Extrusion type conveying device for emulsion explosive and emulsion matrix

A technology of emulsified explosives and latex matrix, which is applied in explosives, explosives processing equipment, offensive equipment, etc. It can solve the problems of easy explosion accidents, easy falling off of rubber injection bushings, wear and heat, etc., and achieve short working stroke and long service life Long-lasting, highly safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

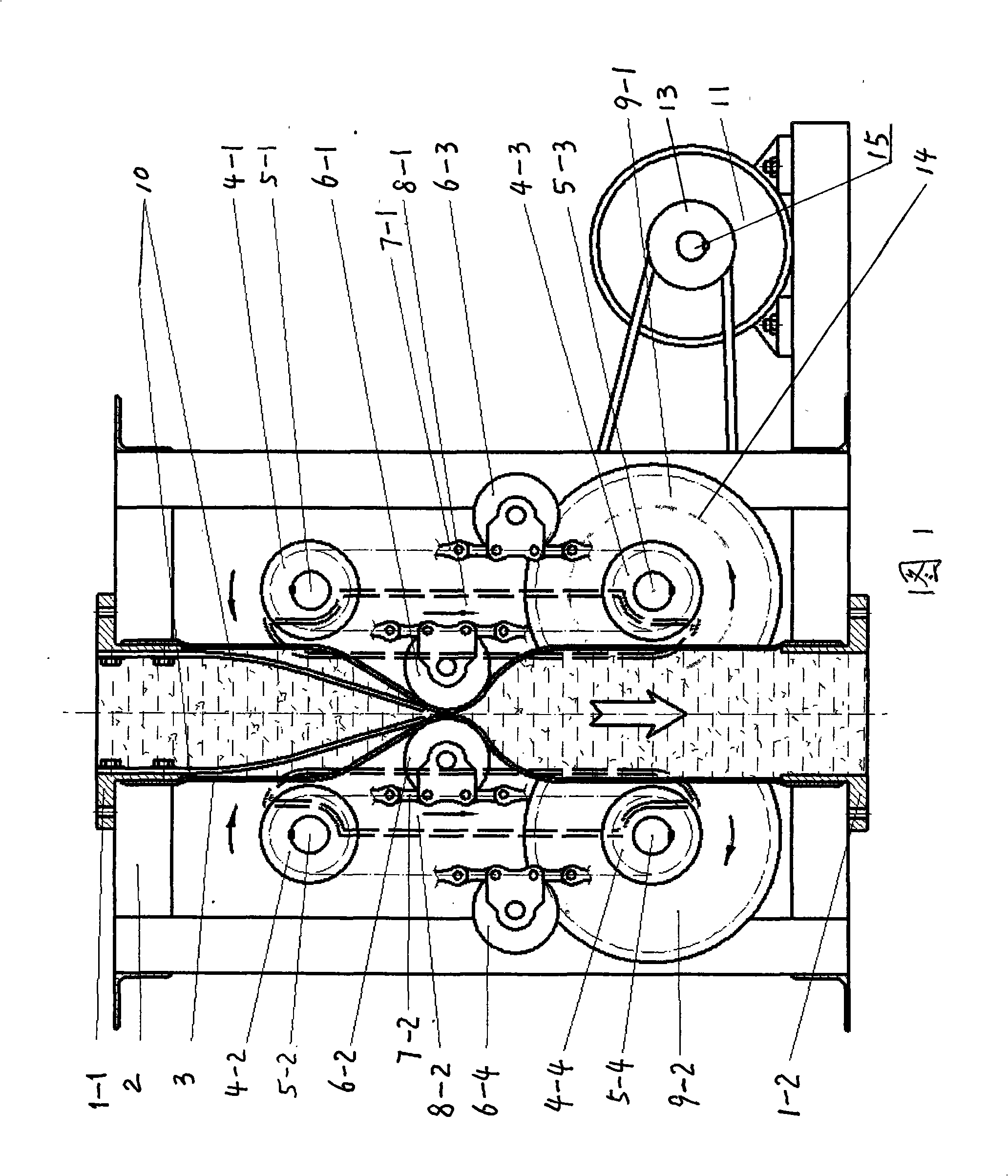

[0012] Embodiment 1: Referring to Fig. 1, the extruded emulsified explosive and latex matrix conveying device in embodiment 1 is a conveying device for extruding the materials in the conveying hose with double-sided rollers. It has a frame 2, and a feeding hose 3 is arranged in the frame 2, and the inlet and outlet ends of the feeding hose 3 are respectively fixedly connected with the respective connecting bodies 1-1, 1-2 and mounted on the frame 2. superior. On the frame 2 that is positioned at the right side of the feeding hose 3, the first driven shaft 5-1 and the first driving shaft 5-3 are hinged, and at the first driven shaft 5-1, the first driving shaft 5-3 The first driven sprocket 4-1 and the first driving sprocket 4-3 are fixedly connected to the top respectively, and the first driven sprocket 4-1 is connected with the first driving sprocket 4-3 through the first chain 7-1. . On the frame 2 that is positioned at the left side of feeding hose 3, be hinged with the s...

