Patents

Literature

53results about How to "Precise control of lifting height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

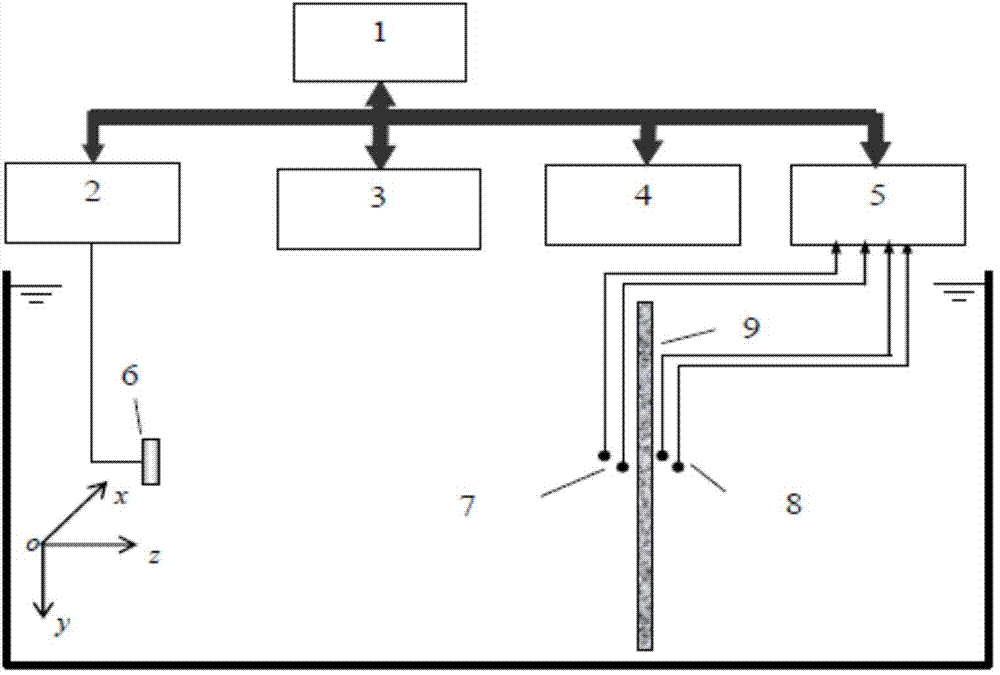

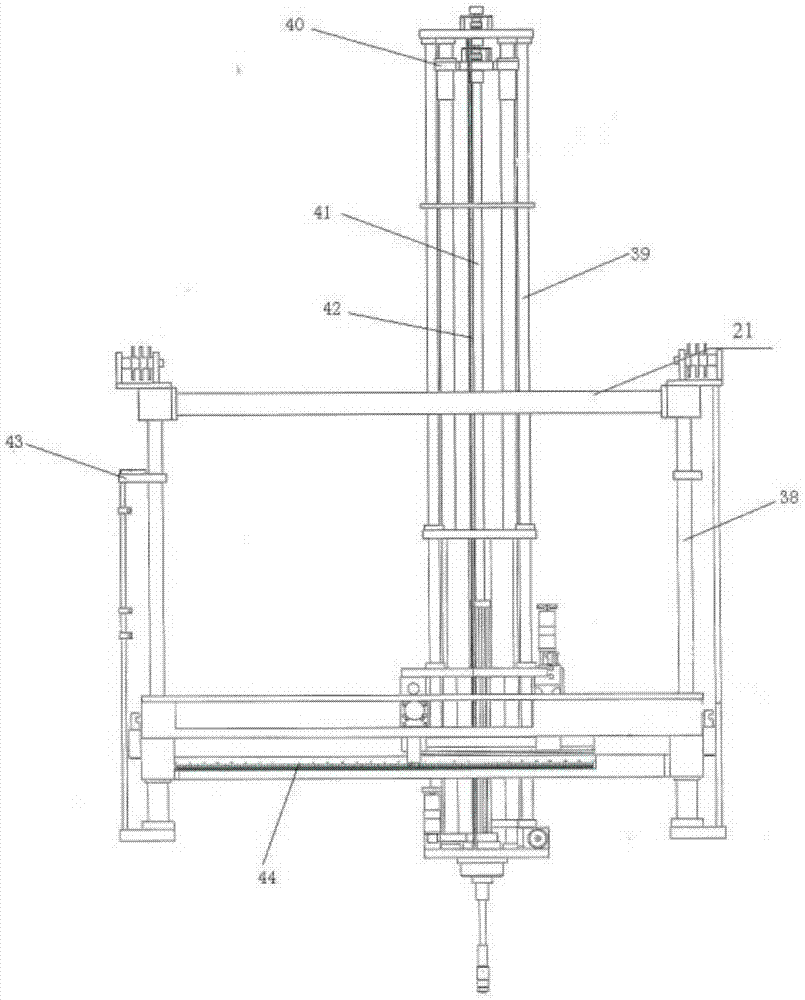

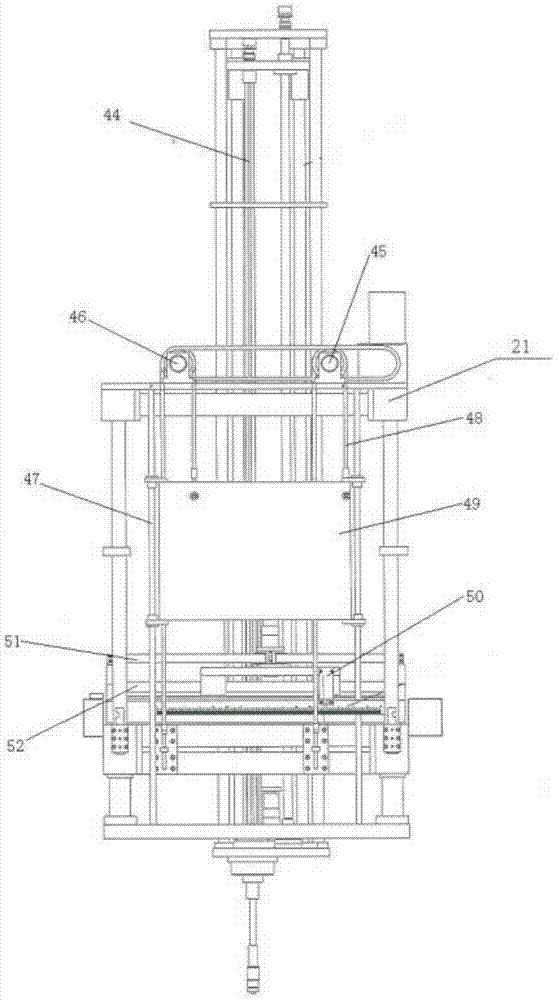

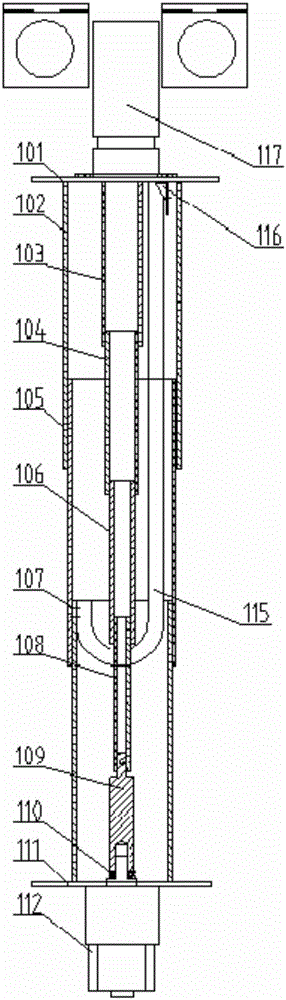

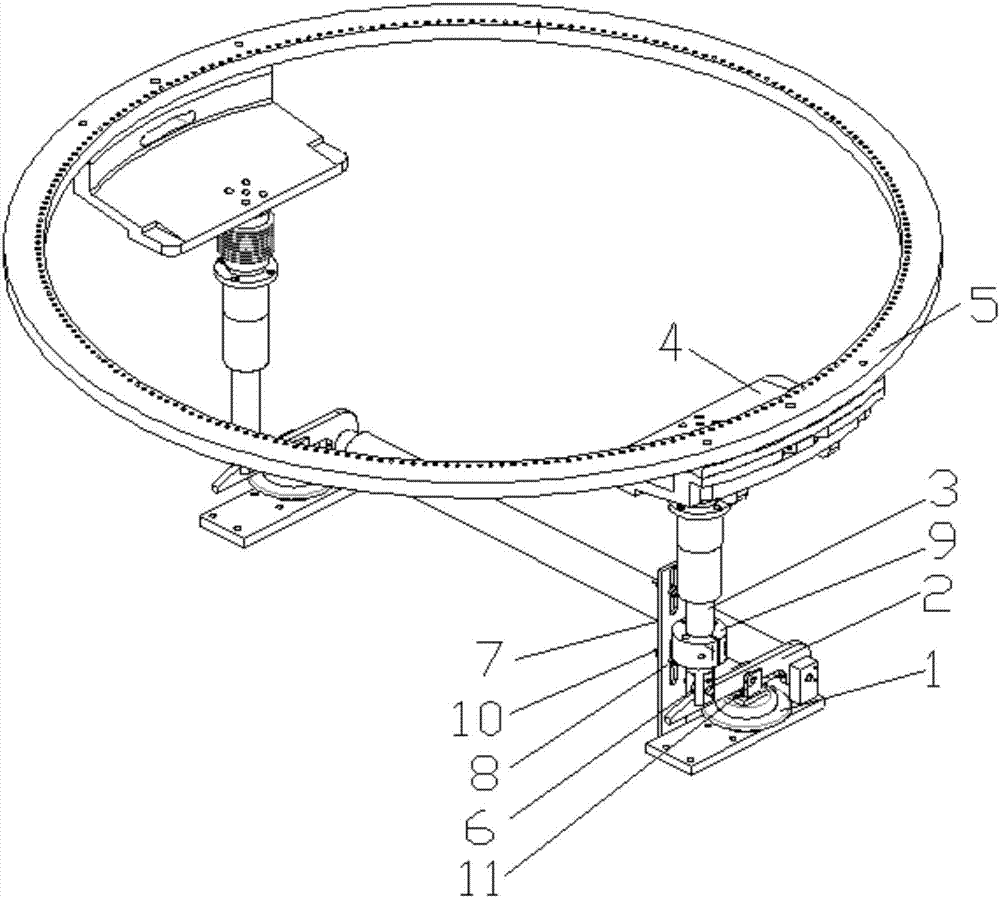

Automatic lifting rotating scanning device of hydrophone

InactiveCN104122543AImprove test accuracyAccelerate development cycleWave based measurement systemsHydrophoneMotor drive

The invention discloses an automatic lifting rotating scanning device of a hydrophone. The automatic lifting rotating scanning device of the hydrophone comprises a rack, the rack is provided with a landing gear, a moving frame, a moving platform, a screw rod, a lifting table and a rotating spindle, the landing gear performs Z-direction lifting movement along the rack, the moving frame performs X-direction translational motion on the landing gear, the moving platform performs Y-direction translational motion on the moving frame, the screw rod is vertically installed on the moving platform, the lifting table is driven by the screw rod to perform lifting movement, the rotating spindle is vertically installed on the lifting table, the rotating spindle and the lifting table are rotatably matched with each other and axially fixed, and the bottom of the rotating spindle is used for suspending the hydrophone or a detected sample which is matched with the hydrophone. A driving mode of the screw rod and the rotating spindle includes that a screw rod driving step motor is mounted on the moving platform, the screw rod driving step motor drives the screw rod to rotate through a screw rod synchronous belt, a rotating sleeve and a step motor are arranged on the moving platform, the step motor drives the rotating sleeve to rotate, the step motor drives the rotating sleeve through a driving belt, and the rotating spindle penetrates the rotating sleeve and is circumferentially positioned and is in axial sliding fit with the rotating sleeve.

