Cross drilling type drilling machine

A drilling machine and outer surface technology, applied in the direction of drilling/drilling equipment, boring/drilling, parts of boring machine/drilling machine, etc., can solve the problem of different drilling depths, reduce drilling procedures, and improve drilling efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

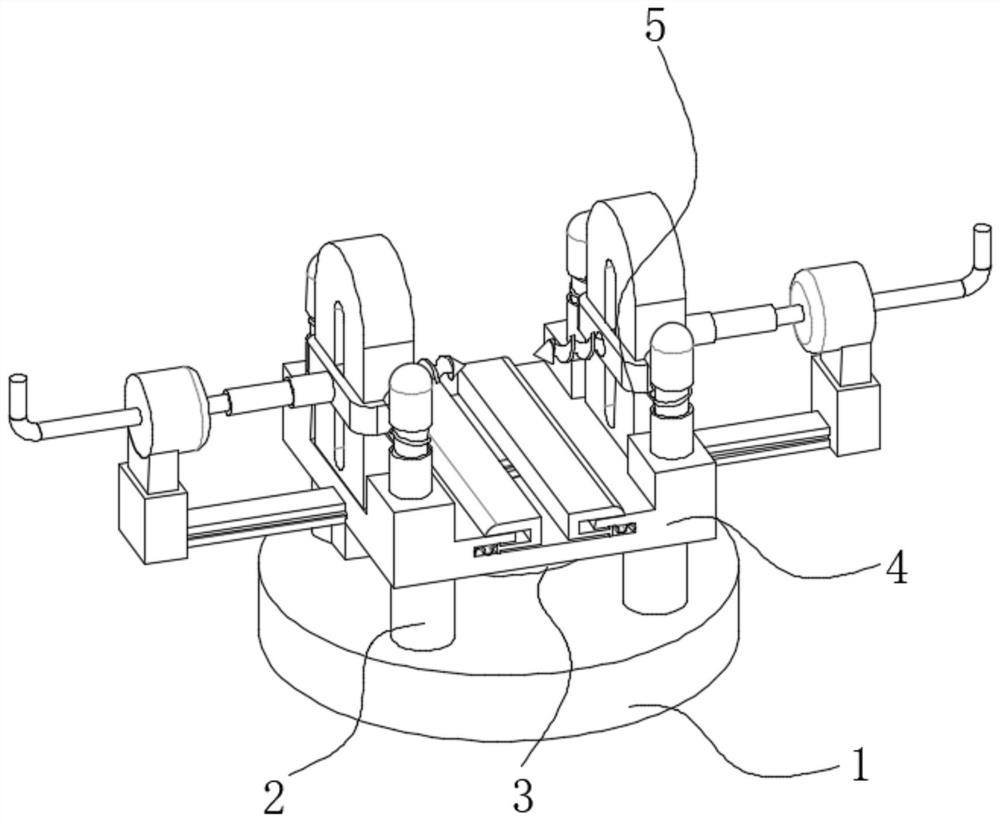

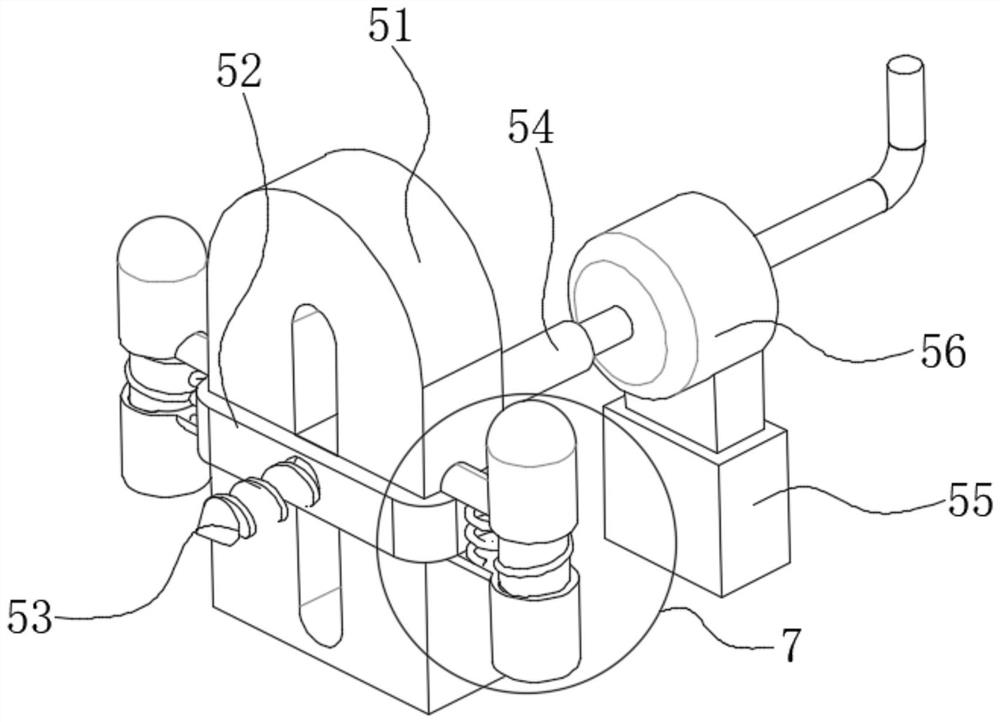

[0033] use Figure 1-Figure 6 A cross-drill type drill according to one embodiment of the present invention will be described below.

[0034] like Figure 1-Figure 6 As shown, a cross-drilling type drilling machine of the present invention includes a support base 1, the upper surface of the support base 1 is uniformly