Gear ring lifting device for double-face polishing machine

A technology of double-sided polishing machine and lifting device, which is applied to the parts of grinding machine tools, grinding/polishing equipment, metal processing equipment, etc. Synchronization and other problems, to achieve the effect of soft inflation, convenient operation and control, and stable lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

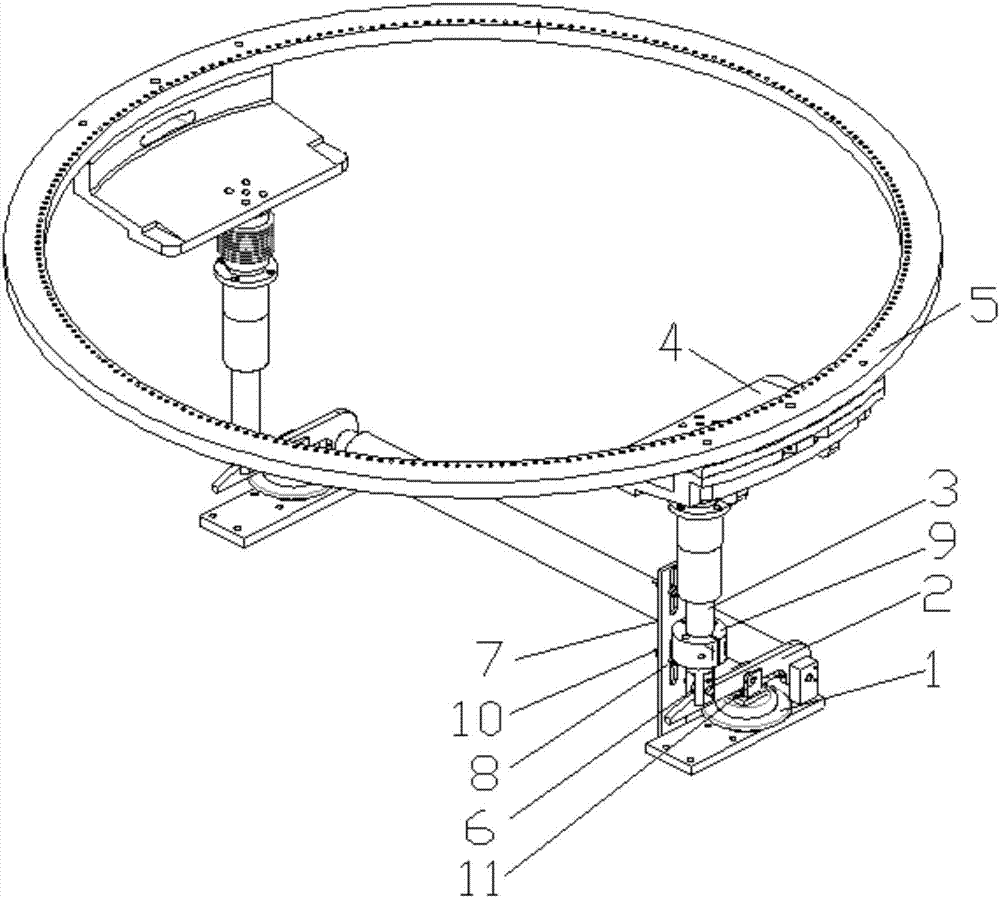

[0021] refer to figure 1 , the present embodiment includes a left lifting device and a right lifting device; the left lifting device includes a lifting air bag 1, a lifting swing rod 2, a main shaft 3 and a ring gear support seat 4, and the lifting air bag 1 is connected with the lifting swing rod 2, The upper end of the main shaft 3 is connected with the ring gear support seat 4, and the lower end of the main shaft 3 is provided with a ball bearing 6, and the ball bearing 6 is in contact with the lifting swing rod 2; the structure of the right lifting device is the same as that of the left lifting device , the right lifting device and the left lifting device are arranged symmetrically, and the lifting swing rod of the right lifting device is connected with the lifting swing rod of the left lifting device through a synchronous rod 7 .

[0022] In this embodiment, the left elevating device is also provided with a proximity switch mounting plate 8, a locking ring 9 and a proximi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com