Owner:ZHEJIANG UNIV

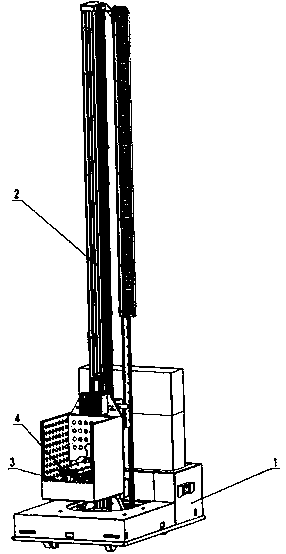

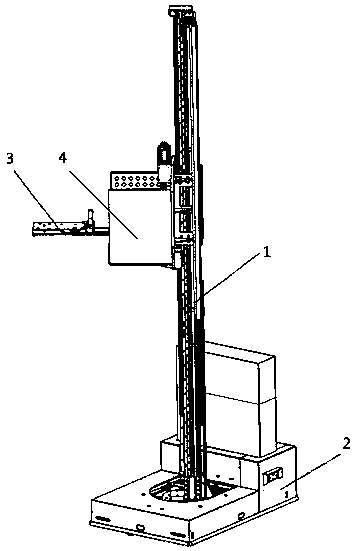

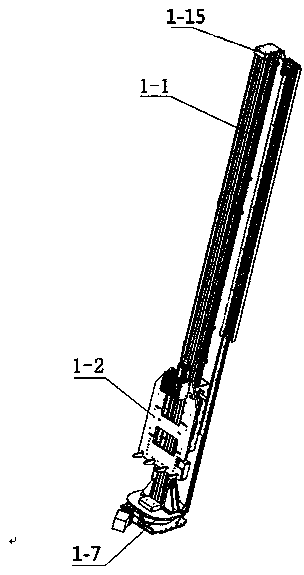

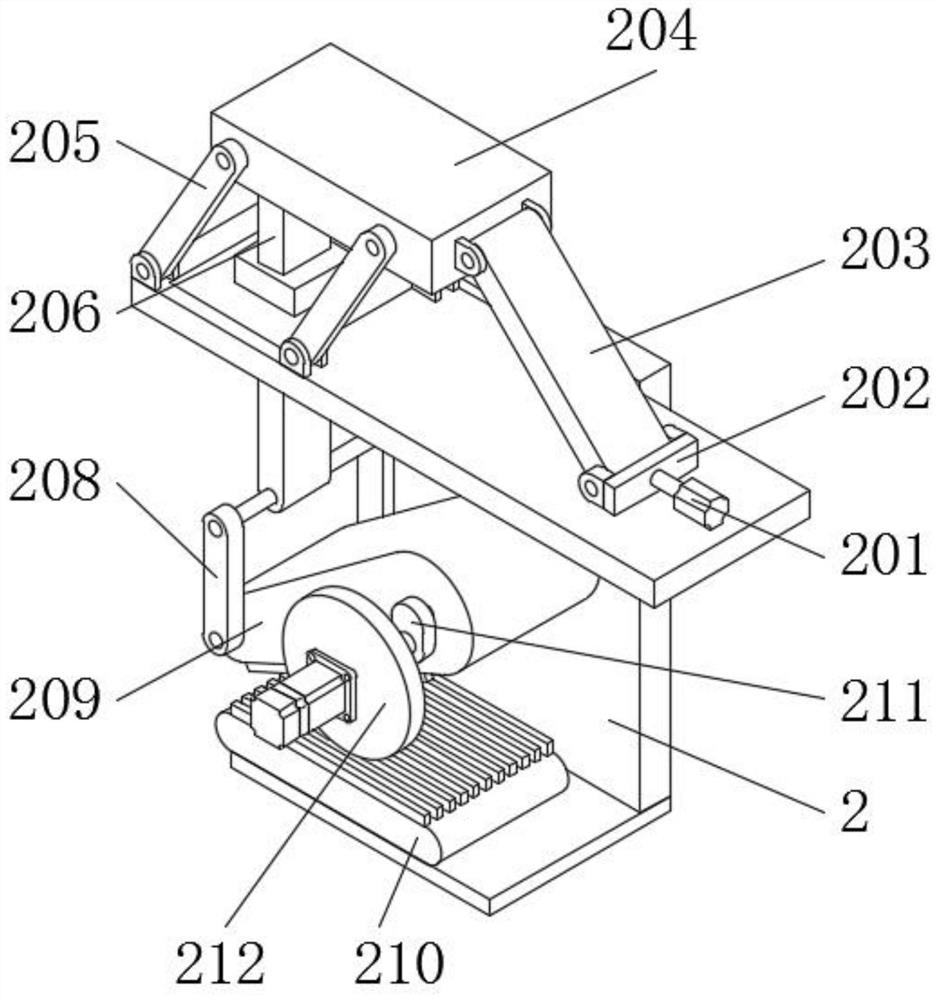

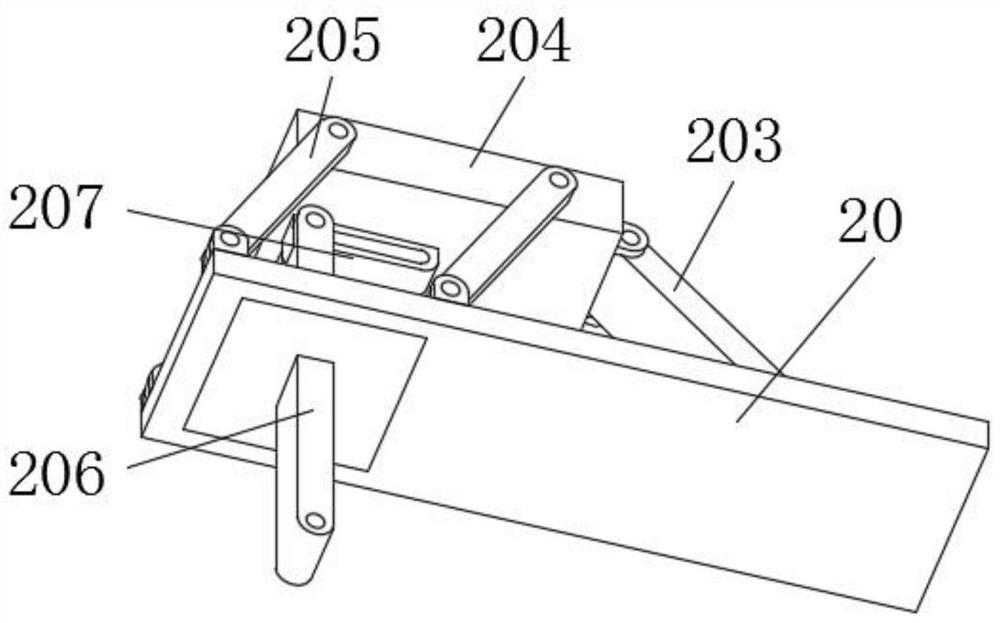

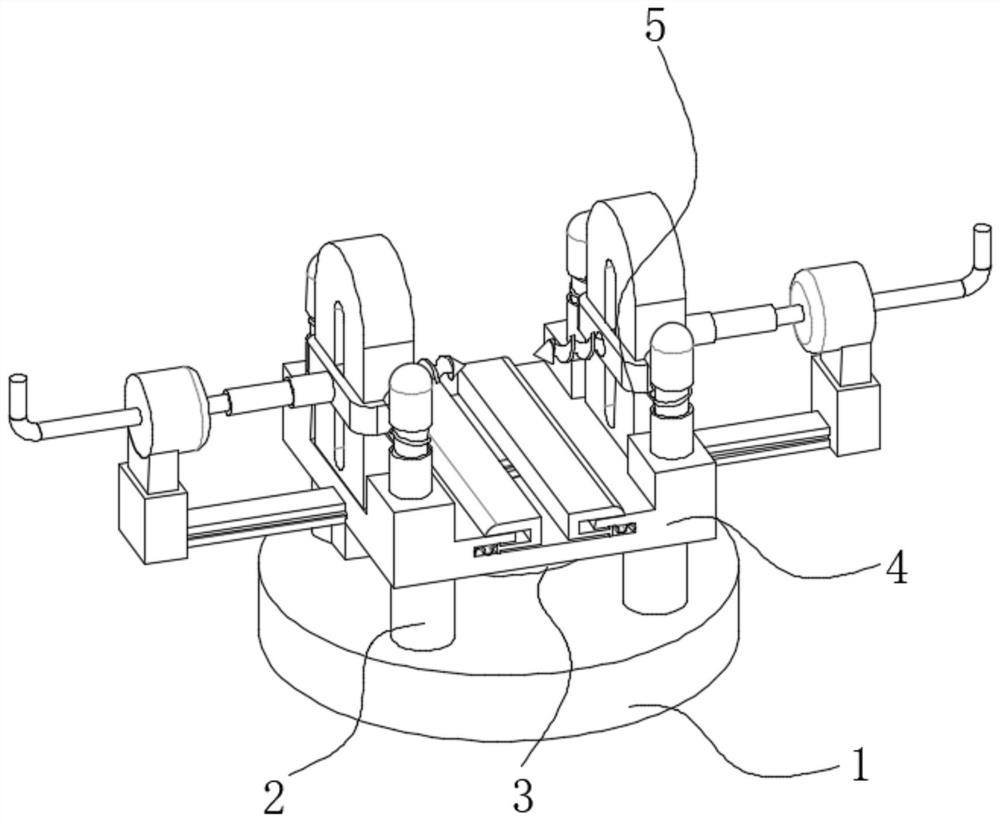

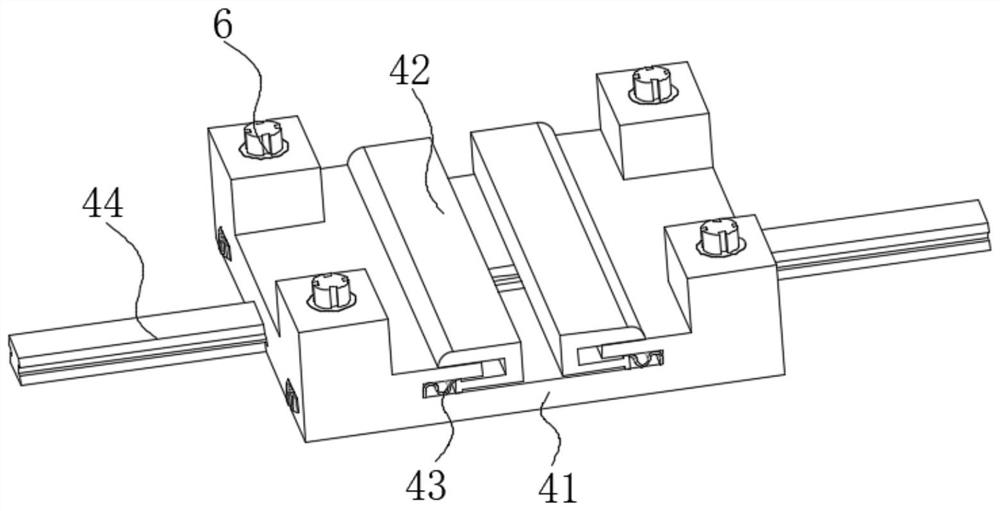

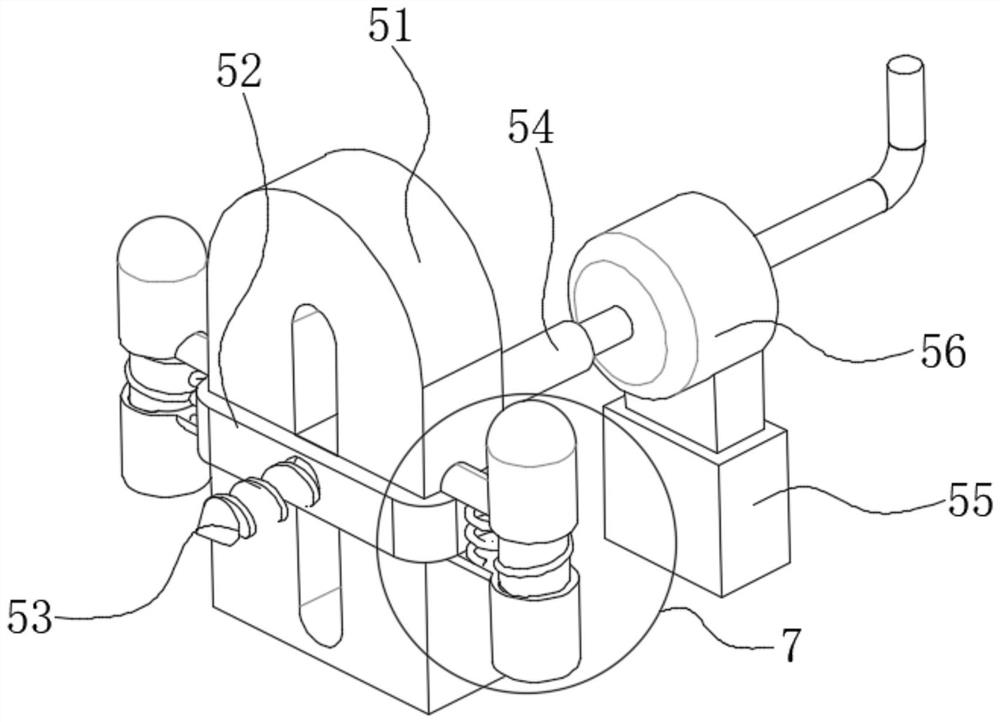

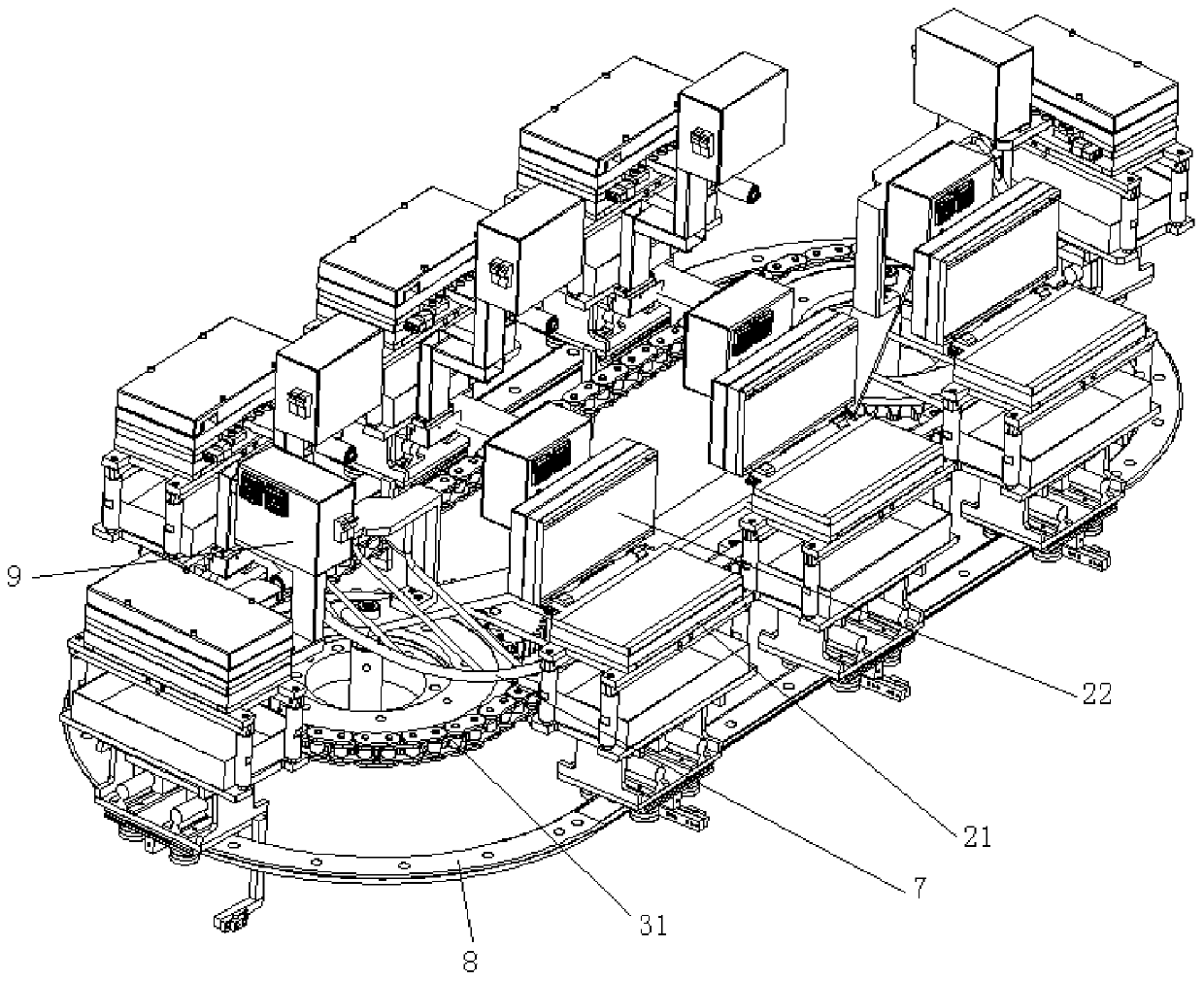

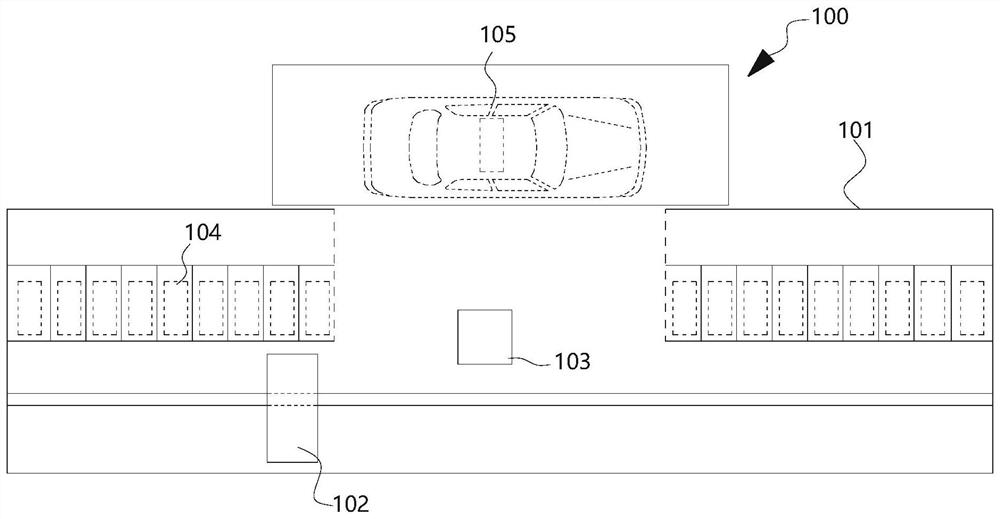

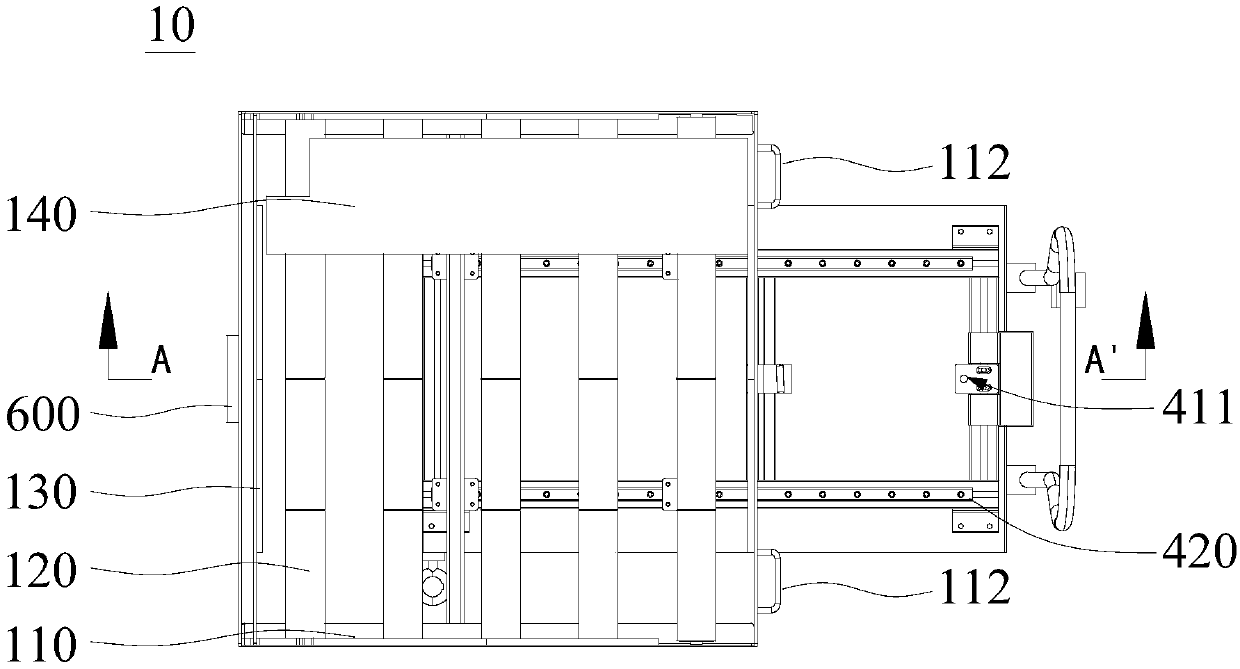

Automatic storing, stacking, picking and placing device for intelligent warehousing

PendingCN110884816AIngenious structural designImprove reliabilityStorage devicesPallet forkElectrical and Electronics engineering

The invention relates to an automatic storing, stacking, picking and placing device for intelligent warehousing, and belongs to the technical field of picking and placing device structures special forintelligent warehousing. The device comprises an AGV, an advancing track code strip pasted on the ground, a pallet fork device capable of automatically adjusting the width of a fork, a horizontal rotating and vertical lifting device capable of driving the fork to ascend, descend and rotate, and a double-shaft XY automatic detecting and adjusting device capable of adjusting the fork to be parallelto goods to be taken. The AGV body is provided with a camera used for identifying the advancing track code strip; the bottom of the horizontal rotating and vertical lifting device is installed on theAGV body, the double-shaft XY automatic detecting and adjusting device is installed on the horizontal rotating and vertical lifting device, the fork is installed above the double-shaft XY automatic detecting and adjusting device, and a battery and a control box are further installed on the AGV body. According to the invention, the device is low in cost and high in flexibility, has a unique function of automatically adapting to the angle of the goods shelf, and greatly improves the goods taking safety of the goods fork of the whole stacking machine on the goods shelf.

Owner:烟台拓伟智能科技股份有限公司

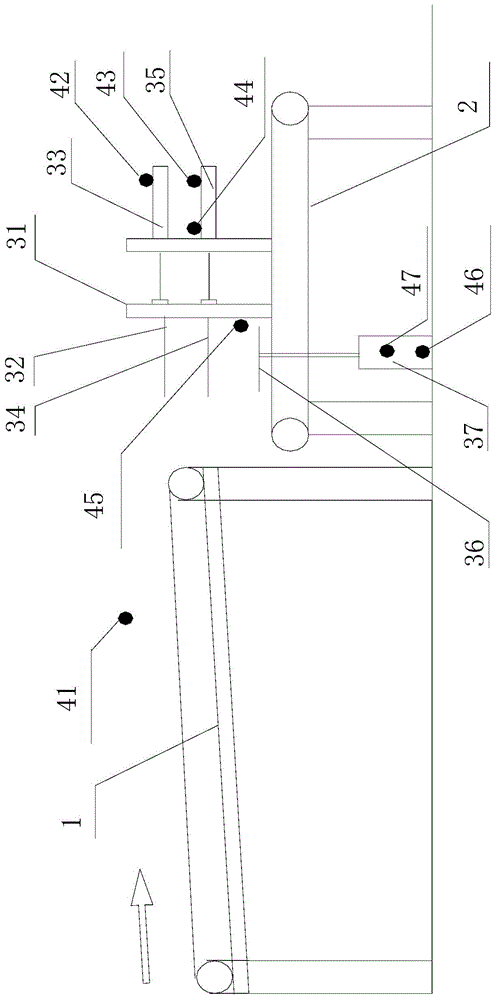

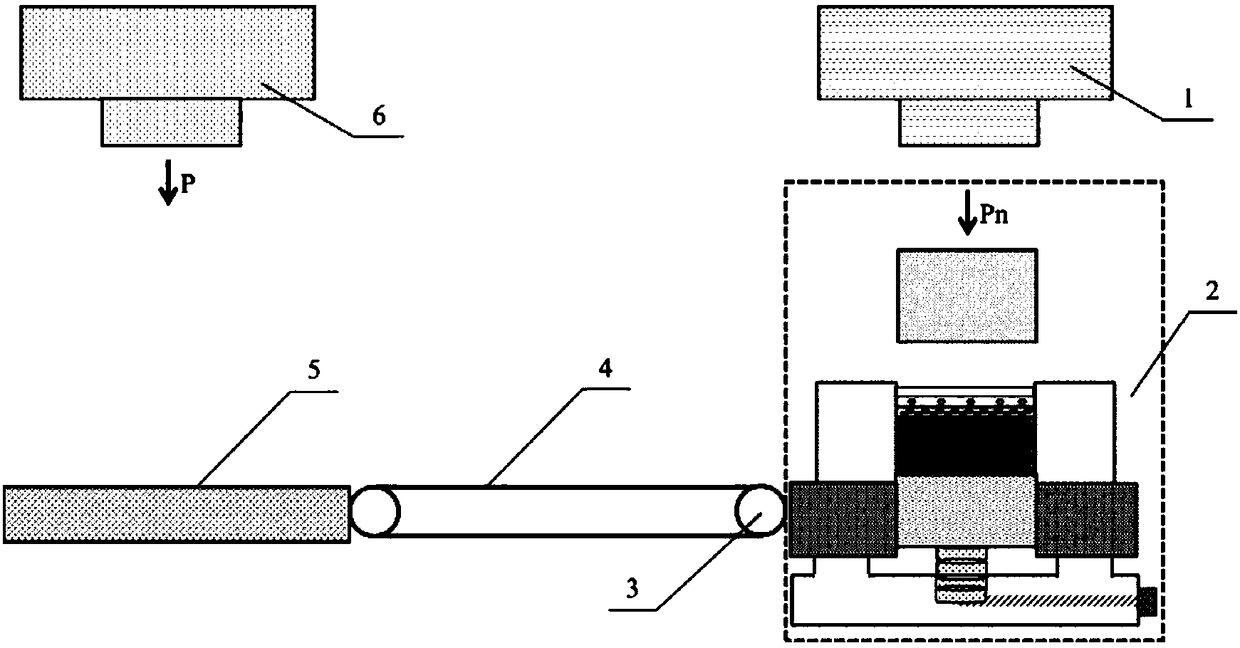

Sheet stacker and method for stacking sheets

ActiveCN104418101ARealize continuous operationAchieve recordControl devices for conveyorsStacking articlesProduction lineEngineering

The invention provides a sheet stacker, comprising a first transmission device, a second transmission device, a stacking device and a controller, wherein the first transmission device is higher than the second transmission device; the second transmission device is arranged in front of a sheet output end of the first transmission device; a first detector is also arranged above the first transmission device, and is used for detecting whether a sheet on the first transmission device comes or not; the controller is used for detecting a sheet coming signal according to the first detector, recording the quantity of coming sheets, and controlling the stacking device to convey the stacked sheets to the second transmission device after the rated quantity of sheets are received and stacked. The invention also provides a method for stacking sheets employing the sheet stacker. According to the sheet stacker disclosed by the embodiment of the invention, the controller is used for detecting the signal through the first detector, so as to control the stacking device, thus accurate control on the sheet stacking action and the sheet quantity is achieved; continuous operation is achieved; the sheet stacker can be applied to a streamlined production line.

