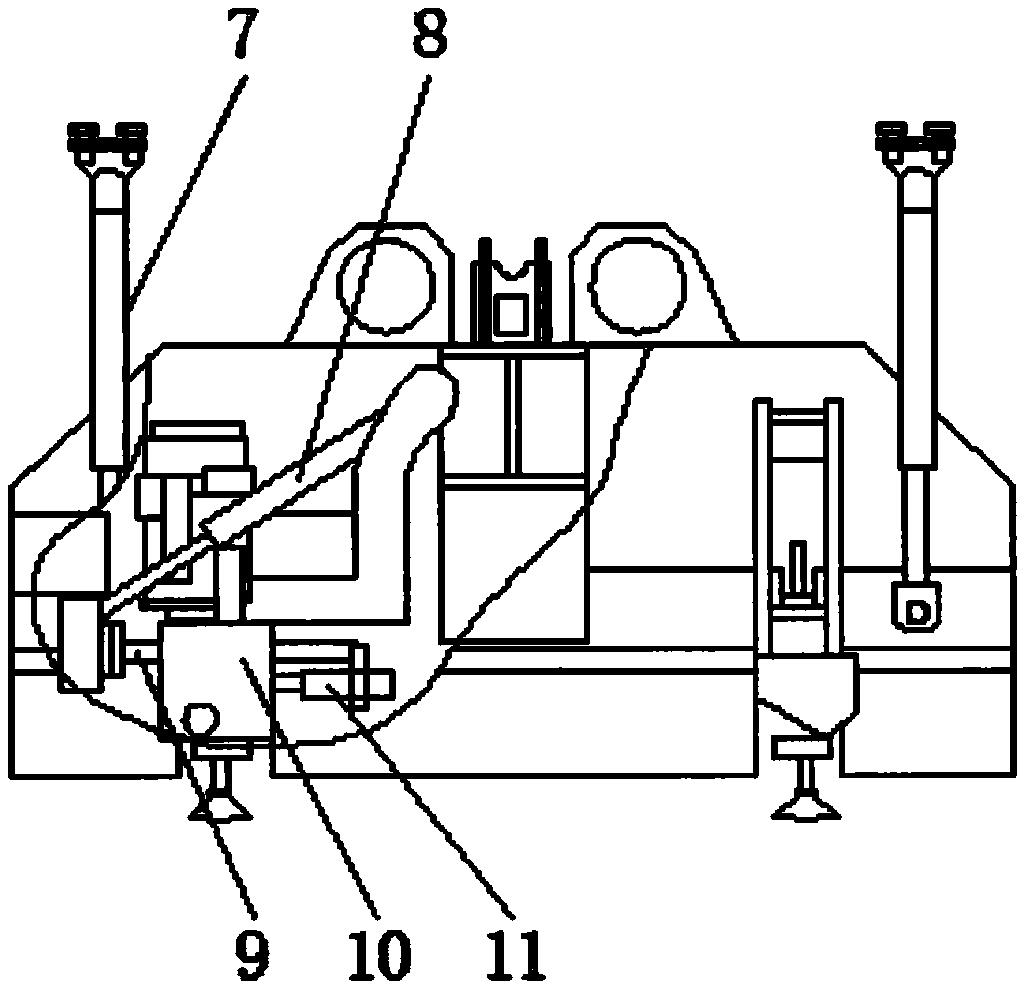

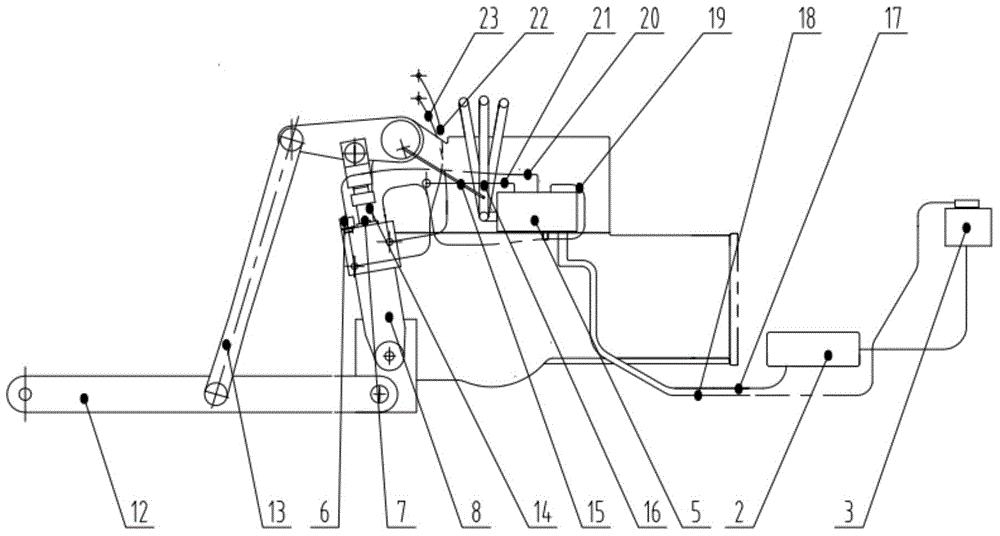

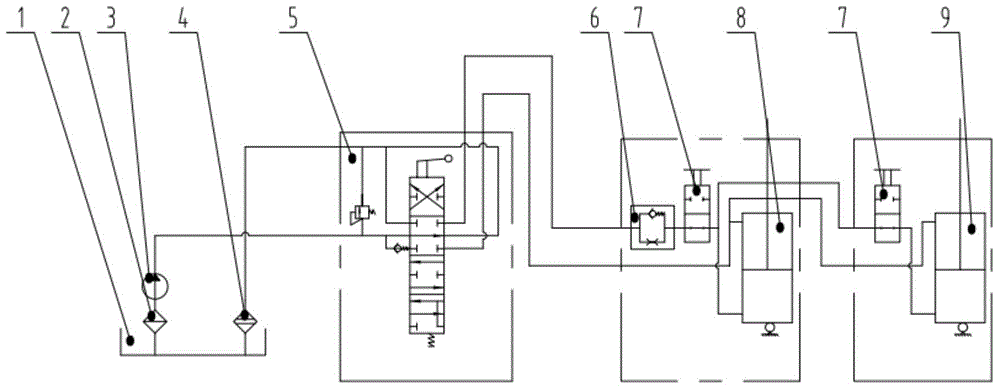

Forced compression device of low power roller tractor

InactiveCN104782258AControlled descent speedImprove protectionAgricultural machinesAdjusting devicesCompression devicePosition control

The invention discloses a forced compression device of a low power roller tractor. The device comprises a lifter, a hydraulic oil cylinder is arranged in the lifter, the lifter is connected with a lifting rod, the lower end of the lifting rod is hinged to a lower link, the device further comprises an oil absorption filter, an oil absorption gear pump, an oil return filter, a floating multiway valve, a right oil cylinder and a left oil cylinder, one end of the oil absorption gear pump is connected to the hydraulic oil cylinder through the oil absorption filter, the other end of the oil absorption gear pump is connected with the inlet path of the floating multiway valve, the floating multiway valve is connected with the right oil cylinder and the left oil cylinder in sequence, the upper end of the right oil cylinder and the upper end of the left oil cylinder are both hinged to the lifting rod, a loop of the floating multiway valve is connected to the hydraulic oil cylinder through the oil return filter, a position control operation handle is further installed on the lifter, and the operation handle is connected with the floating multiway valve through a Q-shaped support. By means of the device, the problems that it is difficult for the low power roller tractor to break ground in hard soil, and the ploughing depth is shallow are solved.

Owner:SHANDONG CHANGLIN DEUTZ FAHR MACHINERY

New energy vehicle charging pile mounting structure

InactiveCN113232543AInstalled and disassembledEasy to adjust lift heightCharging stationsElectric vehicle charging technologyNew energyScrew thread

The invention discloses a new energy vehicle charging pile mounting structure which comprises two mounting bottom plates which are oppositely arranged, a reinforcing plate is connected between the two mounting bottom plates, two supporting columns are oppositely arranged at the upper ends of the mounting bottom plates, and a connecting plate is connected to the upper ends of the two supporting columns. Lead screws are connected between the connecting plates and the mounting bottom plate in a threaded mode, an assembly box is arranged between the two connecting plates, a driving assembly used for driving the two lead screws to rotate synchronously is arranged in the assembly box, lifting plates are connected to the lead screws in a threaded mode, and the lifting plates are slidably connected with the supporting columns on the two sides. Mounting columns penetrating to the upper portion of the connecting plate are arranged on the lifting plate, mounting tables are arranged at the top ends of the mounting columns on the two sides, and clamping assemblies are arranged at the upper ends of the mounting tables. Compared with the prior art, the new energy vehicle charging pile mounting structure has the advantages that dismounting and cyclic utilization are convenient, the lifting height of the charging pile can be conveniently controlled according to the mounting position, and the charging pile is not prone to being soaked by accumulated water.

