Patents

Literature

151results about How to "Easy to pan" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

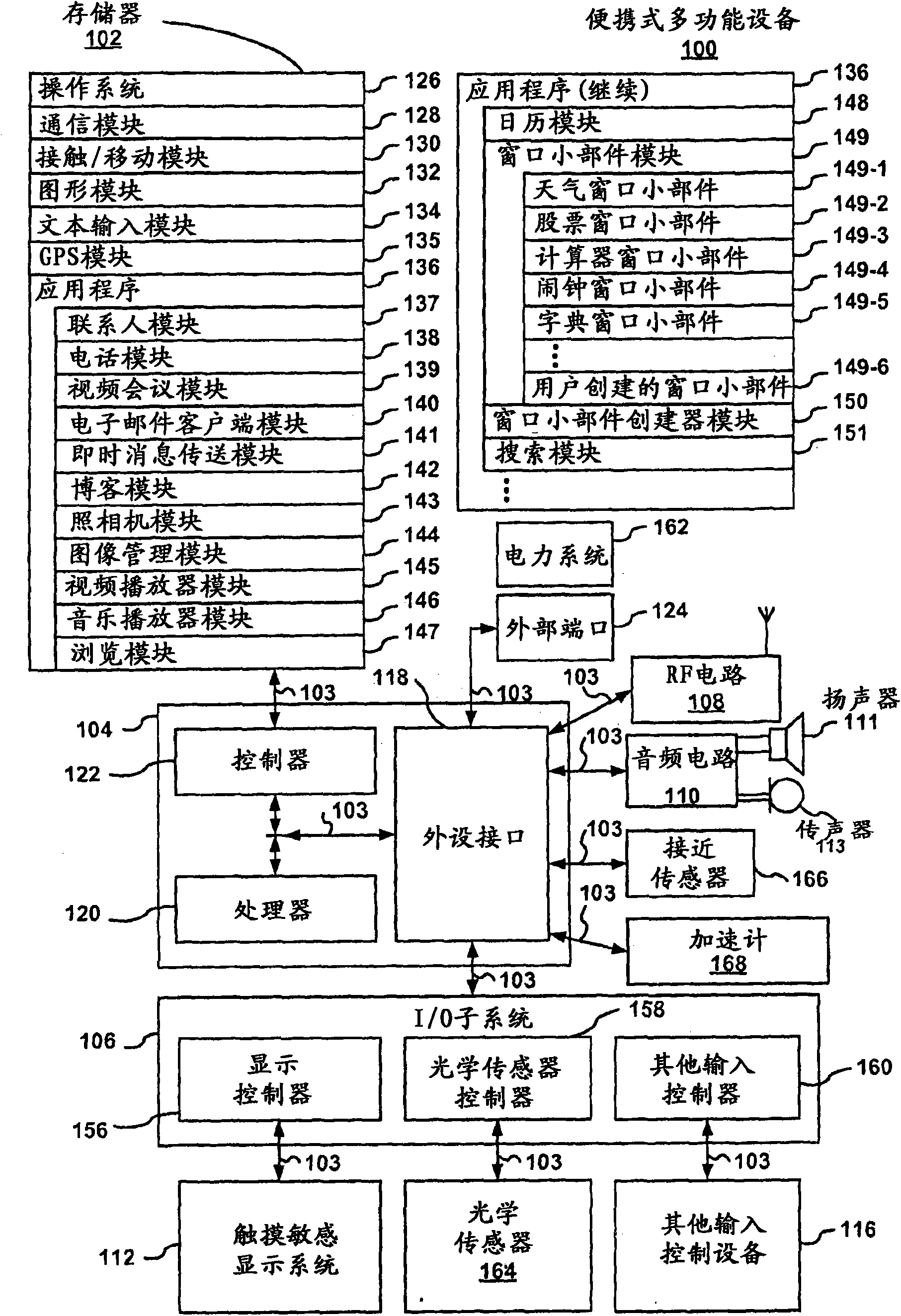