Owner:BEIJING NEW BUILDING MATERIALS PLC

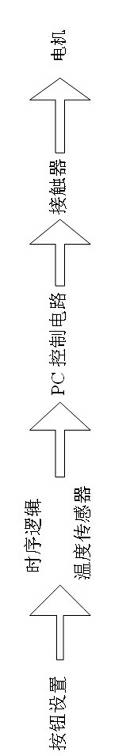

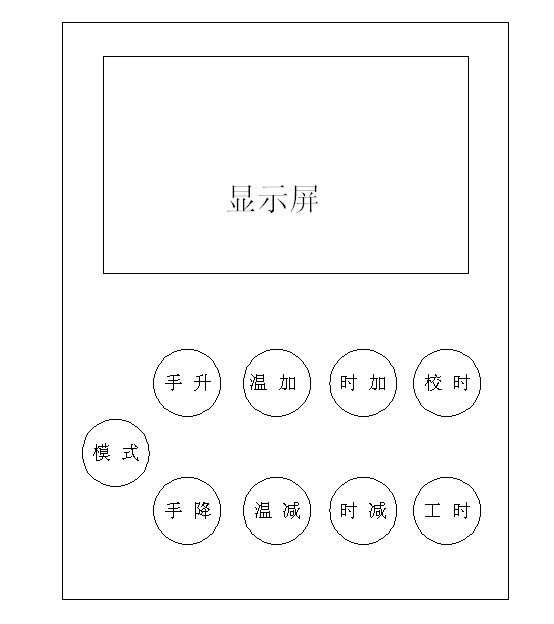

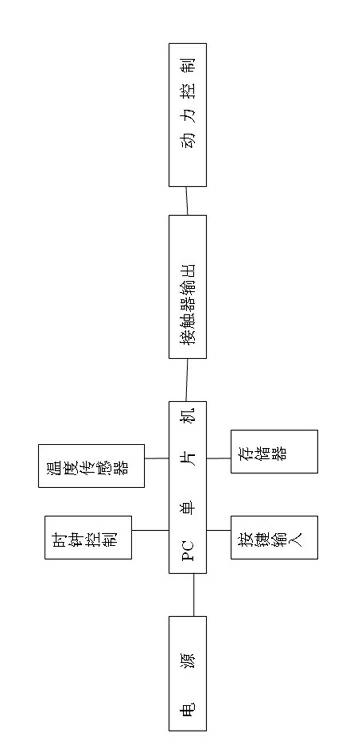

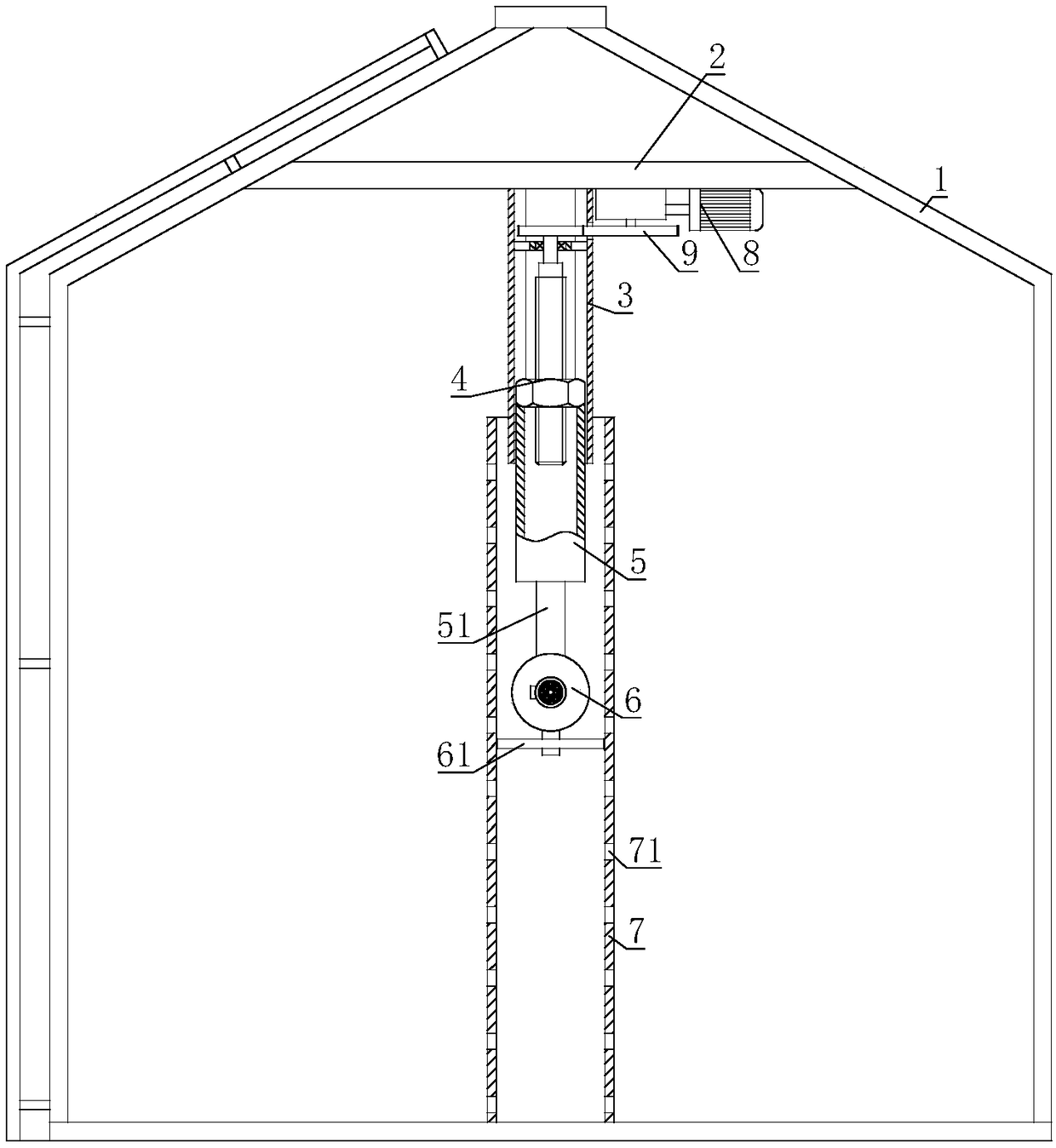

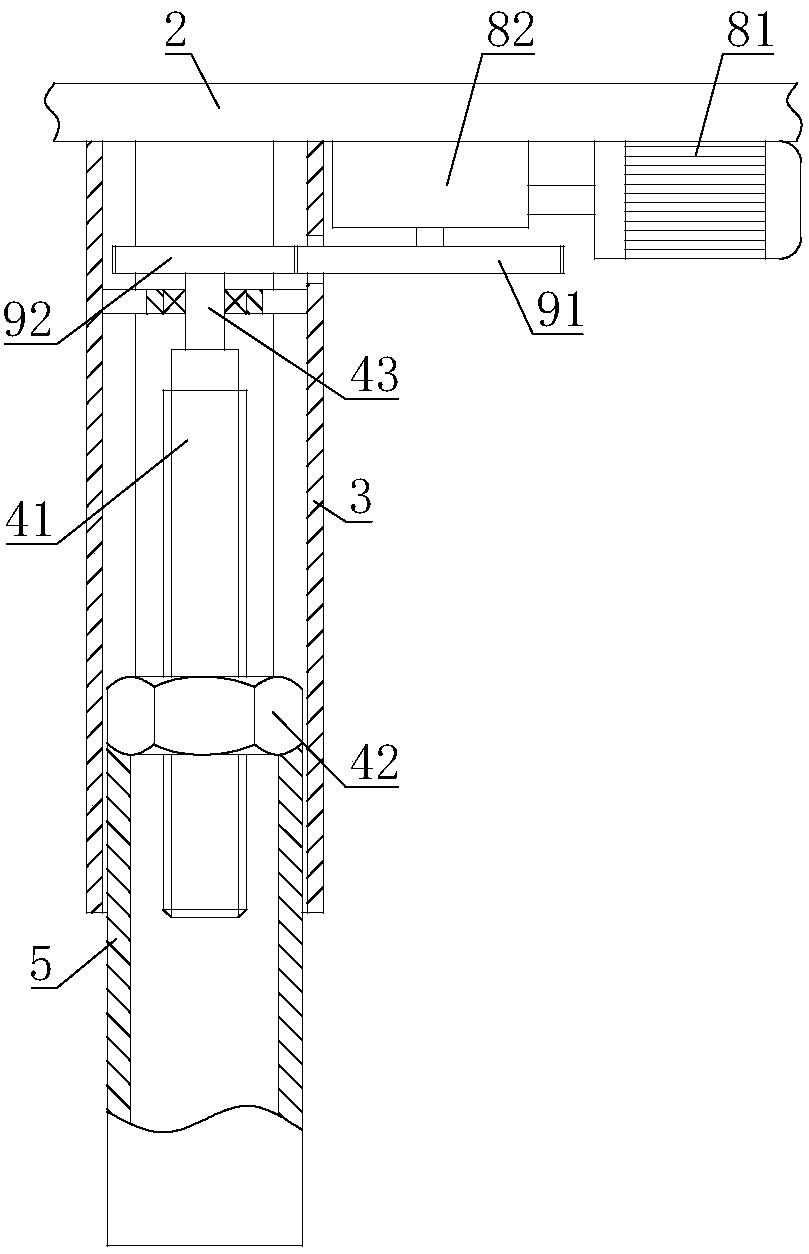

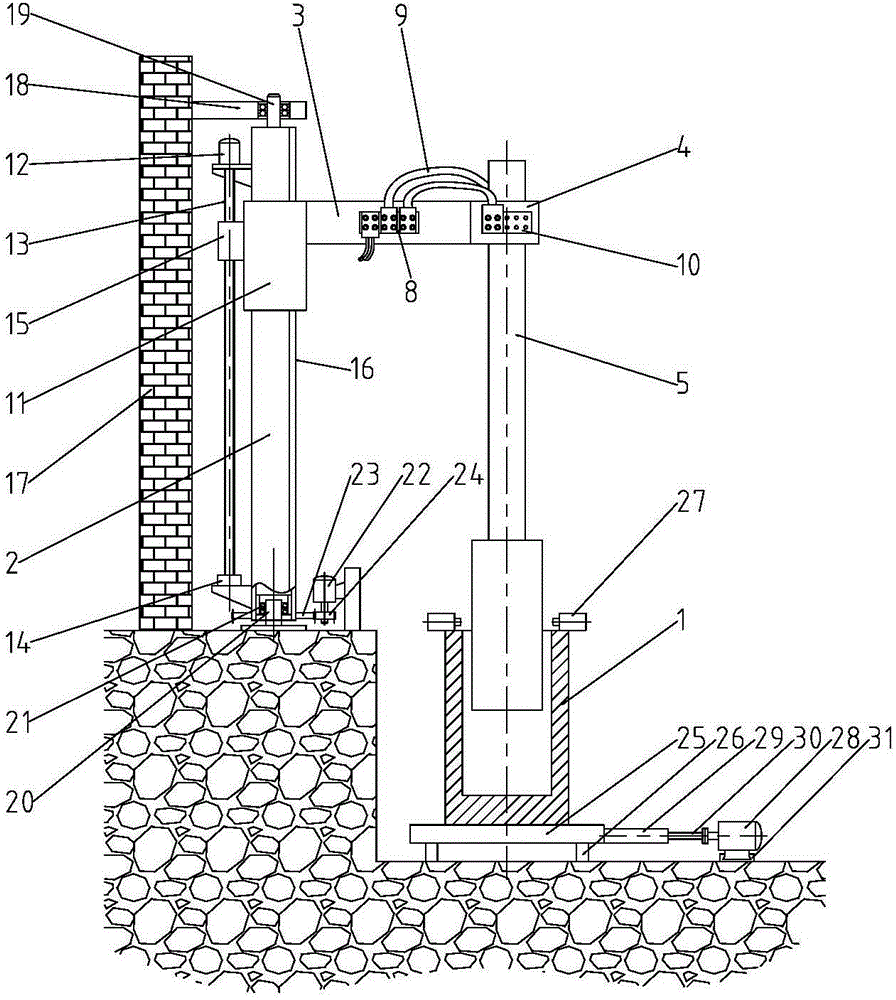

Lifting controller of curtain coiling machine of greenhouse

InactiveCN102540932AMeet growth needsPrecise control of lifting heightClimate change adaptationGreenhouse cultivationInformation controlGreenhouse

The invention relates to a lifting controller of a curtain coiling machine of a greenhouse, which comprises a personal computer (PC) control circuit, a temperature sensor, a contactor and a motor of a curtain coiling machine, wherein the PC control circuit is respectively connected with the contactor and the temperature sensor, and the contactor is connected with the motor of the curtain coiling machine; and the PC control circuit comprises a control chip and also comprises a display and an operating button which are connected with the control chip. The lifting controller of the curtain coiling machine of the greenhouse is safe and reliable and conforms to the special agricultural requirement of protected agriculture. By the double-information control of time-sequence logic and temperature, the requirement of growth of crops is ensured. By setting through intellectualized remote manual operation, the lifting height of a coiling curtain and the light irradiation time and temperature in the greenhouse can be accurately controlled, and the aim of instant management without manpower is realized.

Owner:TANGSHAN LANTUO MACHINERY EQUIP

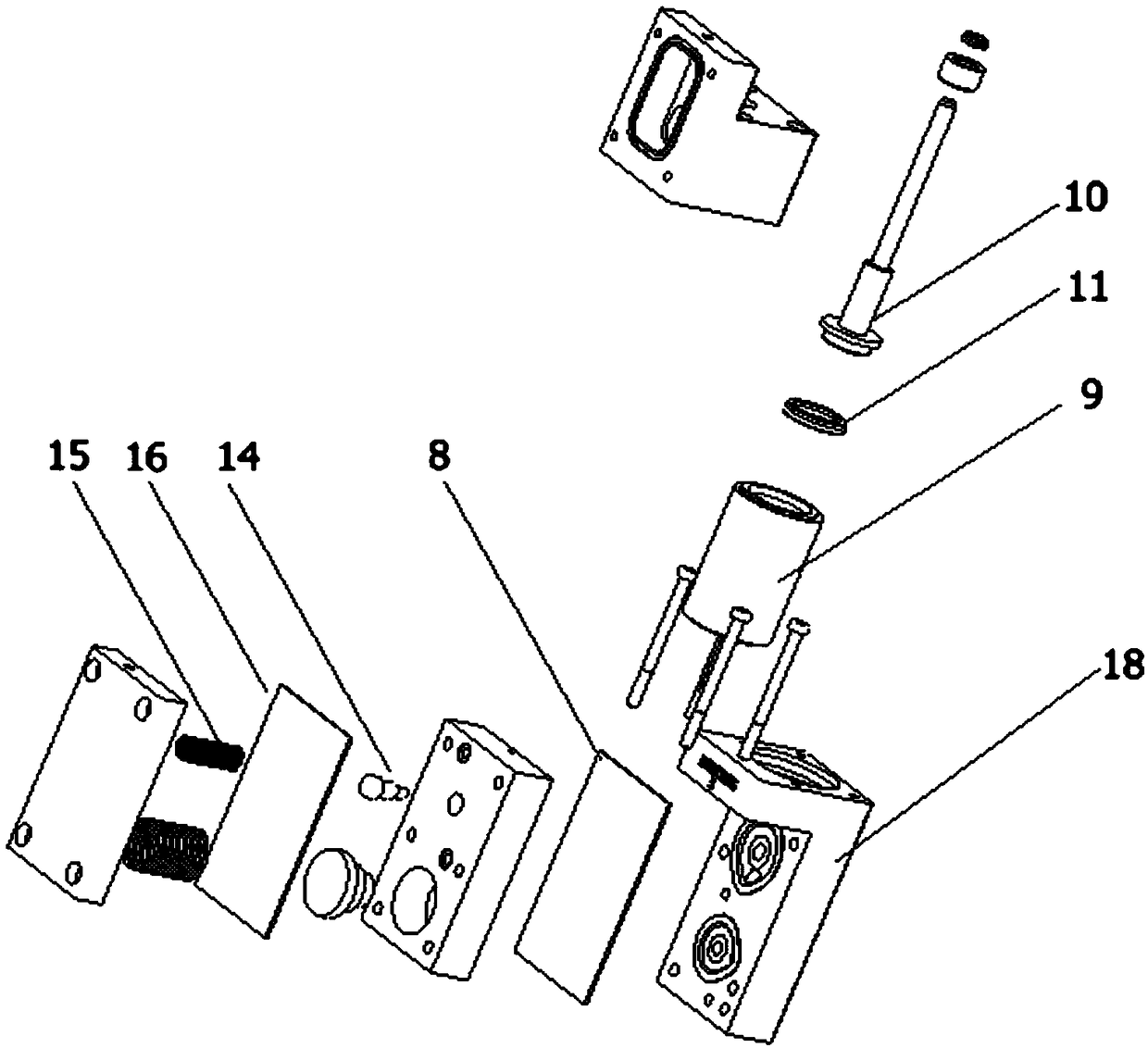

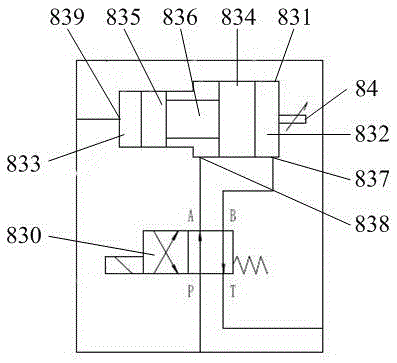

Piston type metering valve

PendingCN108999982ASimplify the base structureShort work scheduleLiquid surface applicatorsOperating means/releasing devices for valvesEngineeringMechanical engineering

The invention relates to a piston type metering valve. The piston type metering valve comprises a glue inlet and outlet control device. The glue inlet and outlet control device comprises a base body.Water-drop-shaped grooves are formed in the upper surface of the base body, and each water-drop-shaped groove comprises a feeding inlet and a discharging outlet, is only used by one kind of glue, andis used for avoiding mixing of the glue. The glue inlet and outlet control device comprises an adapter plate. External glue supply pipelines are arranged on the adapter plate, and the feeding inlets directly communicate with the external glue supply pipelines and are used for enabling the external glue to directly flow into the water-drop-shaped grooves. Only one water-drop-shaped groove is formedin the upper end face of the base body, and only one water-drop-shaped groove is formed in the lower end face of the base body. A piston rod is arranged on the glue inlet and outlet control device, and a gluing control device is arranged on the top of the piston rod. The piston type metering valve can strictly control the glue quantity, can rapidly, accurately and repeatedly conduct glue injection, avoids mixing of the glue, and is high in practicability.

Owner:江苏一控真空注胶技术有限公司

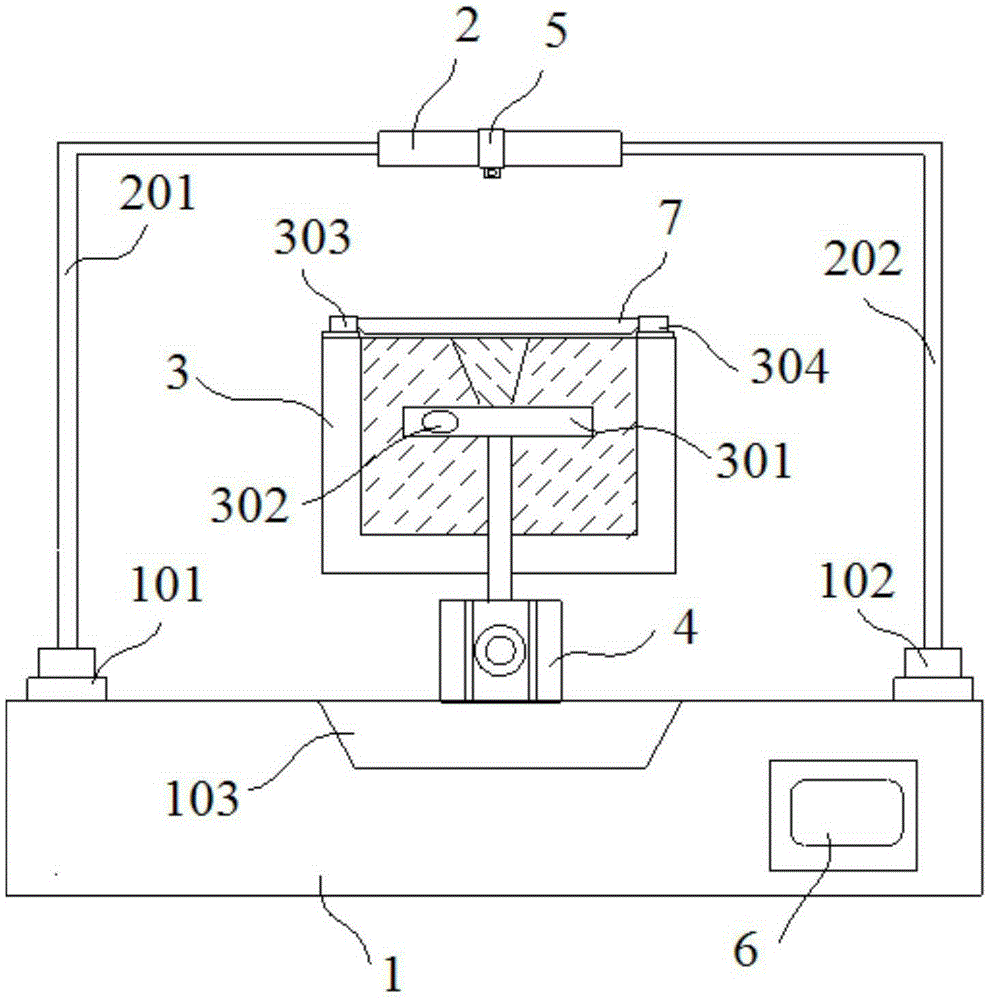

3D printing device and forming method thereof

InactiveCN105346085AImprove molding qualityPrecise control of lifting heightAdditive manufacturing apparatusEngineeringMaterial storage

The invention discloses a 3D printing device and a forming method of the device. The 3D printing device comprises a machine base, a laser radiation device, a material storage device, an air cylinder, an image sensor and a controller. As a sliding device arranged on the machine base drives the laser radiation device to slide, and a plurality of laser diodes are arranged inside the laser radiation device in an array manner, scanning forming from lines to faces can be carried out on workpieces in a large area, the forming speed is high, and the forming efficiency is high; a displacement sensor is arranged in a working platform, position information can be obtained in real time, the lifting height of the working platform can be precisely obtained, and the forming quality of the workpieces can be improved; and the image sensor is arranged so that a formed layer section image can be obtained and sent to a controller, the layer section image can be compared with data of stored layer section, printing correctness of each layer section can be ensured, and the forming quality of the workpieces can be further improved. The device is simple in structure, convenient to operate, good in forming quality, high in forming speed and suitable for large-scale industrial production.

Owner:SUZHOU SUNSHINE LASER & ELECTRONICS TECH CO LTD

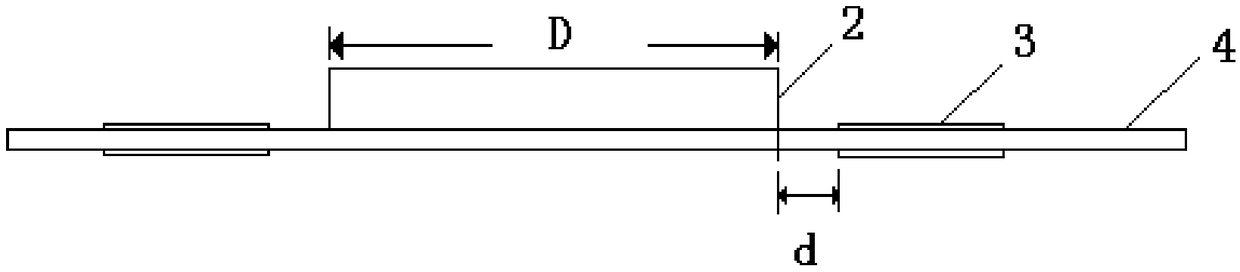

Electronic assembly welding method for automatic elevated wave soldering of components

InactiveCN109104827AImprove work efficiencyPrecise control of lifting heightPrinted circuit assemblingSoldering apparatusStress concentrationElectronic assemblies

An electronic assembly welding method for automatic elevated wave soldering of components is provided. The method comprises the steps of: adopting a mounting machine to mount a lifting cushion strip at the insertion position of components on a printed circuit board before insertion of components, wherein the thickness delta of the lifting cushion strip is 0.2 to 1mm; inserting the components, andafter inserting the components, supporting the main body of the components on the elevating cushion strip; after the wave soldering, withdrawing the elevating cushion strip from the bottom of the component body. The elevating cushion strip is used for automatically lifting a component device, so that work efficiency of the components is improved; the elevating cushion strip can precisely control the elevation height, so that the method prevents the inconsistent and unreasonable elevation height on both sides of the component and solves the defects of pin deformation and stress concentration caused by the unreasonable elevation height. In addition, mounting the elevating cushion strip can eliminate the risk of veneer installation between the component and the printed circuit board with barecircuit on the surface during the insertion process and improve the service reliability of the printed circuit board.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Integrated pump station with decontamination device

ActiveCN113073729AImprove stabilityRealize shredding operationFatty/oily/floating substances removal devicesSewerage structuresEnvironmental engineeringMechanical engineering

The invention discloses an integrated pump station with a decontamination device, and belongs to the technical field of decontamination, the integrated pump station comprises a water inlet pipe, one end of the water inlet pipe is fixedly connected with a crushing mechanism, and the end, away from the water inlet pipe, of the crushing mechanism is fixedly connected with an adjusting mechanism. A crushing pneumatic push rod works to drive a sliding push plate to move through a push plate, the sliding push plate drives a lifting plate to move through supporting connecting plates, the two sets of supporting connecting plates can conveniently drive the lifting plate to move in parallel, and the movement stability of the lifting plate is improved. By changing the height of the lifting column, the distance between the movable crushing plate and the fixed crushing plate is adjusted, waste of different specifications can be conveniently crushed, and the problem that due to the fact that the size of the waste is too large, a pipeline is blocked is solved.

Owner:HANGZHOU ATT PUMP IND LIMITED

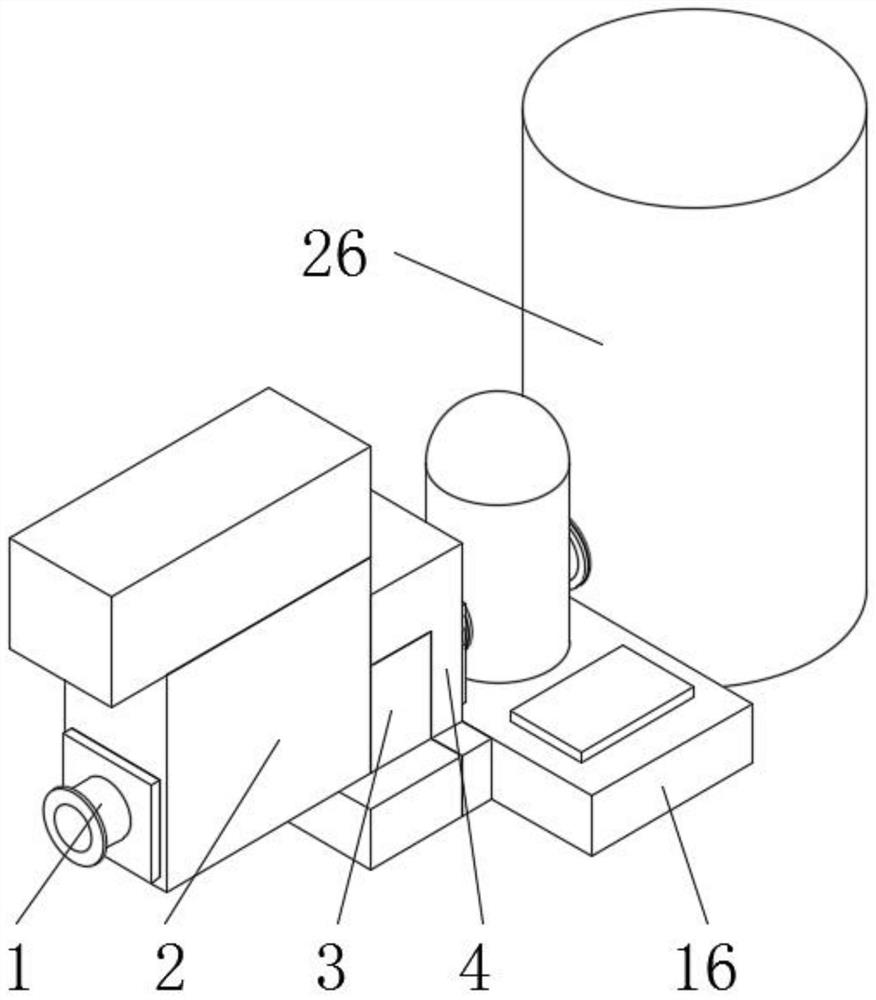

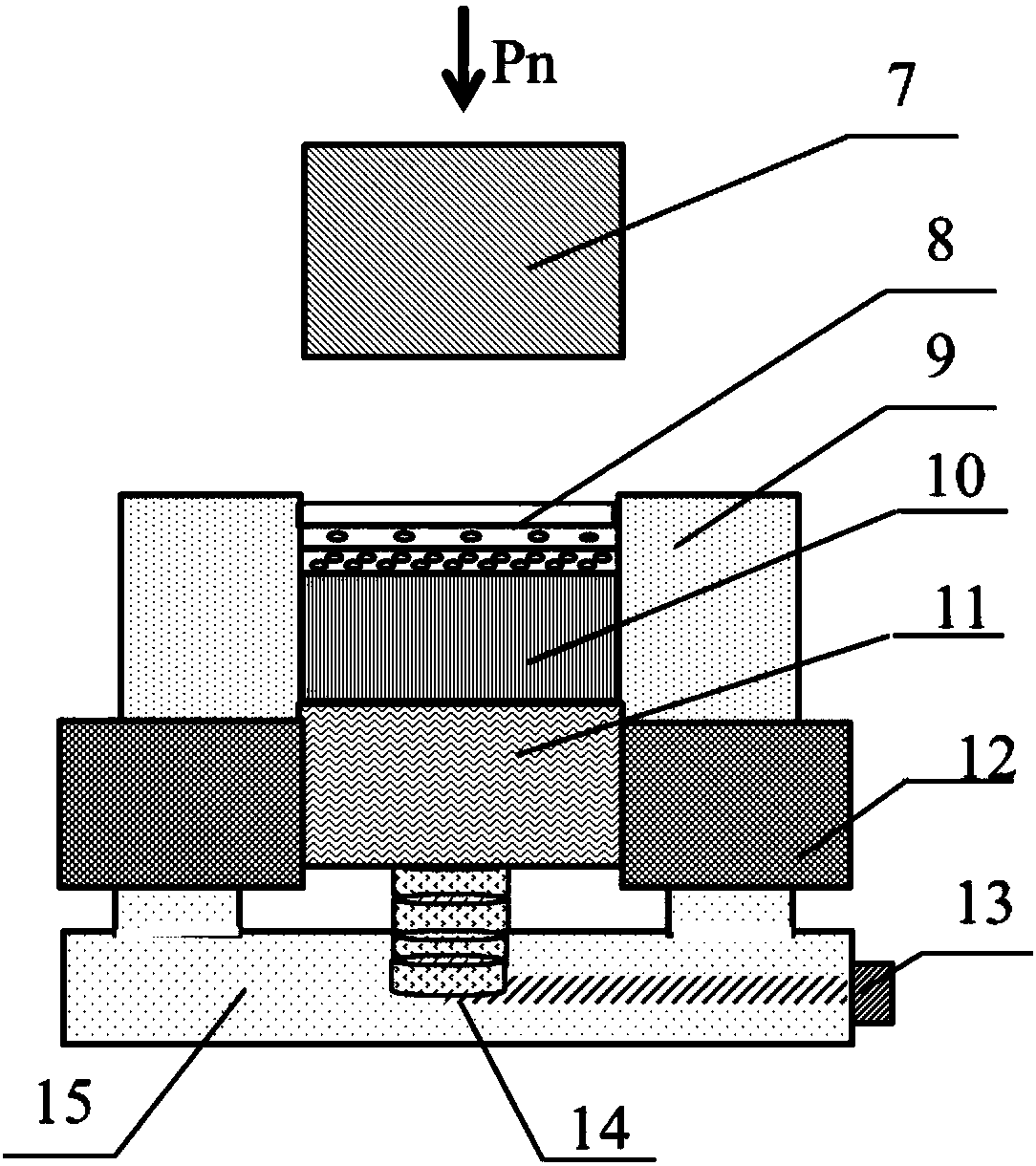

Forming device and application of large-size ultra-thin powder metallurgy gradient material