provided with a support frame column 2, and the top of the support frame column 2 is fixedly connected with an insert plate 4, and the insert plate 4. A control device 3 is arranged at the axis of the lower surface, and a drilling device 5 is arranged symmetrically on both sides of the upper surface of the clamping plate 4. Because the device has a high degree of symmetry, and the device can process both sides of the steel plate at one time. Drilling operations are carried out, so there is no need for repeated drilling procedures, thereby reducing drilling procedures and improving drilling efficiency.

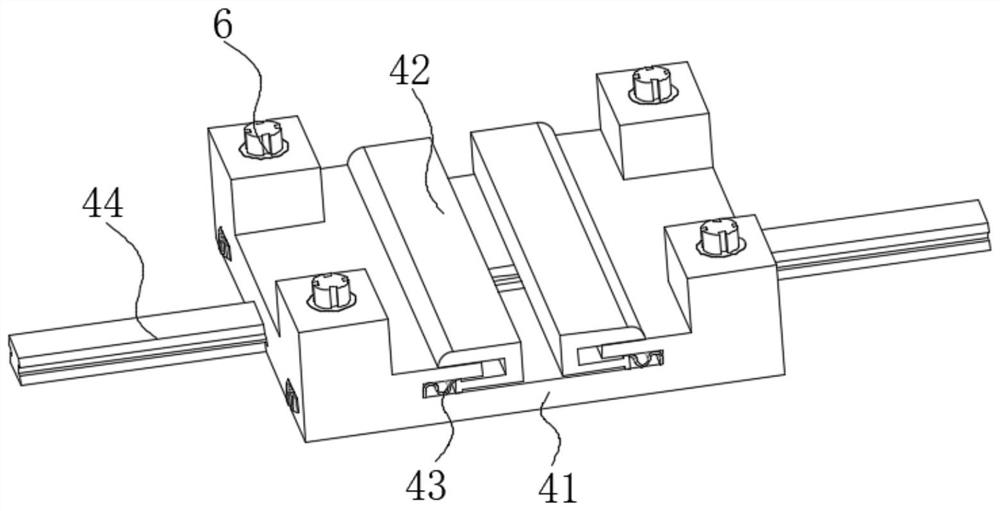

[0035] Insert plate 4 comprises refitting square plate 41,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com