Embodiment 2

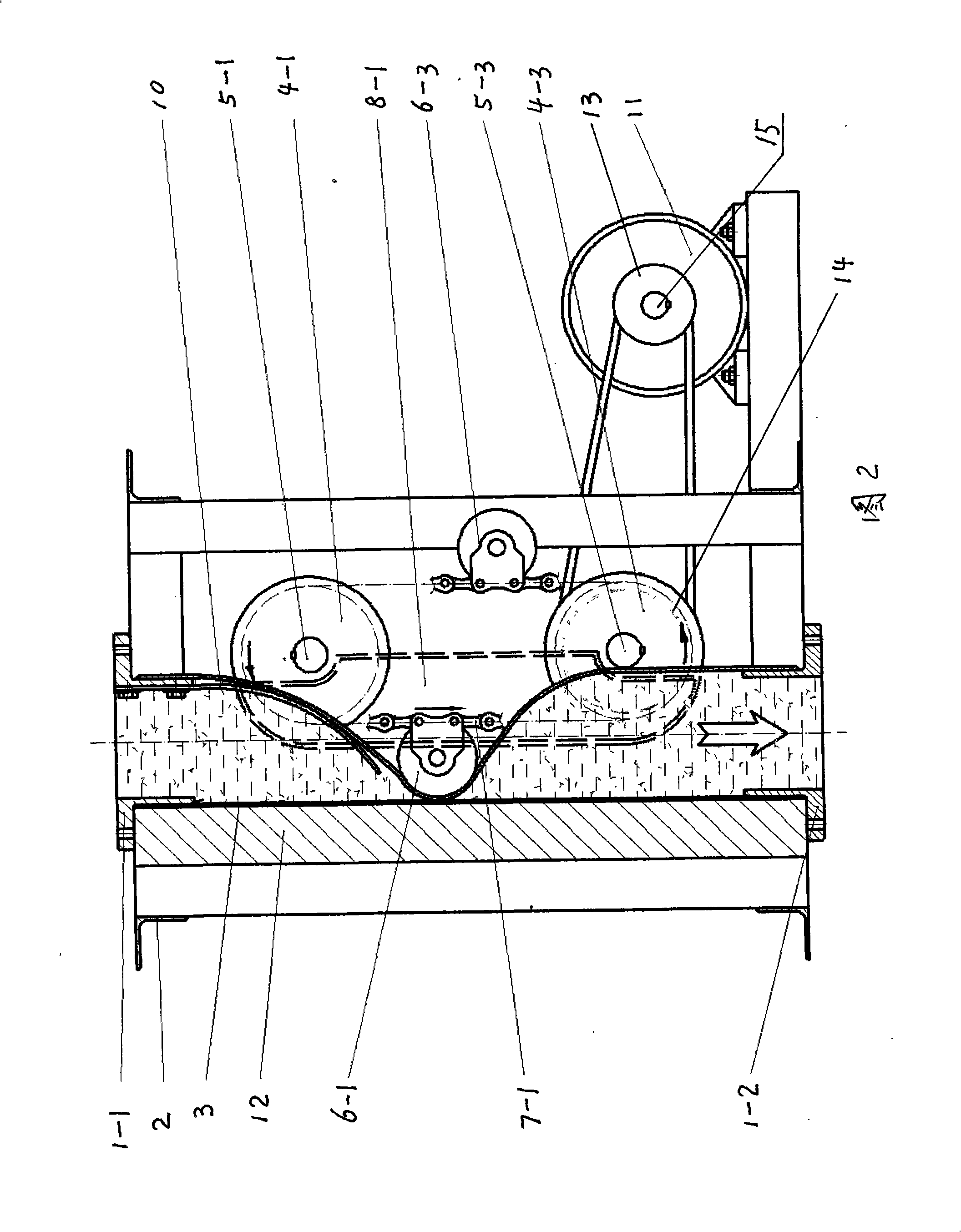

[0014] Embodiment 2: Referring to Fig. 2, another extruded emulsified explosive and latex matrix conveying device is a conveying device that is supported on one side and squeezed by a single-sided roller to squeeze the material in the conveying hose. It includes a frame 2, the inlet and outlet ends of the material delivery hose 3 are fixedly connected with the respective connectors 1-1, 1-2 respectively and installed on the frame 2, the left side of the material delivery hose 3 is connected to the machine The support plate 12 of the frame 2 is in contact with each other, and the first driven shaft 5-1, the first driving shaft 5-3, and the first driven shaft 5-1 are hinged on the frame 2 on the right side of the material delivery hose 3. 1. The first driving shaft 5-3 is fixedly connected with the first driven sprocket 4-1 and the first driving sprocket 4-3 respectively, and the first driven sprocket 4-1 connects with the first chain 7-1 through the first chain 7-1. A driving s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com