Owner:沈阳靓婷新能源有限公司

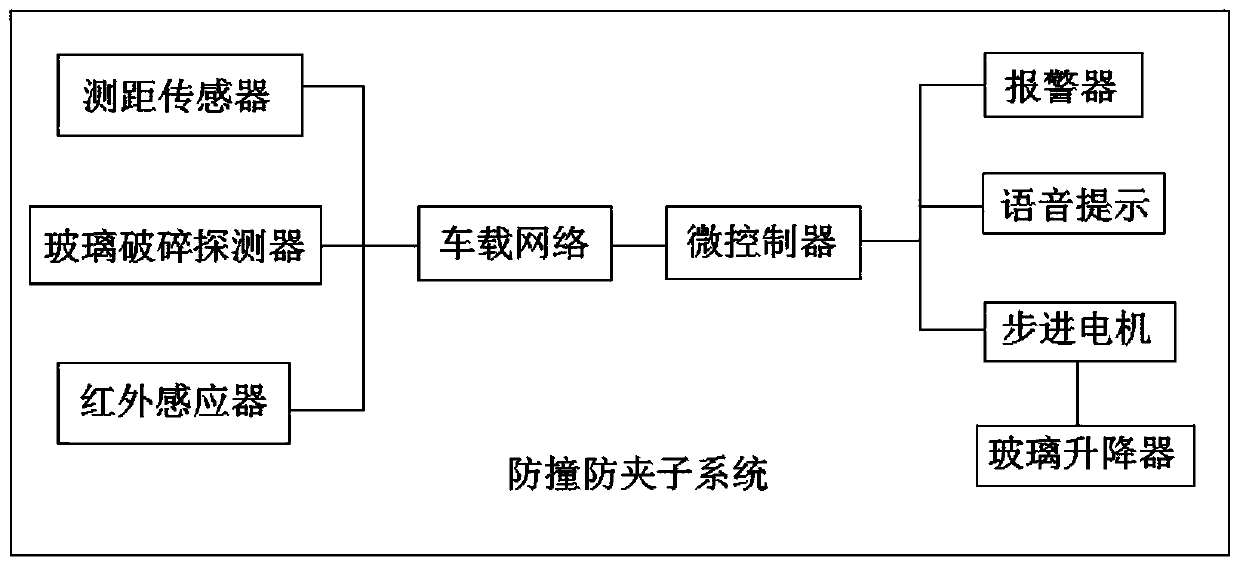

Intelligent vehicle window control system and control method thereof

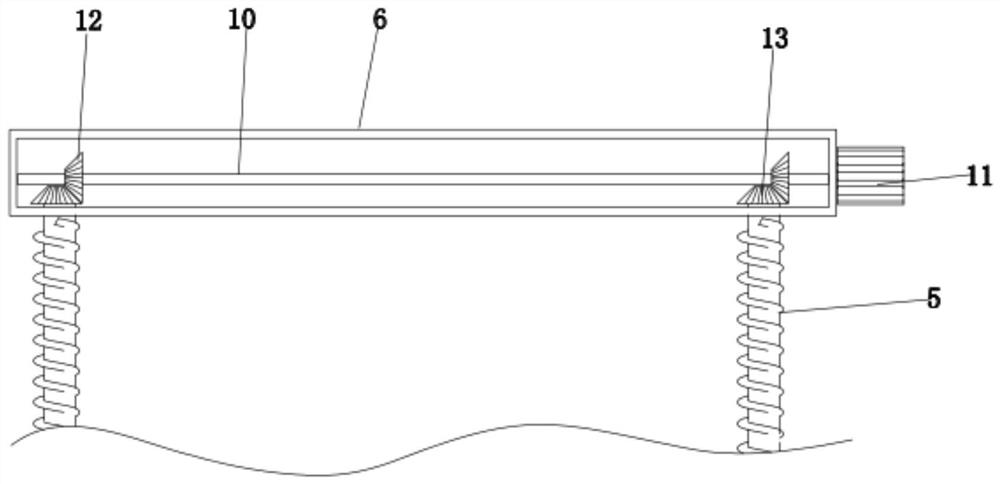

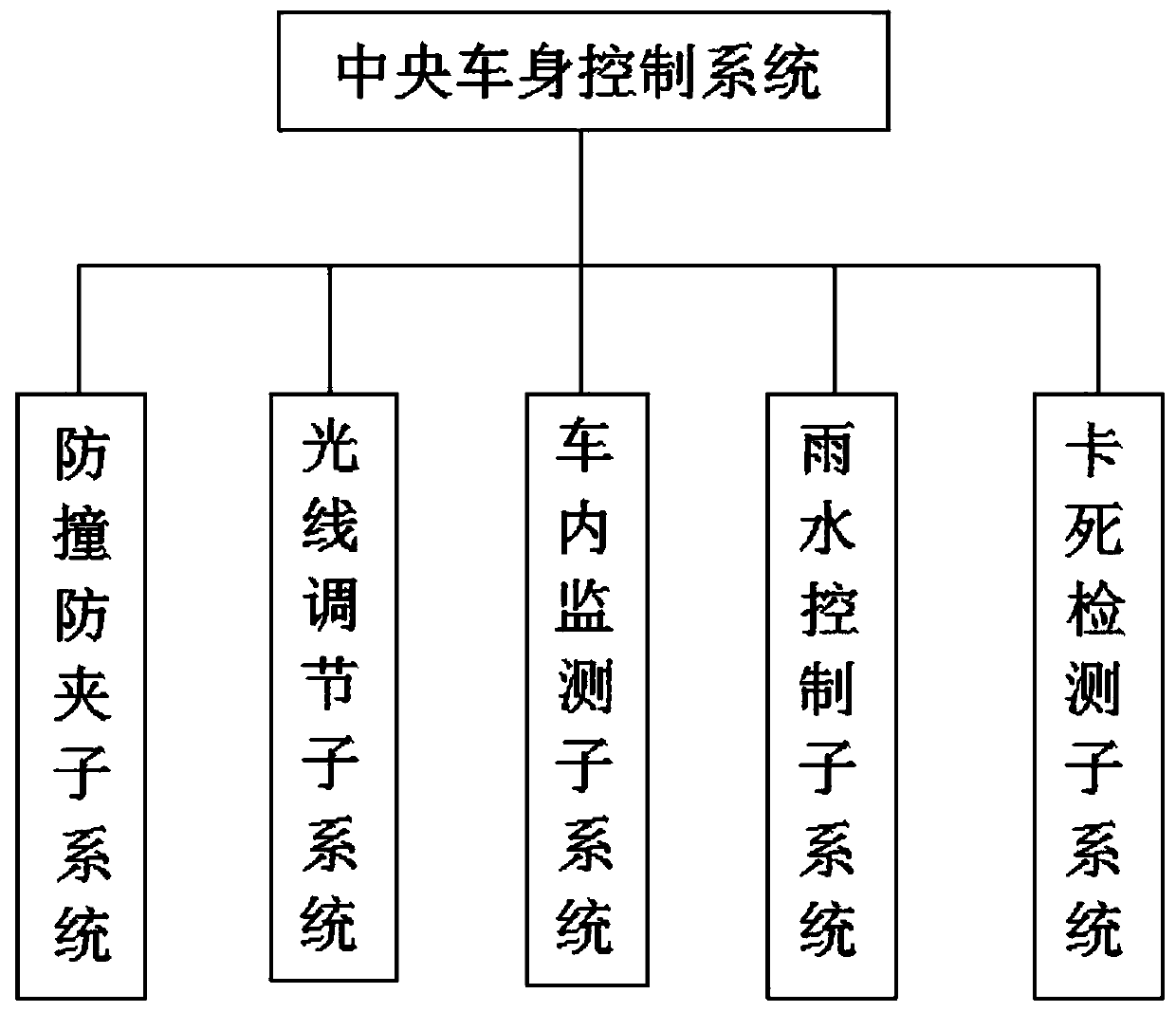

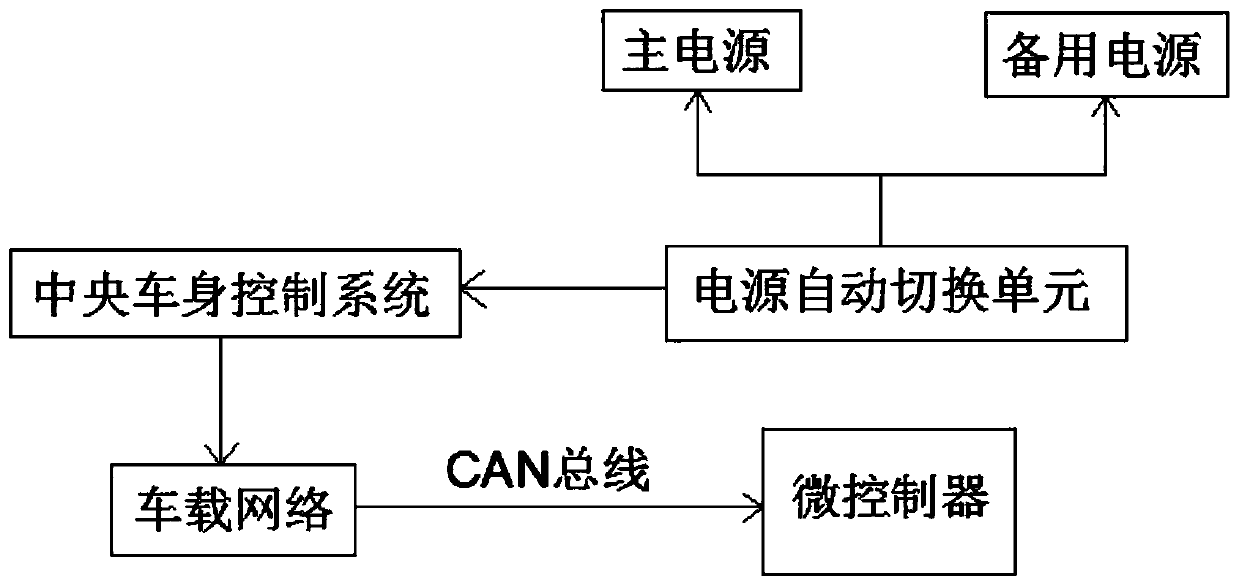

InactiveCN109854119AMonitoring and management intelligent liftingImprove securityPower-operated mechanismSignalling/lighting devicesMicrocontrollerControl system

The invention relates to the technical field of an intelligent vehicle window, and specifically relates to an intelligent vehicle window control system and a control method thereof. The system includes a central vehicle body control system; an anti-collision clamp proof subsystem, a light adjustment subsystem, an in-vehicle monitoring subsystem, a rainwater control subsystem and a dead locking detection subsystem are separately disposed in the central vehicle body control system; an input end of the central vehicle body control system is electrically connected with a power supply automatic switching unit, and an input end of the power supply automatic switching unit is separately electrically connected with a main power source and a backup power source; and an output end of the central vehicle body control system is electrically connected with a vehicle-mounted network, and the vehicle-mounted network is connected with a microcontroller via a CAN bus. The intelligent vehicle window control system and the control method thereof can effectively overcome the defect of lack of security of a traditional intelligent vehicle window control system existing in the prior art.

Owner:范建明

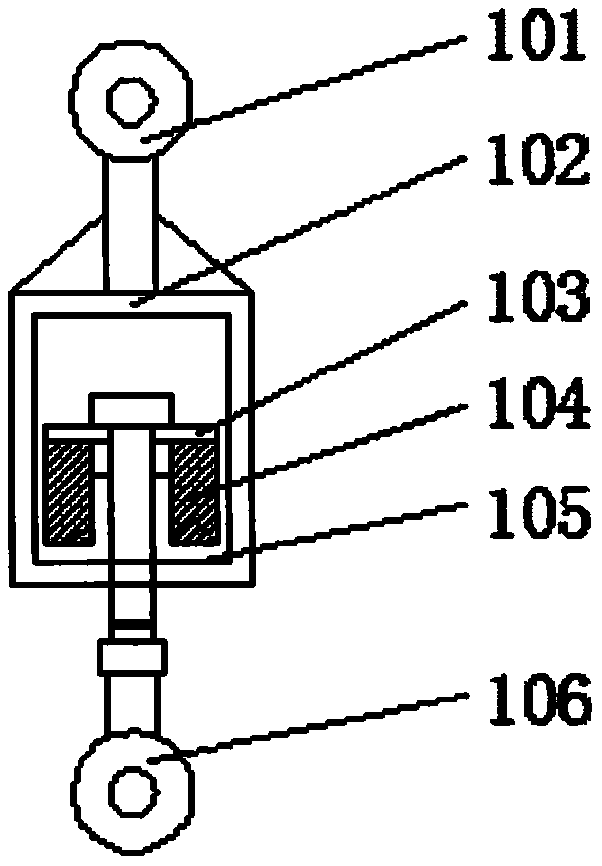

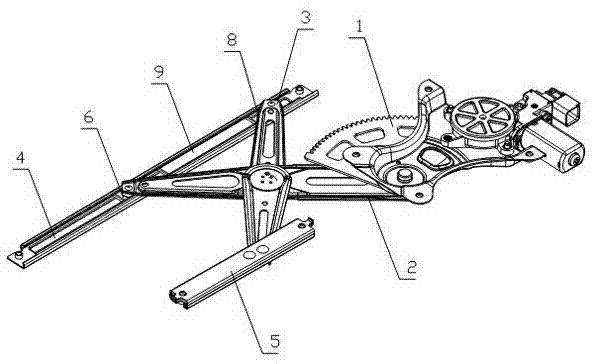

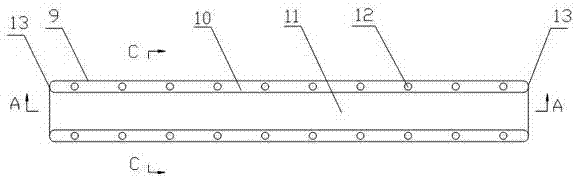

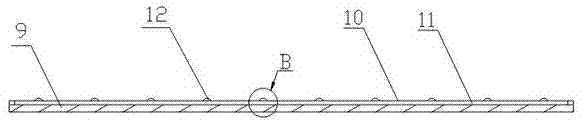

Limiting and damping mechanism for car window glass lifter

ActiveCN103573091AProtection use intensityEasy to manufactureBuilding braking devicesPower-operated mechanismEngineeringCanis lupus familiaris

Owner:浙江顶昌汽车部件有限公司

Novel kite for detecting haze

InactiveCN106984051AEfficient detectionEffective control of light gas volumeTransmission systemsToy aircraftsSolenoid valveDrive motor

The invention relates to a novel kite for detecting haze. The novel kite includes a kite body and a controller; a first air bag is arranged on the top of a kite body; a frame is arranged on a center of the bottom of the kite body; a second air bag is arranged on the bottom of the inner cavity of the frame; a first storage battery is arranged on the top of the second air bag; a GPS positioning device, a pressure container, and a haze detection device are successively arranged on the top of the first storage battery from left to right; a second solenoid valve is arranged on a center of the top of the pressure container; the top of the second solenoid valve is connected to the first air bag through a first guide pipe; a third solenoid valve is arranged on the center of the bottom of the pressure container; and a driving motor and a second storage battery are successively arranged on a left side wall of an inner cavity of the controller from top to bottom. The novel kite can effectively detect haze, is powerful in detection function, can effectively control the lifting height of devices, can fully protect the devices, and is simple to operate.

Owner:王干

New energy automobile charging pile convenient to install

InactiveCN110861525AControl lift heightEasy to useCharging stationsElectric vehicle charging technologyNew energyEngineering

The invention discloses a new energy automobile charging pile convenient to install. The new energy automobile charging pile convenient to install comprises a charging pile shell body, a bottom plateand a charging cable; the lower end of the charging pile shell body is provided with a cavity, a sliding box is slidably embedded into the lower end of the cavity, the bottom plate is fixedly arrangedon the lower surface of the sliding box, the upper end of the sliding box is provided with an opening end, and the two ends of the upper surface of the sliding box are symmetrically provided with grooves; and a fixing plate is fixedly arranged at the lower end of the cavity, the fixing plate is in sliding fit with the grooves, and an inner threaded tube is rotatably arranged between the fixing plate and the cavity through a bearing. The sliding box is designed, the sliding box can be driven to vertically slide along the cavity through meshing of a worm and a worm gear, adjustment on the height of the charging pile is achieved, the lifting height of the charging pile can be conveniently controlled according to the installing position, and then the charging pile is convenient to use, not prone to being soaked by accumulated water and easy and convenient to operate; and compared with a traditional poured cement pier, the installing period is greatly shortened, and installation is more convenient and efficient.

