Granary having directional ventilation function

A granary and functional technology, applied in the field of granary with directional ventilation function, can solve problems such as poor ventilation and grain rot, and achieve the effect of improving ventilation effect, avoiding air overflow, and improving the utilization rate of blasting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

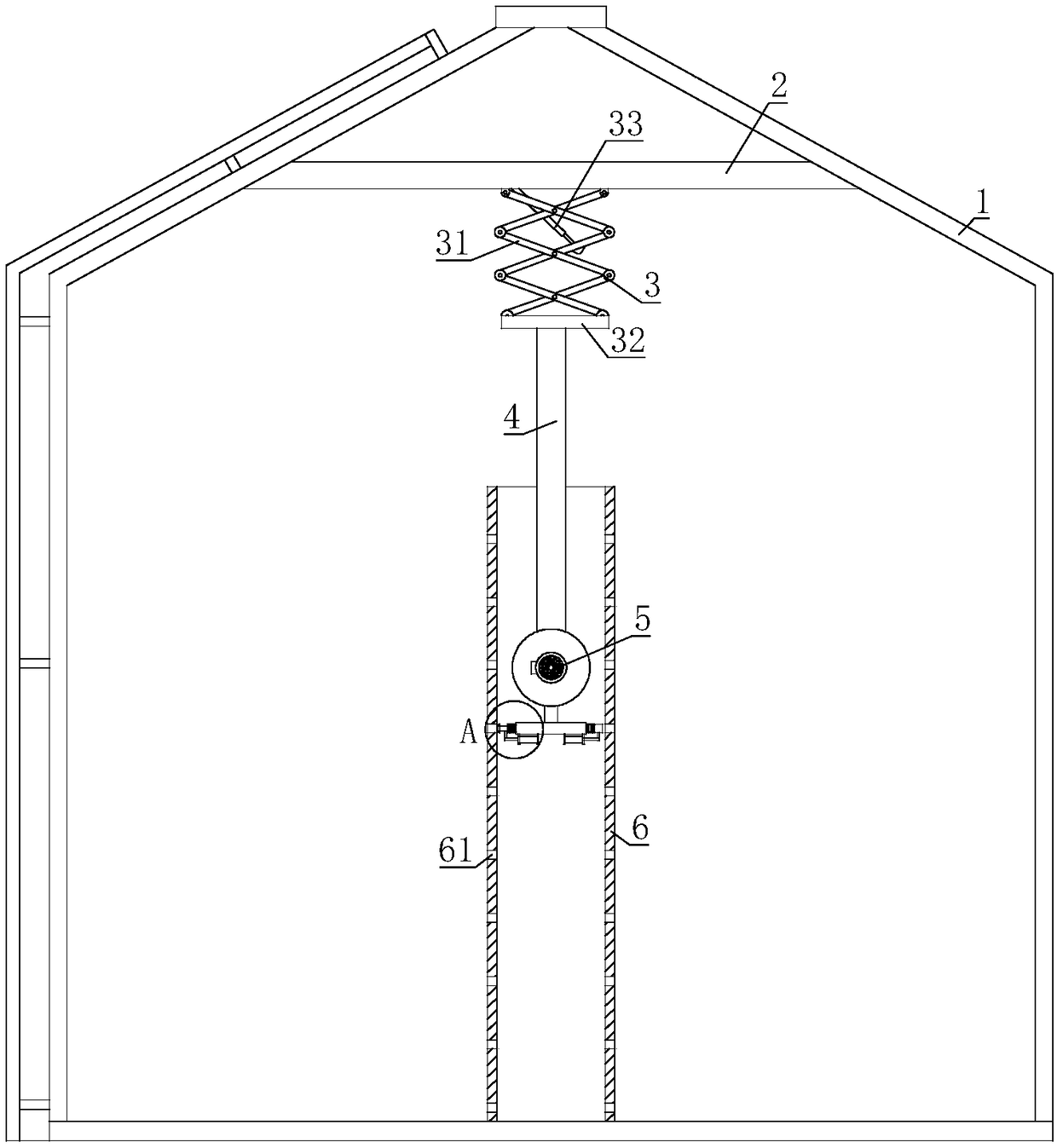

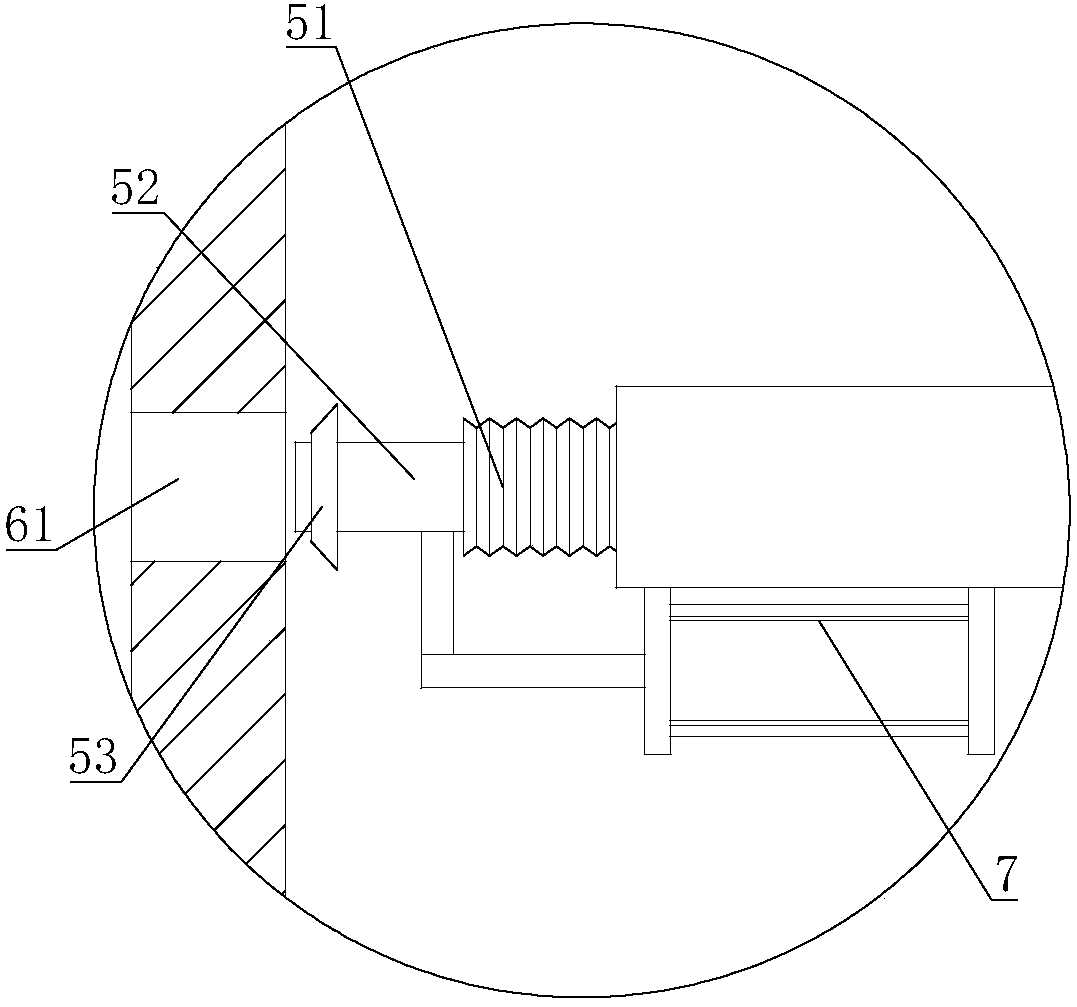

[0020] A granary with a directional ventilation function, comprising a granary main body 1; a horizontal plate 2 is connected to the top of the granary main body 1, a scissor-type lifting mechanism 3 is installed on the horizontal plate 2, and a lifting mechanism 3 is connected to the other end of the scissor-type lifting mechanism 3. Rod 4, the other end of elevating rod 4 is connected with air blower 5, and vent pipe 6 is installed in granary main body 1, and vent pipe 6 is provided with some ventilation holes 61, and air blower 5 and elevating rod 4 are sleeved in air pipe 6; The air outlet pipe of 5 is connected with corrugated hose 51, and the other end of corrugated hose 51 is connected with blower head 52 for connecting ventilation hole 61, and the air outlet pipe of blower 5 is connected with cylinder 7, and the piston rod of cylinder 7 is connected with the blower. Limelight 52 connection.

[0021] The scissor lifting mechanism 3 of the present invention can drive the...

Embodiment 2

[0023] On the basis of Embodiment 1, the scissor lift mechanism 3 includes a scissor lift frame 31, one end of the scissor lift frame 31 is hinged to the horizontal plate 2, and the other end of the scissor lift frame 31 is hinged to a connection A lifting hydraulic cylinder 33 is hinged between the plate 32, the horizontal plate 2 and the scissor lift frame 31.

[0024] When lifting hydraulic cylinder 33 moves, scissor lift frame 31 stretches out or retracts accordingly, and elevating rod 4 can push blower 5 to the grain position that needs blowing, realizes accurate air supply.

Embodiment 3

[0026] On the basis of Embodiment 1 or Embodiment 2, a sealing plug 53 is connected to the blower head 52, and the shape of the sealing plug 53 is a truncated cone.

[0027] The sealing plug 53 can effectively seal the gap between the blower head 52 and the ventilation hole 61 , further increases the amount of air flow through the ventilation hole 61 , and improves the ventilation effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com