PendingCN108326297AImprove bindingPrecise control of lifting heightGradient materialMeasuring instrument

The invention belongs to the field of powder metallurgy forming equipment, and particularly relates to a forming device and application of a large-size ultra-thin powder metallurgy gradient material.The forming device of the large-size ultra-thin powder metallurgy gradient material comprises a pre-pressing forming system and a laminating powder laying forming system; and the laminating powder laying forming system is composed of a mold upper pressing head, a mold sleeve, a mold lower pressing head, a spiral height control instrument lifting table, a spiral height control instrument platform,a spiral rotary knob, a lifting screw rod and a height control instrument base. The laminating powder laying forming system of the forming device of the large-size ultra-thin powder metallurgy gradient material organically combines a spiral height measuring instrument and mold pressing forming, laminating powder laying with the descending height at the micron level is achieved, laying uniformity of each layer of power is guaranteed, and due to the fact that a mold can be replaced at any time, it can be achieved that sample forming blank bodies in different sizes are prepared. The forming device of the large-size ultra-thin powder metallurgy gradient material achieves integration of multi-layer powder laying, prefabricating forming and final forming in the powder metallurgy technology, thepressing forming performance is good, and thickness control of each layer is accurate.

Owner:CENT SOUTH UNIV

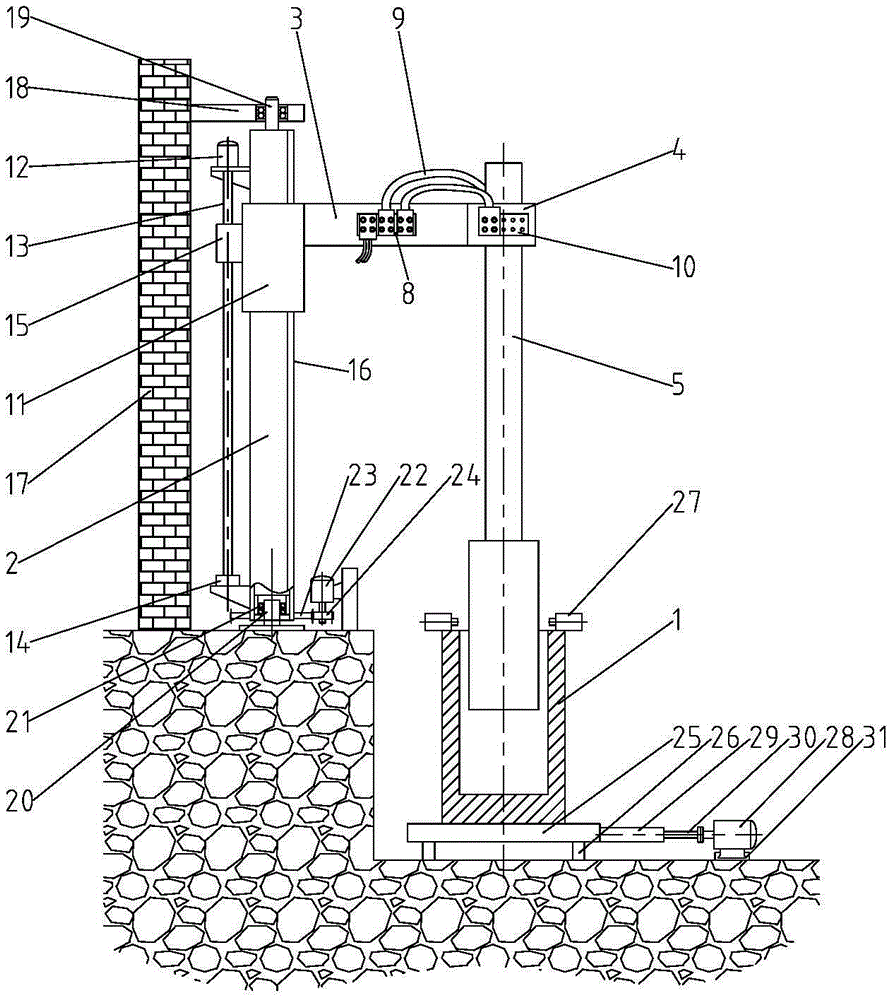

Electroslag remelting furnace with accurate positioning function

InactiveCN106544521APrecise control of lifting heightPrecise position adjustmentEngineeringElectro-slag remelting

The invention discloses an electroslag remelting furnace with the accurate positioning function. The electroslag remelting furnace with the accurate positioning function comprises a crystallizer and a vertical supporting column located on one side of the crystallizer; the vertical supporting column is provided with a transverse arm in sliding fit with the vertical supporting column; the end, away from the vertical supporting column, of the transverse arm is located above the crystallizer and provided with a holder; an electrode extending into the crystallizer is clamped and fixed to the holder; the electroslag remelting furnace with the accurate positioning function further comprises a transverse arm lifting mechanism used for controlling lifting of the transverse arm, a stand column rotation mechanism used for controlling the vertical supporting column to rotate, and an electrode centering mechanism used for centering and positioning of the crystallizer and the electrode; the electrode centering mechanism comprises a supporting seat fixedly arranged below the crystallizer and a position adjusting mechanism used for adjusting the position of the supporting seat; the crystallizer is fixedly installed on the supporting seat; universal idler wheels are arranged below the supporting seat; and photoelectric sensors used for detecting the position of the electrode are annularly and evenly arranged on the top face of the crystallizer.

Owner:RONGCHANG XINDA MACHINERY FORGING CO LTD

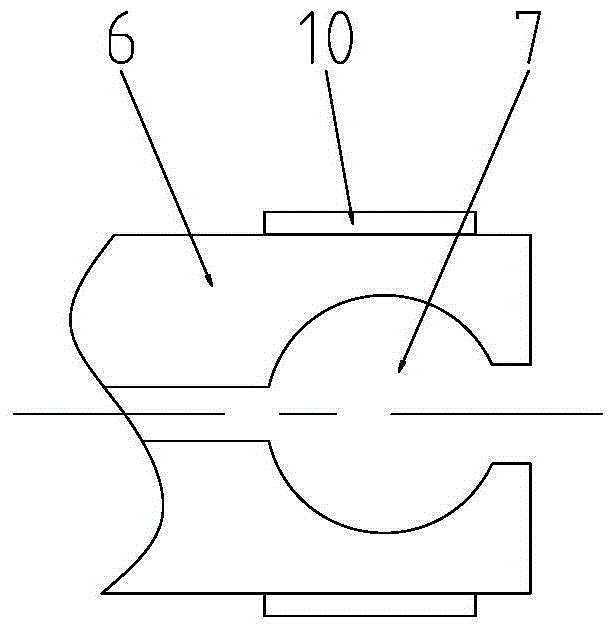

Stroke detection device for crane steel rope

InactiveCN104355234APrecisely control the descending strokePrecise control of lifting heightLoad-engaging elementsEngineeringBlock and tackle

The invention relates to a stroke detection device for a crane steel rope. The stroke detection device comprises a pulley block composed of at least three pulleys, wherein a displacement sensor is arranged on one pulley. Compared with the prior art, the stroke detection device has the advantages as follows: as one pulley block is used, the close fit of the steel rope and the pulleys can be ensured, and the stroke of the hoisting steel rope can be precisely detected, the stroke detection device can carry out overwinding and overunwinding limiting of a crane and can accurately control the position of a grab hook. The invention further relates to a limiting and controlling method for a crane hoisting mechanism using the detection device.

