Grain elevator capable of ventilating determined position

A technology to determine the location and granary, which is applied in the field of granaries that can ventilate the determined location, can solve the problems of grain rot and poor ventilation, and achieve the effect of avoiding unventilated rot and facilitating fixed-point ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

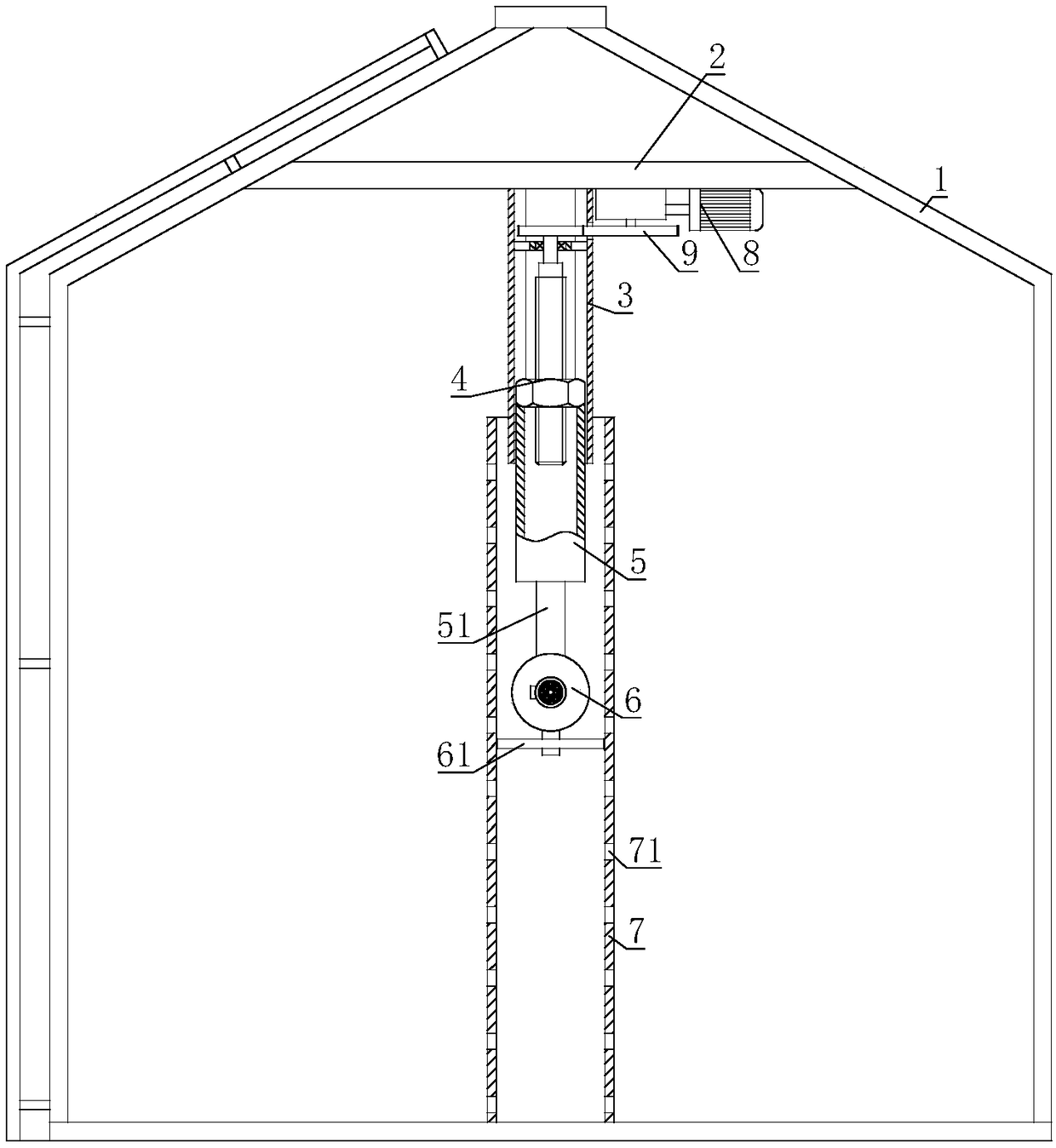

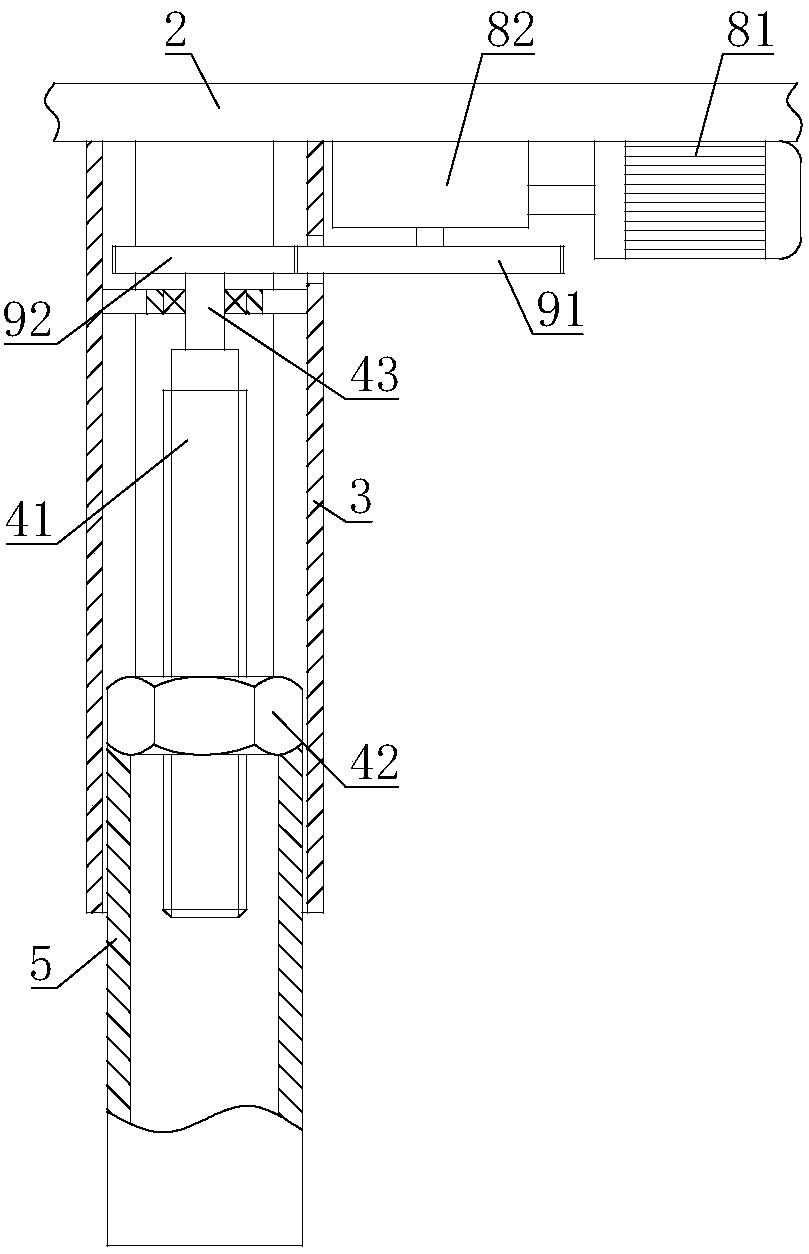

[0024] The granary that can ventilate a certain position includes a granary main body 1; a horizontal plate 2 is connected to the top of the granary main body 1, and a casing 3 is fixed on the horizontal plate 2, and a lead screw and nut mechanism 4 is connected inside the casing 3, and the screw and nut mechanism 4 is connected inside the casing 3. The other end of the lever nut mechanism 4 is connected with a lift pipe 5, and the other end of the lift pipe 5 is connected with a lift rod 51, and the other end of the lift rod 51 is connected with a blower 6, and a ventilation pipe 7 is installed in the main body of the granary 1. A number of ventilation holes 71 are provided, and the blower 6 and the lifting rod 51 are sleeved in the ventilation pipe 7; the horizontal plate 2 is also equipped with a driving mechanism 8, and the output shaft of the driving mechanism 8 is connected with a transmission mechanism 9, and the output end of the transmission mechanism 9 is connected to ...

Embodiment 2

