Control method for screen lifting platform capable of accurately controlling lifting distance and off-grid speed

A lifting table, distance technology, applied in screen printing machines, general parts of printing machinery, printing and other directions, can solve problems such as lifting distance and poor controllability of off-grid speed, achieve strong self-locking ability, improve stability, lift Accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail below in conjunction with accompanying drawing:

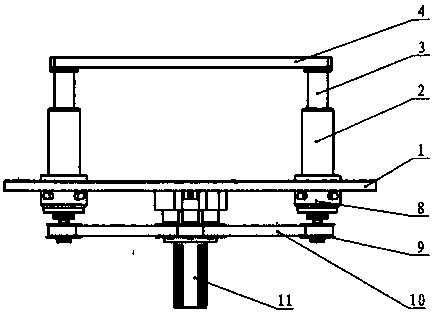

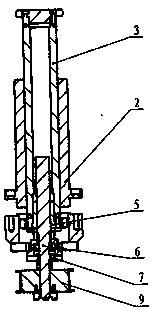

[0015] A wire mesh lifting platform that can accurately control the lifting distance and off-grid speed, including a rectangular lifting platform base plate 1, a servo motor 11 is arranged on the lower bottom surface of the rectangular lifting platform base plate 1, and a rectangular lifting platform base plate 1 Linear bearing housings 2 are arranged on the four top corners, a hollow guide shaft 3 is arranged in the linear bearing housing 2, a screen printing platen 4 is arranged on the top of the hollow guide shaft 3, and the lower end of the hollow guide shaft 3 is connected to There is trapezoidal screw nut 5, and trapezoidal screw nut 5 is provided with trapezoidal screw nut 6, and the screw seat 7 of trapezoidal screw nut 5 is arranged on the lower bottom surface of rectangular lifting platform base plate 1 by screw mounting plate 8, The upper end of the trapezoidal scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com