Piston type metering valve

A metering valve and piston type technology, applied in the field of glue injection equipment, can solve the problems that the material quantity cannot be guaranteed accurately, easy to produce deviation, and the working accuracy is not significantly improved, so as to shorten the working stroke, simplify the structure of the substrate, and ensure the accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

[0034] The problem to be solved by the present invention is to provide a piston-type metering valve device that can strictly control the amount of glue and can inject glue stably.

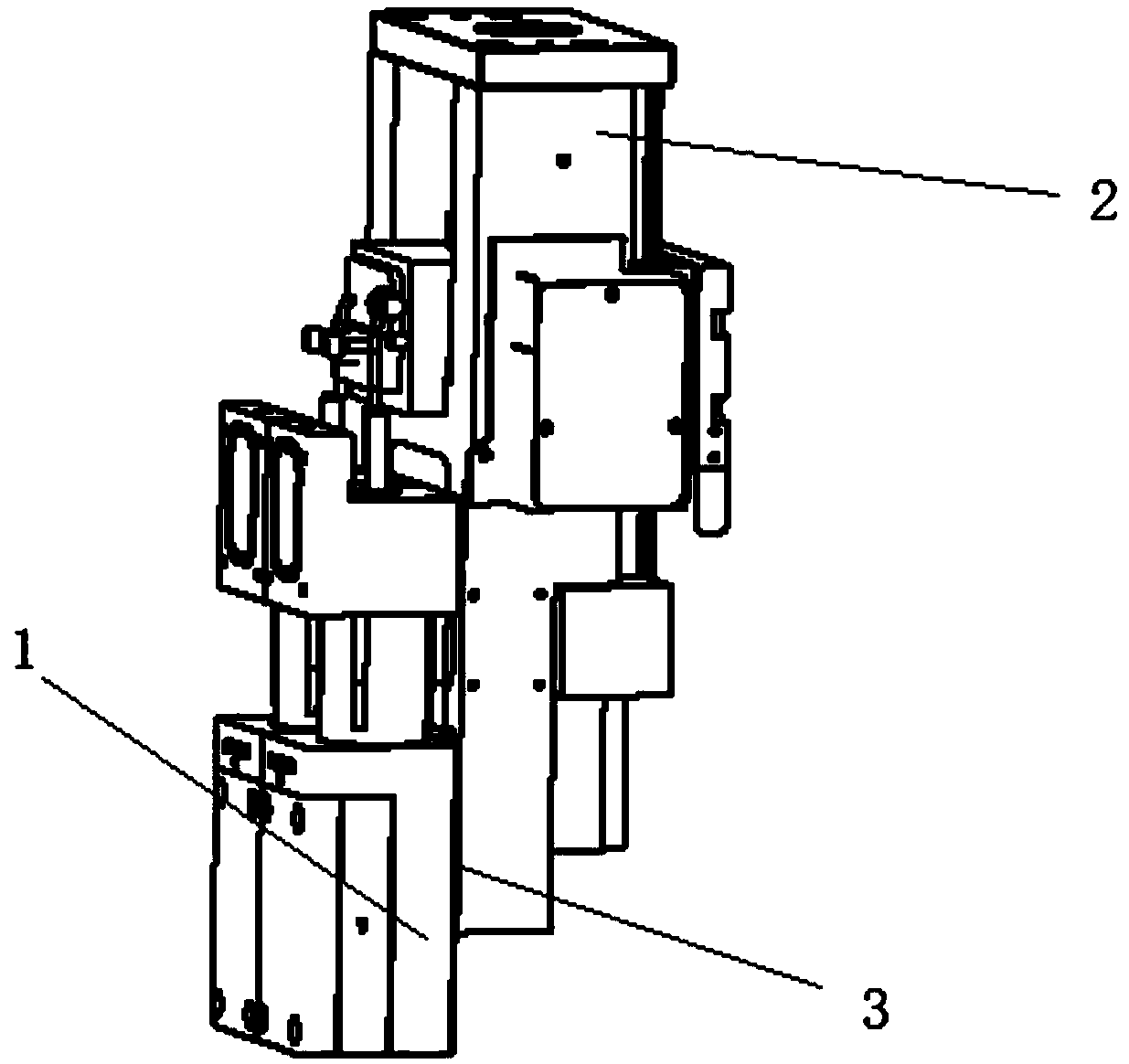

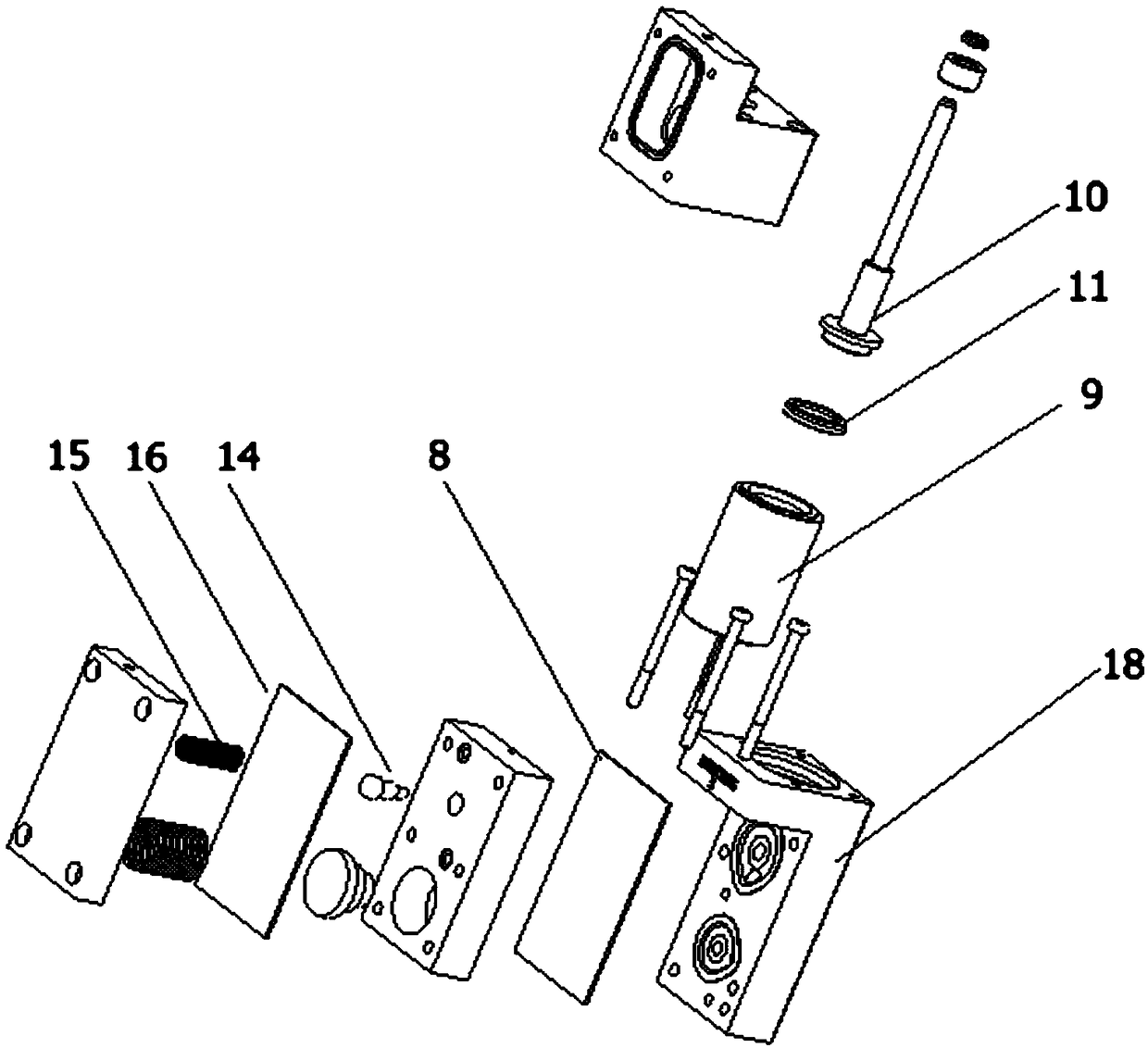

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 10 As shown, in order to solve the above problems, the present invention provides a piston metering valve device, comprising:

