Preparation method of macromolecular synthesized building mold plate

A building template and polymer technology, which is applied in the field of polymer synthetic building template preparation, can solve problems such as decay, expansion and deformation, and achieve the effects of light weight, good toughness and excellent physical and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

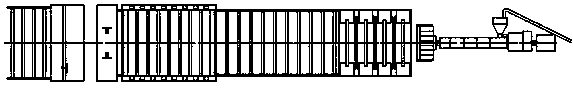

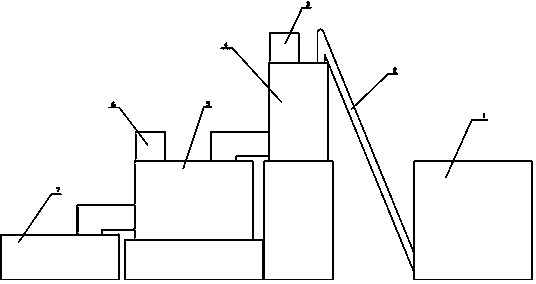

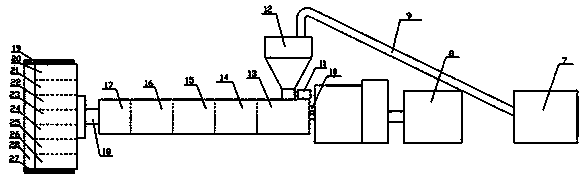

Image

Examples

Embodiment Construction

[0018] Compound 150KG waste PVC, 25KG light calcium carbonate powder, 1KG lubricant-1, 0.8KG lubricant-2, 0.7KG foaming agent-A, 1.5KG foaming agent-B, 12KG foaming regulator, 3.5KG Stabilizer, 5KG toughening agent, 3KG plasticizer, 2.5KG composite elastomer are poured into the hopper, pumped into the high-mixing pot by the screw pump for high-speed stirring, and the temperature rises rapidly until it reaches the range of 110°C-120°C. Put it into a low-mixing pot, stir slowly and cool it down, and when it cools down to 40°C-50°C, put it into a hopper for use.

[0019] Pump the mixed material into the hopper for use, and set the heating temperature of the barrel area and each area of the machine head at the same time. Temperature setting is one of the important links in the production process of this product. Only when a certain temperature is reached, the mixed materials can be in a molten state. The melt temperature has a great influence on the bubble structure, densi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com