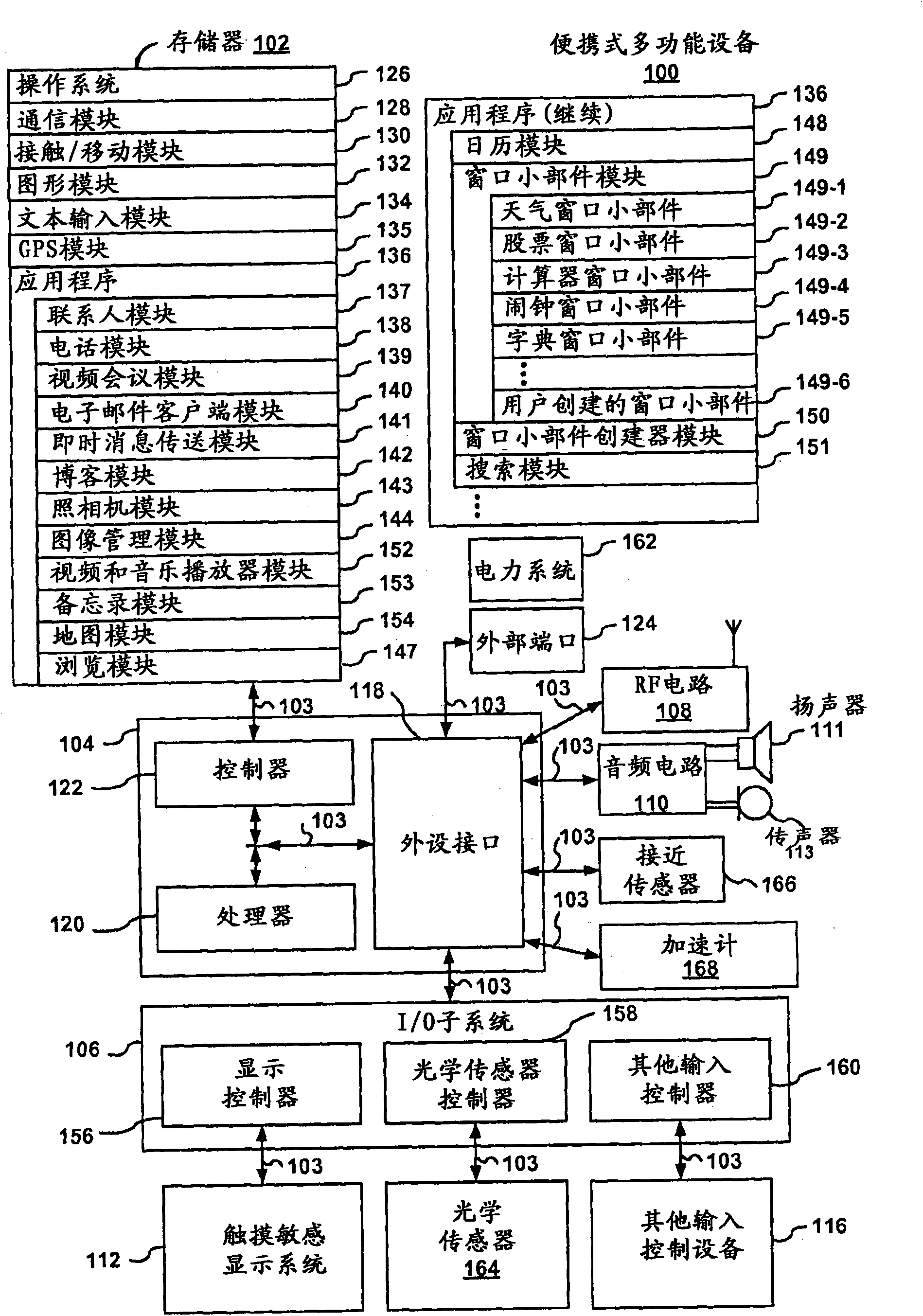

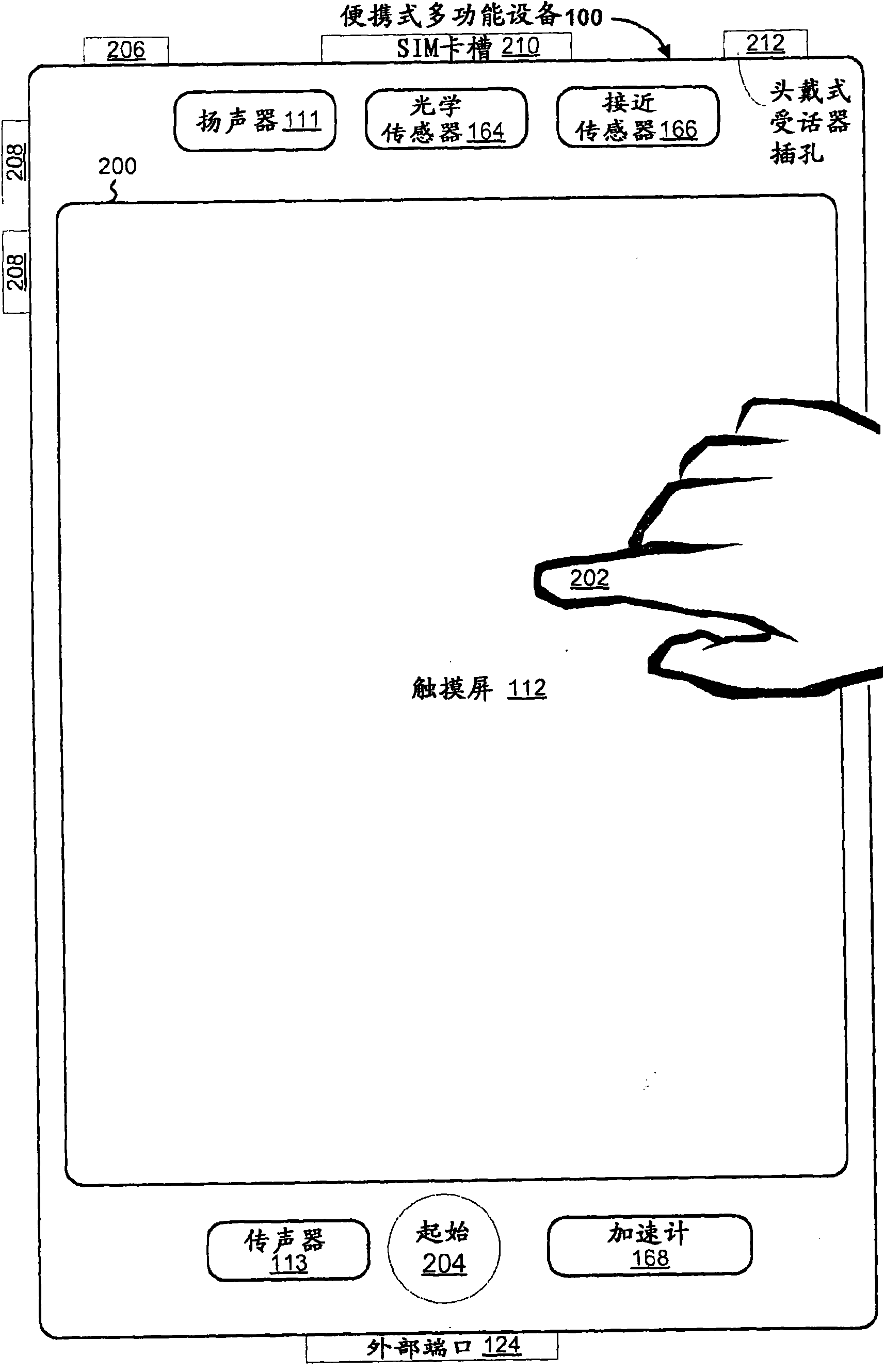

Portable multifunction device,method, and graphical user interface for translating displayed content

InactiveCN101617288AEasy to panInput/output processes for data processingGraphicsGraphical user interface

