Egg roll processing device

A processing device and egg roll technology, which is applied in the direction of special commodity baking, baking, food science, etc., can solve the problems of complex structure of guide rail components, and achieve the effect of simple and compact structure, simple structure and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

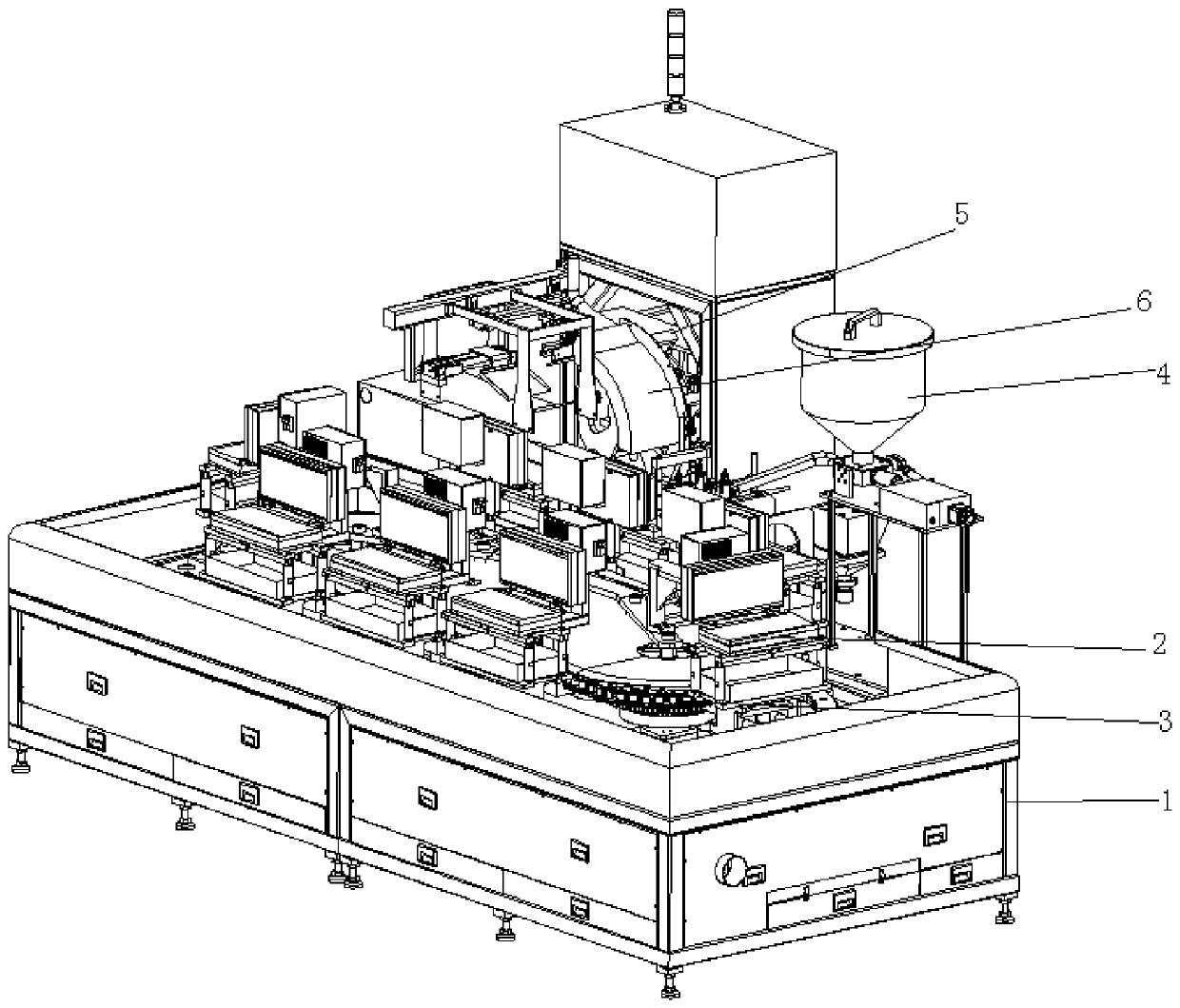