Owner:韶关市博仕乐液压机械制造有限公司

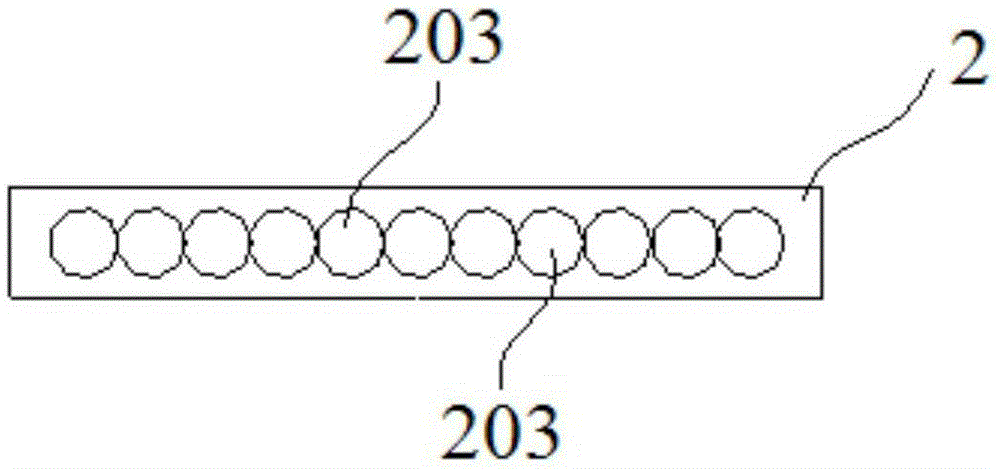

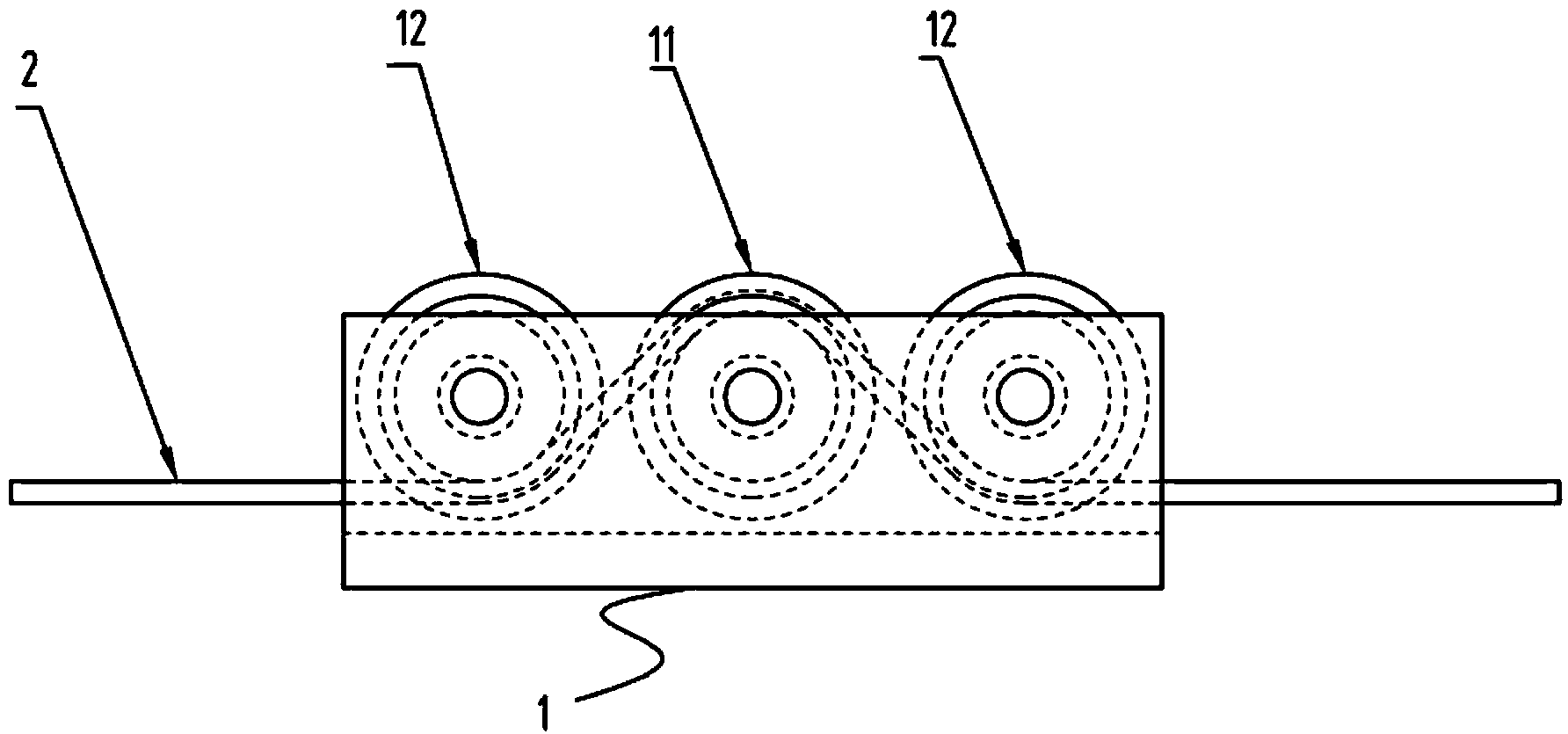

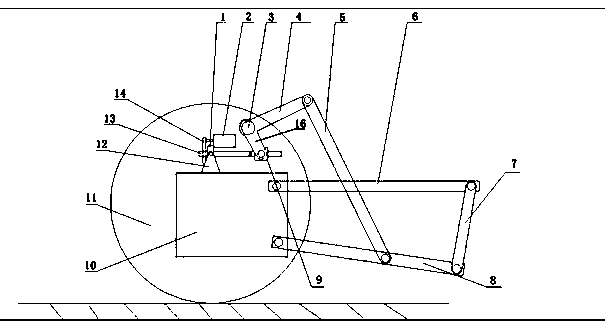

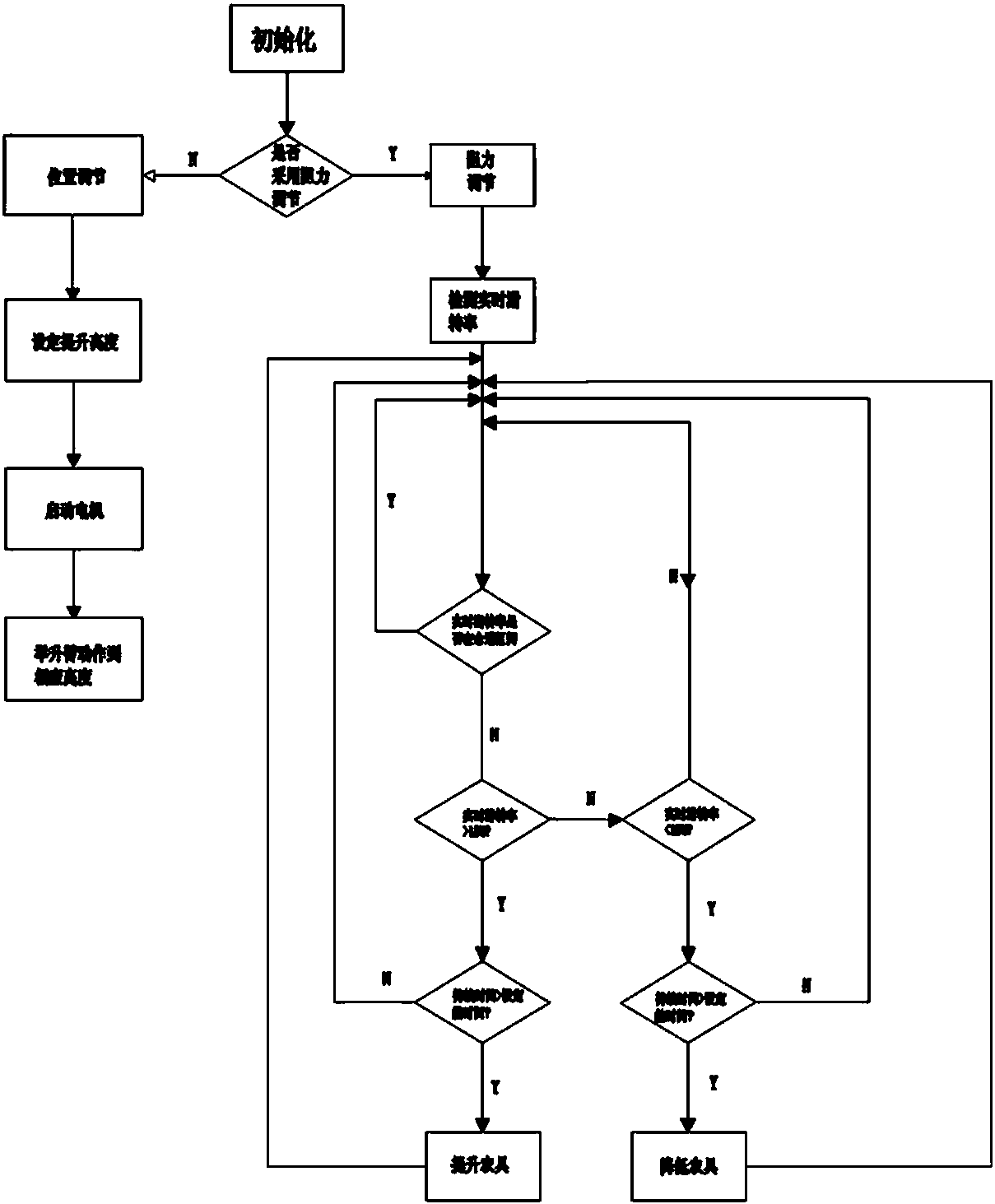

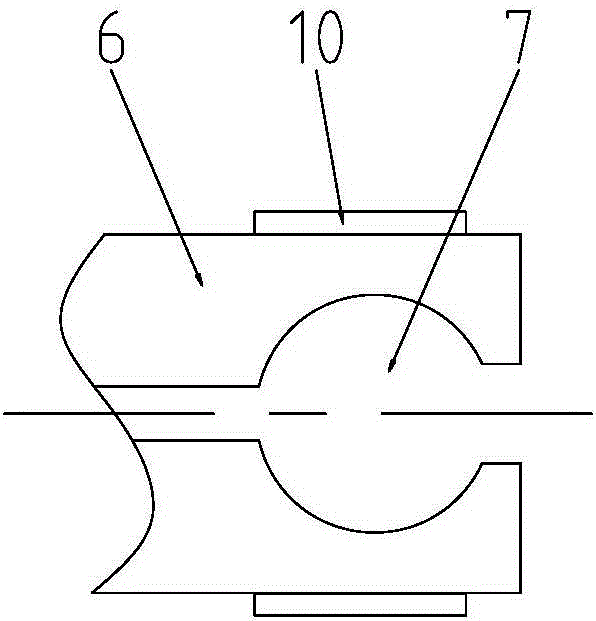

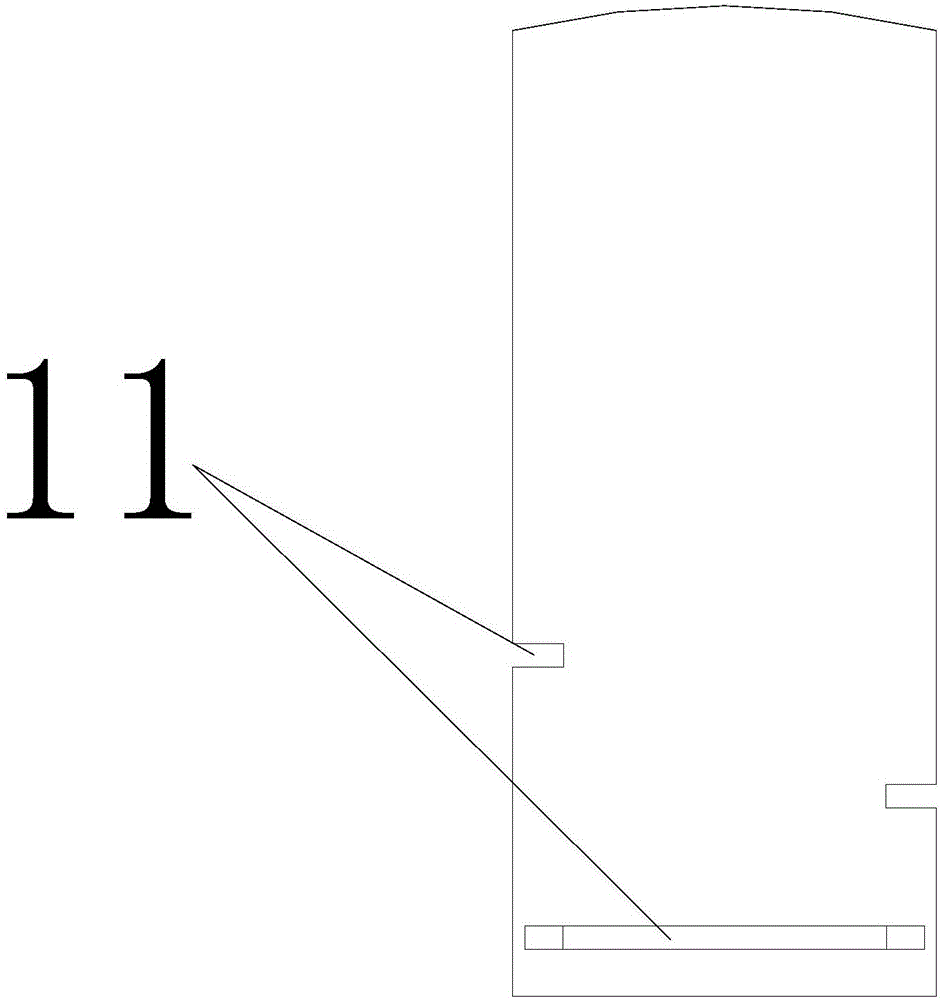

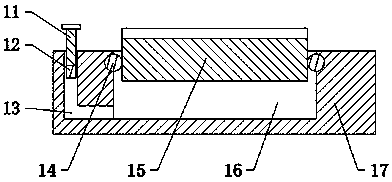

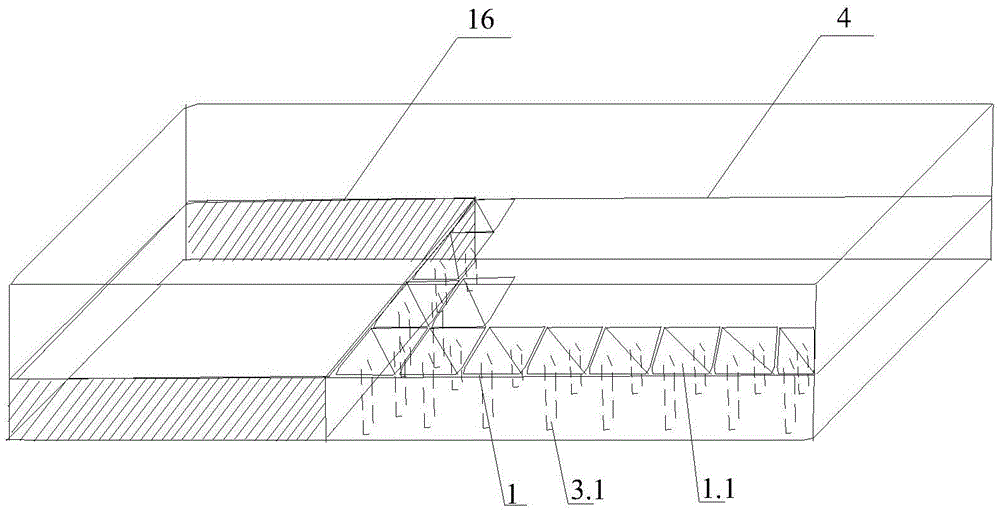

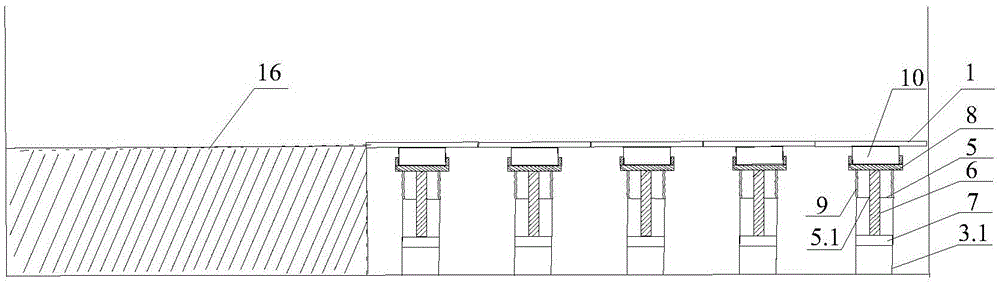

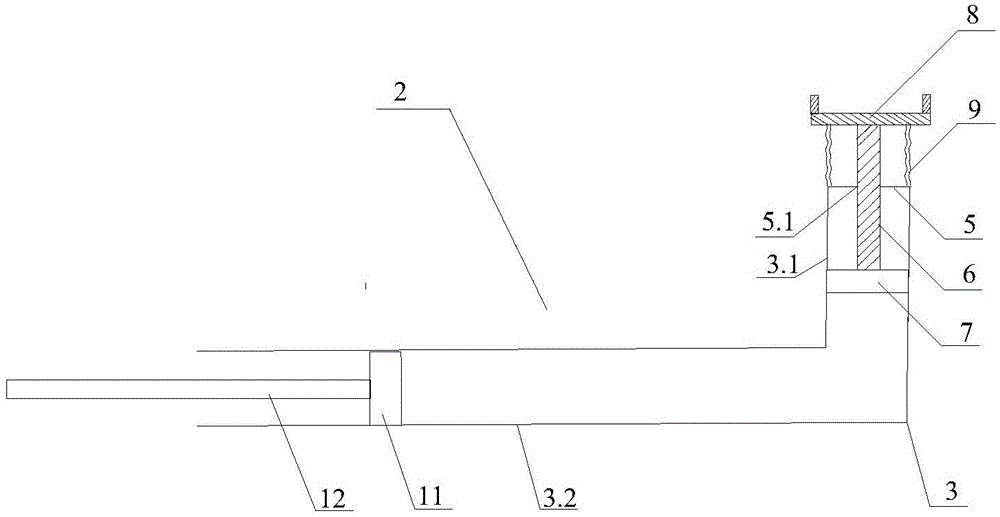

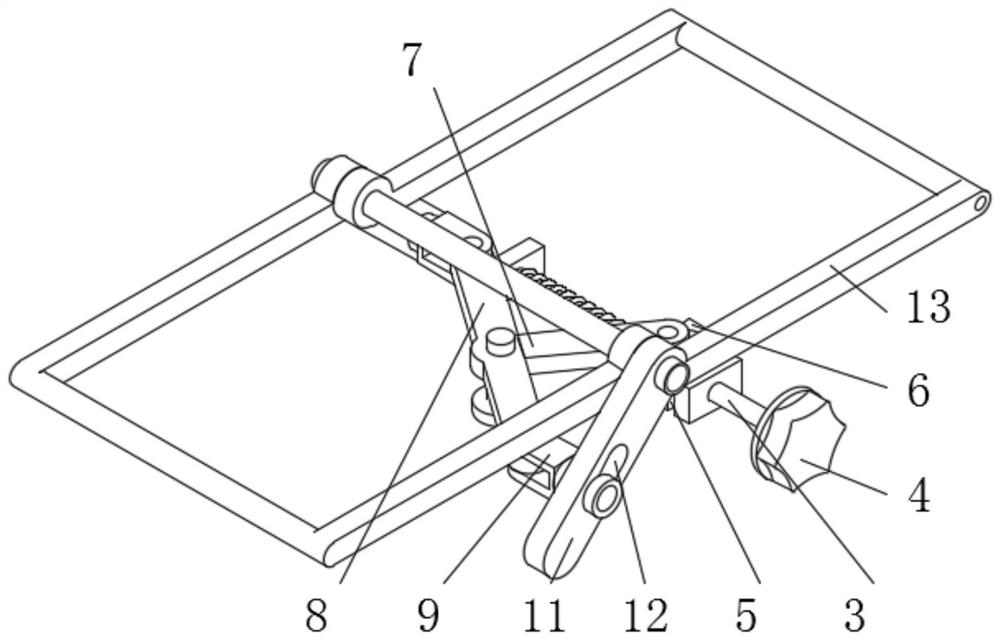

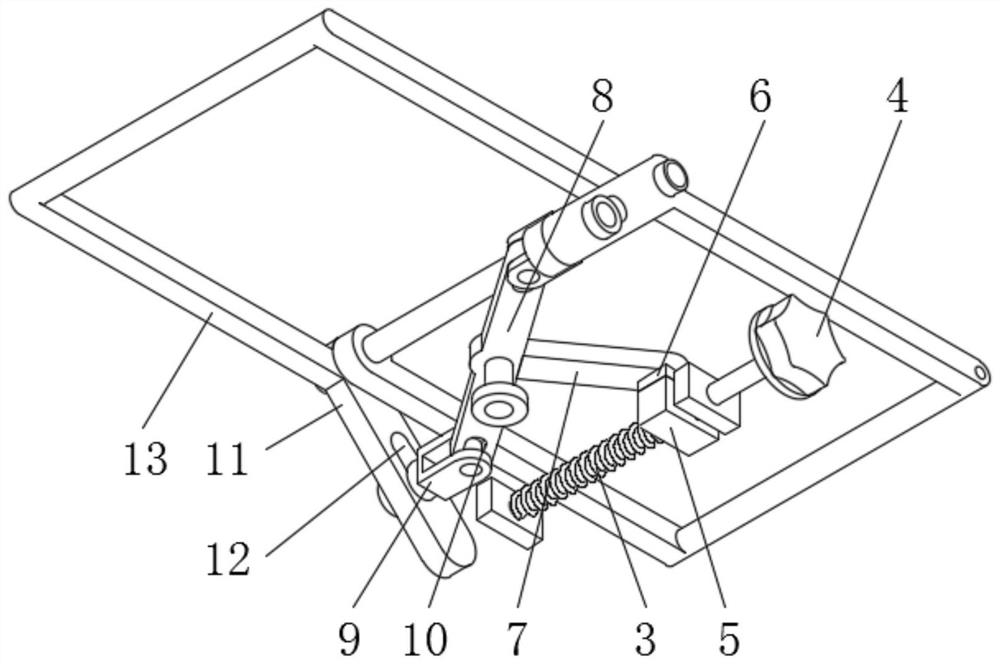

Control method for screen lifting platform capable of accurately controlling lifting distance and off-grid speed

InactiveCN109263272APrecise liftingReduce stroke errorScreen printersPrinting press partsScreen printingEngineering

The invention discloses a control method for a screen lifting platform capable of accurately controlling lifting distance and off-grid speed, and the method solves the problem of poor controllabilityof lifting distance and off-grid speed existing in the existing lifting platform. According to the lifting height of the lifting platform required by the screen printing process, the rotation angle ofa servo motor (11) is calculated, and the accurate lifting of a rectangular lifting platform base seat plate (1) is realized by controlling the rotation angle of the servo motor (11), and a synchronous belt (10), synchronous belt wheels (9) and a trapezoidal lead screw (6) in sequence; a screen printing platform plate (4) can slowly separate and rapidly rise when the screen printing platform plate (4) is separated from a printed raw ceramic sheet by controlling the servo motor (11), the 120-time reduction of stroke error is realized, and the platform lifting height and lifting speed can be accurately controlled.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 2 RES INST

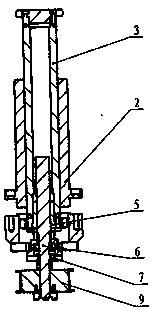

Grain elevator capable of ventilating determined position

InactiveCN108271542AFix rotPrecise control of lifting heightAgriculture tools and machinesHarvested fruit hanging devicesGrain elevatorAgricultural engineering

The invention relates to the field of grain storage equipment, in particular to a grain elevator capable of ventilating the determined position. According to the technical scheme, the grain elevator capable of ventilating the determined position comprises a grain elevator body; a transverse plate is connected to the top of the grain elevator body, a sleeve is fixedly arranged on the transverse plate, a lead screw and nut mechanism is connected to the sleeve, a lifting pipe is connected to the other end of the lead screw and nut mechanism, a lifting rod is connected to the other end of the lifting pipe, an air blower is connected to the other end of the lifting rod, a vent pipe is installed inside the grain elevator body, a plurality of vent holes are formed in the vent pipe, and the air blower and the lifting rod are sleeved with the vent pipe; a driving mechanism is installed on the transverse plate, an output shaft of the driving mechanism is connected with a transmission mechanism,and the output end of the transmission mechanism is connected with the lead screw and nut mechanism. The grain elevator capable of ventilating the determined position can effectively ventilate grains,and the problem that grains are corroded due to the fact that ventilation of an existing grain elevator is not smooth is solved.

Owner:河南创卓仓储科技股份有限公司

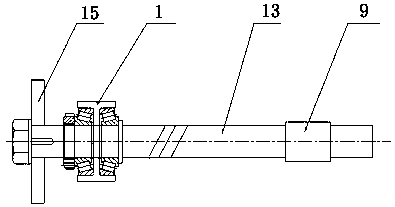

Electric suspension and lifting system for tractor and control method thereof

ActiveCN108189638AAchieve deep cultivationMeet job requirementsAgricultural vehiclesResilient suspensionsElectric machineryElectrical control

The invention discloses an electric suspension and lifting system for a tractor and a control method thereof. The suspension and lifting system comprises a mechanical structure part and an electricalcontrol part; the mechanical structure part comprises a lifting device, and the lifting device comprises a driving motor, a speed reducer and a lead screw nut mechanism; a support is fixedly arrangedon a frame, a rotation base is fixedly connected to the support, and a lead screw is arranged in a bearing in the rotation base. The electrical control part comprises a controller, a driver, a motor,a GPS velometer and a wheel speed sensor, the controller is connected with the driver, the driver is connected with the motor, the GPS velometer is arranged on the frame, and the wheel speed sensor isarranged on a driving wheel; the wheel speed sensor and the GPS velometer are in communication with the controller through CAN buses. According to the electric suspension and lifting system for the tractor, the functions of resistance adjustment and position adjustment are achieved, resistance adjustment is achieved by additionally arranging the GPS velometer and the wheel speed sensor for detecting the sliding rotation rate, and position adjustment is achieved through precise rotation of the stepping motor and a geometrical relationship of a lifting structure.

Owner:HENAN UNIV OF SCI & TECH

Electroslag remelting furnace with uniform smelting function

InactiveCN106544522APrecise control of lifting heightPrecisely control the positional relationshipElectro-slag remeltingDistributor

The invention discloses an electroslag remelting furnace with the uniform smelting function. The electroslag remelting furnace with the uniform smelting function comprises a crystallizer and a vertical supporting column located on one side of the crystallizer; the vertical supporting column is provided with a transverse arm in sliding fit with the vertical supporting column; the end, away from the vertical supporting column, of the transverse arm is located above the crystallizer and provided with a holder; an electrode extending into the crystallizer is clamped and fixed to the holder; the holder comprises two oppositely-arranged clamping pieces; a clamping cavity used for clamping the electrode is formed between the two clamping pieces; a distributor plate connected with a power supply device is arranged on the lateral wall of one side of the transverse arm; a connection cable is arranged between the distributor plate and each clamping piece; the electroslag remelting furnace with the uniform smelting function further comprises a transverse arm lifting mechanism used for controlling lifting of the transverse arm, a stand column rotation mechanism used for controlling the vertical supporting column to rotate, and an electrode centering mechanism used for centering and positioning of the crystallizer and the electrode; and photoelectric sensors used for detecting the position of the electrode are annularly and evenly arranged on the top face of the crystallizer.

Owner:RONGCHANG XINDA MACHINERY FORGING CO LTD

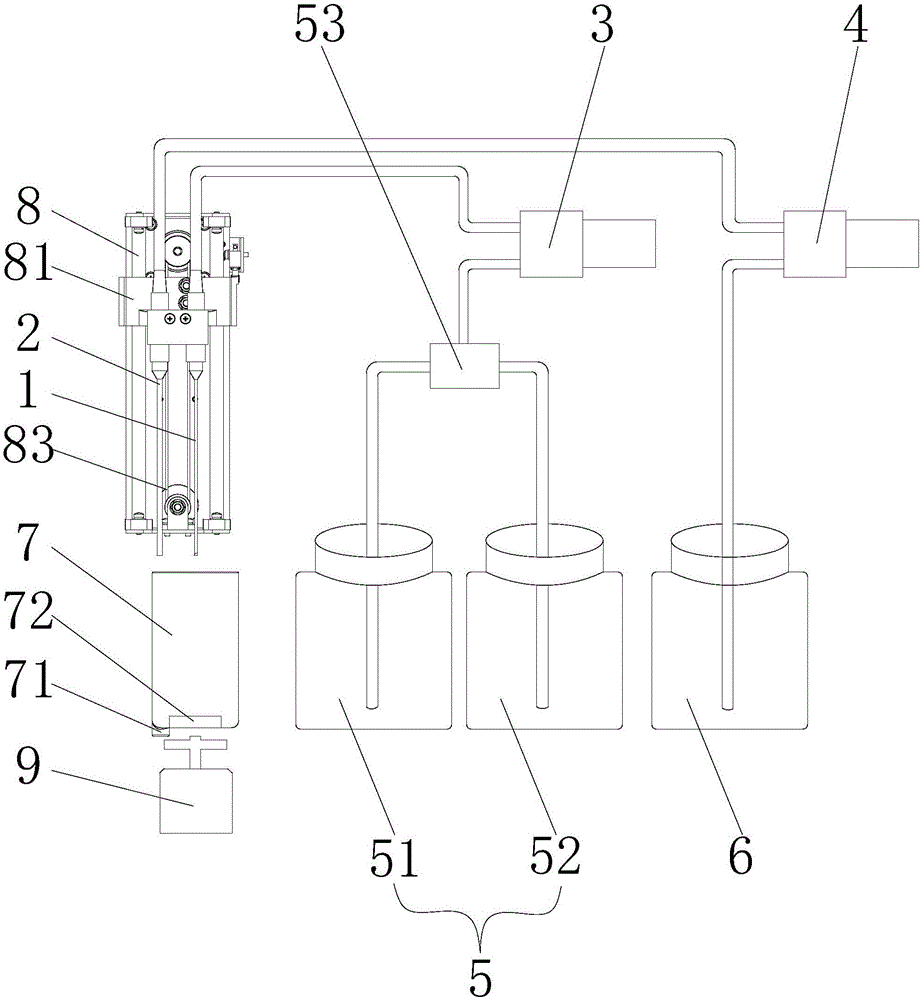

Utensil washing device

PendingCN106694490APrecise control of lifting heightEasy to cleanHollow article cleaningChemical reactionCleaning needle

The invention discloses a utensil washing device. The utensil washing device is characterized by comprising a cleaning needle and a liquid drainage needle, wherein the washing needle is connected with a washing pump through a tube; the liquid drainage needle is connected with a liquid drainage pump through a tube; the other end of the washing pump is connected with washing liquid containers containing washing liquid; the other end of the liquid drainage pump is connected with a waste liquid container; the washing needle and the liquid drainage needle extend into a utensil to be washed; the washing needle sprays the washing liquid to perform washing; and the liquid drainage needle sucks out the washing liquid. According to the utensil washing device disclosed by the invention, the washing operation and the liquid drainage operation are automatically completed without manual operation, so that the labor strength of staff is reduced; the washing efficiency is high; the washing cleanliness is high; remains and cross contamination are effectively avoided; and a subsequent chemical reaction is prevented from being influenced by residual components, so that the detection accuracy is guaranteed.

Owner:CHINA GRAIN RESERVES CORP CHENGDU GRAIN STORAGE SCI INST +1

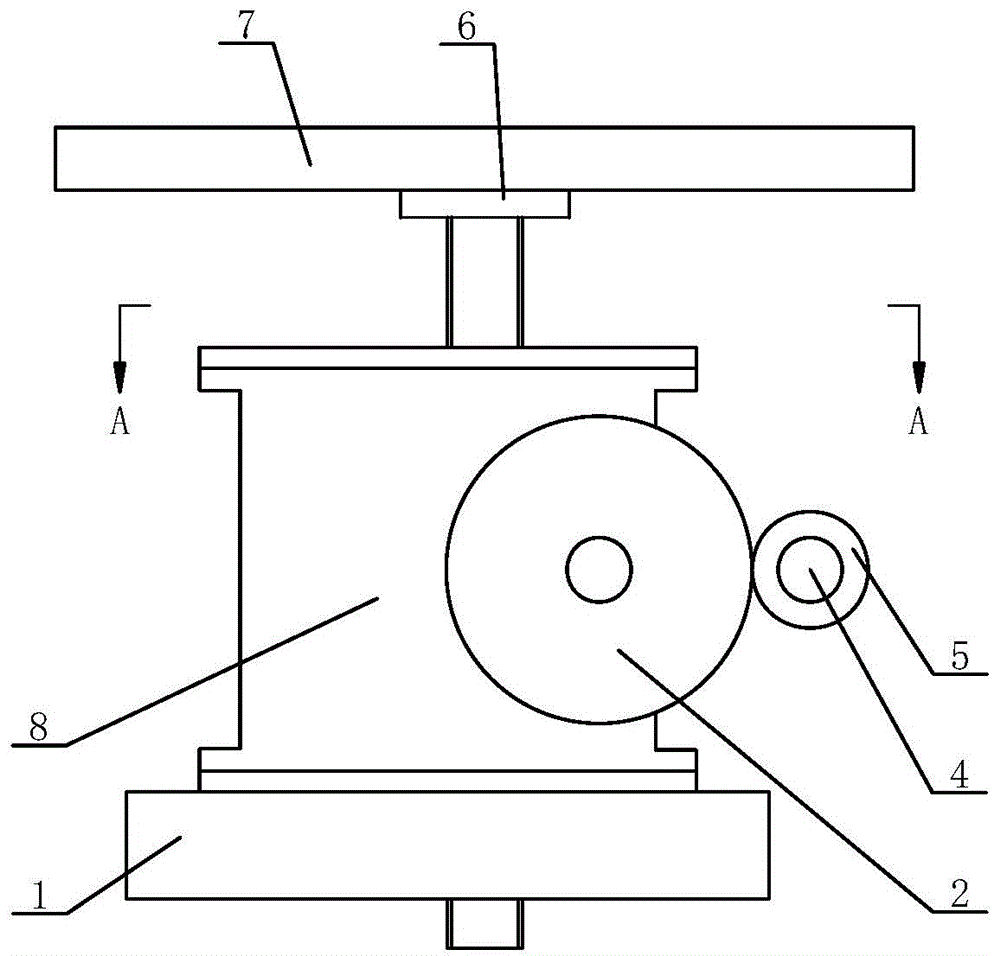

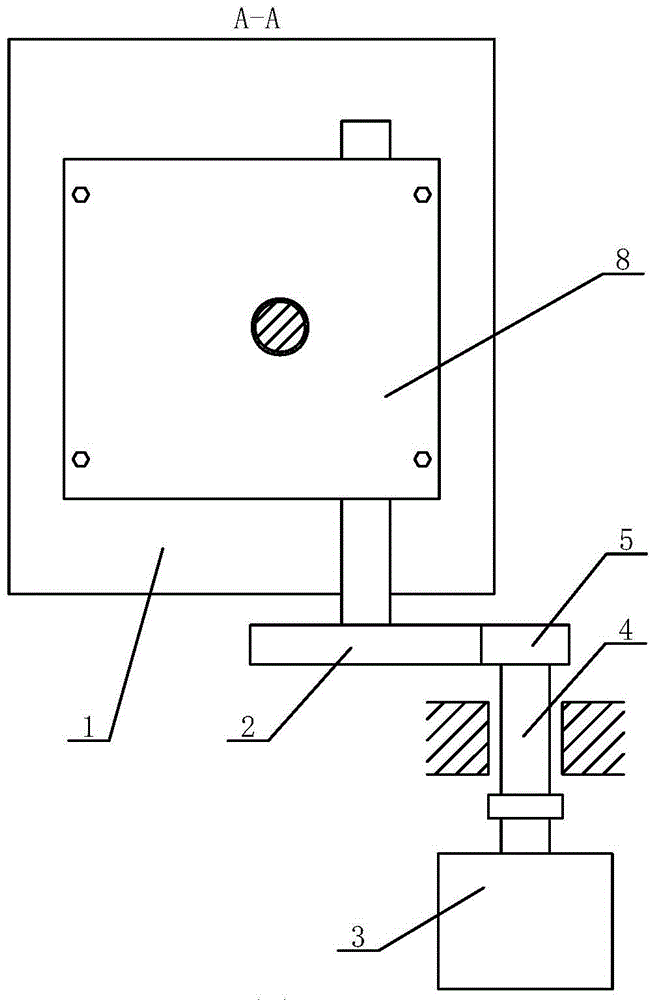

Self locking type elevating platform

The invention discloses a self locking type elevating platform comprising a base, a drive motor and at least one self locking type elevating device driven by the drive motor. The self locking type elevating device is fixedly installed on the base, the power output shaft of the drive motor is connected to one end of a gear shaft through a coupling, a second gear is fixedly installed on the other end of the gear shaft, the first gear and the second gear are engaged to form a gear pair, the first gear is fixedly installed at the end of the power input shaft of the self locking type elevating device, and a table plate is fixedly installed at the upper end of the power output shaft of the self locking type elevating device through an installing seat. The self locking type elevating platform has the advantages that design is reasonable, structure is simple, self locking can be performed at anytime, the reliability is high, the elevating height can be controlled accurately, operation is stable, rigid impacting is avoided, the service life is long, size is small, the platform is light, transportation is facilitated, using cost is low, and the adaption range is expanded.