Owner:APPLE INC

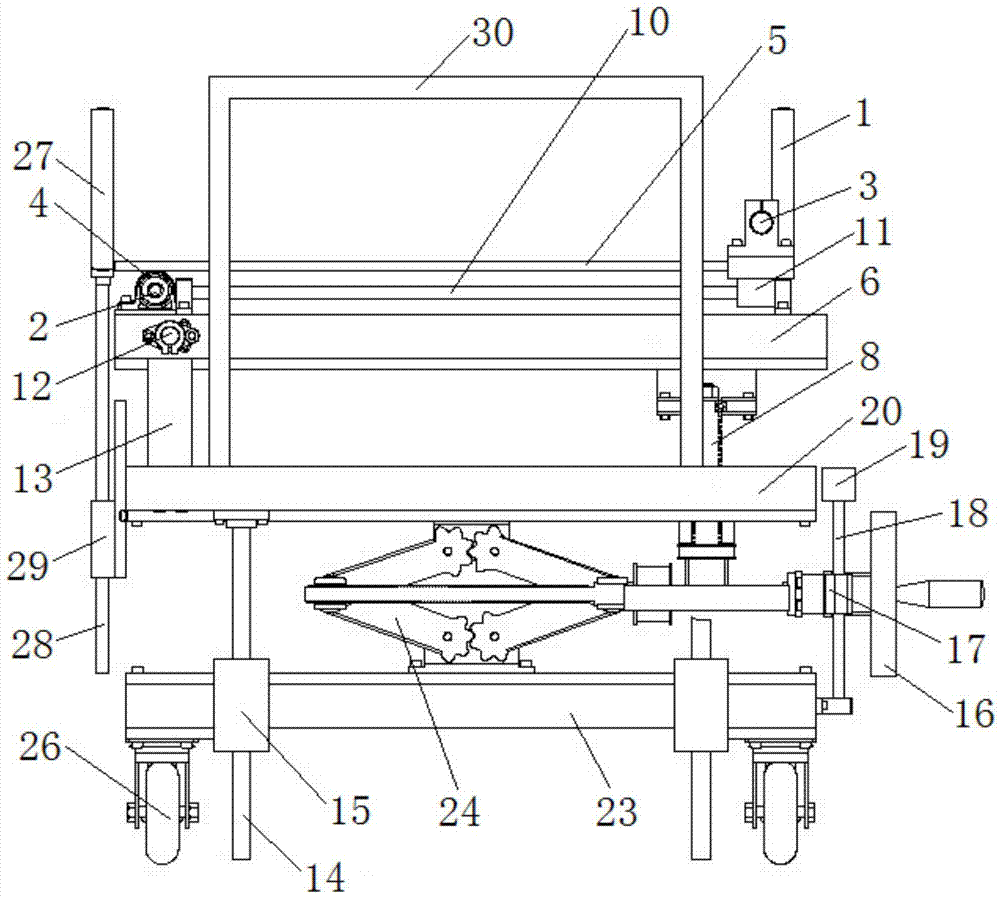

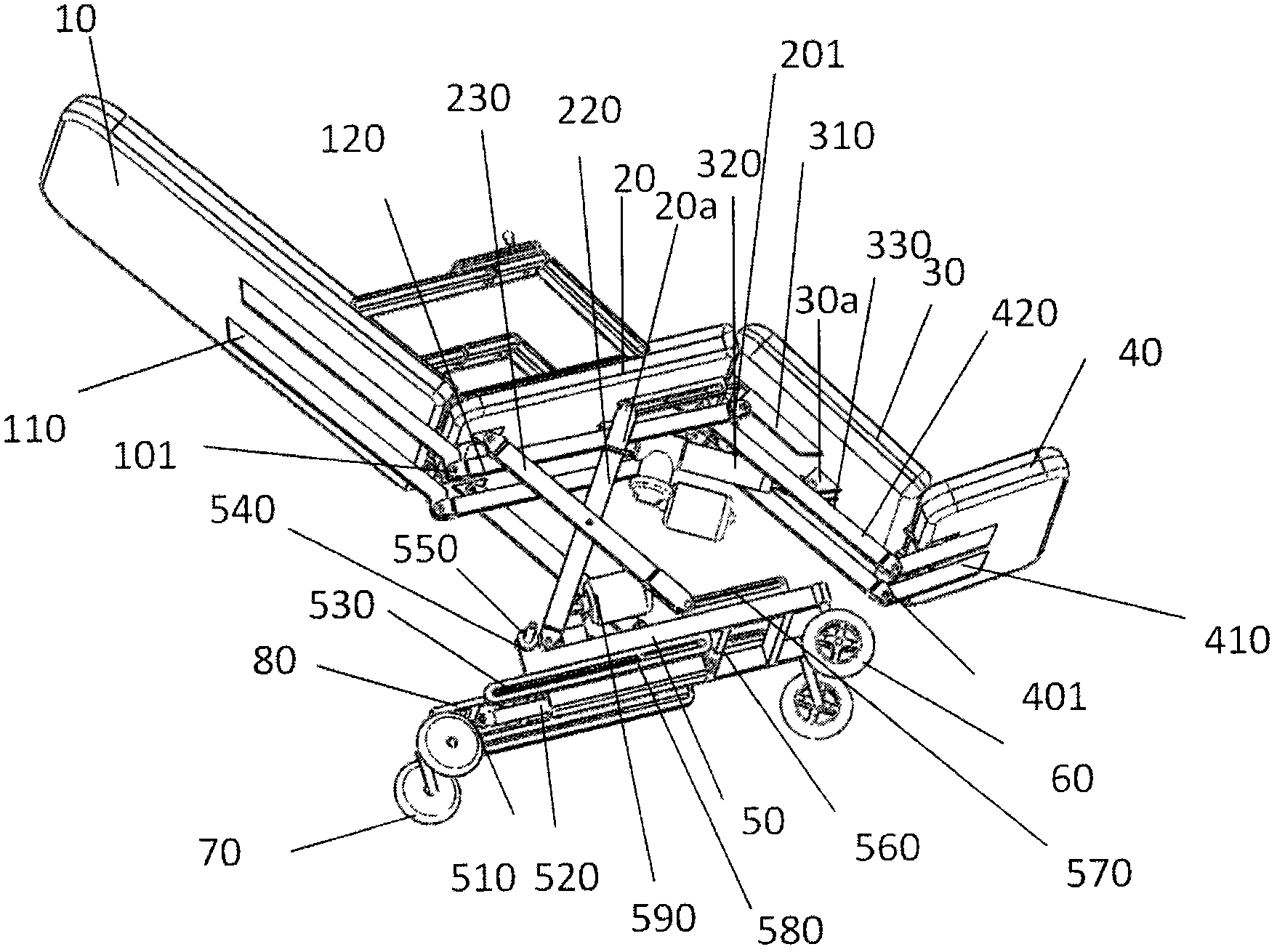

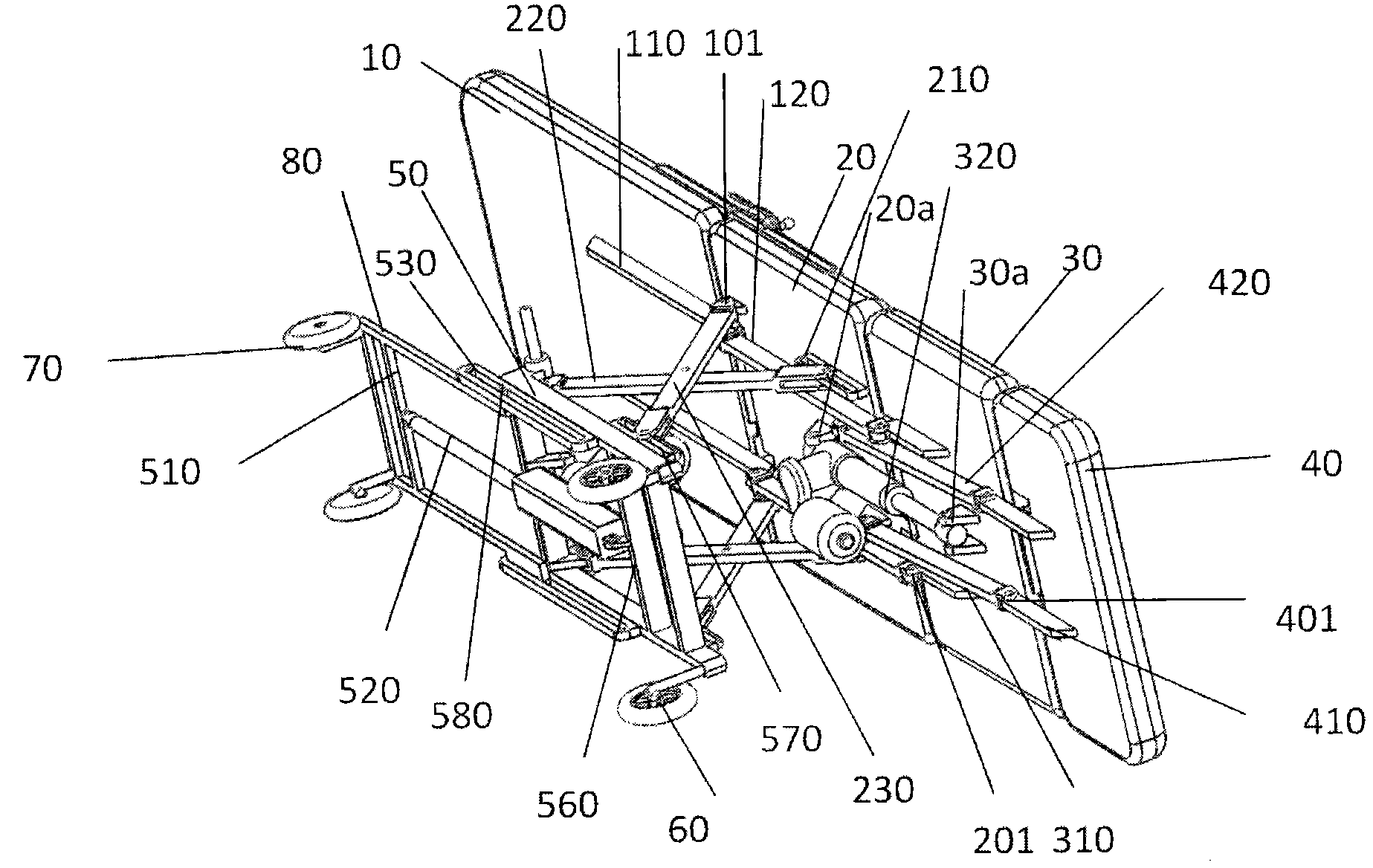

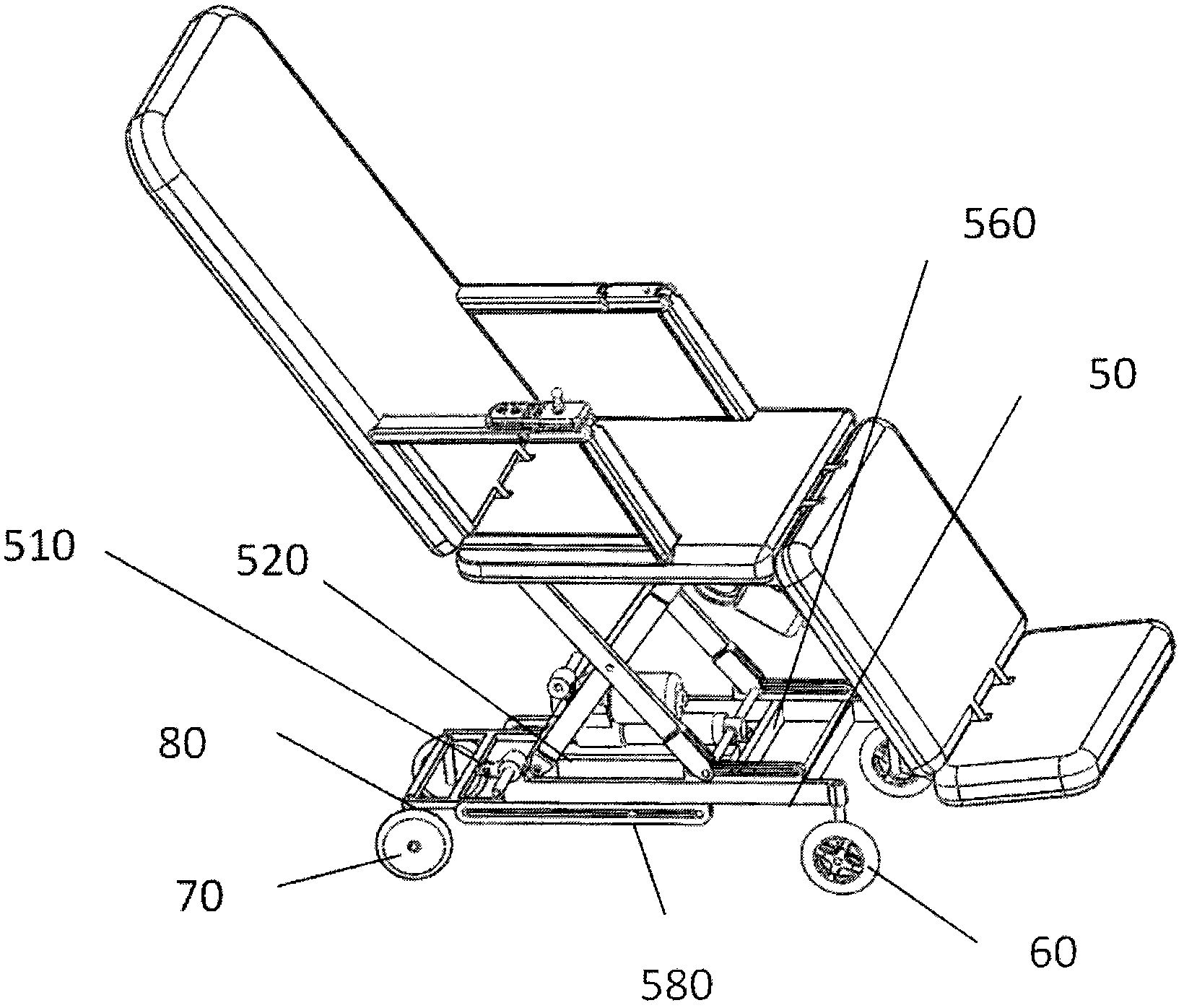

Mechanical patient transferring trolley

The invention discloses a mechanical patient transferring trolley and belongs to the field of special patient transportation tools. The mechanical patient transferring trolley comprises an upper trolley frame, a middle trolley frame, a lower trolley frame, a lifting device arranged between the lower trolley frame and the middle trolley frame, an overturning device arranged between the middle trolley frame and the upper trolley frame, a horizontal moving device arranged on the upper trolley frame and multiple sliding carrying plates which are mutually isolated. A scissor jack is used for ascending and descending the upper trolley frame and the middle trolley frame. A screw nut pair is used for overturning the upper trolley frame. A horizontal guide rail and a rolling bearing are used for horizontally moving the sliding carrying plates which are used for flexibly transferring a patient. The mechanical patient transferring trolley is flexible and convenient to operate, small in number of nursing personnel, needless of greatly moving the patient and capable of avoiding secondary injury in the patient transferring process and has the advantages of being simple in structure, low in cost, convenient to maintain, stable in operation and low in noise.