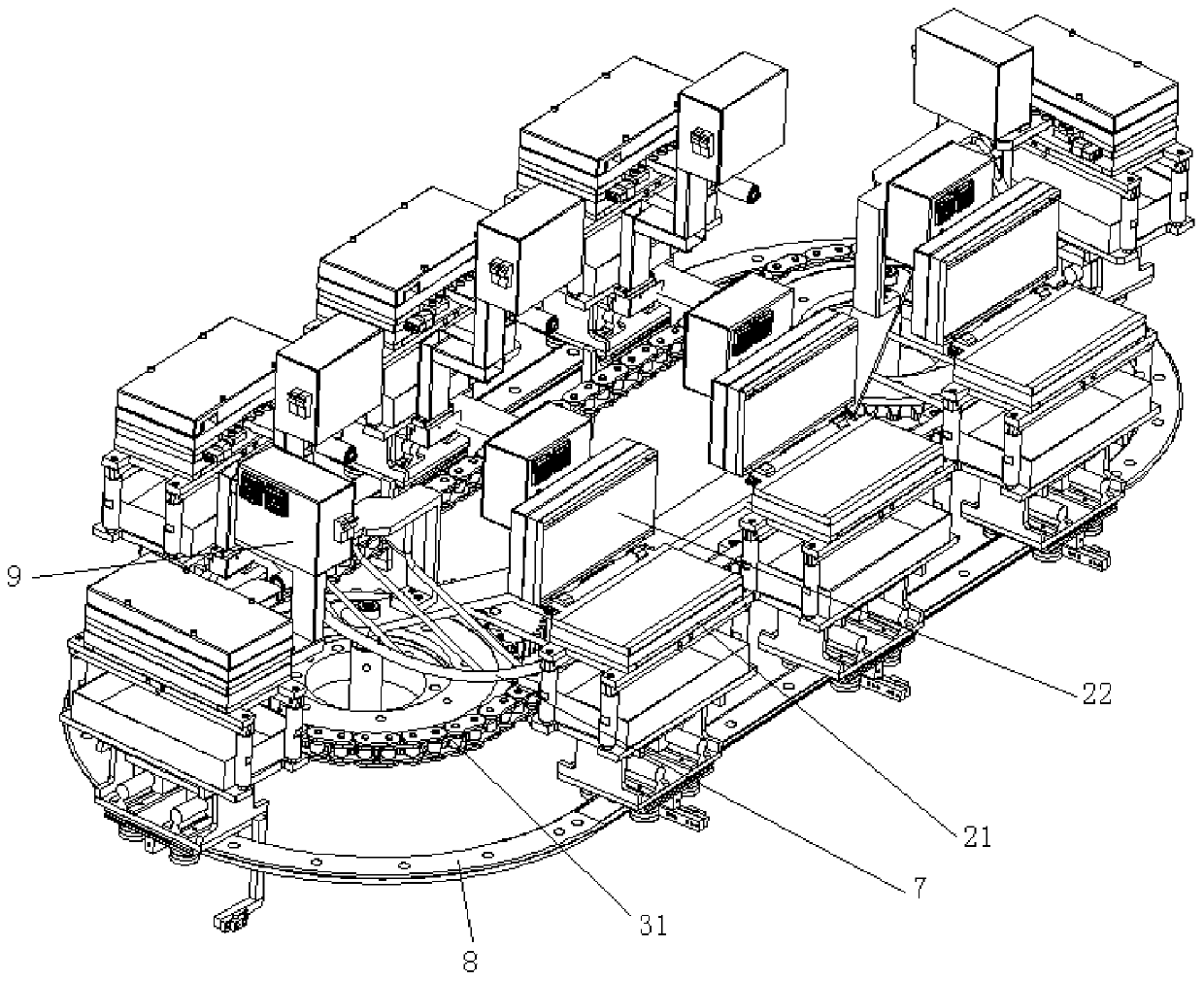

[0063] This embodiment provides a specific implementation of an egg roll processing device, such as Figure 1 to Figure 6 , including a frame 1 , a baking pan assembly 2 , a moving assembly 3 , a guide rail 7 , a grouting assembly 4 , a coil assembly 5 , a cooling device 6 , a clamping assembly 10 , a cleaning assembly 20 , and an electric control device 9 .

