Electronic assembly welding method for automatic elevated wave soldering of components

A technology of wave soldering and soldering method, which is applied in the direction of assembling printed circuits with electrical components, welding equipment, metal processing equipment, etc. Unreasonable and other problems, to achieve the effect of improving work efficiency, improving service reliability, and preventing inconsistency in height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

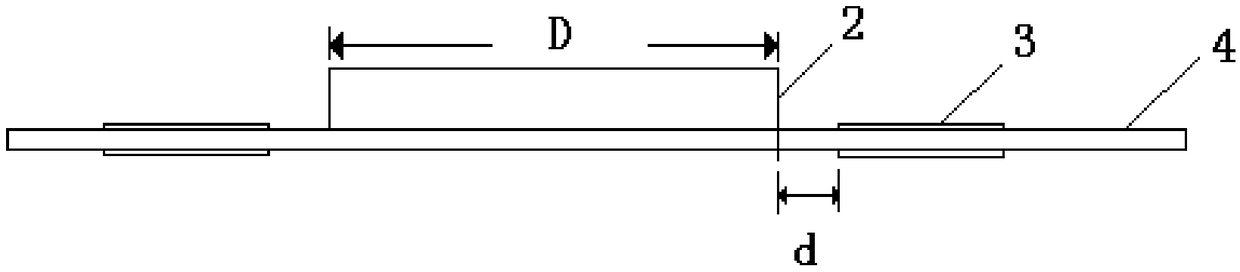

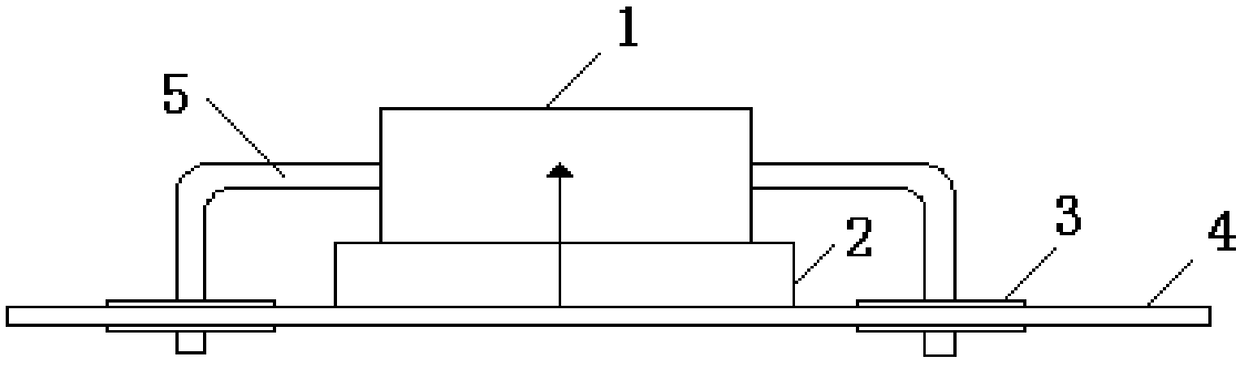

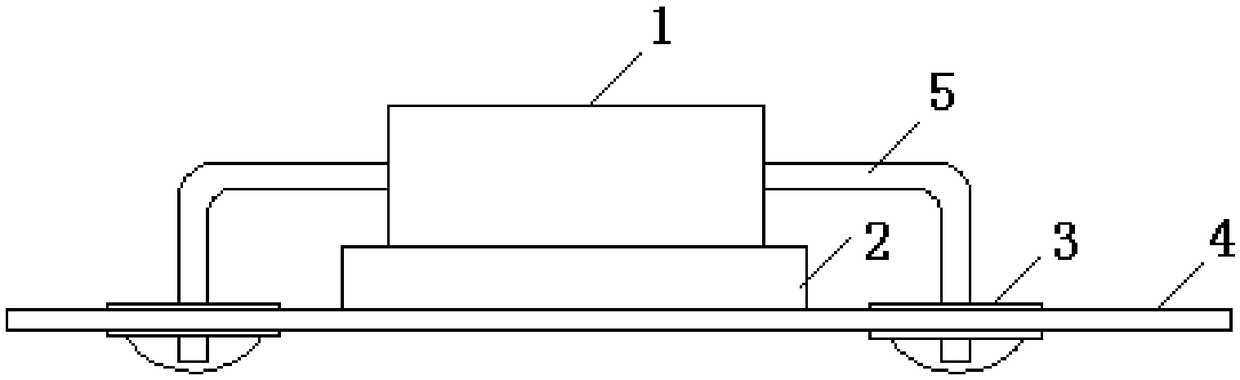

[0022] The following will combine Figure 1 ~ Figure 4 A further detailed description will be made on the electronic assembly welding method of the automatic lifting wave soldering of components of the present invention.

[0023] The electronic assembly and welding method for components with automatic lifting wave soldering of the present invention is suitable for the electronic assembly process that requires lifting components, and the components are mostly through-hole plug-in components, such as plug-in diodes , Plug-in resistors, plug-in relays, etc.

[0024] The electronic assembly and welding method for automatically raising wave soldering of components in a preferred embodiment of the present invention includes the following steps:

[0025] 1) Production preparation

[0026] Carry out visual quality inspection of components, and check the type, specification, model and quantity of components. The appearance and quality of components should be intact, with clear marki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com