[0036] Glue in and out control device 1;

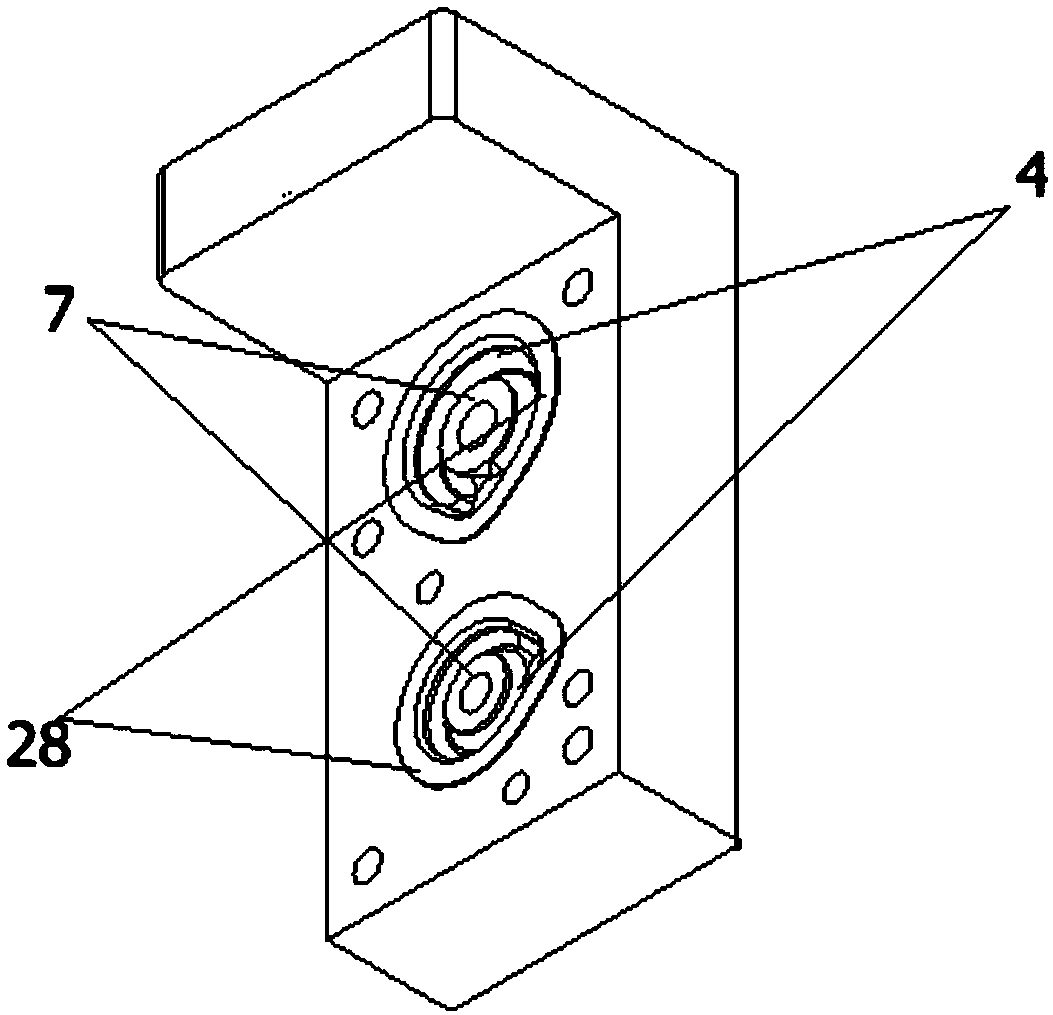

[0037] Described glue in and out control device 1 is provided with substrate 18; Described substrate 18 upper surface is provided with drop-shaped groove 4; Described drop-shaped groove 4 is provided with a feeding port 5 and a discharging port 6, and only uses It is a kind of glue, which is used to avoid glue stringing; the glue in and out control device 1 is provided with an adapter plate 27; the adapter plate 27 is provided with an ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com