Commutator rotor processing device and application method thereof

A technology of processing device and commutator, applied in positioning device, grinding drive device, metal processing equipment, etc., can solve the problems affecting rotor quality, rotor rotation operation deviation, insufficient rotor machining accuracy, etc., to improve the processing quality , the effect of lifting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

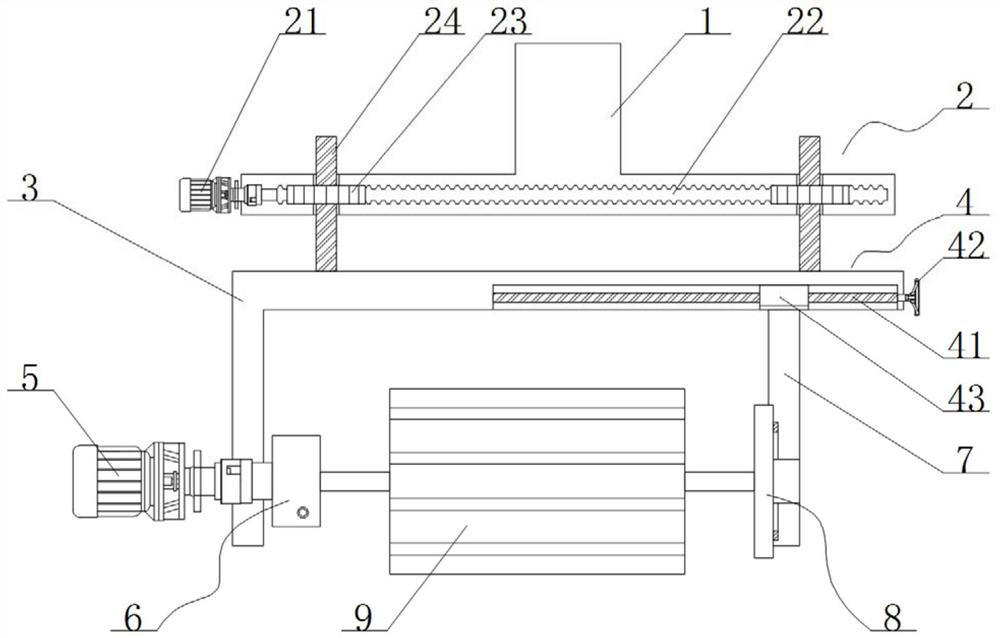

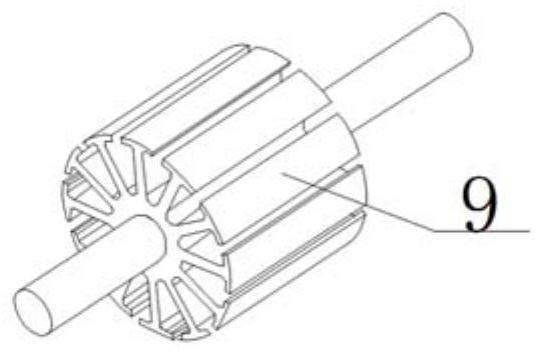

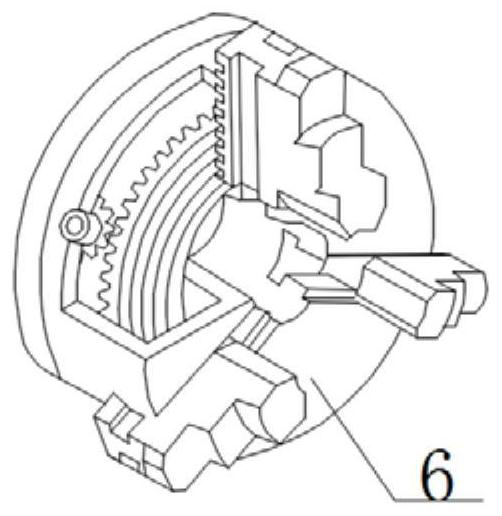

[0028] see figure 1 According to the commutator rotor processing device of the embodiment of the present invention, it includes a fixed block 1, the inside of the fixed block 1 is provided with a lifting mechanism 2, the bottom end of the lifting mechanism 2 is provided with a fixing frame 3, and the inside of the fixing frame 3 is provided with a horizontal The moving mechanism 4, the lower left end of the fixed frame 3 is fixedly connected with the main reducer 5, the end of the main shaft of the main reducer 5 is fixedly connected with the three-jaw chuck 6, the bottom end of the horizontal moving mechanism 4 is provided with a fixed plate 7, the fixed plate 7 The left end of is provided with clamping mechanism 8, and the inboard of three-jaw chuck 6 and clamping mechanism 8 is provided with commutator rotor 9.

[0029] The lifting mechanism 2 includes a servo motor 21, the end of the main shaft of the servo motor 21 is fixedly connected with a worm 22, the front end of the...

Embodiment 2

[0032] see Figure 1-4 According to the commutator rotor processing device of the embodiment of the present invention, it includes a fixed block 1, the inside of the fixed block 1 is provided with a lifting mechanism 2, the bottom end of the lifting mechanism 2 is provided with a fixing frame 3, and the inside of the fixing frame 3 is provided with a horizontal The moving mechanism 4, the lower left end of the fixed frame 3 is fixedly connected with the main reducer 5, the end of the main shaft of the main reducer 5 is fixedly connected with the three-jaw chuck 6, the bottom end of the horizontal moving mechanism 4 is provided with a fixed plate 7, the fixed plate 7 The left end of is provided with clamping mechanism 8, and the inboard of three-jaw chuck 6 and clamping mechanism 8 is provided with commutator rotor 9.

[0033] The horizontal movement mechanism 4 comprises a second screw mandrel 41, the second screw mandrel 41 is rotationally connected with the fixed frame 3, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com