Owner:上海稼多医疗器械有限公司

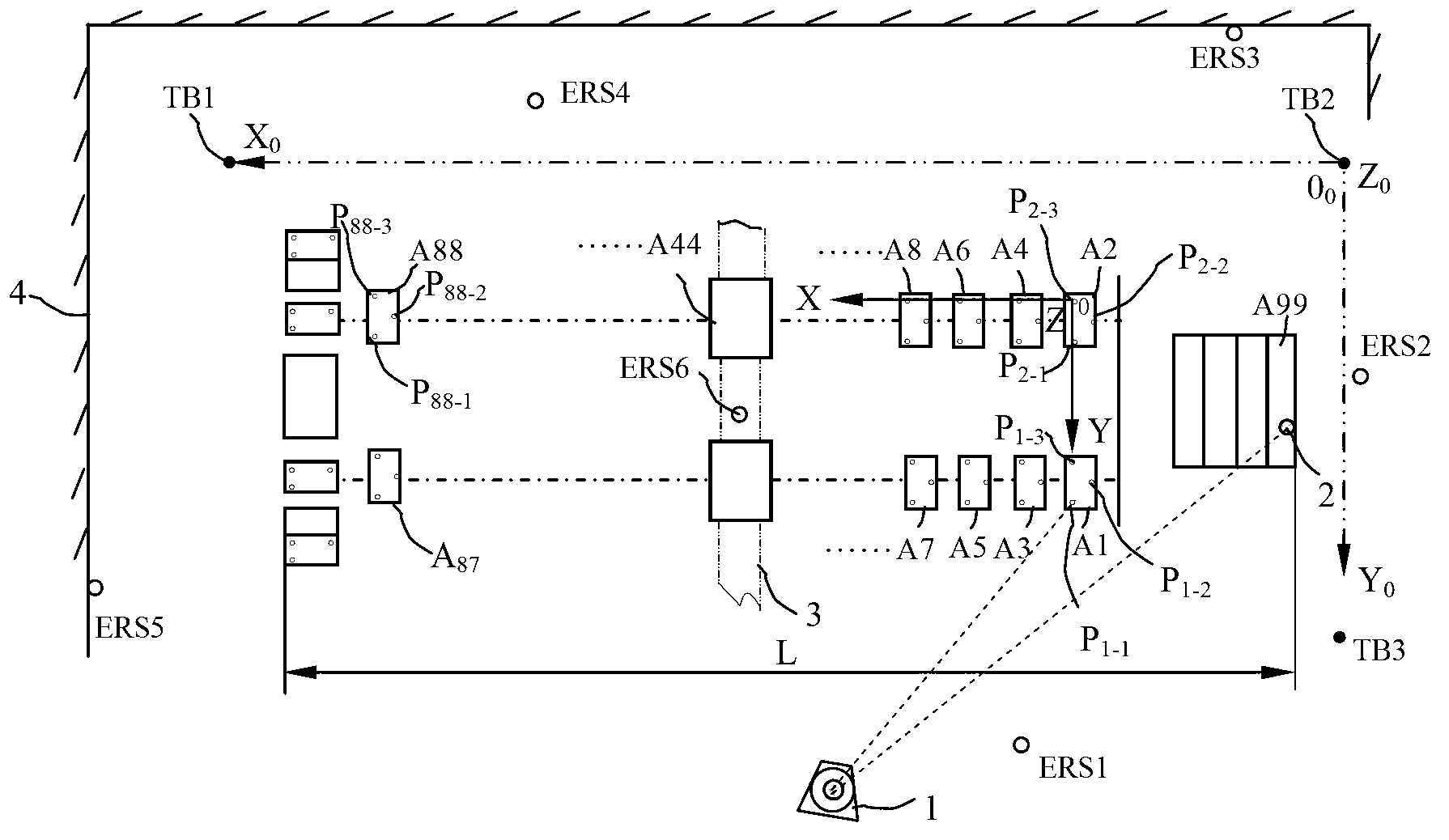