Owner:杭州星柏新能源科技有限公司

Finished data line winding device

InactiveCN110803588ALimit range of movementAutomatic adjustment of winding diameterFilament handlingDrive wheelElectric machine

The invention discloses a finished data line winding device, and relates to the technical field of data line processing. The device comprises a winding device body, the inner side wall of the windingdevice body is fixedly connected with a deceleration motor, and the output end of the deceleration motor is fixedly connected with a driving wheel; the inner bottom wall of the winding device body isfixedly connected with a first bearing seat, and the inner ring of the first bearing seat is fixedly connected with a rotating shaft; the outer surface of the rotating shaft is fixedly connected witha driven wheel, and the driving wheel and the driven wheel are in transmission connection through a transmission belt; and the top end of the rotating shaft penetrates through the winding device bodyand extends to the outside of the winding device body. The device has the following beneficial effects that a sliding block is driven to move through rotating a winding motor to drag a steel wire so as to change the position of winding columns, meanwhile, a pulley also limits the offset of the steel wire, and thus the winding diameter of the data line is automatically adjusted; and the sliding block can only move between two stop blocks through arranging a first baffle and a second baffle, and the moving range of the sliding block is limited, so that the effect of controlling the maximum distance and the minimum distance of the two winding columns is achieved.

Owner:耒阳市浩鑫电子有限公司

Electric remote control clothes hanger

InactiveCN104328628AControl lift heightEasy to lift heightOther drying apparatusTextiles and paperRemote controlRechargeable cell

The invention relates to an electric remote control clothes hanger which comprises a clothes hanging pipe, wherein a power driving device, a transmission device and a long shaft are sequentially arranged inside the clothes hanging pipe, the two end parts of the long shaft are respectively provided with a first rolling wheel and a second rolling wheel which are supported inside the clothes hanging pipe, hanging ropes are respectively arranged at the two rolling wheel positions of the long shaft, one end of each hanging rope is fixed on the long shaft, the other end of each hanging rope penetrates out of a line hole formed in the clothes hanging pipe, axial grooves are formed in the inner wall of the clothes hanging pipe, first protrusions matched with the grooves are arranged on the two rolling wheels, a chargeable battery and a controller are arranged inside the clothes hanging pipe, end caps are arranged at the two ends of the clothes hanging pipe, a chargeable inserting hole is formed in the end cap close to the chargeable battery end, the chargeable battery and the controller are connected, the controller is connected with the power driving device, and the chargeable inserting hole is connected with the controller. The electric remote control clothes hanger is small in occupied space, convenient to carry and install, capable of charging the chargeable battery and safe and convenient to use.

