3D printing device and forming method thereof

A 3D printing and equipment technology, applied in the field of 3D printing, can solve the problems affecting the forming quality of parts, large lifting displacement error, low forming efficiency, etc., and achieve the effect of simple structure, fast forming speed and high forming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

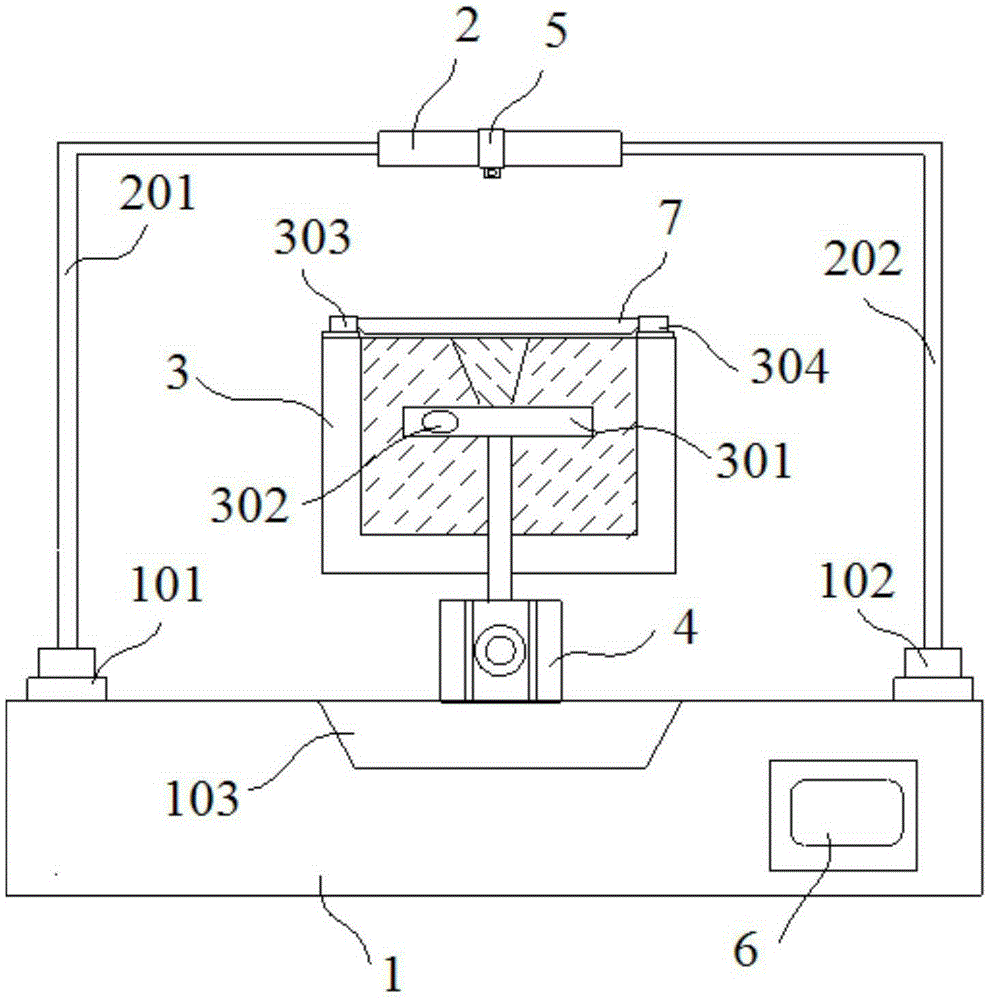

[0038] like figure 1 As shown, the 3D printing device of the present invention includes:

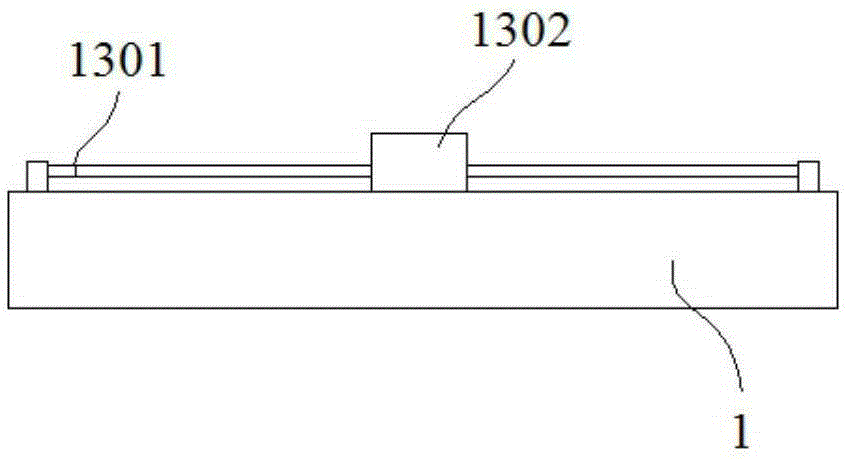

[0039] A machine base 1, a first sliding device 101 and a second sliding device 102 are provided on both sides of the machine base 1 . A recovery device 103 is also arranged on the machine base 1 , and the recovery device 103 is arranged directly below the storage device 3 and the cylinder 4 .

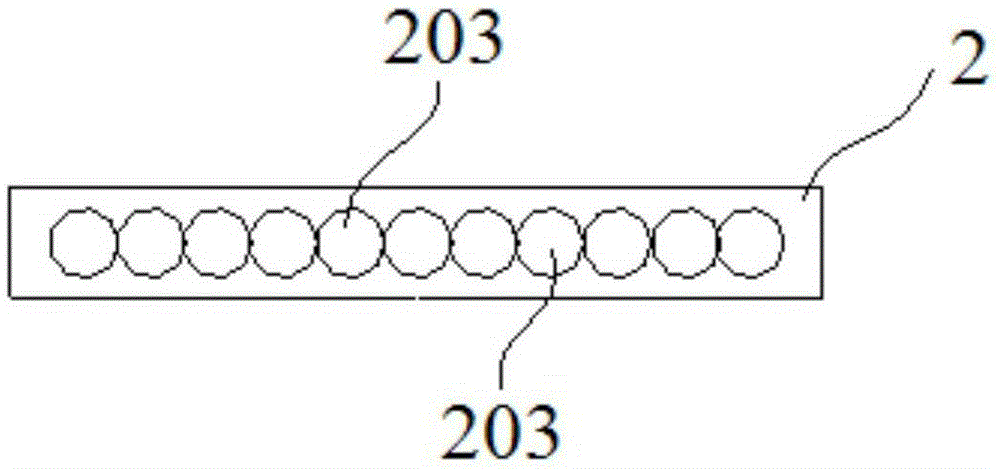

[0040] A laser irradiation device 2, the laser irradiation device 2 is arranged above the base 1, the first end of the laser irradiation device 2 is connected to the first sliding device 101 through a first connecting rod 201, the laser The second end of the illuminating device 2 is connected to the second sliding device 102 through a second connecting rod 202, and both the first connecting rod 201 and the second connecting rod 202 are L-shaped connecting rods. like figure 2 As shown, a plurality of laser diodes 203 are arrayed in the laser irradiation device 2 . In this embodiment, the lase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com