Self locking type elevating platform

A lifting platform, self-locking technology, applied in the field of lifting platforms, can solve the problems of inaccurate control of lifting height, large volume of hydraulic lifting platforms, complex system, etc., and achieve the effect of light weight, simple structure and stable working process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

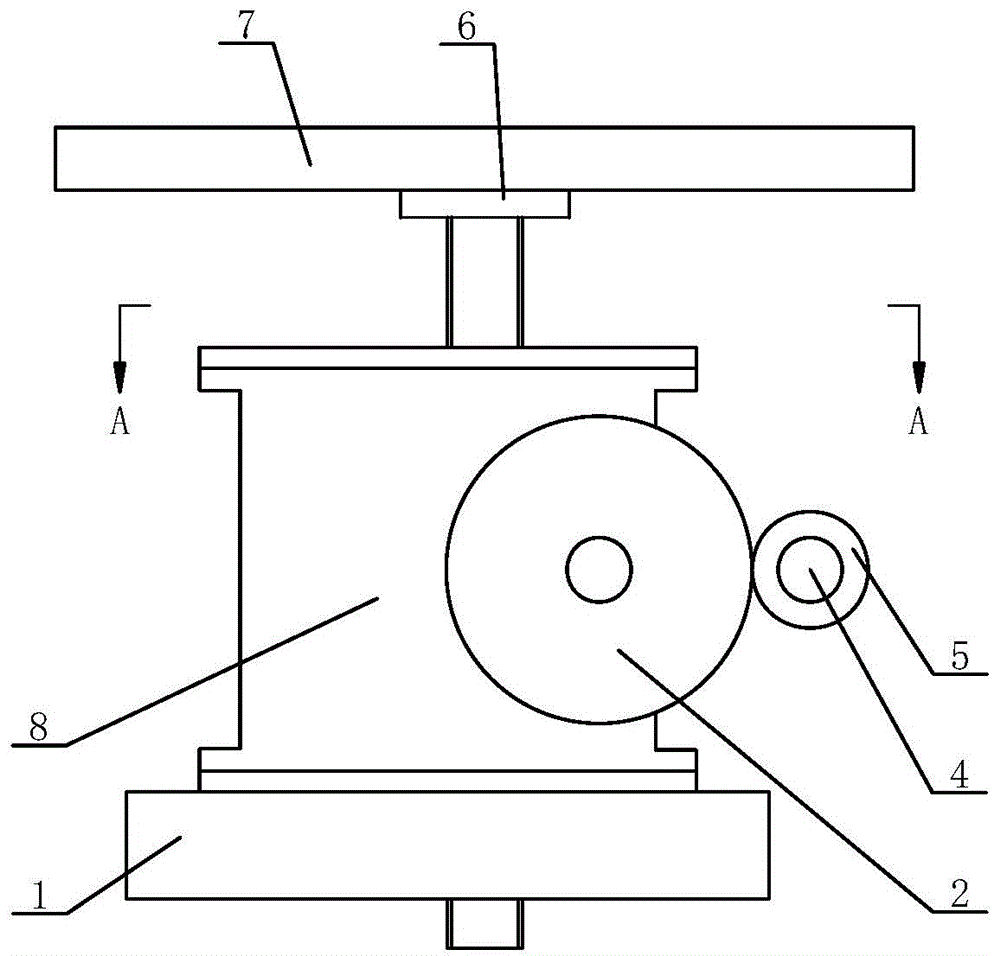

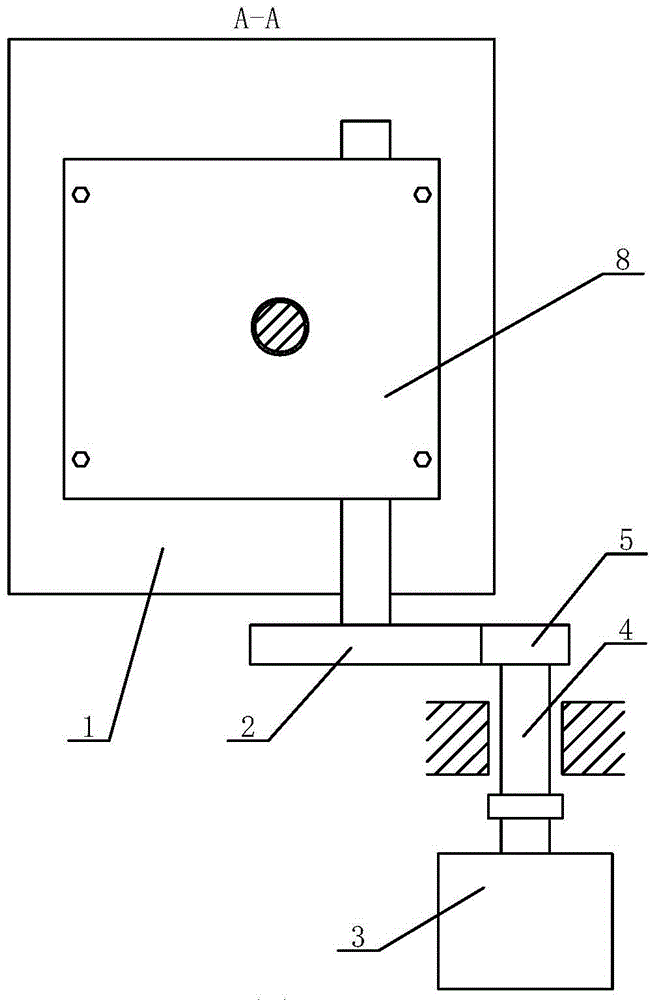

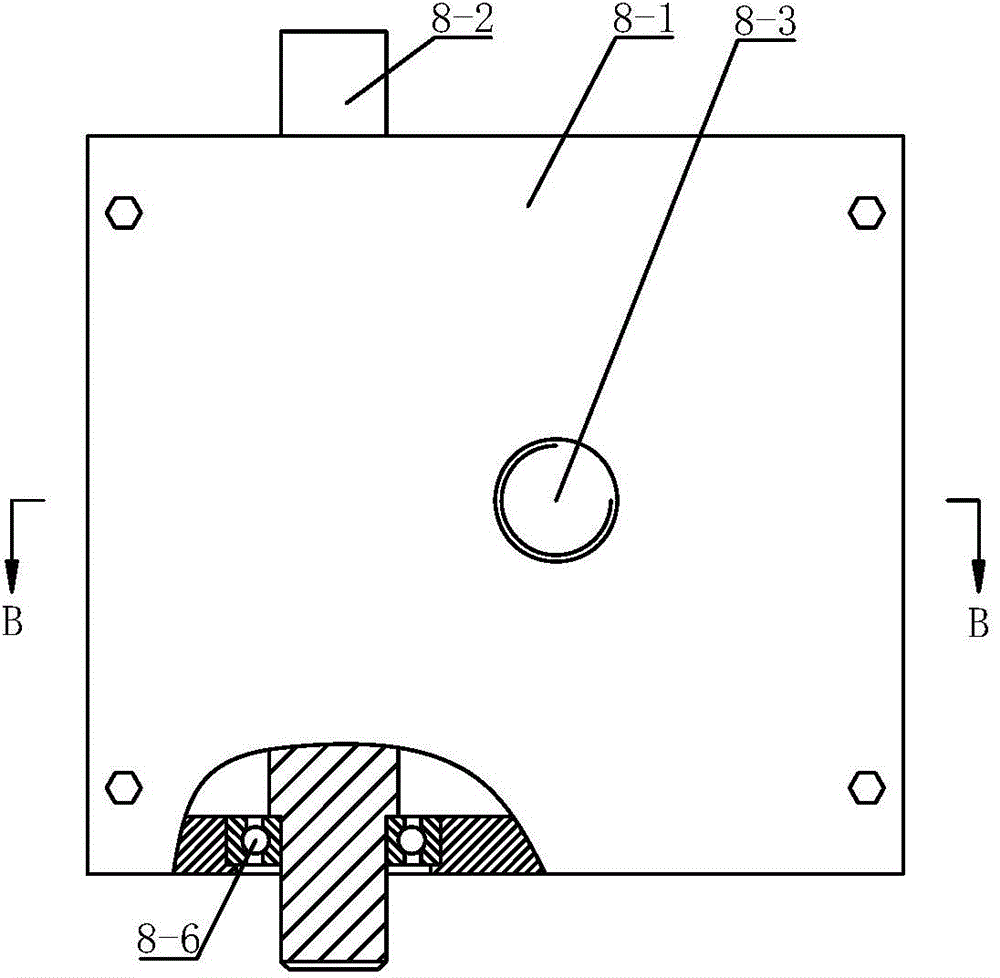

[0033] Such as Figure 1-Figure 4 As shown, the self-locking lifting platform only includes one self-locking lifting device 8 . When it works, start the drive motor 3 to rotate in the forward direction, and the drive motor 3 drives the worm 8-2 to rotate in the forward direction through the gear shaft 4, gear two 5 and gear one 2, and the worm 8-2 drives the worm gear 8 that meshes with it to form a worm gear pair -5 rotates in the forward direction, and the worm gear 8-5 drives the platen 7 to move upward through the threaded auxiliary drive screw 8-3. When the driving motor 3 reversely rotates, the platen 7 moves downward.

Embodiment 2

[0035] Such as Figure 5 with Image 6 As shown, the difference between the second embodiment and the first embodiment is that the self-locking lifting platform includes two self-locking lifting devices 8 arranged in parallel. During work, the driving motor 3 can simultaneously drive the worms 8-2 of the two self-locking lifting devices 8 to rotate forward or reversely through the gear shaft 4, the second gear 5 and the first gear 2, thereby driving the lifting of the platen 7 or drop.

Embodiment 3

[0037] Such as Figure 7 with Figure 8 As shown, the difference between the third embodiment and the first embodiment is that the self-locking lifting platform includes two self-locking lifting devices 8 arranged in series. The worms 8-2 of the two self-locking lifting devices 8 are connected by couplings. When working, the drive motor 3 can simultaneously drive the two self-locking lifting devices through the gear shaft 4, gear two 5 and gear one 2. The worm 8-2 of the device 8 rotates forward or reversely, thereby driving the lifting or lowering of the platen 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com