Owner:XIAN ZHIYUE ELECTROMECHANICAL TECH

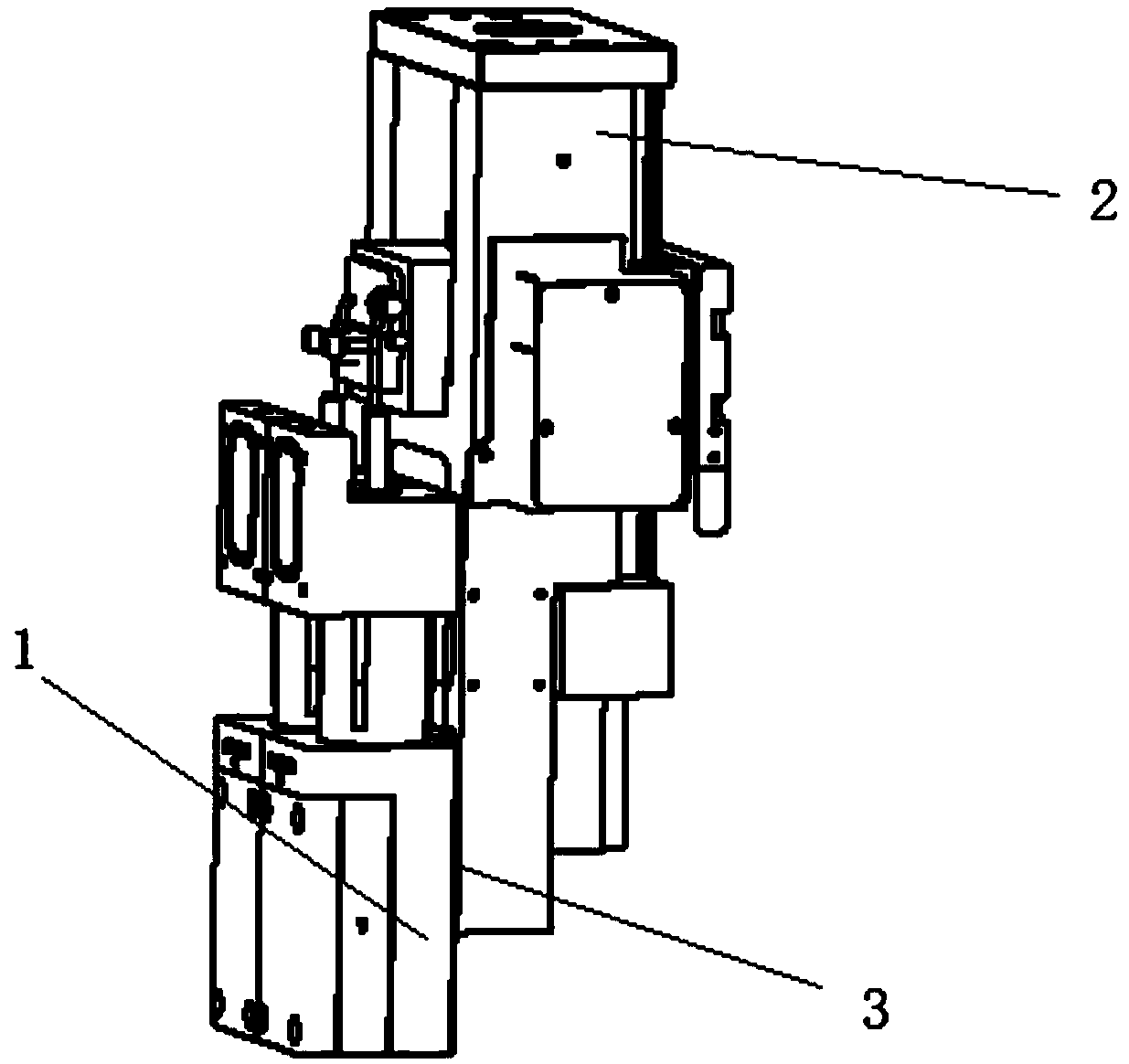

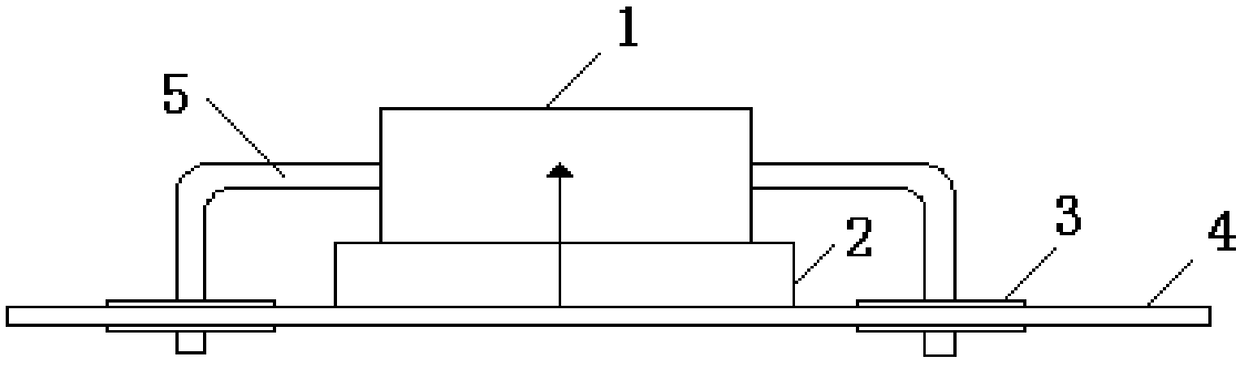

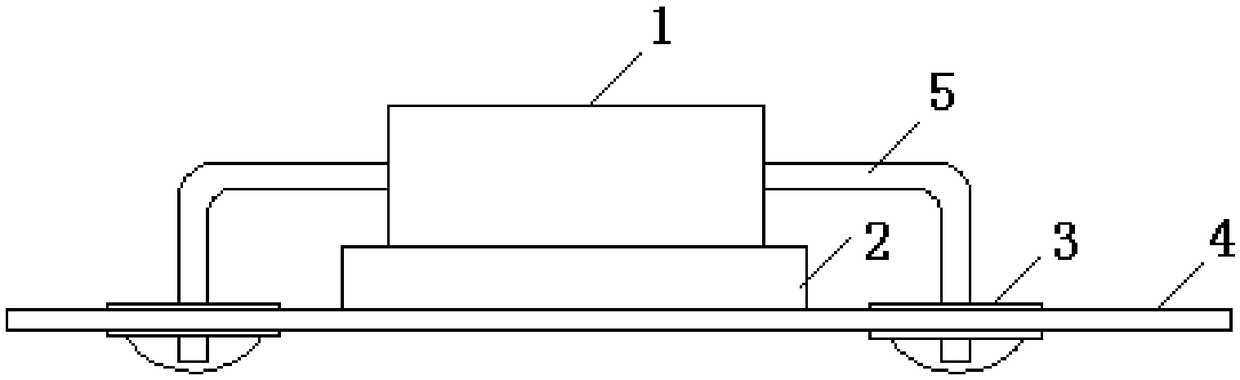

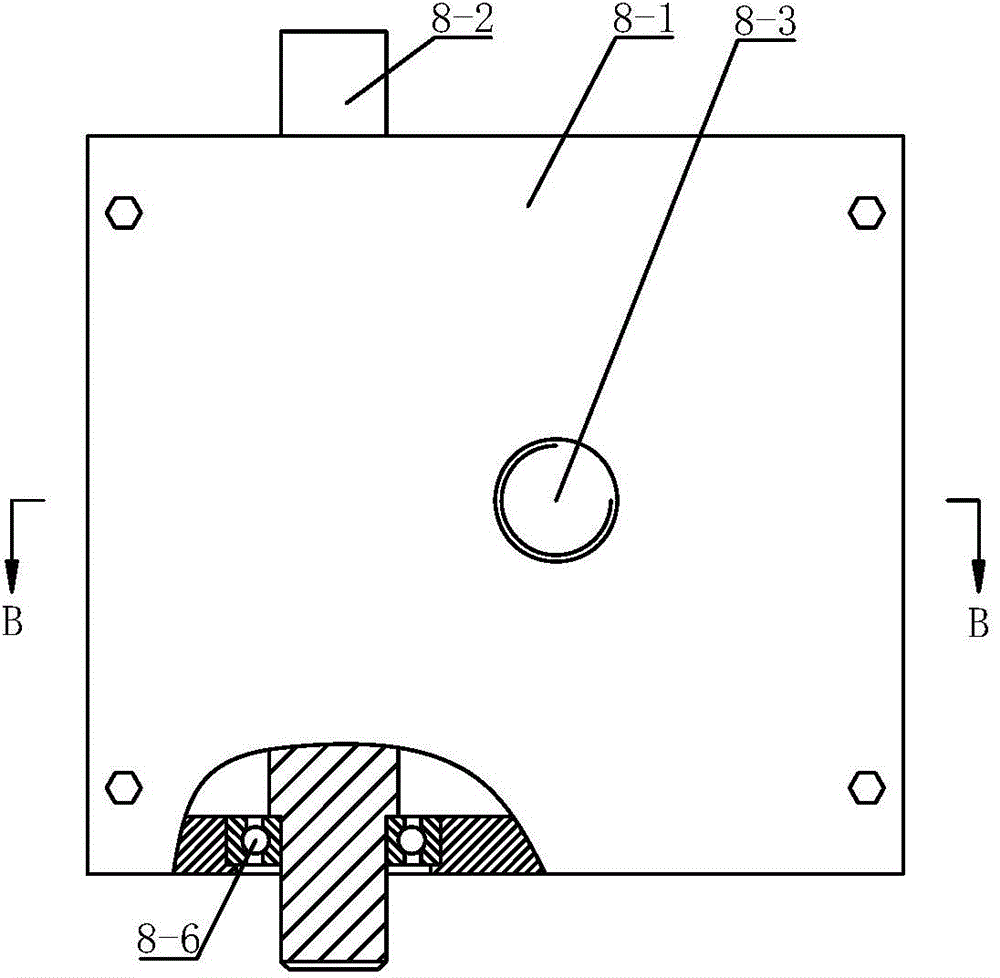

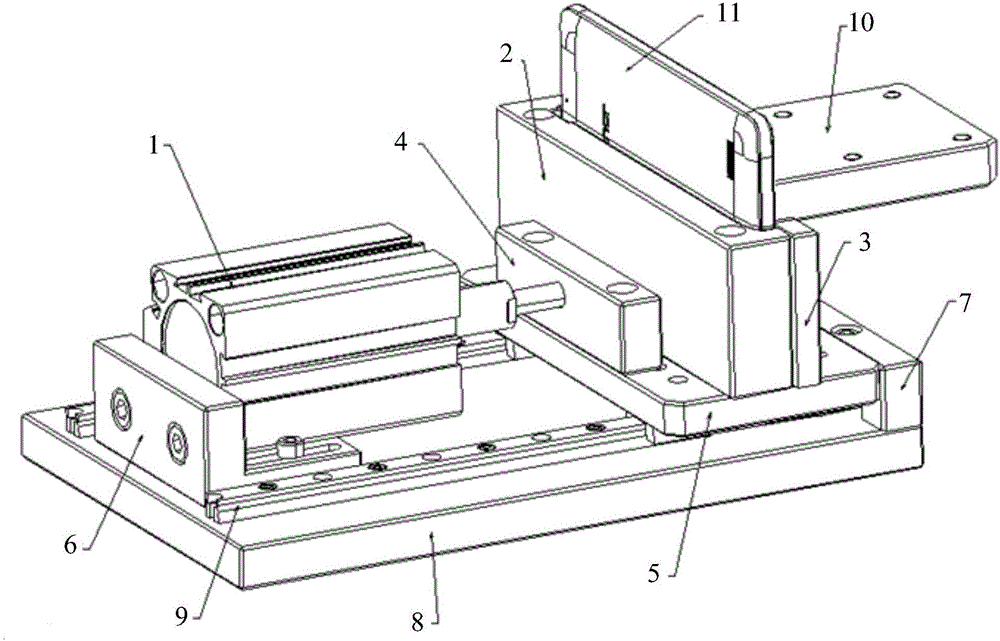

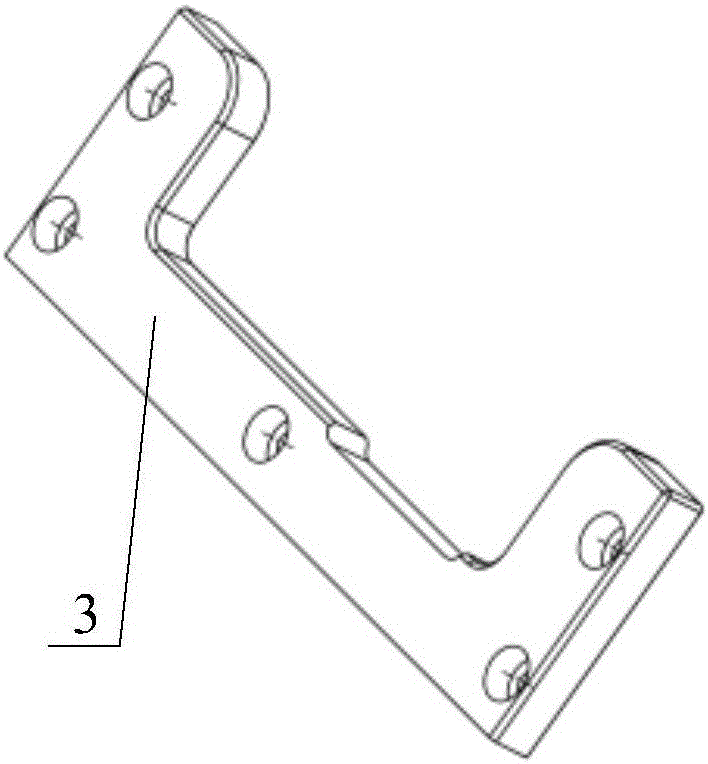

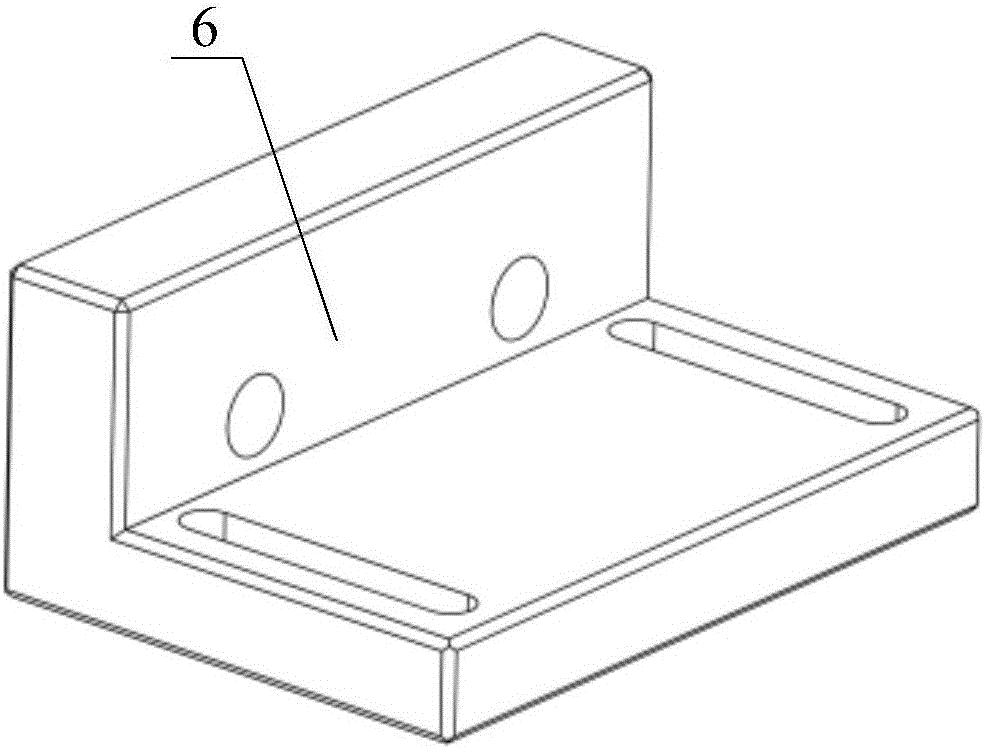

Hot melting mechanism

InactiveCN105751314AAvoid manual fixing of products to be processedAvoid the situation where the heat fusion strength is differentMetal working apparatusEngineeringHot melt

Owner:DONGGUAN GOOD MARK NEW PRECISION TECH CO LTD

Cross drilling type drilling machine

InactiveCN114309715AHighly symmetricalReduced drilling processPositioning apparatusBoring/drilling componentsClassical mechanicsMachining

The invention belongs to the technical field of drilling machines, and particularly relates to a cross drilling type drilling machine which comprises a supporting base, supporting frame columns are evenly arranged on the upper surface of the supporting base, a clamping plate is fixedly connected to the top ends of the supporting frame columns, and a control device is arranged at the axis of the lower surface of the clamping plate. And drilling devices are symmetrically arranged on the two sides of the upper surface of the clamping plate, the clamping plate comprises a modified square plate, and sliding grooves are symmetrically formed in the lower surface of the modified square plate. When the drilling device carries out drilling operation, the control device adjusts the drilling depth of the drilling device, and the plug pushing pieces on the two sides are subjected to the same stress, so that the moving distances of the plug pushing pieces on the two sides each time are certainly the same, the depths of orifices drilled by threaded drill bits on the two sides are certainly the same, and operation errors caused by manual drilling, for example, force application is not uniform, are prevented. The drilling depths of the drilling devices on the two sides are different due to the conditions of wrong reading observation and the like, and poor machining of the steel plate is caused.

Owner:黎靖

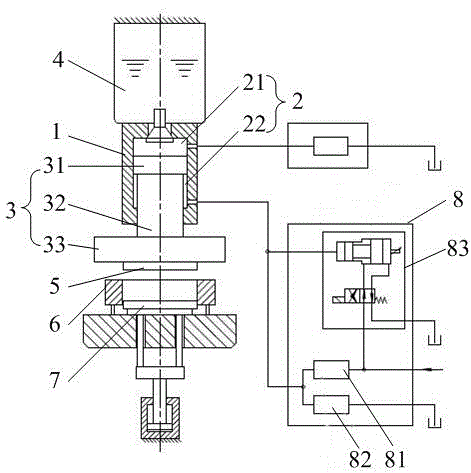

Green brick gas-exhaust mechanism and method controlled by volume cylinder

ActiveCN105545840APrecise control of lifting heightImprove molding qualityServomotor componentsServomotorsBrickProduct gas

The invention discloses a green brick gas-exhaust mechanism controlled by a volume cylinder. The green brick gas-exhaust mechanism comprises a main oil cylinder, wherein a main accommodating cavity is arranged in the main oil cylinder; a piston rod assembly is arranged in the main accommodating cavity; the piston rod assembly is used for dividing the main accommodating cavity into an upper cavity and a lower cavity; the upper cavity is connected to an upper oil tank; the lower cavity is connected to a control oil path; the lower end of the piston rod assembly extends out of the main accommodating cavity and is connected to an upper mould core; the control oil path comprises a gas-exhaust control oil path; the gas-exhaust control oil path is provided with the volume cylinder; and the volume cylinder is used for introducing hydraulic oil with predetermined volume into the lower cavity or discharging the hydraulic oil with predetermined volume to the outside of the low cavity, so that the upper mould core ascends or descends by a predetermined distance. The invention further discloses a green brick gas-exhaust method controlled by the volume cylinder. The green brick gas-exhaust mechanism and the green brick gas-exhaust method can precisely control the lifting height of the upper mould core, so that a gap between the upper mould core and a green brick is a constant value, and inside and outside gas pressure difference of the green brick is also a constant value, and therefore, the molding quality of the green brick is improved.