Owner:荣芳芳

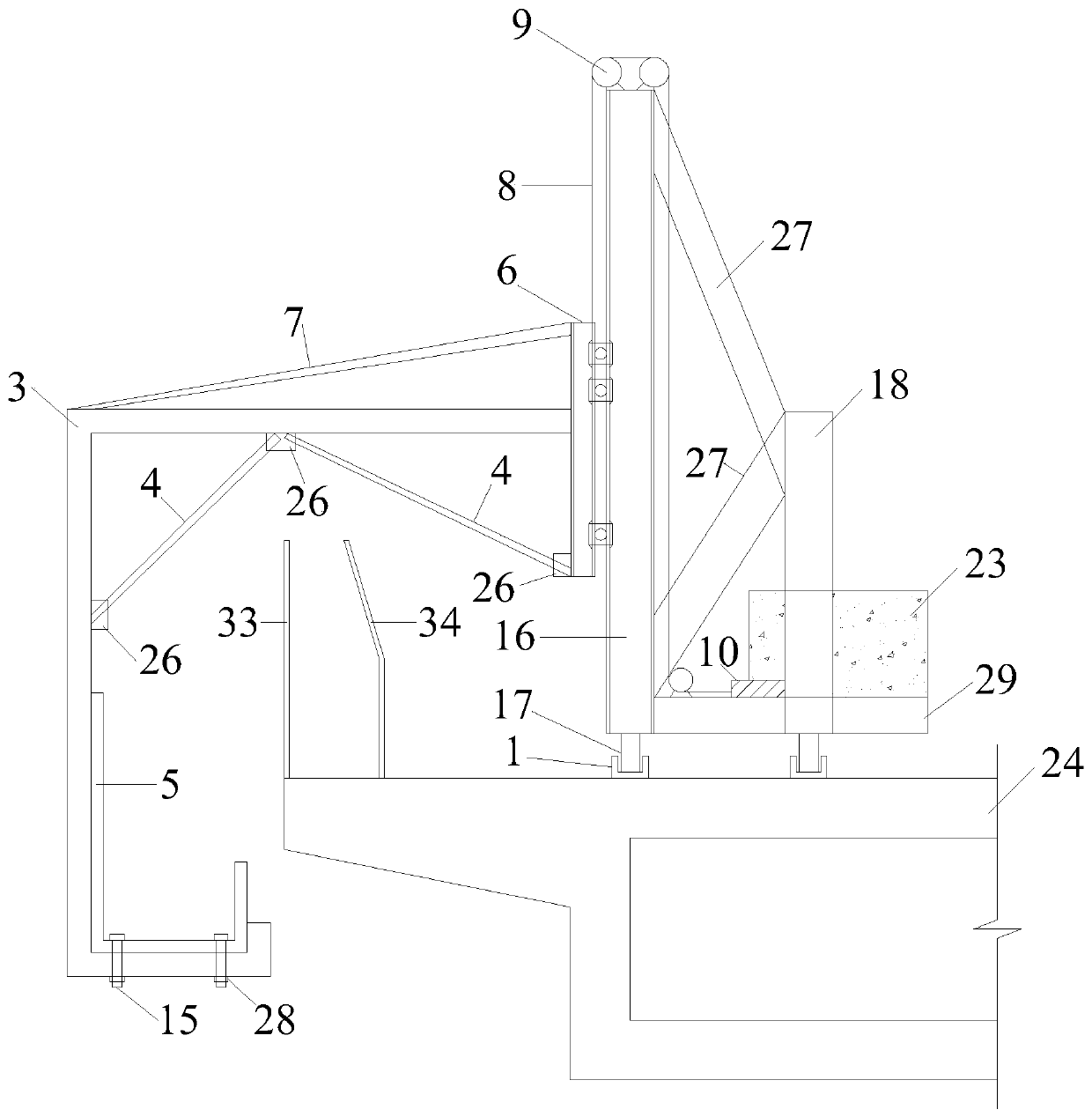

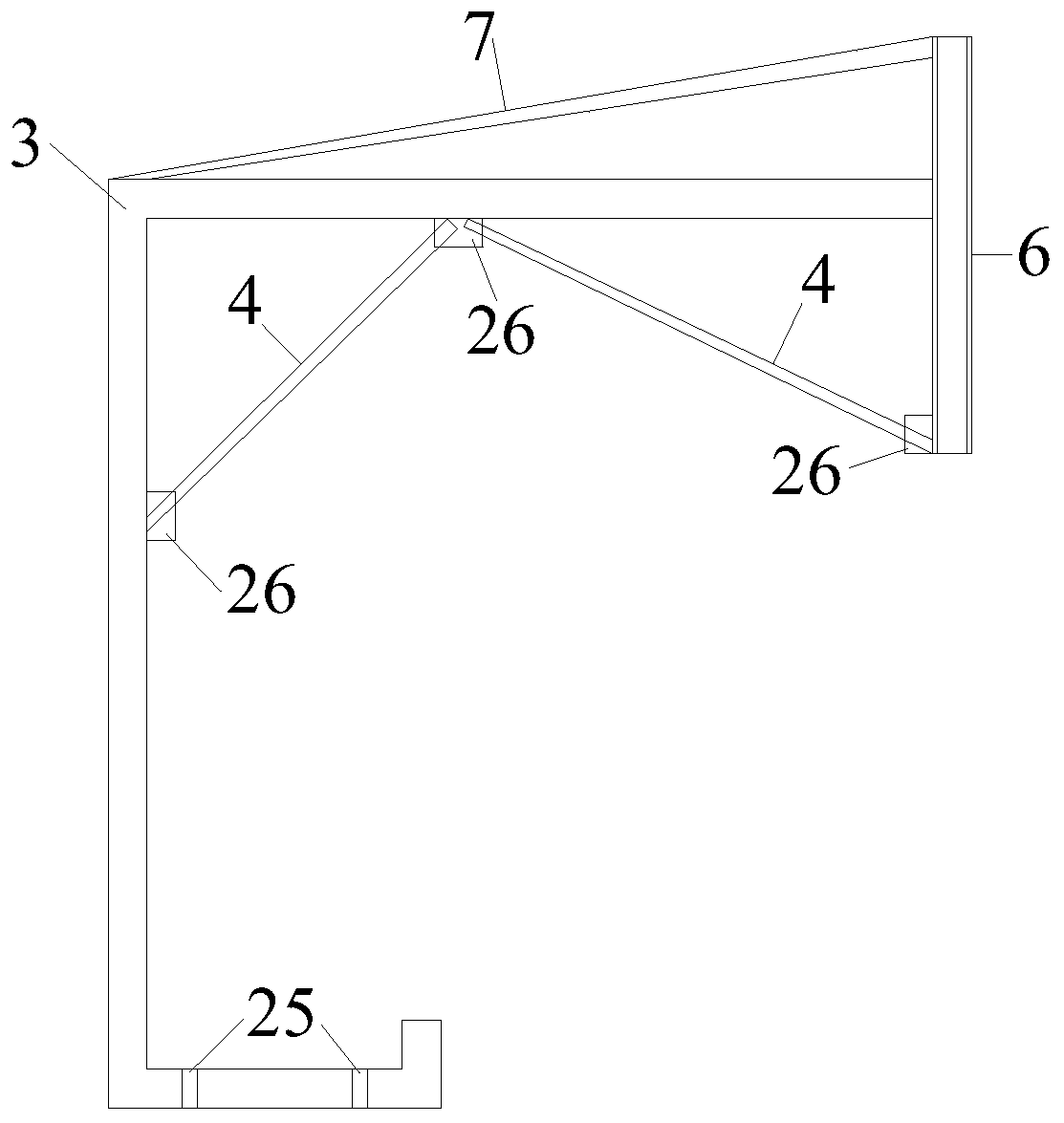

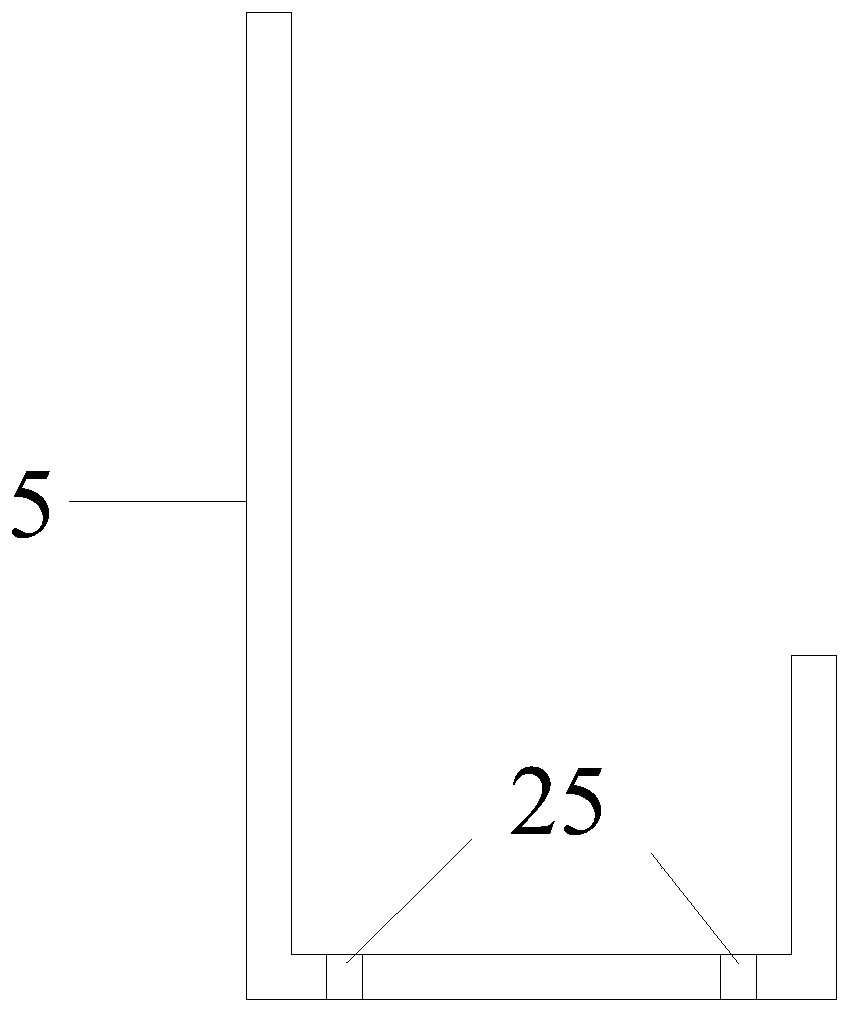

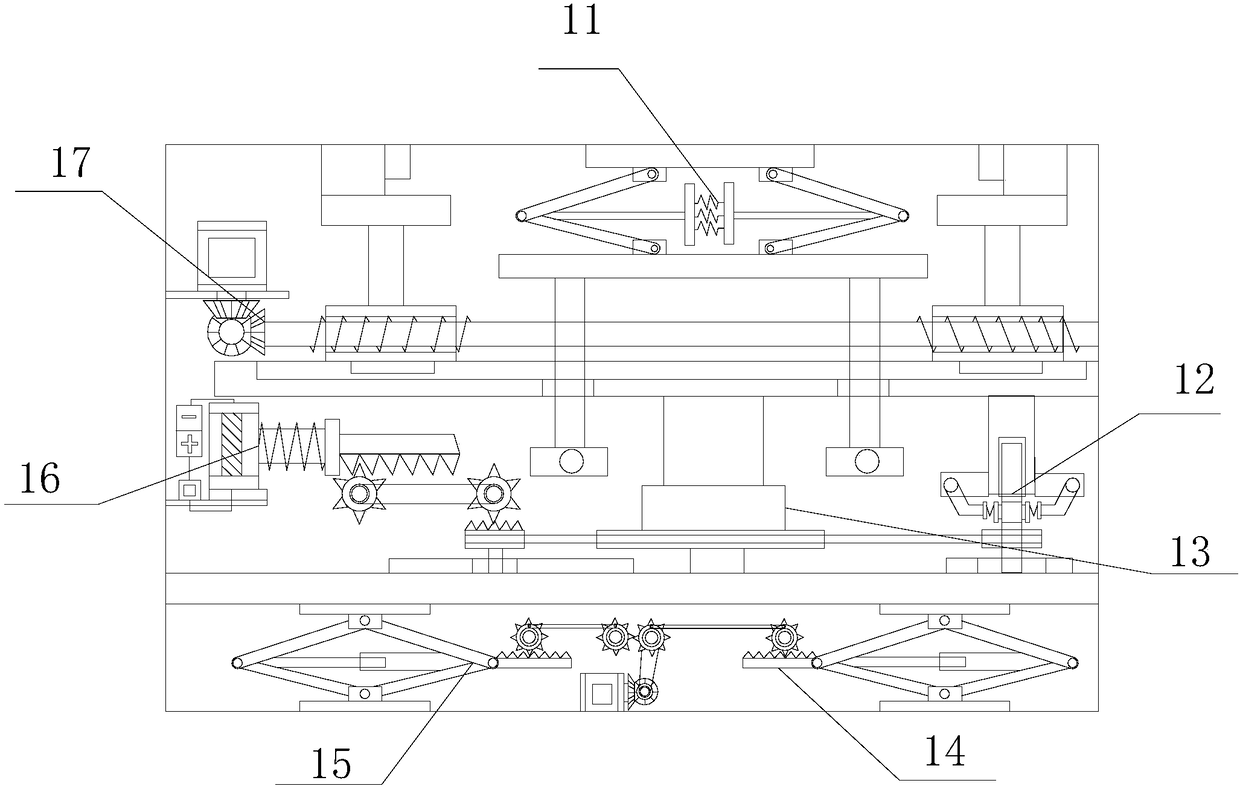

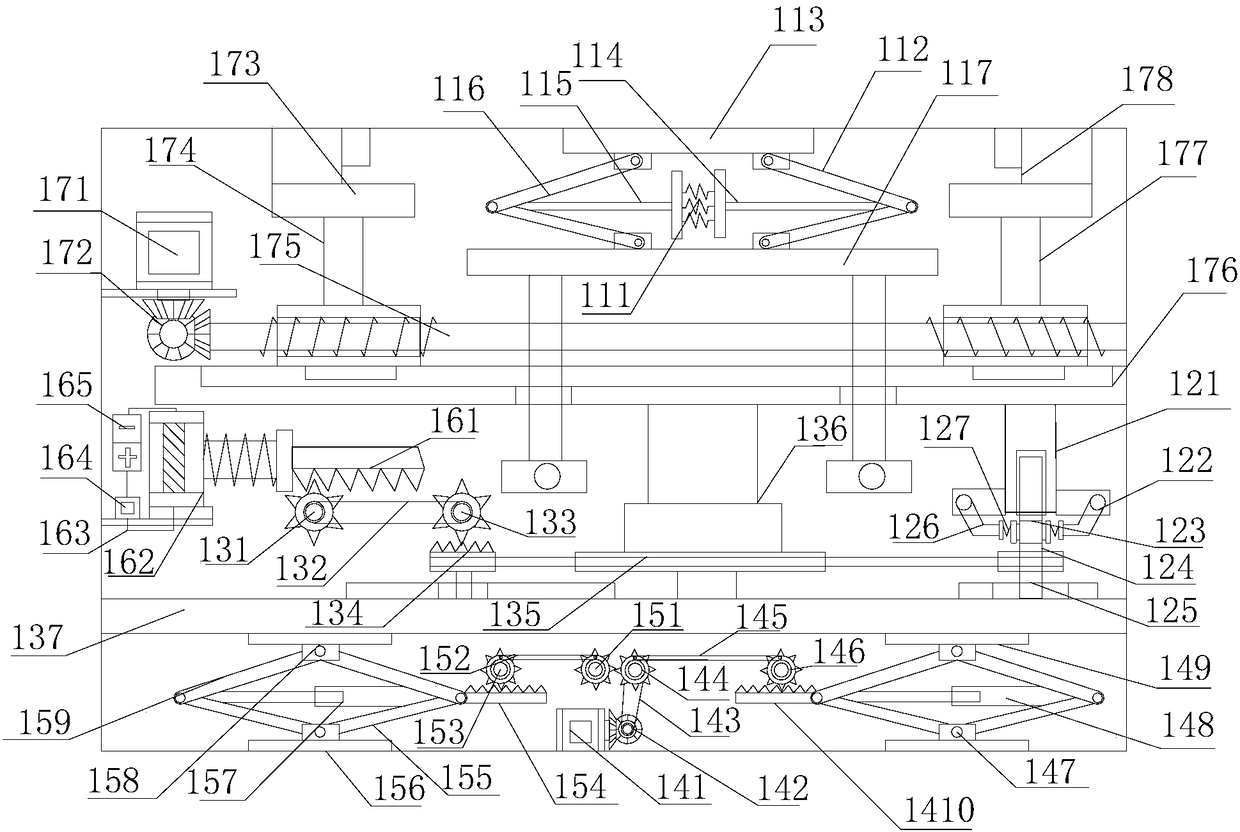

Mobile type simple concrete guardrail template vehicle and manufacturing method thereof

ActiveCN110080117AEasy to installControl lift heightBridge erection/assemblyPulleyBuilding construction

The invention provides a mobile type simple concrete guardrail template vehicle and a manufacturing method thereof. The mobile type simple concrete guardrail template vehicle comprises a suspension system, a lifting system, a counterweight vehicle, a track and a trailer. The lifting system is composed of a pulley, a steel wire and a winding engine and is arranged on the counterweight vehicle. Thesuspension system is clamped on outer side I-shaped steel on the counterweight vehicle through a clamping buckle, and the lifting height of the suspension system can be controlled by using the liftingsystem. The trailer is connected with the counterweight vehicle, and when one construction section is completed, the template vehicle can be quickly moved to a next construction section by using thetrailer.

Owner:倡创(上海)咨询管理事务所

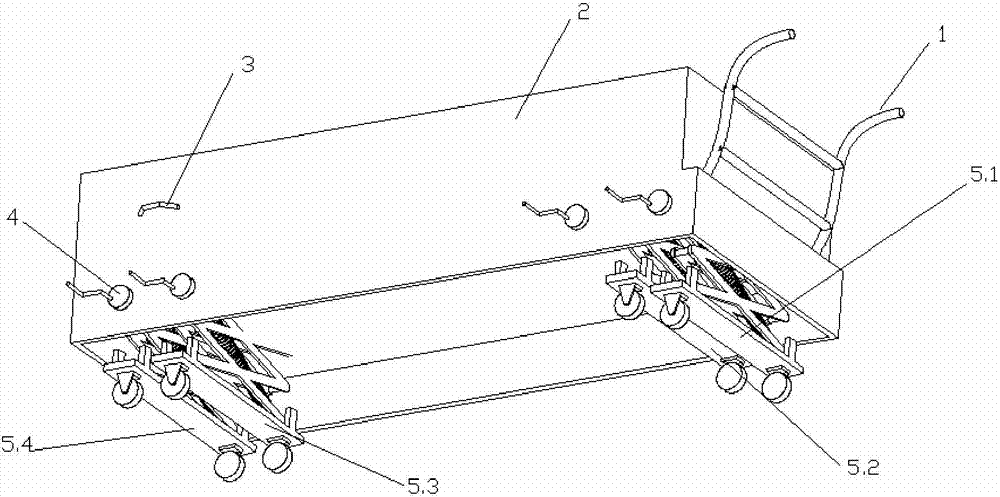

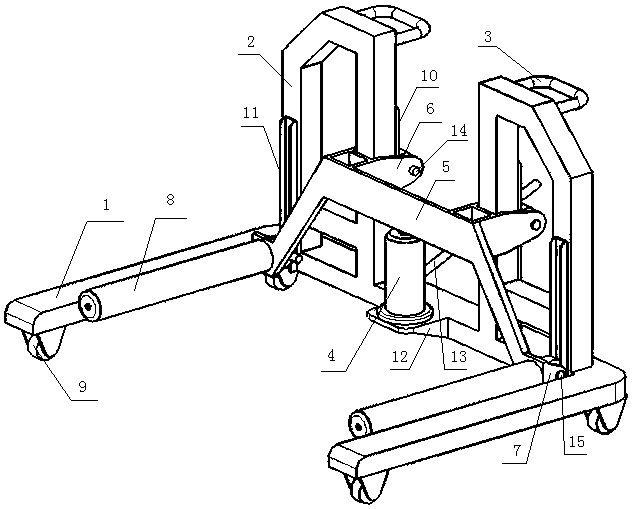

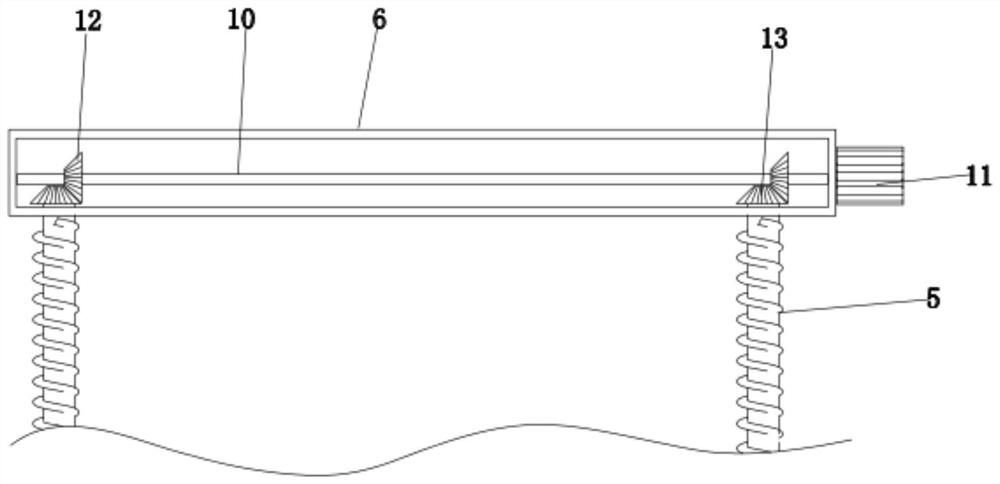

Transport plane wheel rapid dismounting and mounting device

PendingCN108284709AEasy to operate and control the lifting heightControl lift heightWheel mounting apparatusTyre repairingEngineeringHandrail

The invention discloses a transport plane wheel rapid dismounting and mounting device. The transport plane wheel rapid dismounting and mounting device comprises a main body frame and a lifting hydraulic wheel fork, the main body frame comprises a supporting frame, a connecting frame and an armrest, and the lifting hydraulic wheel fork comprises a hydraulic jack, a sliding support and rolling bars.The connecting frame is arranged at the upper end of the supporting frame, universal wheels are arranged at the lower end of the supporting frame, and the armrest is arranged on the connecting frame.Sliding rails are arranged on the inner side and the outer side of the connecting frame correspondingly, the connecting frame is connected with the sliding support through the sliding rails, and therolling bars are arranged on the lower sides of the two sides of the sliding support. A tray is arranged on the position, below the sliding support, of the inner side of the supporting frame, the hydraulic jack is arranged on the tray, and a hand-cranking rod is arranged on the hydraulic jack. According to the transport plane wheel rapid dismounting and mounting device, the dismounting and mounting time of a plane wheel is saved, and the problem that the waist of a person is hurt is effectively avoided.