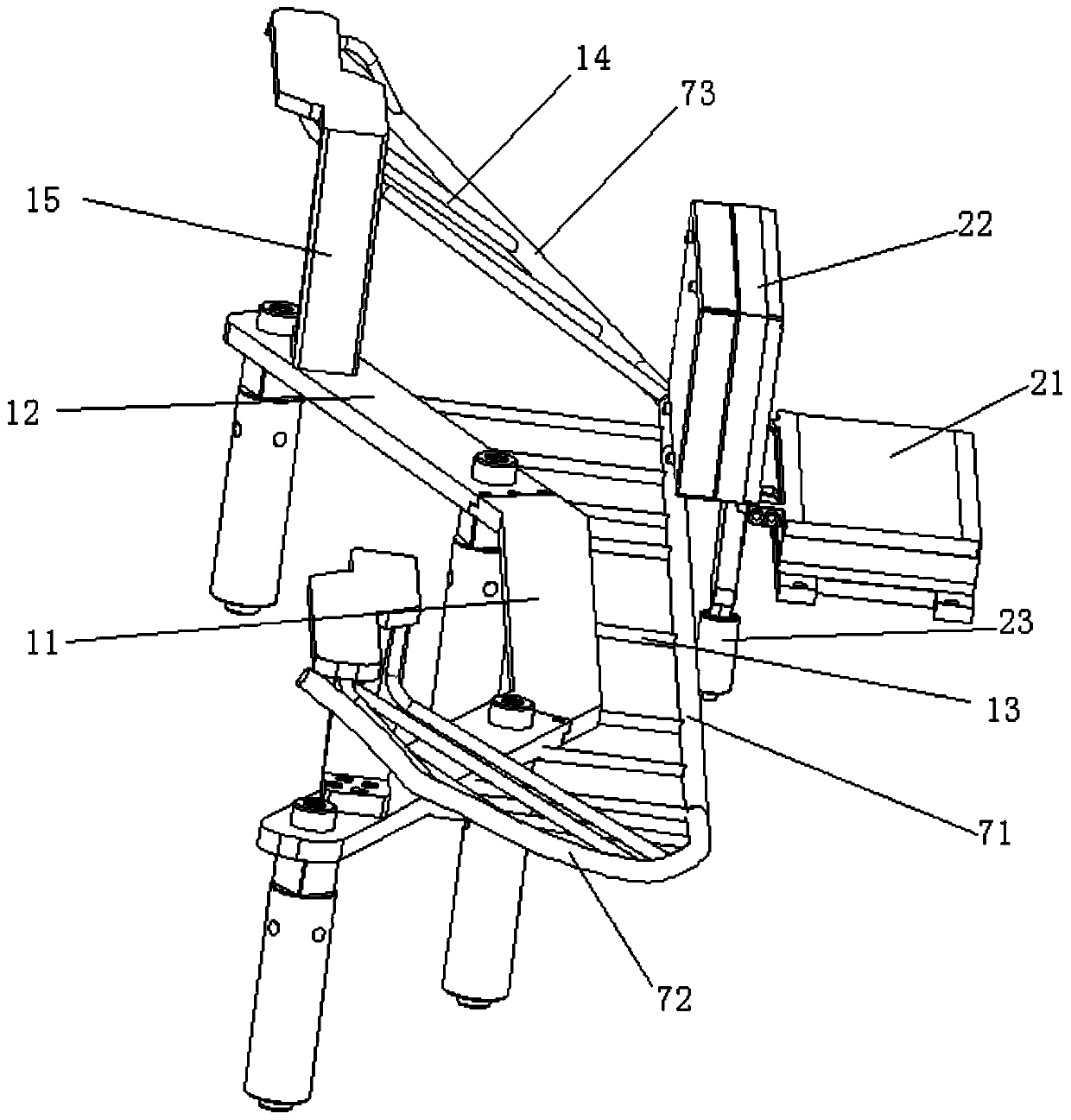

[0064] Among them, there are multiple baking tray assemblies 2, specifically eight, which are eight-station egg roll processing devices. Each baking tray assembly 2 includes an upper baking tray 22 and a lower baking tray 21 hinged to the upper baking tray 22. The baking pan 22 can rotate relative to the lower baking pan 21, so that the upper baking pan 22 has a closed position covered on the lower baking pan 21 and an open position separated from the lower baking pan 21. When the upper baking pan 22 is in the closed position, the grill The pan assembly 2 heats the slurry on the lower baking pan 21 . Each grill assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com