Owner:FOSHAN HENGLITAI MACHINERY

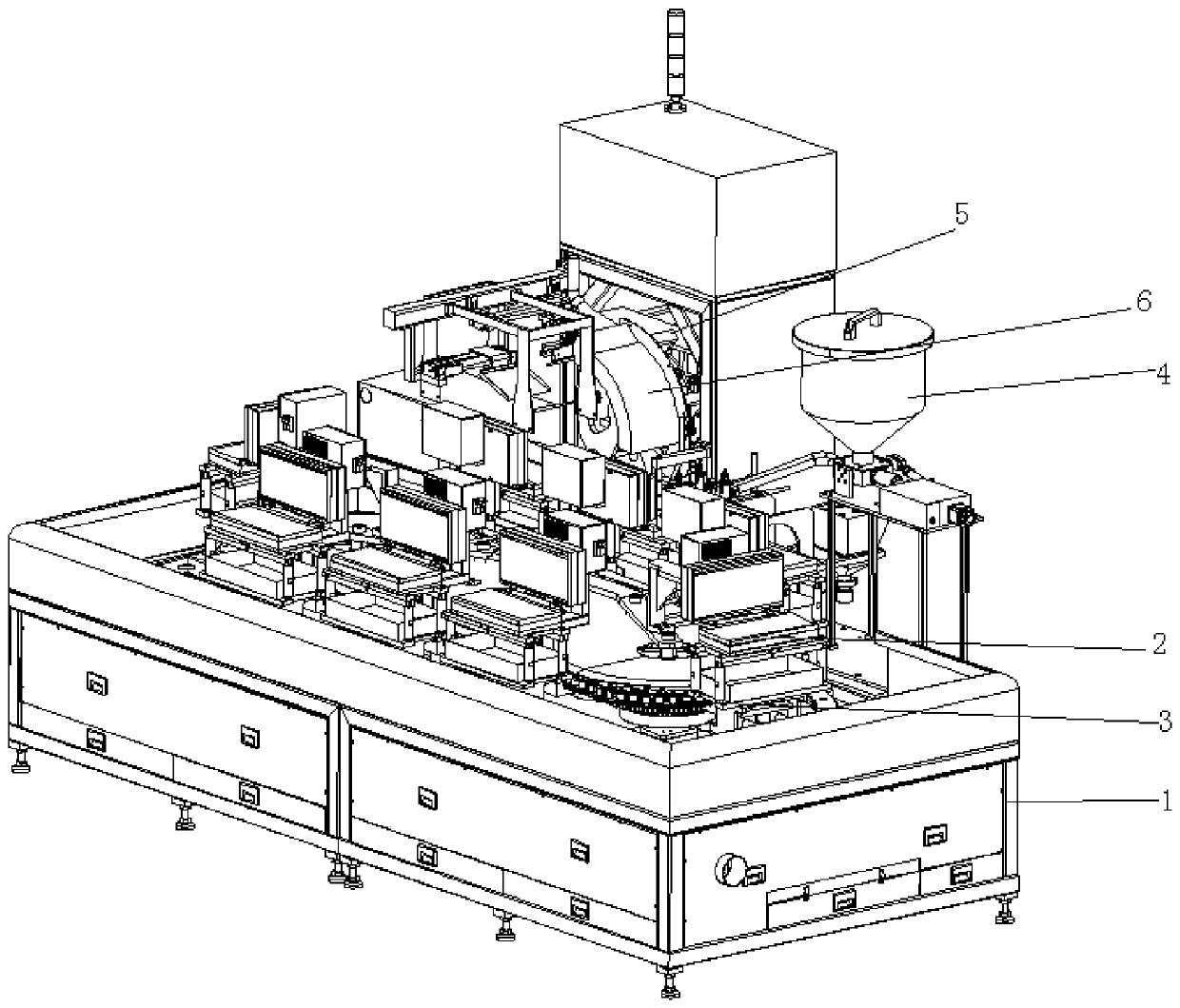

Egg roll processing device

PendingCN111280191ASimple structureRealize automatic heatingSpecial goods bakingEngineeringMechanical engineering

The invention provides an egg roll processing device. The egg roll processing device comprises a rack; a baking tray assembly which comprises an upper baking tray and a lower baking tray hinged to theupper baking tray, wherein the upper baking tray can rotate relative to the lower baking tray, so that the upper baking tray has a closing position covering the lower baking tray and an opening position separated from the lower baking tray; a guide part which is arranged on the upper baking tray, wherein the length extension direction of the guide part is parallel to the tray surface of the upperbaking tray; a moving assembly which is movably arranged on the rack, is connected with the lower baking tray and is used for driving the baking tray assembly to move relative to the rack; and a guide rail which comprises a horizontal section and a twisted section connected to at least one end of the horizontal section; wherein the shape of the twisted section is matched with the moving track ofthe guide part when the baking tray assembly moves relative to the rack and the upper baking tray rotates relative to the lower baking tray, the guide part abuts against the guide rail, when the baking tray assembly is located at the position corresponding to the horizontal section, the upper baking tray is kept at the opening position, and when the baking tray assembly is located at the positioncorresponding to the twisted section, the upper baking tray is located at the closing position.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

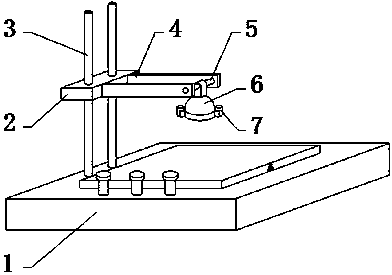

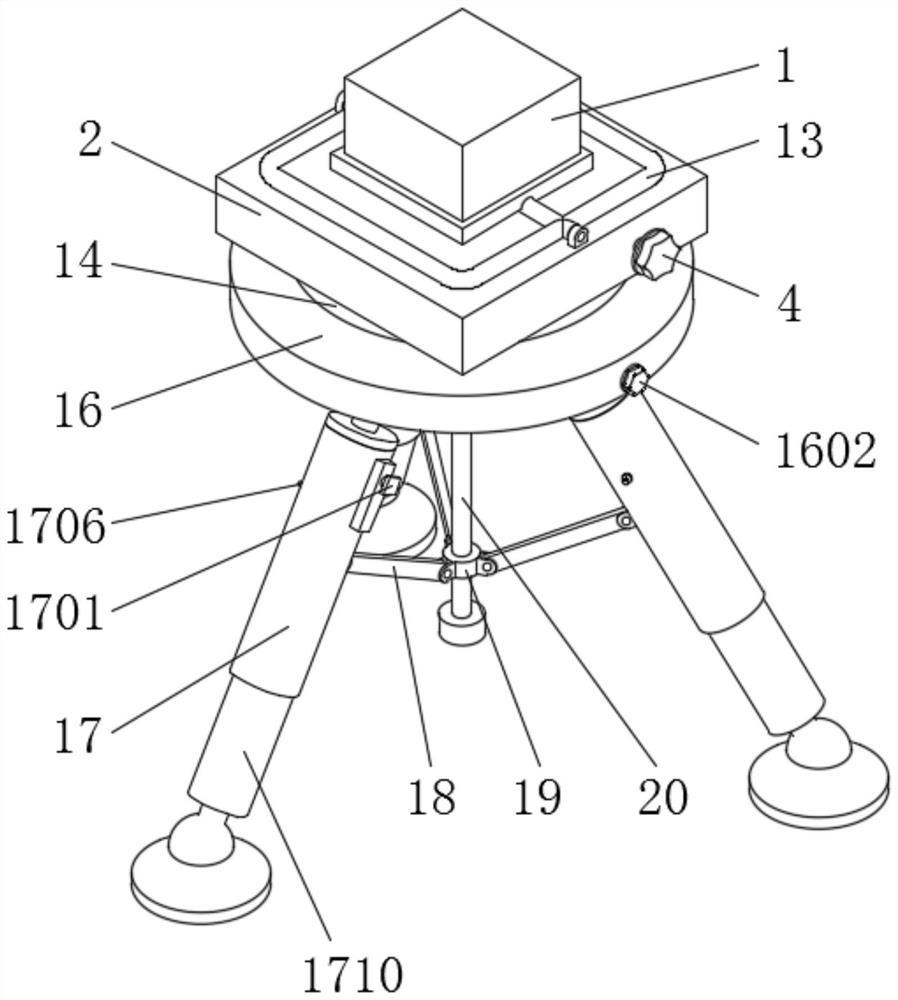

Camera holder with lifting function

The invention discloses a camera holder with a lifting function. A lifter is that a direct current motor drives a screw rod to rotate; the screw transmission of the screw rod is changed into linear motion of the camera holder in the vertical direction; a bracing wire encoder is additionally arranged in the lifter so as to realize position feedback; and an STM32 development plate arranged in the direct current motor is used for accurately controlling the lifting height of the camera holder.

Owner:江苏哈工智新科技股份有限公司

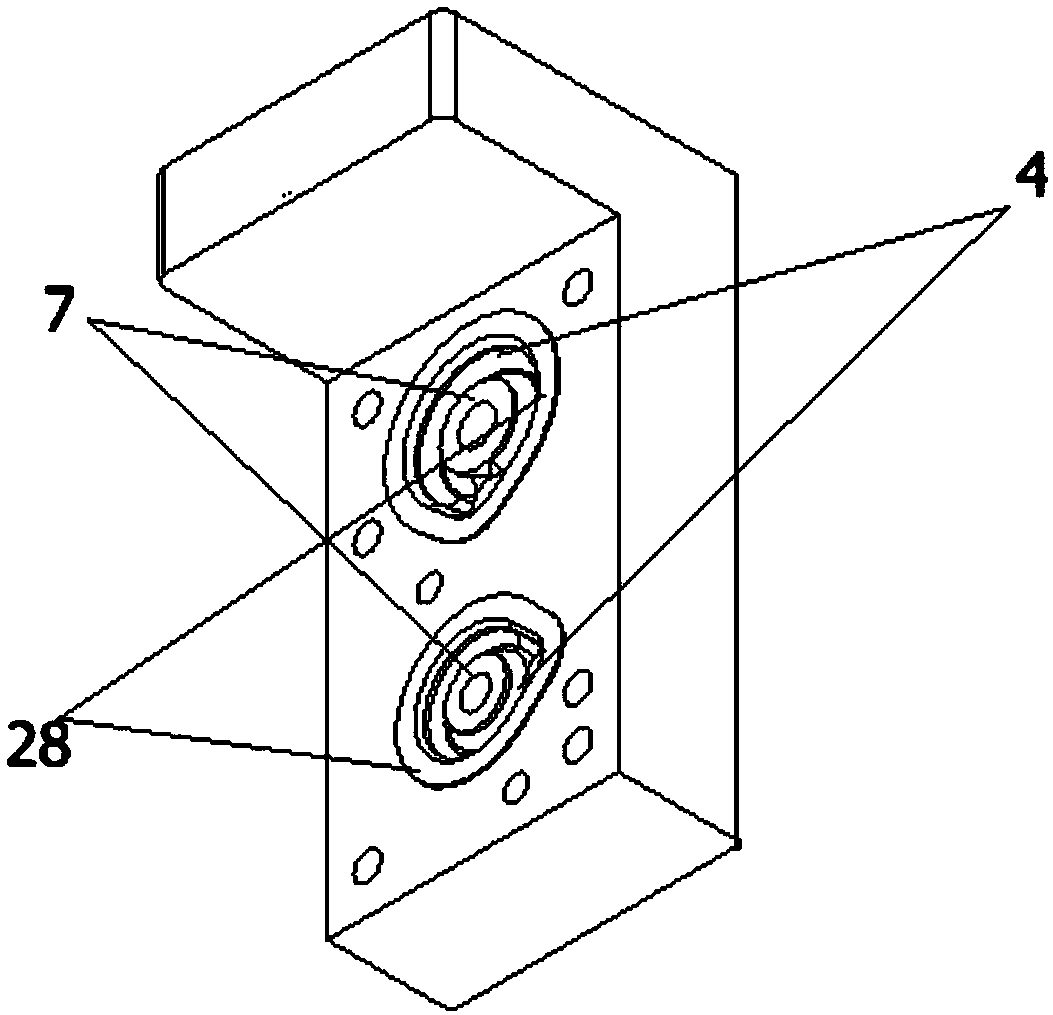

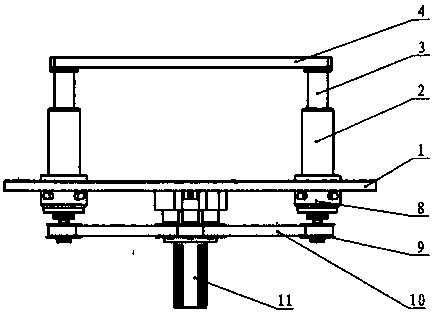

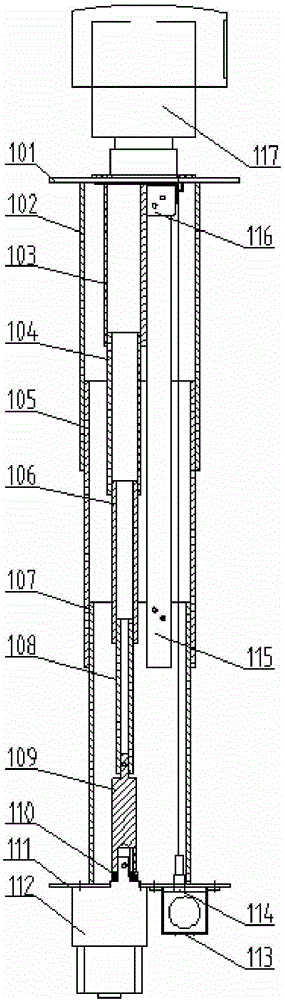

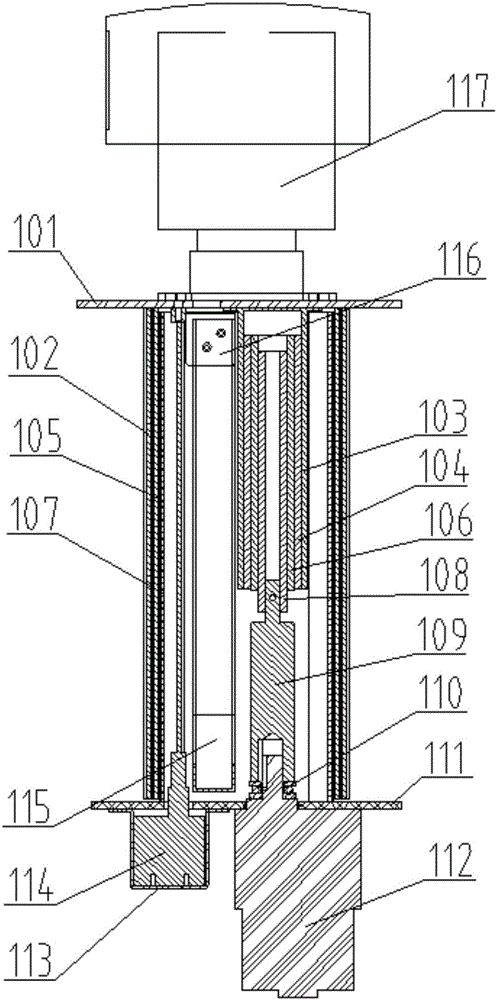

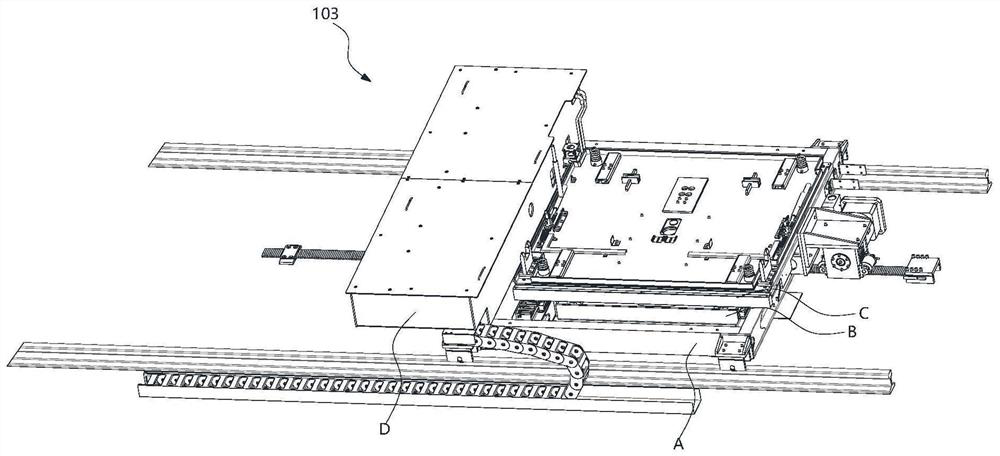

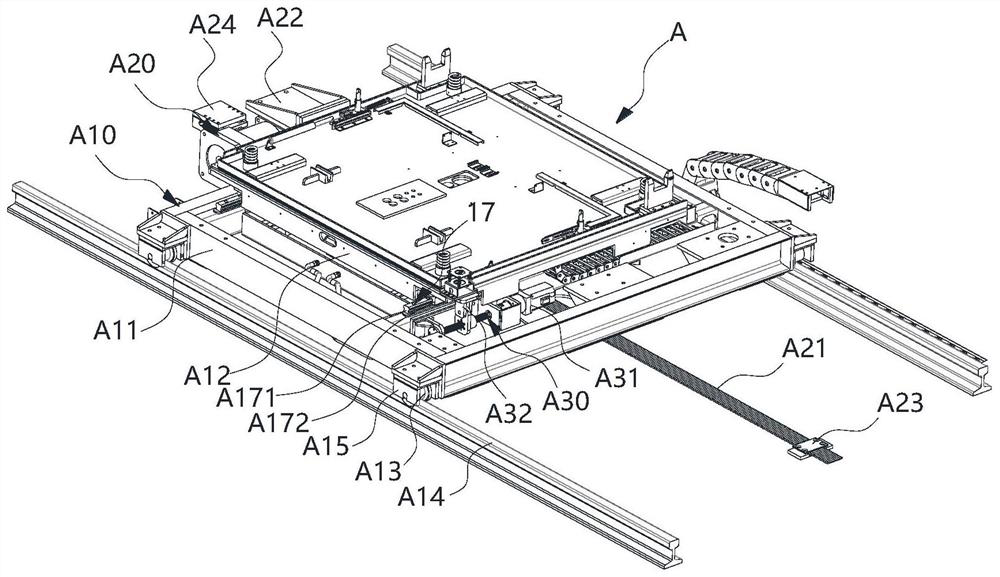

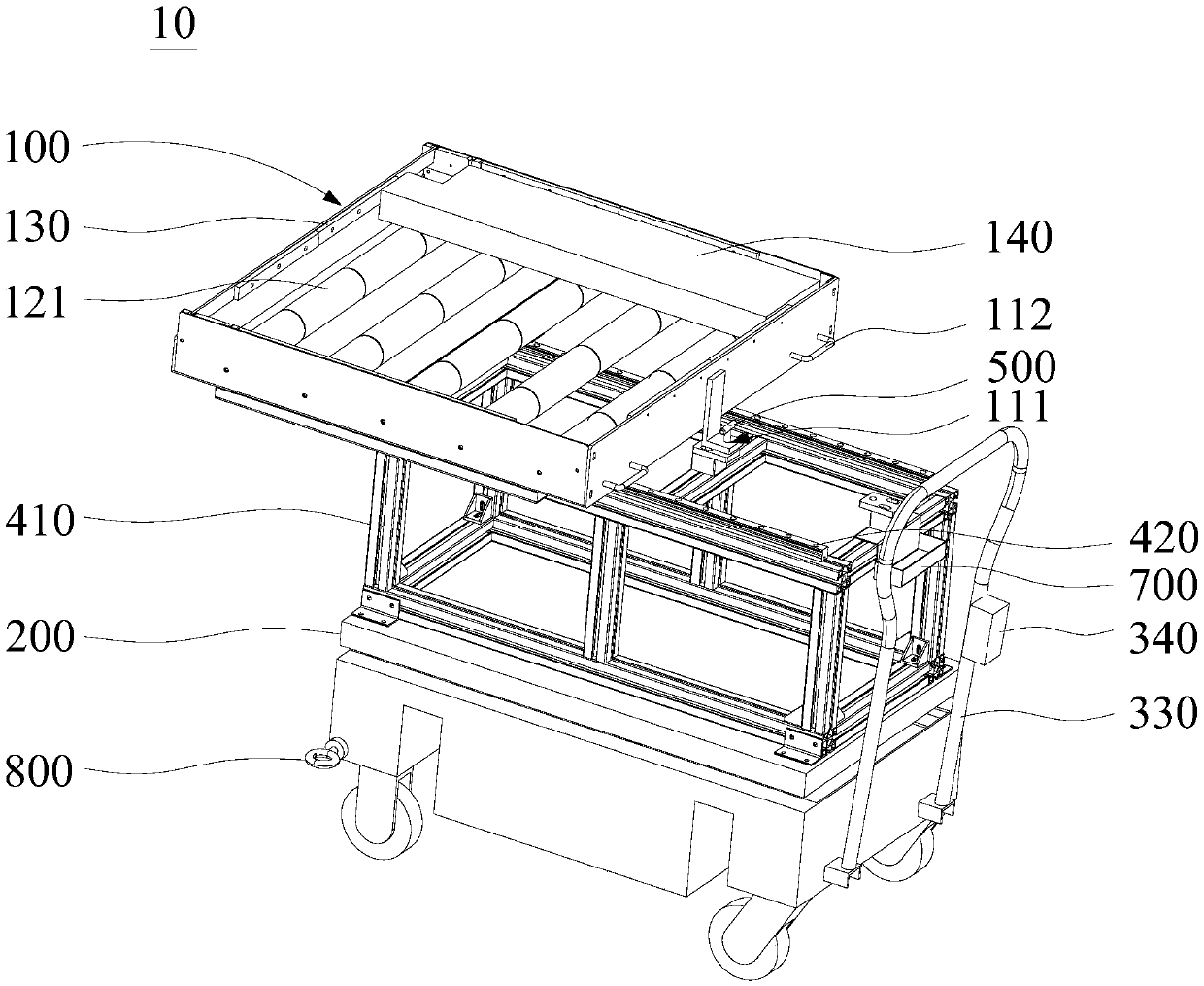

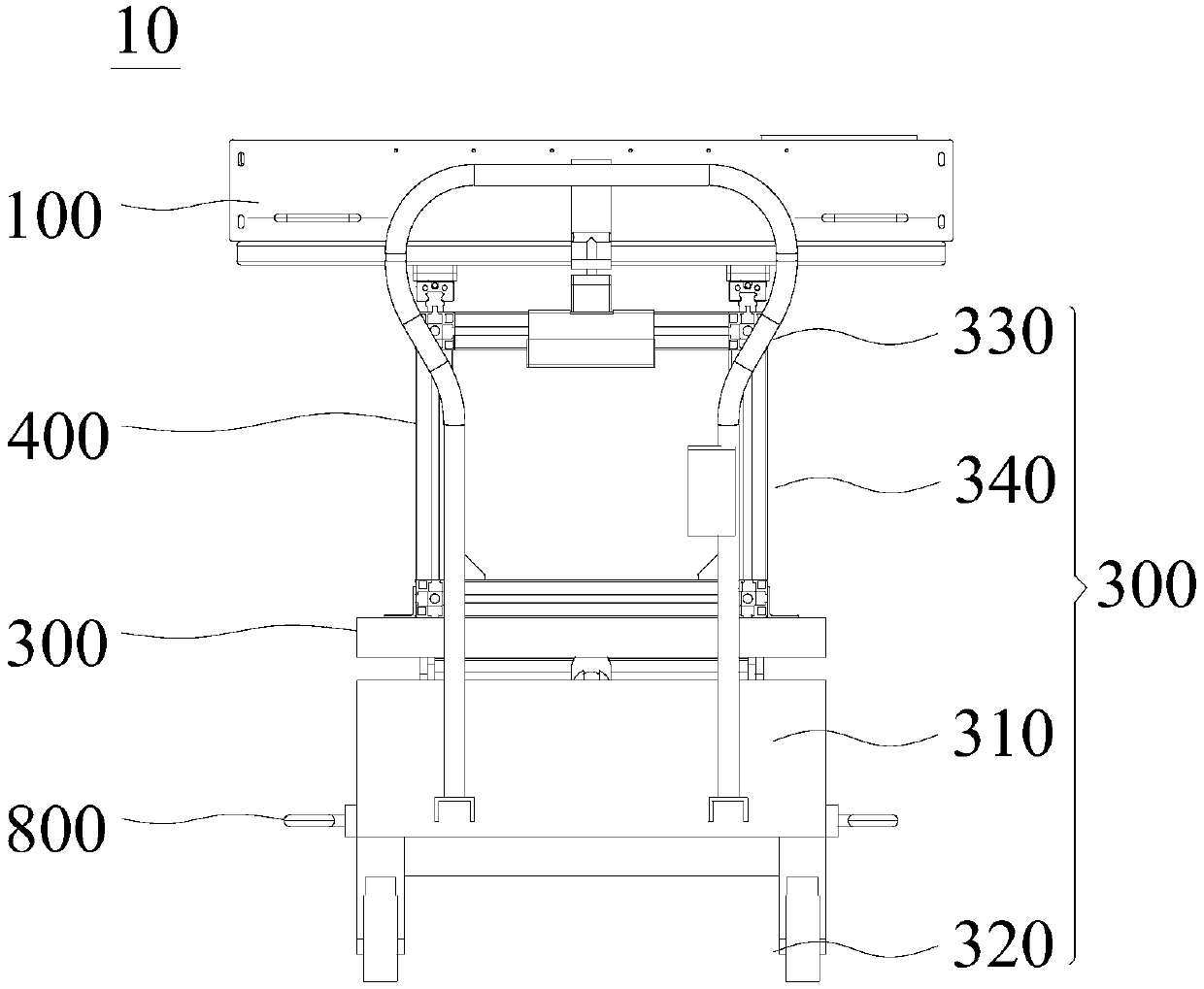

Battery replacement platform, battery mounting part and battery replacement moving device

PendingCN111645562ALower operating heightReduce replacement spaceCharging stationsVehicular energy storageElectrical batteryControl engineering

The invention discloses a battery replacement platform, a battery mounting part and a battery replacement moving device. The battery replacement moving device comprises a horizontal moving part used for driving the whole battery replacement equipment to move horizontally and comprises a moving frame used for moving and providing a mounting base and a horizontal driving device used for driving themoving frame to move; a vertical lifting part which is mounted on the horizontal moving part and used for driving the battery replacement platform to ascend and descend in the vertical direction; anda battery mounting part which is mounted on the vertical lifting part, is used for replacing and dismounting a battery, and comprises a battery replacement platform and a battery unlocking device mounted on the battery replacement platform. By means of the vertical lifting part, the operation height can be reduced to the maximum extent; therefore, the required replacement space is reduced, the movement stability and accurate positioning can be improved through the horizontal moving part, a battery at the bottom of the electric automobile can be automatically disassembled and replaced through the battery mounting part, and the disassembly and transportation of the battery of the electric automobile and the replacement of a new battery are automatically realized in the whole scheme.