Owner:AIR FORCE ENG UNIV OF PLA AIRCRAFT MAINTENACE MANAGEMENT SERGEANT SCHOOL

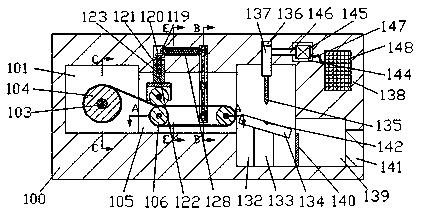

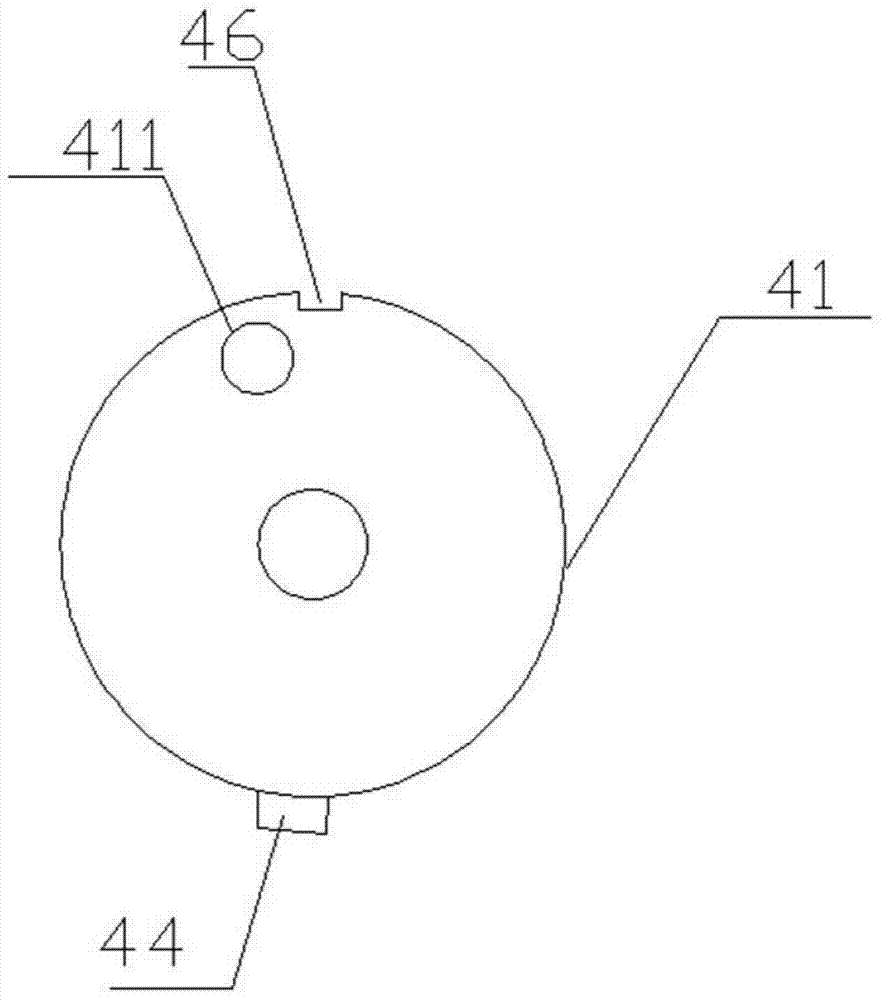

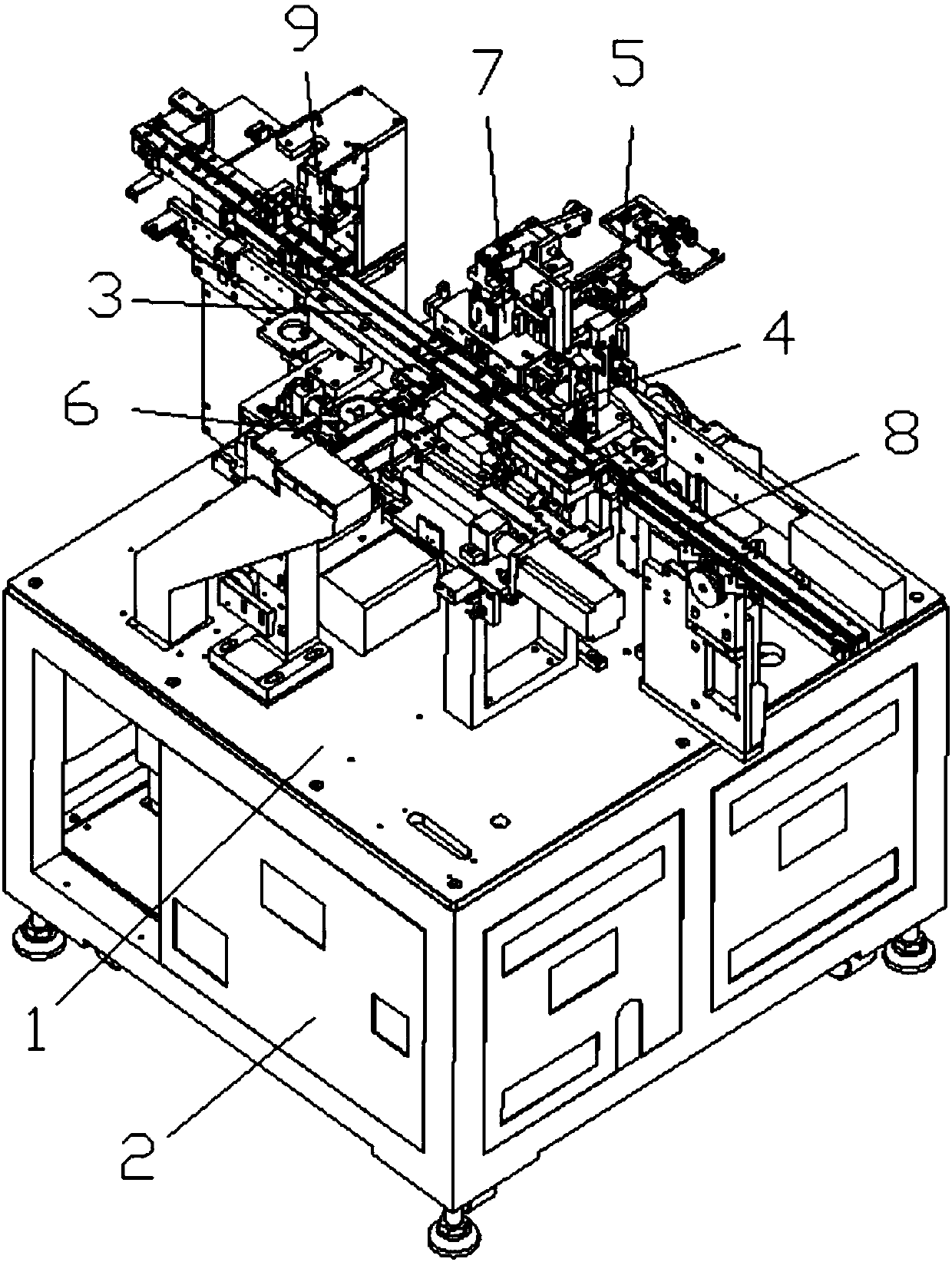

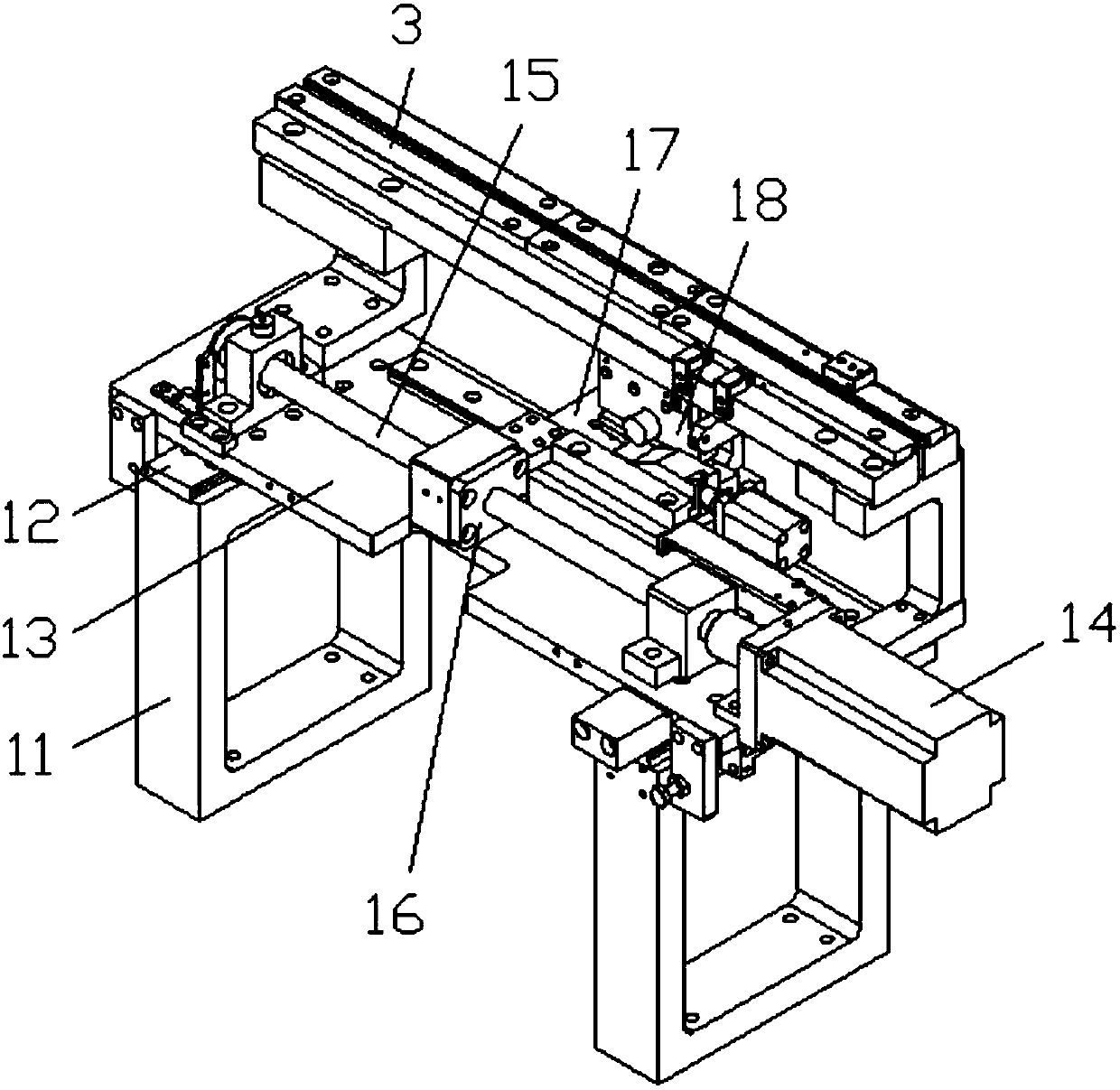

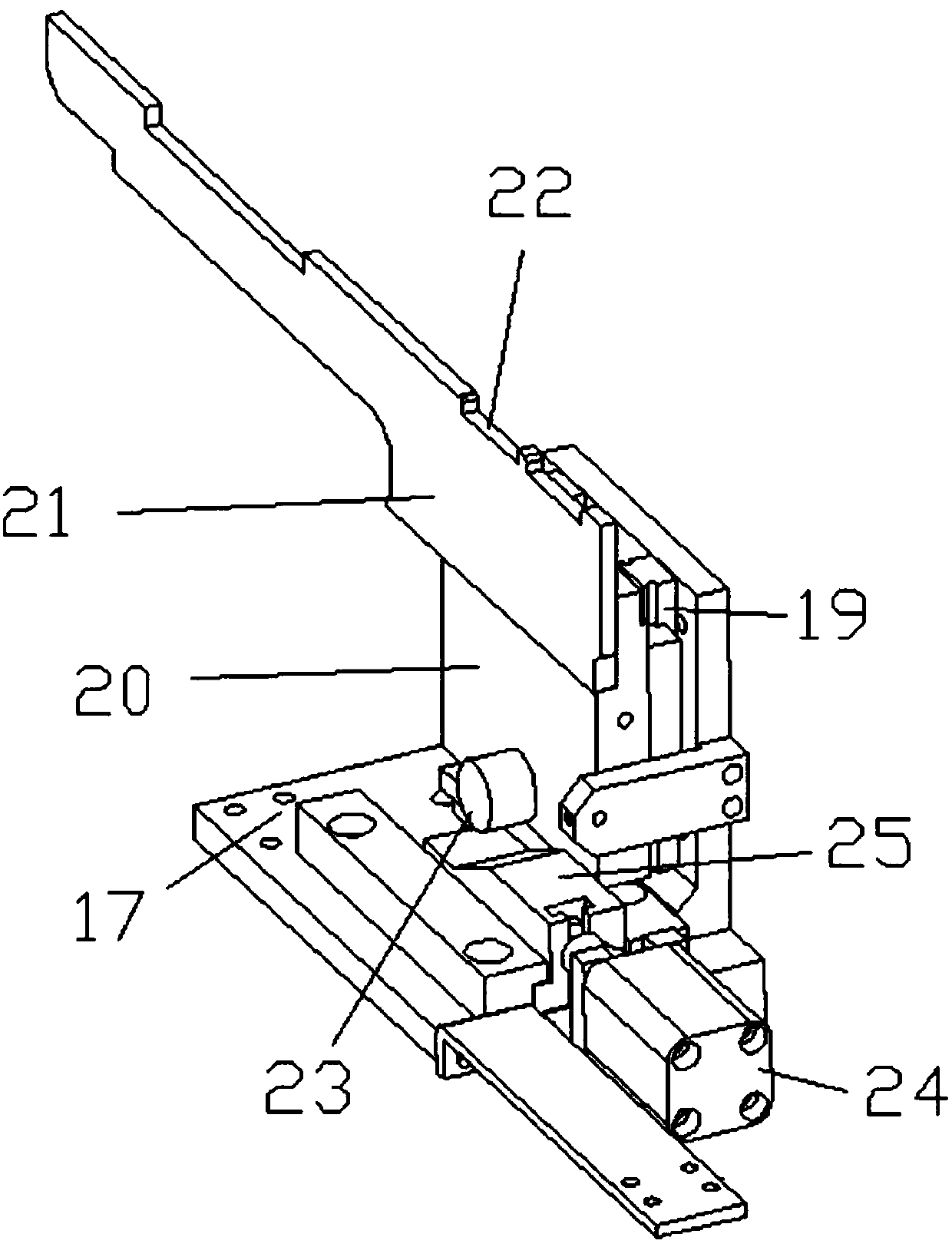

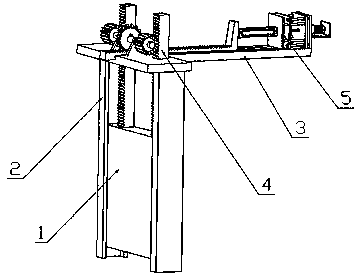

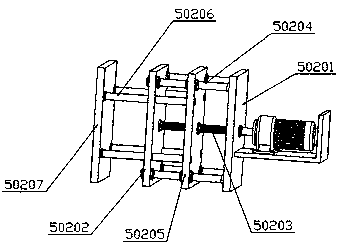

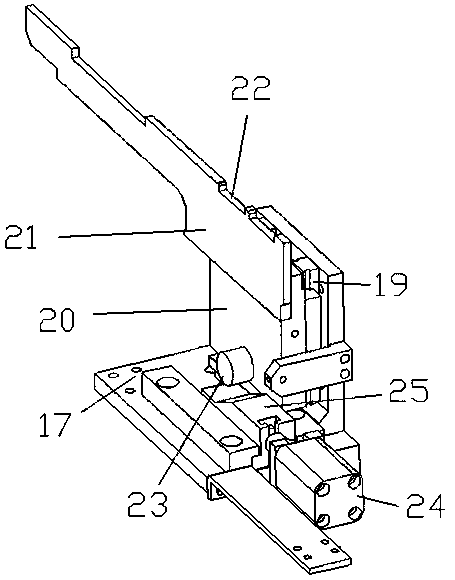

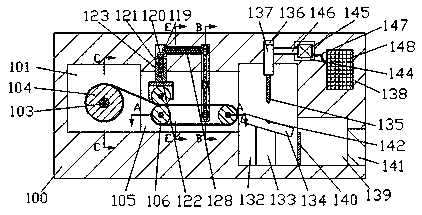

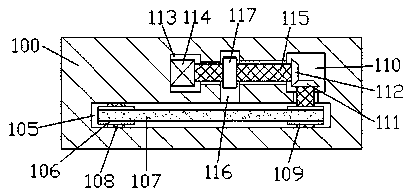

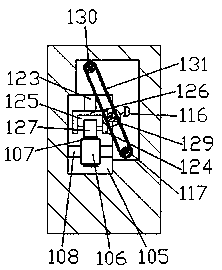

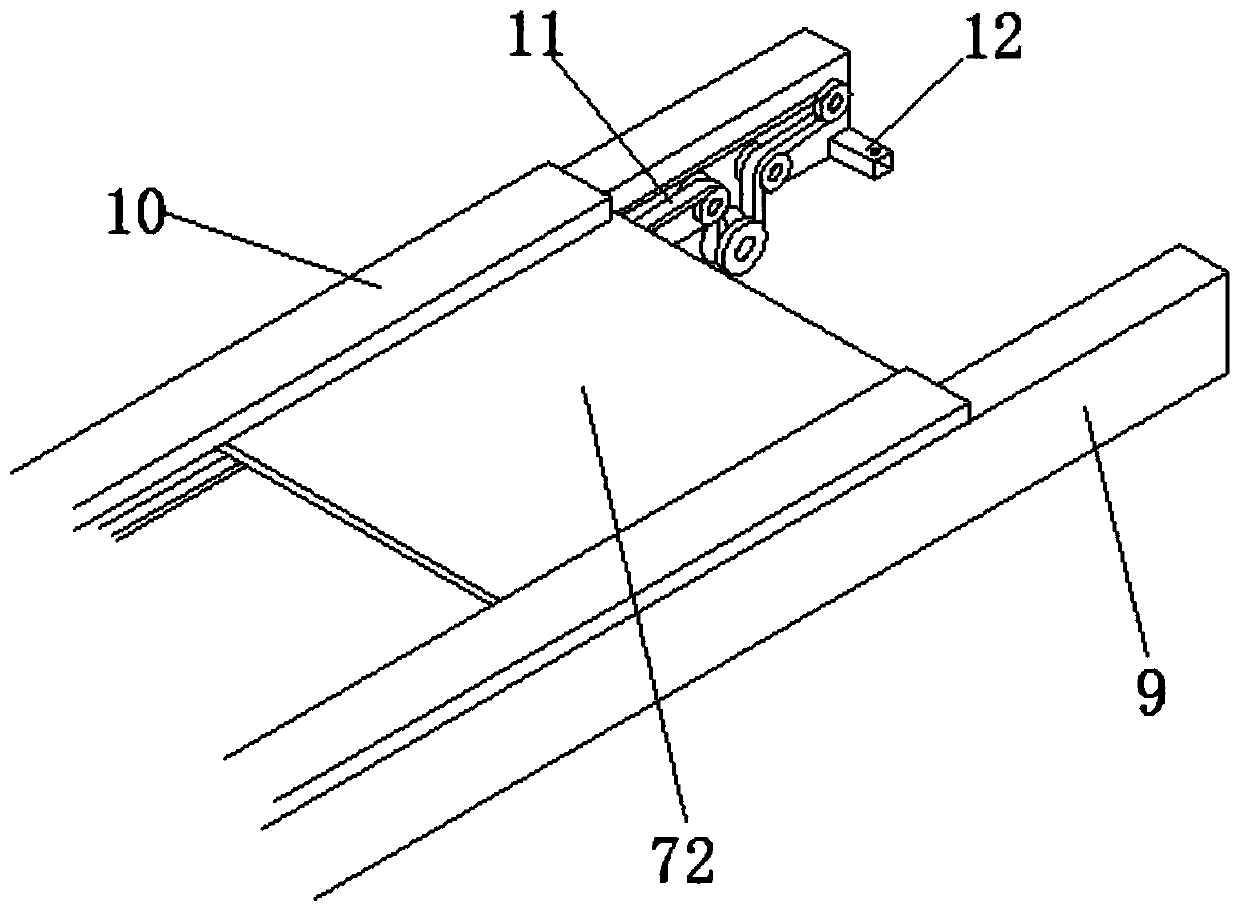

Continuous pin insertion machine for dipolar plug

ActiveCN107749548AHigh precisionRealize vertical conveyingContact member manufacturingContact member cases/bases manufactureEngineeringManipulator

The invention relates to a continuous pin insertion machine for a dipolar plug. A frame is provided with a feeding groove and a feeding device, wherein an upper portion of the feeding groove is provided with a pin insertion mechanism and a carrier belt pin conveying device which are mutually matched, the carrier belt pin conveying device comprises a carrier belt pin conveying seat arranged on theframe, the carrier belt pin conveying seat is provided with a carrier belt pin conveying guiding cylinder and a carrier belt pin conveying groove, the carrier belt pin conveying groove is internally further provided with a carrier belt feeding sliding groove, the middle portion of the carrier belt pin conveying groove is matched with a carrier belt feeding ratchet, the carrier belt feeding ratchetis connected with a carrier belt feeding motor, the carrier belt pin conveying groove is provided with a pin insertion groove at an upper portion of the feeding groove, and the pin insertion groove is matched with a pin insertion block of the pin insertion mechanism. The continuous pin insertion machine is advantaged in that the carrier belt pin conveying device