Stroke detection device for crane steel rope

A technology of stroke detection and steel wire rope, which is applied in the field of detection devices, can solve the problems of insufficient precision, troublesome use and adjustment, etc., and achieve the effect of precise control of lifting height and precise control of descending stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

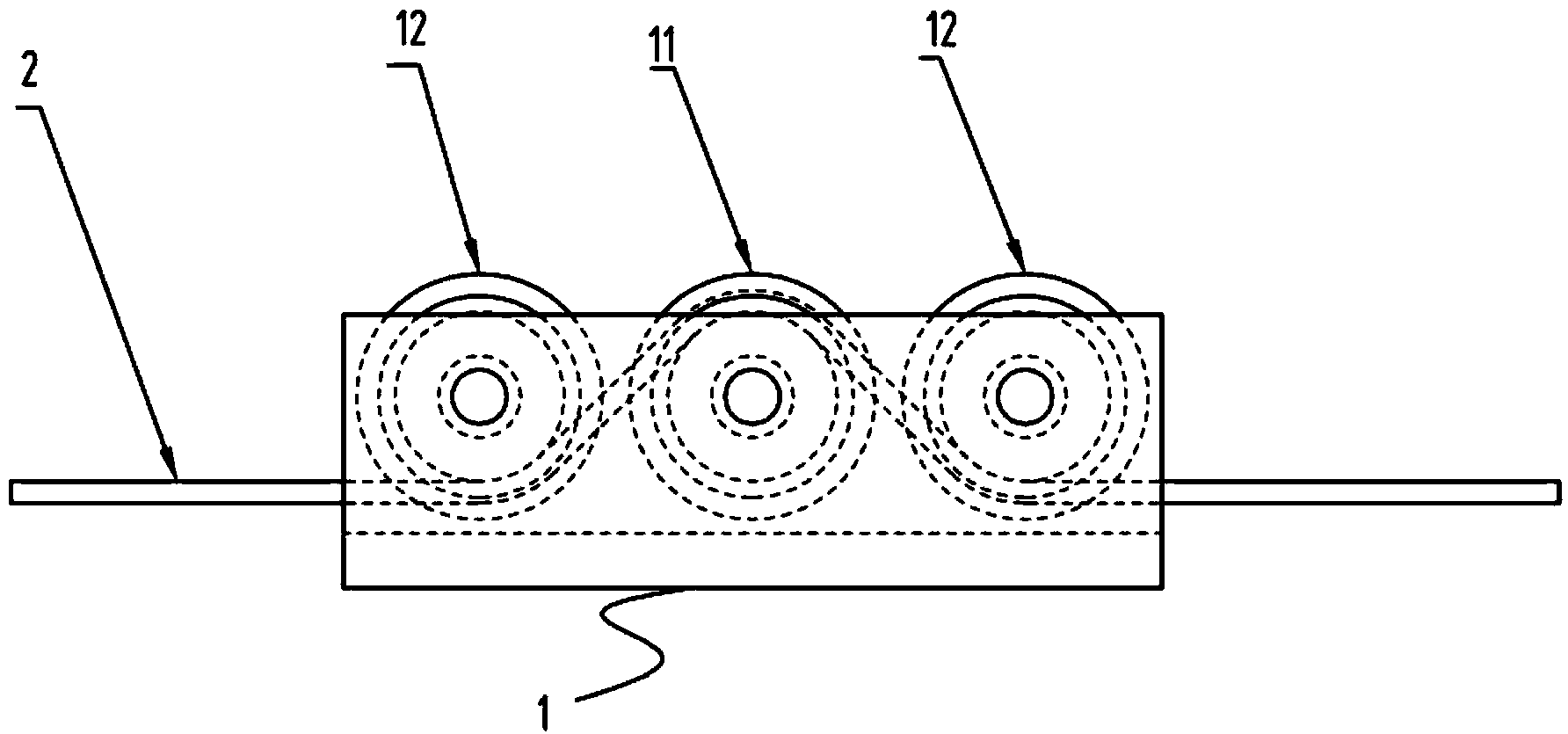

[0014] see figure 1 , which is a structural schematic diagram of the crane wire rope stroke detection device of the present invention. It includes a pulley block 1 composed of three pulleys side by side, and a displacement sensor is arranged on the middle pulley. Specifically, in this embodiment,

[0015] For better understanding and implementation, the present invention will be described in detail below in conjunction with the accompanying drawings. Described pulley block comprises 3 pulleys, wherein is positioned at the main pulley 11 of middle pulley, and the pulley that is positioned at main pulley two ends is auxiliary pulley 12. The crane wire rope 2 is hung on the top of the main pulley 11 , and the two ends of the wire rope go out along the bottom of the auxiliary pulley 12 .

[0016] During the working process, the up and down movement of the crane hook is realized by the rotation of the drum. When performing over-rolling limit, the displacement travel during the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com