Owner:SHANGHAI DIANBA NEW ENERGY RESOURCES SCI & TECH

Detection supporting device for electric meter detection

InactiveCN108919173APrecise control of lifting heightIncrease exposureElectrical measurementsEngineeringMechanical engineering

The invention provides a detection supporting device for electric meter detection. The detection supporting device comprises threaded rods, piston blocks, L-shaped air guiding grooves, an O-shaped ring, a supporting plate, a cavity and a base plate. The piston blocks are fixed to the lower ends of the threaded rods. The L-shaped air guiding grooves are formed in the front portion in the base plateand internally provided with the piston blocks. The cavity is formed in the upper end of the base plate, and the front end of the cavity communicates with the L-shaped air guiding grooves. The supporting plate is mounted on the cavity, and the O-shaped ring is arranged on the outer side face of the supporting plate and inlaid in the inner side face of the cavity. The threaded rods are mounted onthe front portion of the upper end face of the base plate. The detection supporting device achieves the lifting supporting function and is convenient to use and operate, the lifting function is achieved, and the irradiating detection effect is improved.

Owner:SUZHOU HONGSUN ELECTROMECHANICAL TECH CO LTD

Deposition simulation experiment base plate based on hydraulic drive apparatus

InactiveCN105160979ARelieve stressReduced strength requirementsEducational modelsMaterial analysisTransverse planeEngineering

The invention discloses a deposition simulation experiment base plate based on a hydraulic drive apparatus, which comprises a movable base plate and multiple hydraulic drive apparatuses; the hydraulic drive apparatus comprises an L-shaped communicated piston cylinder formed by a vertical steel pipe and a horizontal steel pipe; the movable base plate is set above the vertical steel pipe inside an elevating groove; a first sealing piston connected with a lifting bar is set inside the vertical steel pipe; the top end of the lifting bar extends out of the vertical steel pipe and an elastic sealing member is set at the peripheral of the lifting bar; one end of the horizontal steel pipe extends out of the elevating groove and a second sealing piston connected to a piston rod is set inside the horizontal steel pipe; the piston rod extends out of the transverse plane of the horizontal steel pipe; and light oil if filled between the first sealing piston and the second sealing piston. In deposition simulation experiment, the lifting bar is driven up or down and the elastic sealing member is driven long or short by pushing the piston rod outside the elevating groove, thereby lifting or decreasing the movable base plate. The structure is simple and the operation is convenient.

Owner:YANGTZE UNIVERSITY

Support for atmospheric pollution prevention and control sampling and using method

PendingCN113092196AReduce lax opening and closingAvoid damageWithdrawing sample devicesEngineeringWorkbench

The invention discloses a support for atmospheric pollution prevention and control sampling and a using method, and belongs to the technical field of atmospheric sampling auxiliary equipment. The support for atmospheric pollution prevention and control sampling comprises a workbench, and a protection framework is fixedly connected to the bottom end of the workbench. According to the support for atmospheric pollution prevention and control sampling and the using method, a swing connecting plate is arranged, in the protection frame, an adjusting knob rotates to drive a threaded sliding block to slide along the inner wall of the protection frame through a working threaded rod, the threaded sliding block drives the swing connecting plate integrally connected with a swing plate to rotate through a sliding hole plate, the swing connecting plate rotates to drive two sets of movable sliding blocks to move through swing sliding grooves, the two sets of movable sliding blocks can synchronously move, the phenomenon of water leakage caused by untight opening and closing of waterproof umbrella cloth is reduced, the movable sliding blocks drive the two sets of waterproof umbrella cloth connected with the swing hole plate to relatively rotate by 90 degrees through the movable sliding grooves to close the workbench, and waterproof operation on the workbench is achieved.

Owner:贺铭

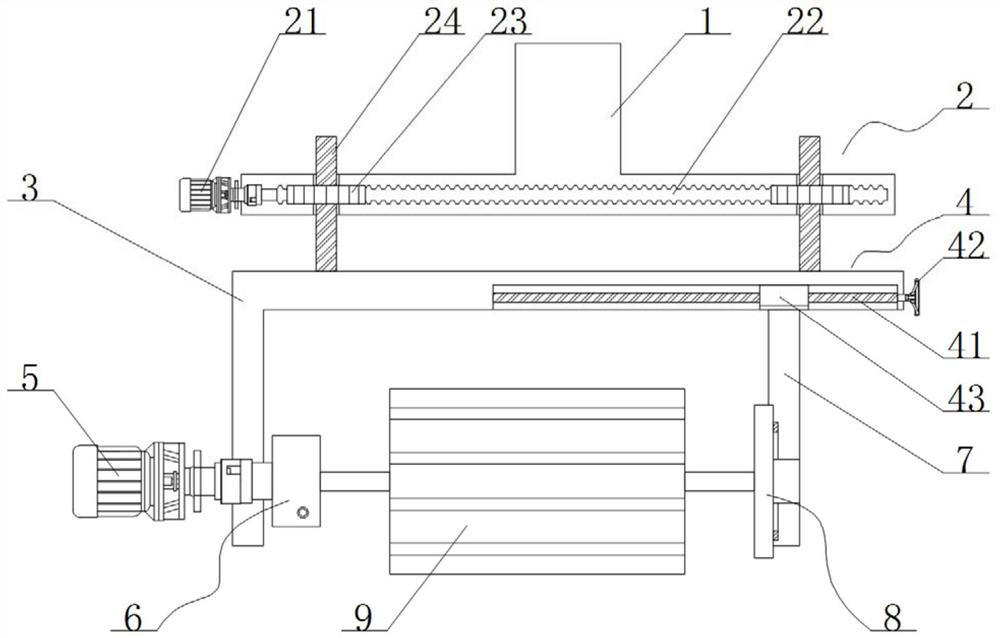

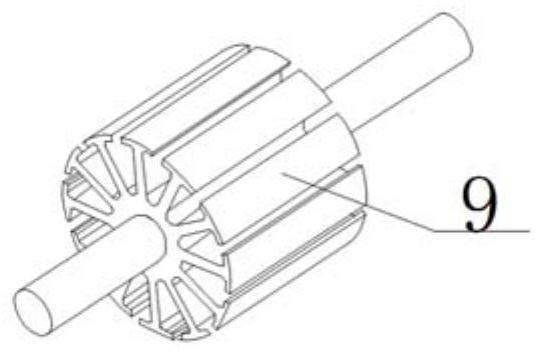

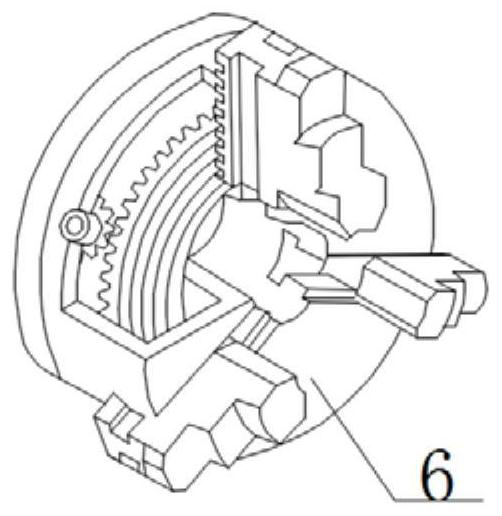

Commutator rotor processing device and application method thereof

PendingCN113787364AImprove processing qualitySmooth liftGrinding drivesPositioning apparatusEngineeringReducer

The invention relates to a commutator rotor processing device. The device comprises a fixing block and is characterized in that a lifting mechanism is arranged at the inner side of the fixing block, a fixing frame is arranged at the bottom end of the lifting mechanism, a horizontal moving mechanism is arranged at the inner side of the fixing frame, and a main speed reducer is fixedly connected to the left end of the lower side of the fixing frame; and the tail end of a main shaft of the main speed reducer is fixedly connected with a three-jaw chuck, a fixing plate is arranged at the bottom end of the horizontal moving mechanism, a clamping mechanism is arranged at the left end of the fixing plate, a commutator rotor is arranged at the inner side of the three-jaw chuck and the inner side of the clamping mechanism, and the device is easy and convenient to operate and prevents the commutator rotor from deviating in the machining process.

Owner:温州鼎龙电子科技有限公司

Gear ring lifting device for double-face polishing machine

InactiveCN107877365AThe inflation process is gentleSmooth liftGrinding machine componentsEngineeringAirbag

A gear ring lifting device for a double-face polishing machine comprises a left lifting device body and a right lifting device body. The left lifting device body comprises a lifting airbag, a liftingswing rod, a main shaft and a gear ring supporting base. The lifting airbag is connected with the lifting swing rod, the upper end of the main shaft is connected with the gear ring supporting base, and the lower end of the main shaft is in contact with the lifting swing rod. The structure of the right lifting device body is the same as that of the left lifting device body. The right lifting devicebody and the left lifting device body are symmetrically arranged, and the lifting swing rod of the right lifting device body and the lifting swing rod of the left lifting device body are connected through a synchronous rod. The gear ring lifting device is simple in structure, convenient to operate and control, stable in ascending and descending and capable of being widely applied to lifting control over gear rings of the grinding and polishing machine.

Owner:HUNAN YUJING MACHINE

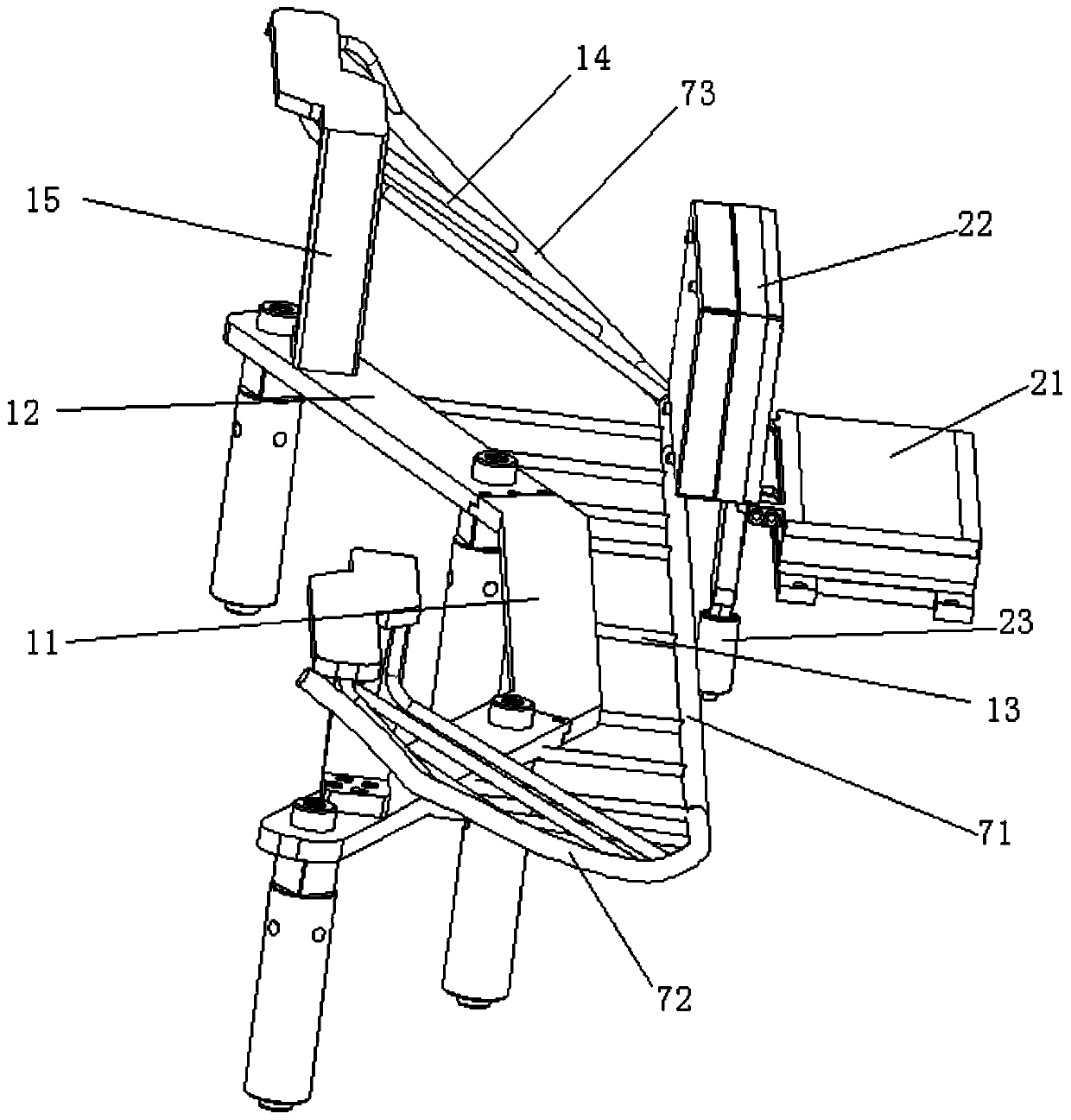

Syringe transportation device

The invention relates to a syringe transportation device. The syringe transportation device comprises a bearing part, a lifting part, a fixing part and a shifting part; the bearing part comprises a bearing frame, and a bearing plane arranged on the bearing frame; the bearing frame is slidingly connected to the lifting part; the fixing part for fixing the position of the bearing frame; the liftingpart is arranged on the shifting part; the lifting part is used for driving the bearing frame to perform a lifting motion; and the shifting part is used for driving the lifting part and the bearing frame to move. The syringe transportation device is convenient to operate during replacing syringes without needing manual carrying, only needs one worker for direct operation, saves both time and power, greatly relieves the labor intensity of workers, and improves the production efficiency.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

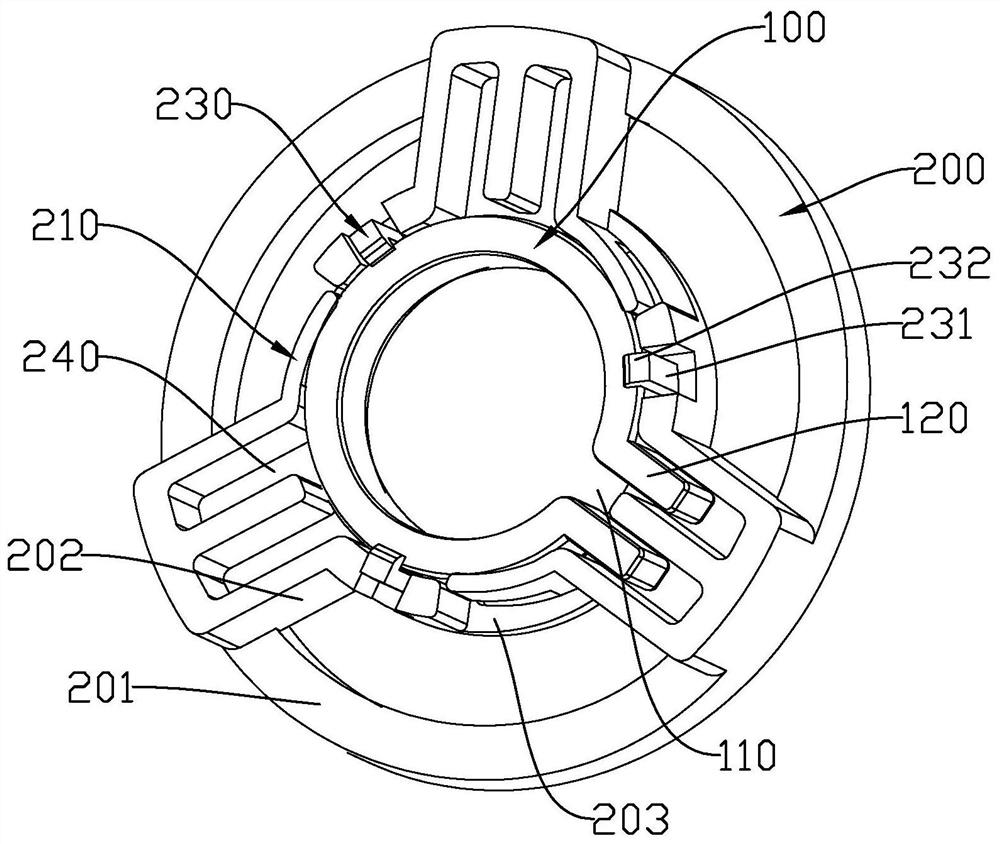

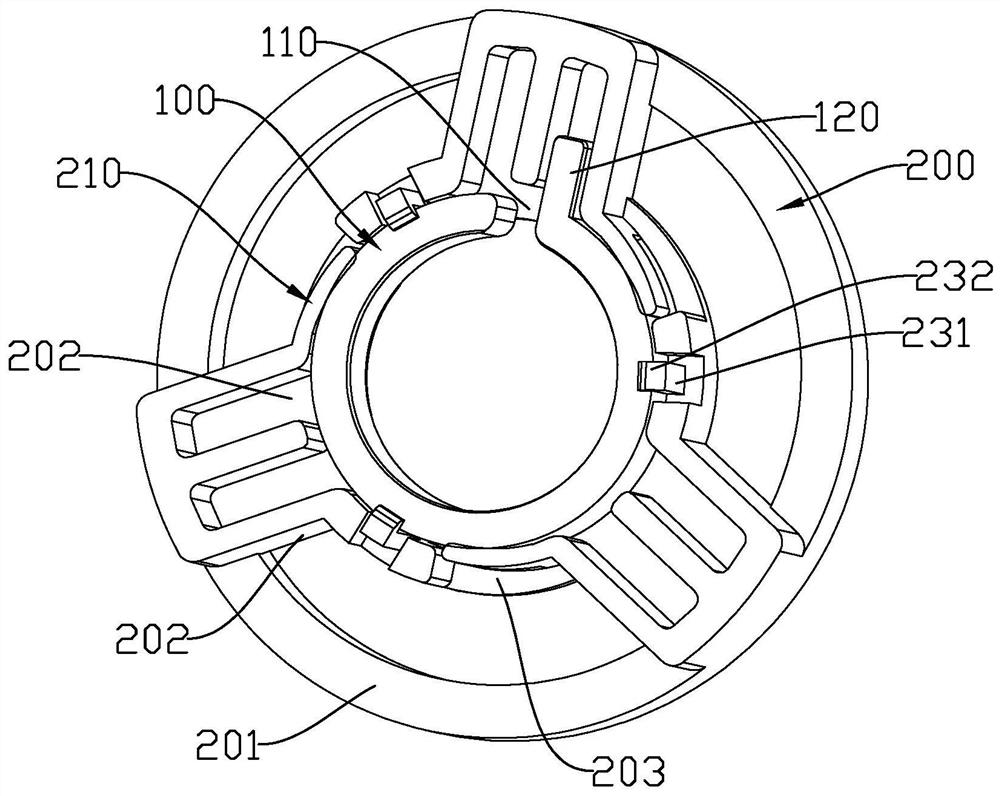

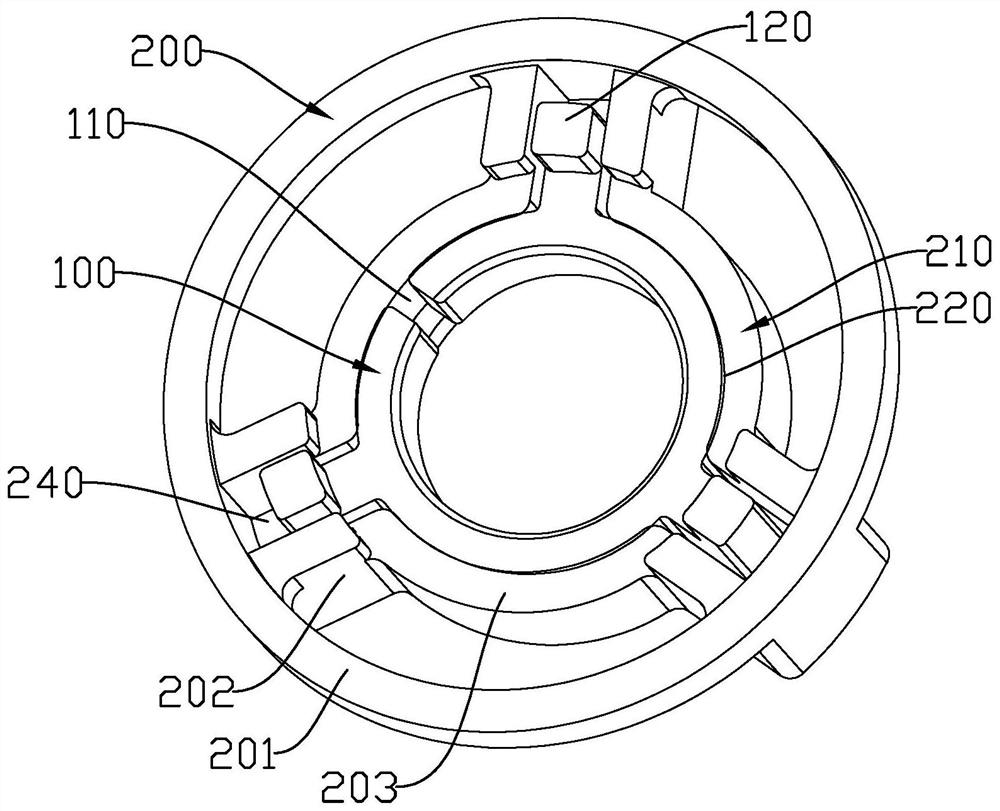

Self-locking mechanism, motor and linear actuator

ActiveCN113651271AGood self-locking performanceSmall inner diameterLifting devicesBraking membersClassical mechanicsEngineering

The invention discloses a self-locking mechanism, a motor and a linear actuator, and belongs to the field of self-locking mechanisms. The self-locking mechanism has stable self-locking performance and comprises a friction ring and a mounting seat, the mounting seat is fixed relative to the friction ring, a notch is formed in the friction ring, and the friction ring is arranged on a rotary body needing to be braked in a sleeving mode. A mounting part used for mounting the friction ring is defined on the mounting seat, and the mounting part extrudes the friction ring in the direction of the notch so as to apply braking force to the rotary body.

Owner:ZHEJIANG JIECHANG LINEAR MOTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com