is employed to realize vertical conveying of carrier belts, vertical conveying of the insertion pins can be further realized, the carrier belt pin conveying device is matched with a material casing feeding device and the pin insertionmechanism, continuous pin insertion can be realized, work efficiency is improved, compared with a manipulator for pin insertion, the error rate is substantially reduced, and pin insertion accuracy isimproved.

Owner:新沂市邵店众创工贸发展有限公司

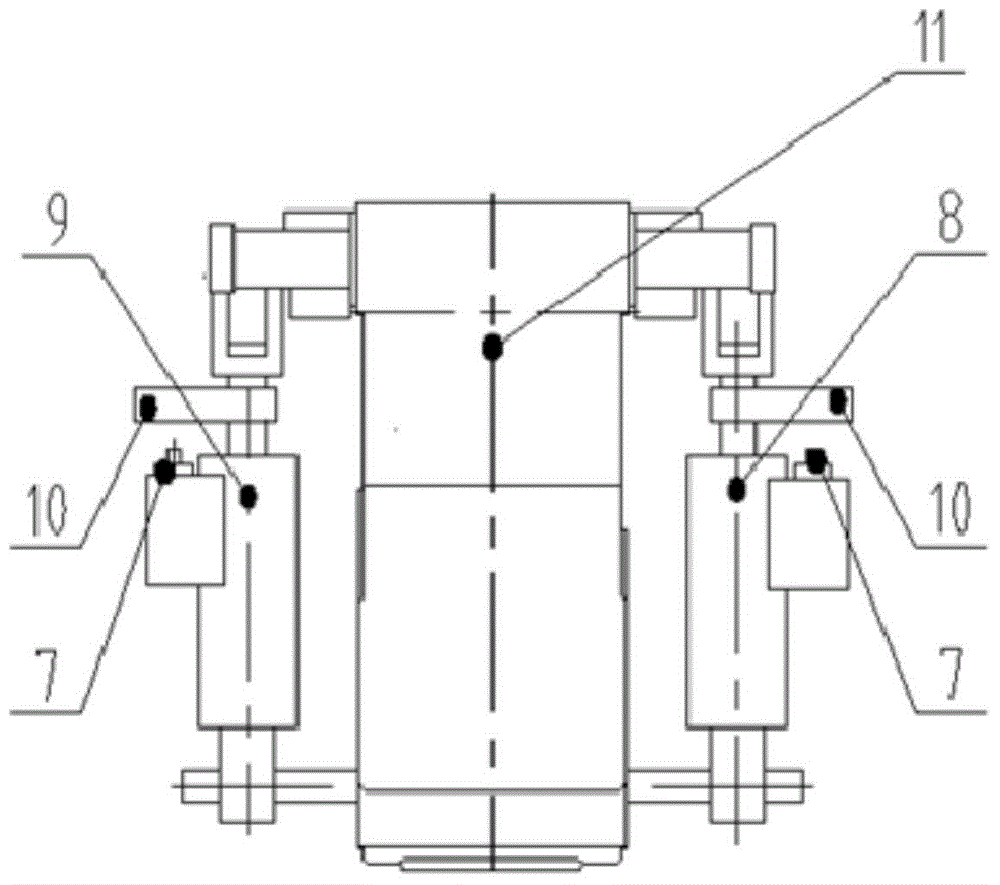

Flashboard lifting device used for energy storage power station

PendingCN109235383AAvoid raising inconsistenciesReduce damage rateBarrages/weirsPower stationEngineering

The invention discloses a flashboard lifting device used for an energy storage power station, and belongs to the technical field of energy storage power stations. In the technical scheme, the flashboard lifting device comprises a flashboard and flashboard racks on the two sides of the flashboard, the flashboard is slidingly connected with the flashboard racks, a base is arranged at the tops of theflashboard racks, fixedly connected with the flashboard racks, and provided with a lifting mechanism, one end of the lifting mechanism is connected with the flashboard, the flashboard is driven by the lifting mechanism to ascend and descend, the other end of the lifting mechanism is connected with a driving mechanism, and the driving mechanism is arranged on the base. In the technical scheme, theflashboard lifting device has the advantages that the design is simple, using is convenient, when the flashboard is lifted, the two sides of the flashboard are uniformly stressed, synchronous ascending or descending is realized, it is avoided that since stress is not uniform, the two sides of the flashboard are lifted without uniformity, in this way, the probability of flashboard damage or sliding groove damage is lowered, and working efficiency is improved.

