Electroslag remelting furnace with uniform smelting function

An electroslag remelting furnace, uniform technology, applied in the field of electroslag remelting furnace, can solve the problems of uneven smelting, arc failure, poor position accuracy, etc., to achieve uniform smelting, stable operation, and the effect of ensuring overlap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

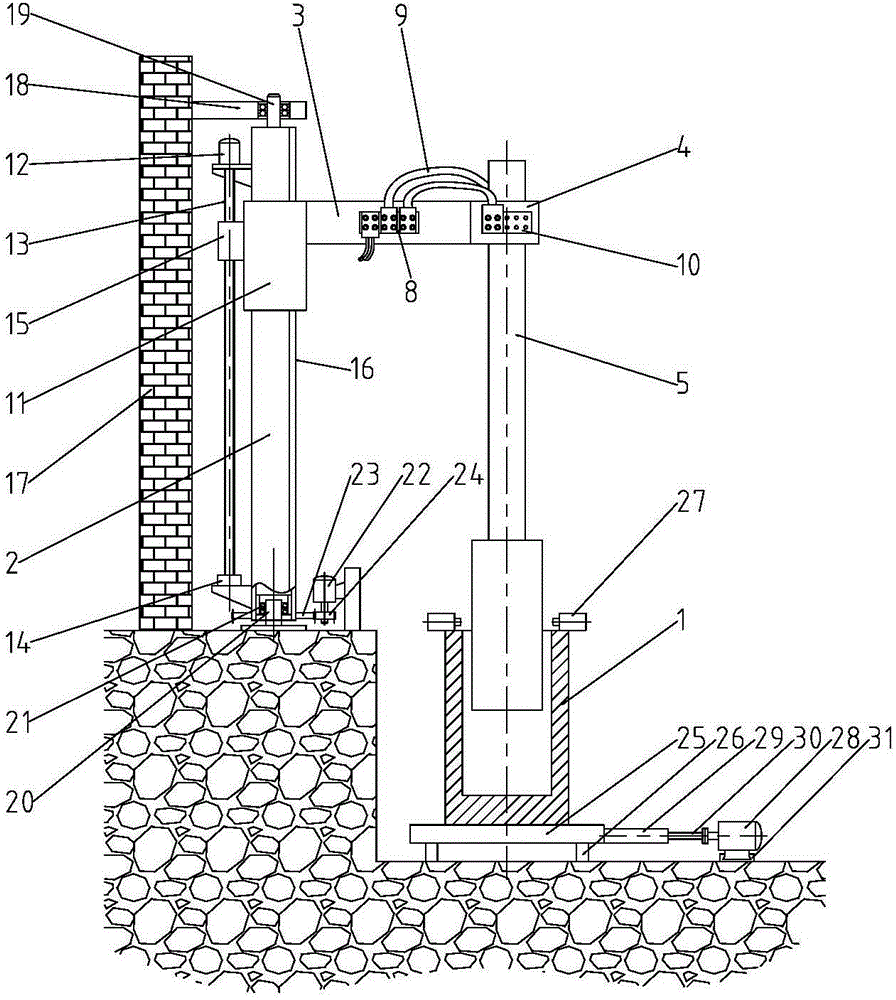

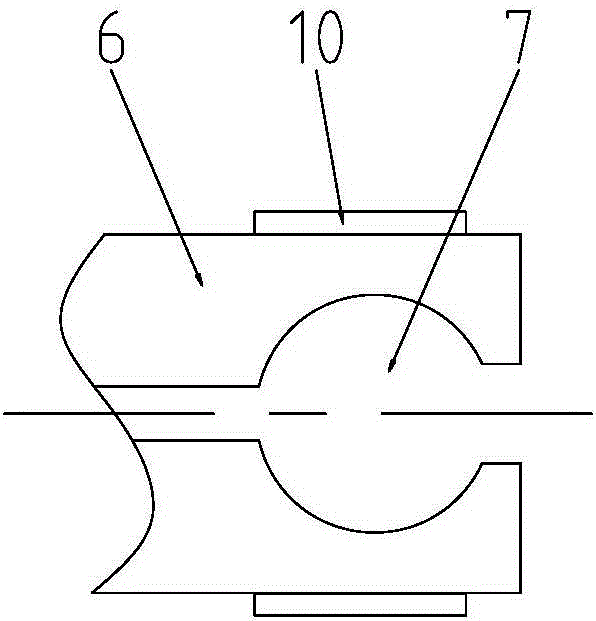

[0029] Such as figure 1 Shown is a schematic structural view of an embodiment of an electroslag remelting furnace with uniform smelting in the present invention. The electroslag remelting furnace with uniform smelting in this embodiment includes a crystallizer 1 and a vertical pillar 2 located on one side of the crystallizer 1. The vertical pillar 2 is provided with a cross arm 3 slidingly fitted thereon, and the cross arm 3 is far away from the vertical pillar. One end of 2 is located above the crystallizer 1 and is provided with a holder 4 on which an electrode 5 protruding into the crystallizer 1 is clamped and fixed. The holder 4 includes two oppositely disposed clamping piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com