[0027] On the basis of Embodiment 1, the lead screw nut mechanism 4 includes a lead screw 41, the lead screw 41 is sleeved in the casing 3, the lead screw 41 is threadedly connected with a nut 42, and the lifting tube 5 is fixed on the nut 42; One end of bar 41 is connected with connecting shaft 43, and connecting shaft 43 is connected in the sleeve pipe 3 by bearing, and the other end of connecting shaft 43 is connected with transmission mechanism 9; The inner ring shape of the section of sleeve pipe 3 is polygonal.

[0028] When the transmission mechanism 9 drives the screw 41 to rotate, the rotation of the nut 42 is restricted by the sleeve 3, and the nut 42 rises and falls linearly under the drive of the screw 41, and the lifting tube 5 and the lifting rod 515 rise and fall under the promotion of the nut 42, so that the blower 6 Can be moved to a certain location. The screw nut mechanism 4 has a definite transmission ratio, and the moving distance of the blower 6 is propor...

Embodiment 3

[0030] On the basis of Embodiment 1 or Embodiment 2, the drive mechanism 8 includes a motor 81, the output shaft of the motor 81 is connected with a speed reducer 82, the motor 81 and the speed reducer 82 are all installed on the horizontal plate 2, and the speed reducer 82 The output shaft is connected with the input end of the transmission mechanism 9 .

[0031] After the motor 81 starts, the motor 81 drives the speed reducer 82 to act, and the speed reducer 82 transmits the power to the transmission mechanism 9, so the transmission mechanism 9 can drive the lead screw nut mechanism 4 to act. The present invention is driven by motor 81, then the start-up time of motor 81 determines the lifting height of blower 6, and the turning direction of motor 81 determines the moving direction of blower 6, easy to control, simple to operate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com