Owner:STATE GRID CORP OF CHINA +2

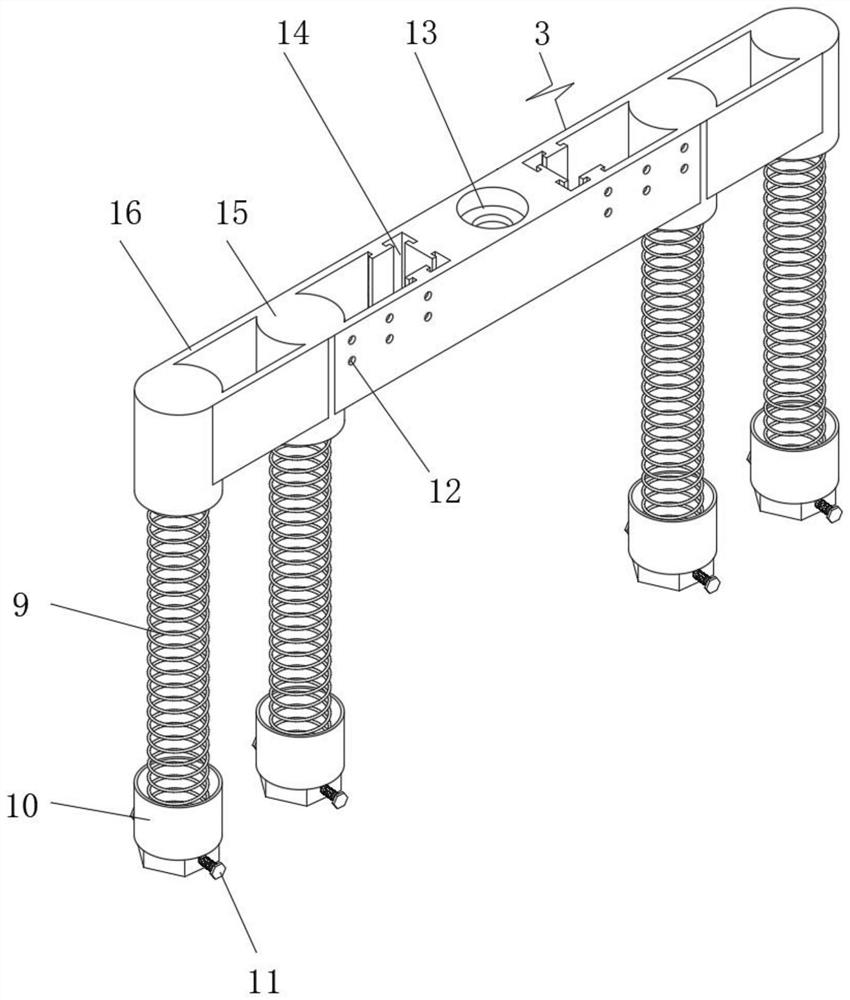

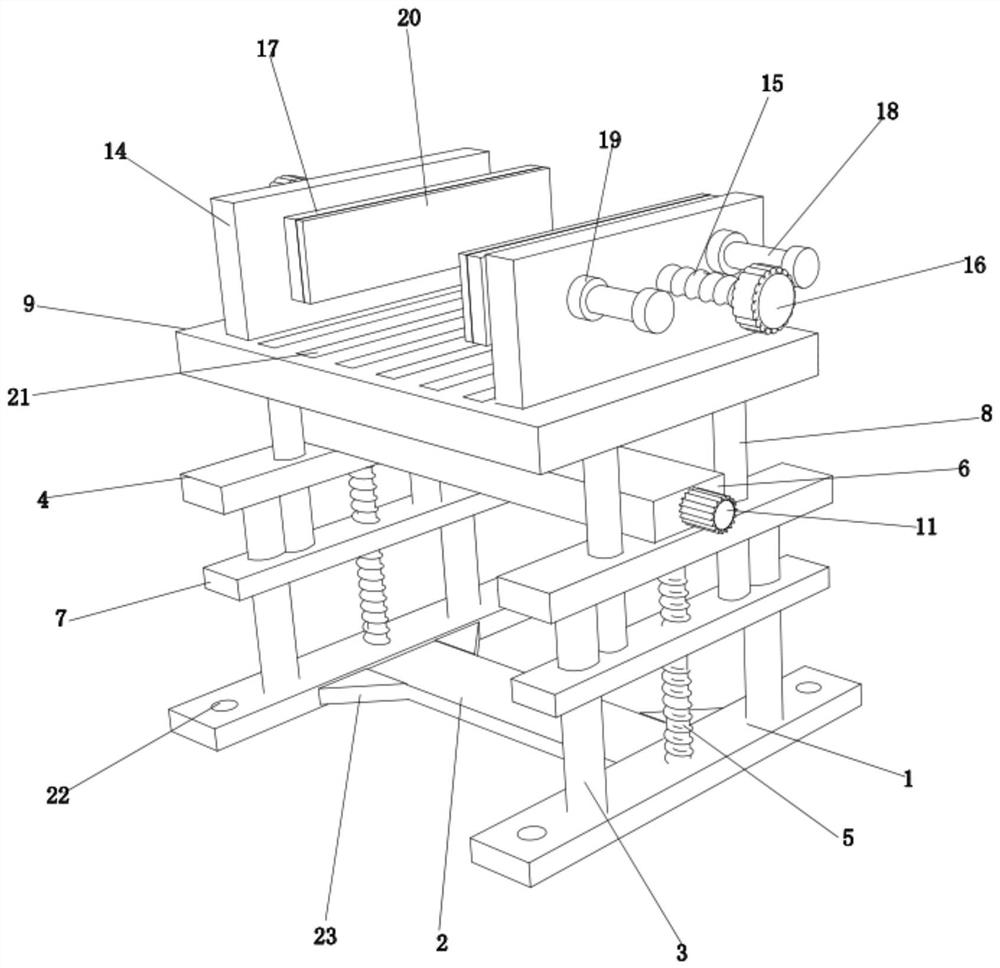

Real-time lifting control console for material conveying

ActiveCN112225110AAdjust control lift heightControl lift heightLifting framesVibration suppression adjustmentsStructural engineeringMechanical engineering

The invention discloses a real-time lifting control console for material conveying. The real-time lifting control console comprises a control device, a lifting device, a protecting device, a mountingand fixing base, mounting and fixing holes, a lifting conveying table, first fastening bolts and an adjustment control device, wherein the mounting and fixing holes symmetrically run through the two ends of the mounting and fixing base. The lifting device is fixedly installed in the middle of the upper end face of the mounting and fixing base, the protecting device is installed at the bottom of the lifting device, the bottom end of the protecting device is located on the upper end face of the mounting and fixing base, and the lifting conveying table is fixedly installed at the upper end of theprotecting device through the first fastening bolts. In the using process, forward and reverse rotation and rotation time of a threaded adjusting column can be controlled by controlling the directionand time of cranking an adjusting control handle, so that the lifting and the lifting height of the lifting plate and the lifting conveying table are indirectly controlled, using and adjusting are convenient and rapid, and control is accurate.

Owner:山东天意高科技有限公司

New energy automobile charging pile mounting structure

InactiveCN114274812AInstalled and disassembledEasy to adjust lift heightCharging stationsElectric vehicle charging technologyNew energyScrew thread

The invention discloses a new energy automobile charging pile mounting structure which comprises two mounting bottom plates which are oppositely arranged, a reinforcing plate is connected between the two mounting bottom plates, two supporting columns are oppositely arranged at the upper ends of the mounting bottom plates, and a connecting plate is connected to the upper ends of the two supporting columns. Lead screws are connected between the connecting plates and the mounting bottom plate in a threaded mode, an assembly box is arranged between the two connecting plates, a driving assembly used for driving the two lead screws to rotate synchronously is arranged in the assembly box, lifting plates are connected to the lead screws in a threaded mode, and the lifting plates are slidably connected with the supporting columns on the two sides. Mounting columns penetrating to the upper portion of the connecting plate are arranged on the lifting plate, mounting tables are arranged at the top ends of the mounting columns on the two sides, and clamping assemblies are arranged at the upper ends of the mounting tables. Compared with the prior art, the charging pile has the advantages that dismounting and cyclic utilization are convenient, the lifting height of the charging pile can be conveniently controlled according to the mounting position, and the charging pile is not prone to being soaked by accumulated water.

Owner:沈阳靓婷新能源有限公司

Dipolar plug continuous pin inserting device capable of detecting

ActiveCN111180978AHigh precisionRealize vertical conveyingContact member manufacturingContact member cases/bases manufactureRatchetEngineering

Owner:DEZHOU LINGCHENG POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

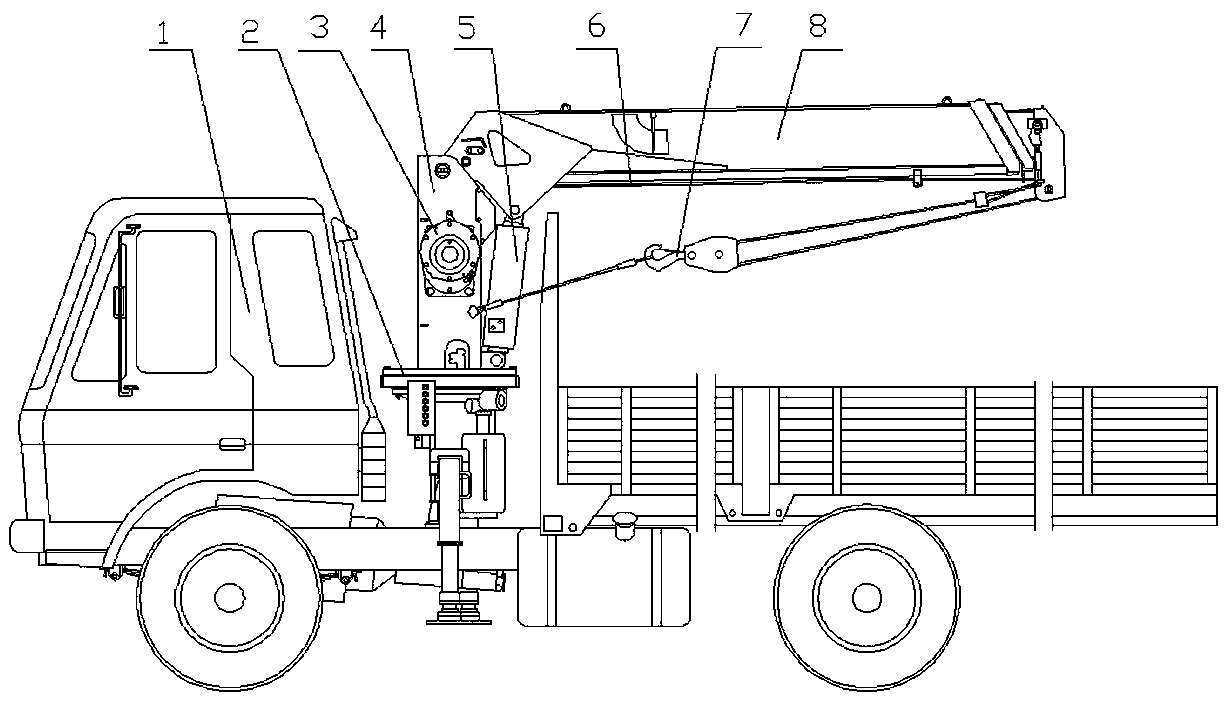

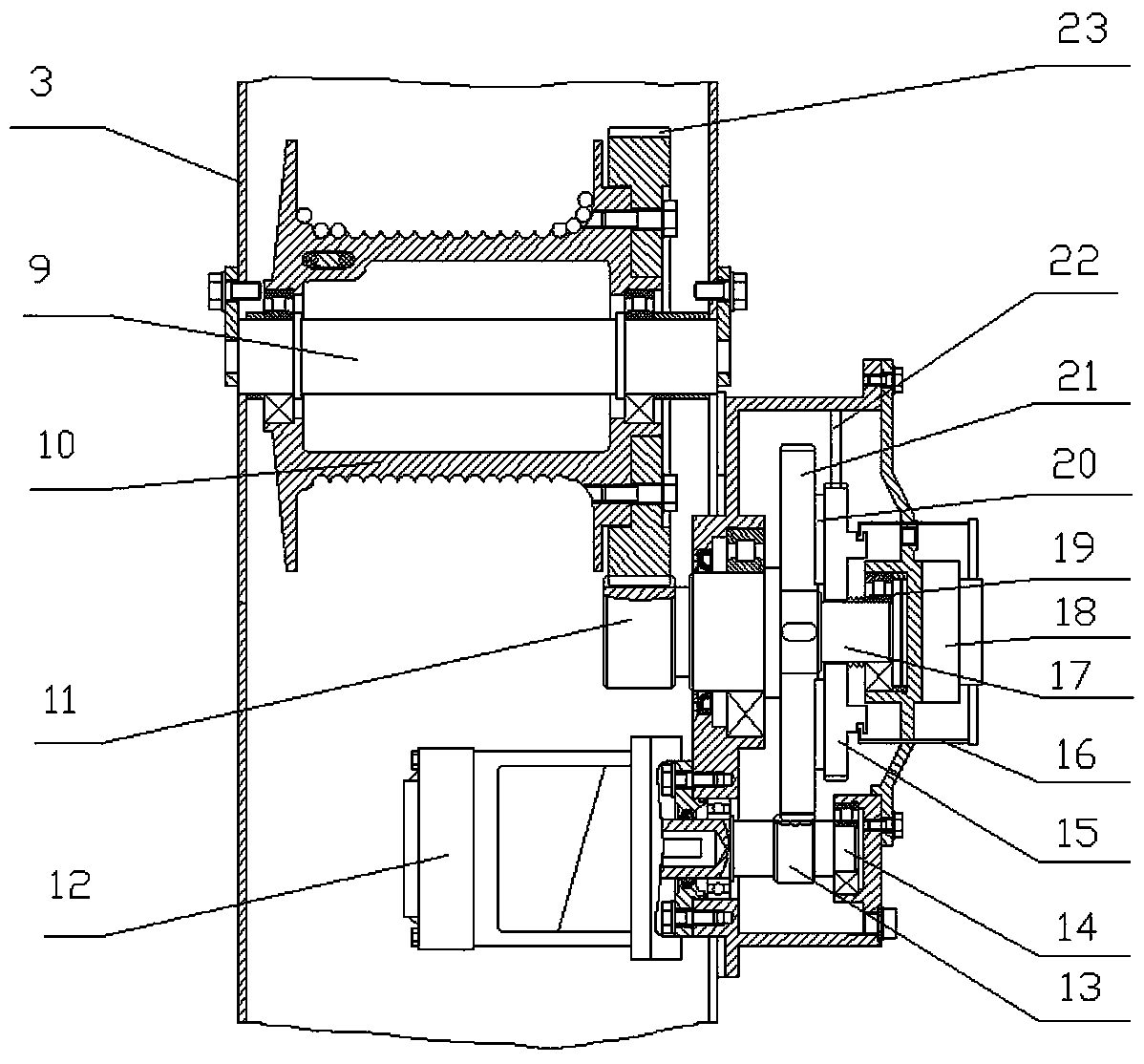

A vehicle-mounted hoist

ActiveCN108408606BPrevent rotationControl lift heightWinding mechanismsCranesVehicle frameIn vehicle

Owner:LUOYANG INST OF SCI & TECH

Use method of woven bag making device

InactiveCN109130319AUnified specificationsControl lift heightBag making operationsPaper-makingSlide plateWork space

The invention discloses a use method of a woven bag making device. The woven bag making device comprises a fixed body, wherein an installing chamber is arranged inside the left end wall of the fixed body, and the front and rear end walls of the installing chamber are fixedly provided with an arc block. The upper end surface of the arc block is rotatably provided with a detachable rotating shaft, the rotating shaft is sleeved with and connected with a film cartridge, a working space is arranged inside the right end wall of the installing chamber, and two rolling cylinders are arranged bilaterally symmetrically on the left side of the interior of the working space. A sliding cavity is arranged inside the rear end wall of a driving cavity, and a sliding plate is slidably arranged inside the sliding cavity. The rear end of a first rack is fixedly connected with the front end surface of the sliding plate after penetrating through the rear end wall of the driving cavity. A pneumatic space isarranged inside the rear end wall of the sliding cavity, wherein a pneumatic pump is fixedly arranged inside the pneumatic space, the rear end surface of the pneumatic pump communicates with a gas-absorbing pipe, and the rear end of the gas-absorbing pipe extends into the outer space after penetrating through the rear end wall of the pneumatic space.

Owner:绍兴初汇纺织有限公司

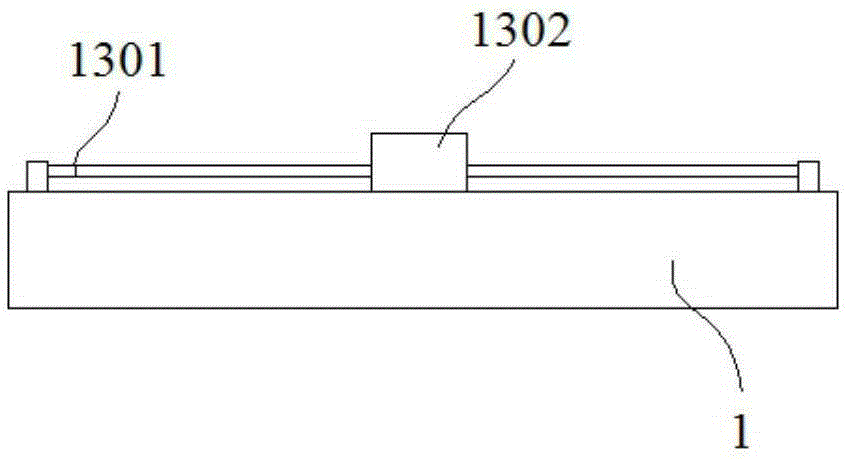

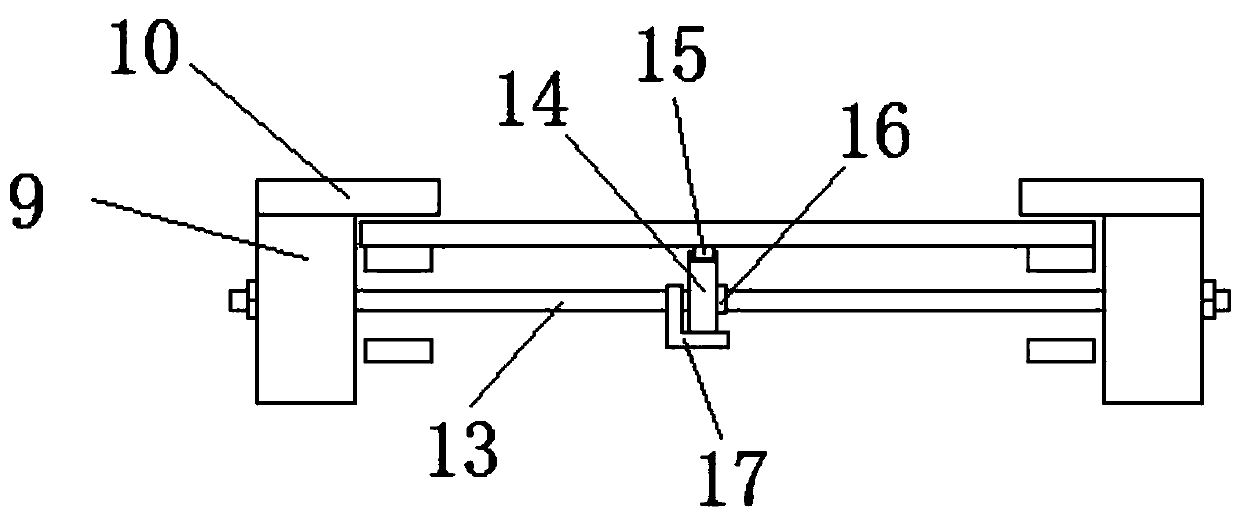

A kind of led light production line

ActiveCN108480999BControl lift heightReduce damage rateControl devices for conveyorsOther manufacturing equipments/toolsProduction linePulp and paper industry

The invention discloses an LED lamp production line, and belongs to the technical field of LED lamp production equipment. The LED lamp production line is characterized by comprising an element inserting machine, a wave soldering machine, an assembling station, an aging machine, an inspection device, an automatic packaging machine and a conveying line; the element inserting machine comprises an inserting machine body, a conveying track is arranged in the middle of the inserting machine body, and a feeding machine table is arranged on the lower portion of the left side of the conveying track; supporting frames are arranged on the front side of the inserting machine body, and feeding pieces are arranged on the supporting frames; and the conveying track comprises two guide rails which are arranged in parallel, the upper parts of the guide rails are connected with clamping plates respectively, a conveying belt is arranged on the inner side of each guide rail, and a first sensor is arrangedon each guide rail. The LED lamp production line is stable in operation, safe, reliable and high in production efficiency.

Owner:绍兴舜宇照明工程有限公司

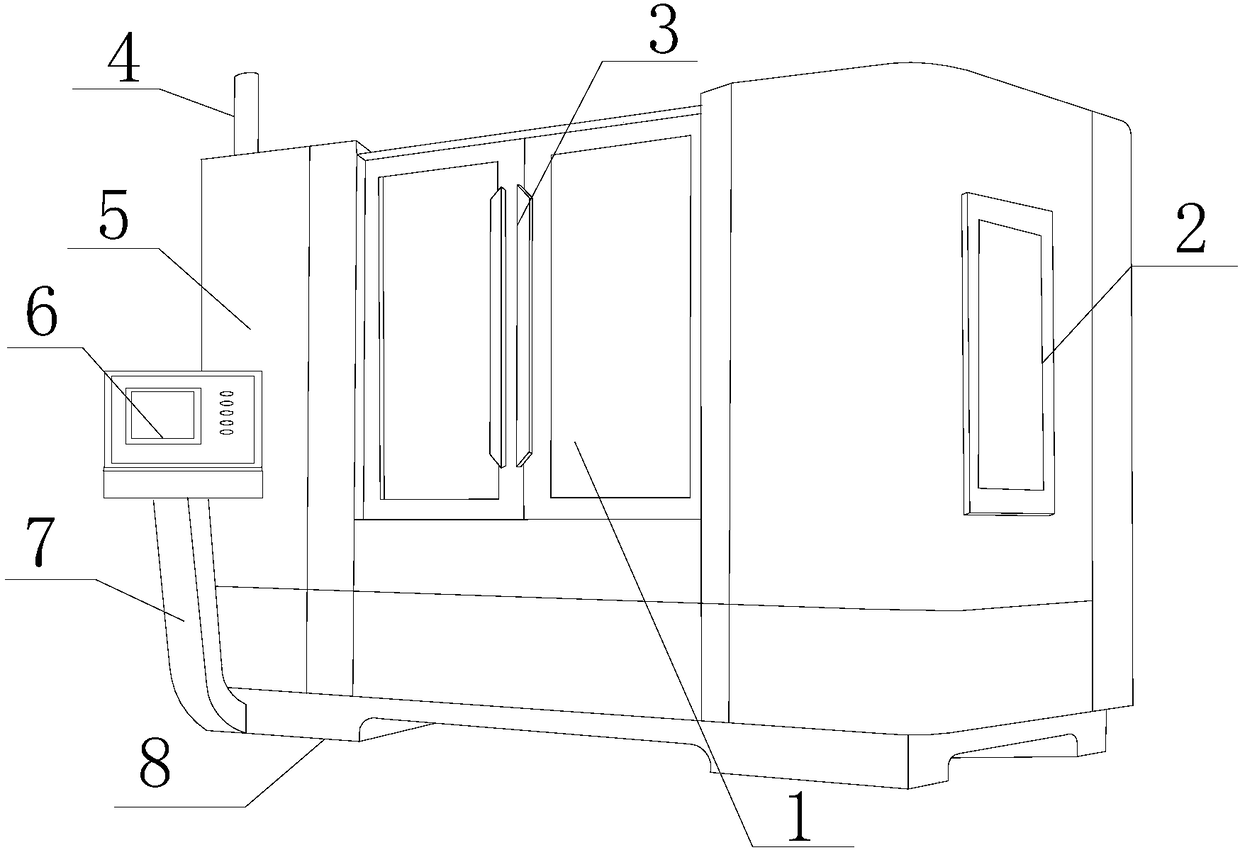

Automobile welding clamp

InactiveCN108581322AFixed height adjustmentControl fixedWelding/cutting auxillary devicesAuxillary welding devicesPulp and paper industry

The invention discloses an automobile welding clamp which structurally comprises a clamping device, tempered glass, a sliding door, an alarm indication lamp, a welding machine body, a control cabinet,a connection frame and a base. The clamping device is installed inside the welding machine body, the bottom of the welding machine body is fixedly connected with the top of the base, the side face ofthe tempered glass is embedded inside the right end of the welding machine body, the sliding door is installed inside the front end of the welding machine body, the bottom of the alarm indication lamp is perpendicularly connected with the top of the left end of the welding machine body, the bottom end of the connection frame is fixedly connected with the front side of the left end of the base, and the top of the connection frame is perpendicularly connected with the bottom of the control cabinet. The clamp can rapidly clamp and fix an automobile and meanwhile can rapidly adjust the fixing position and height of the automobile so that using convenience can be increased for work staff, and the clamp is good in buffer effect and avoids damage when the automobile is placed.

Owner:莆田市荔城区任西贸易有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com