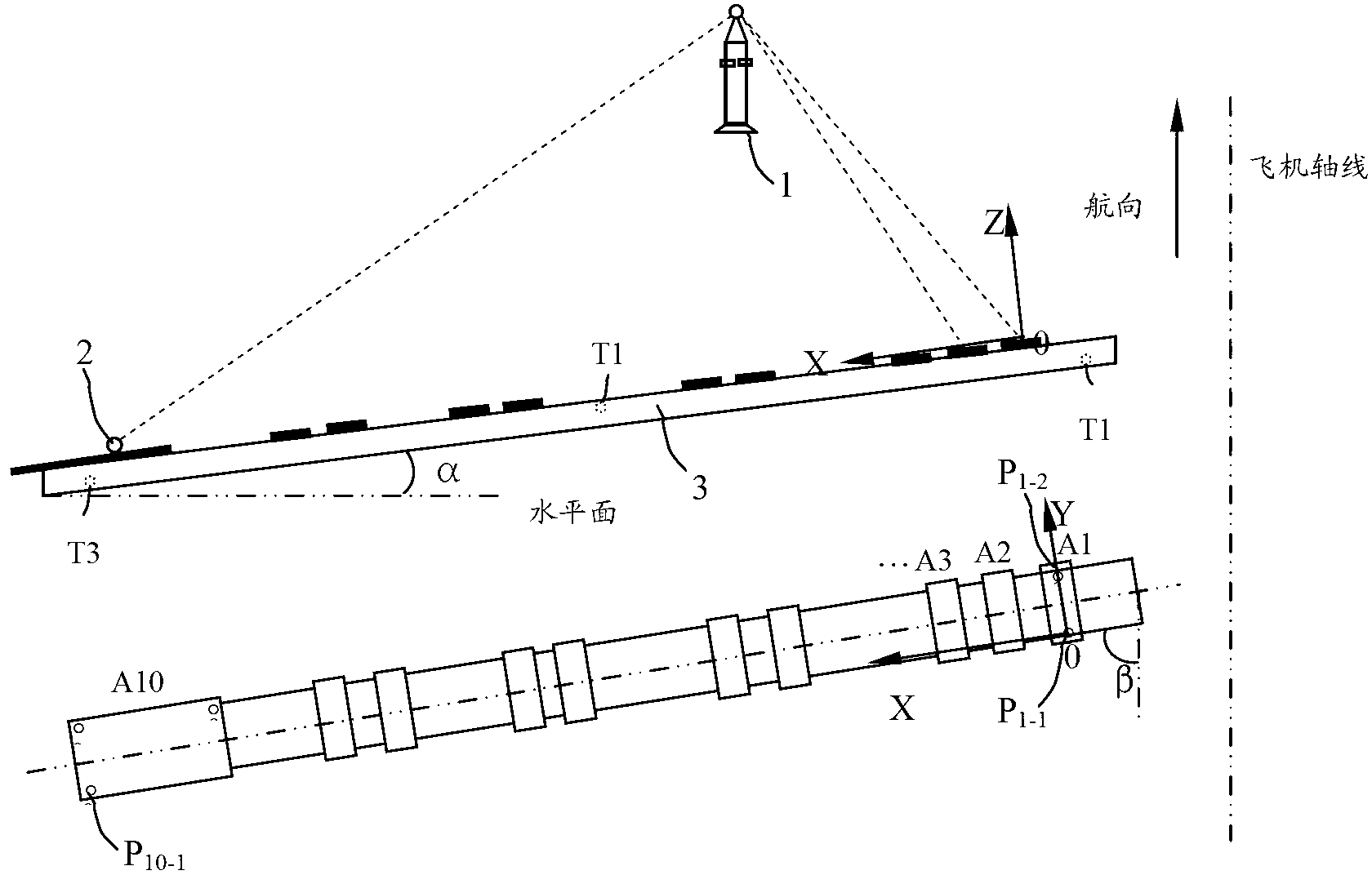

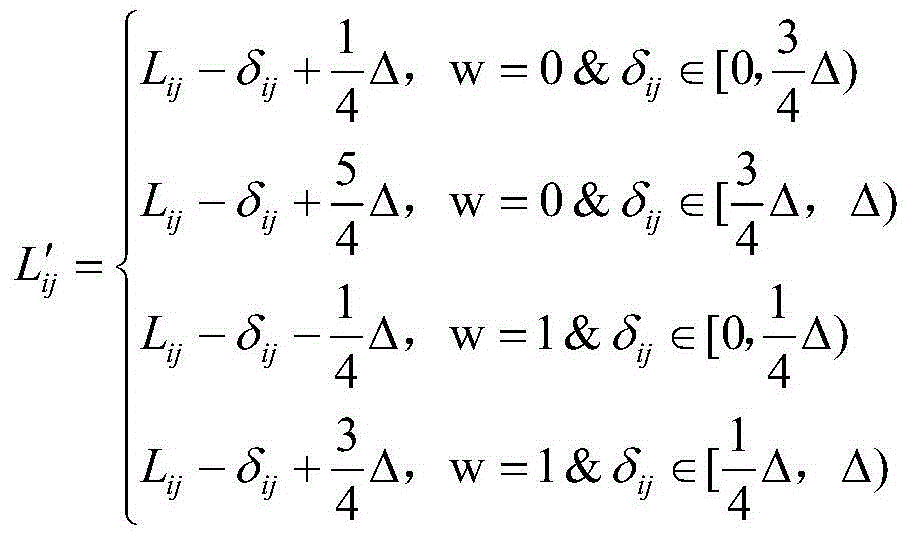

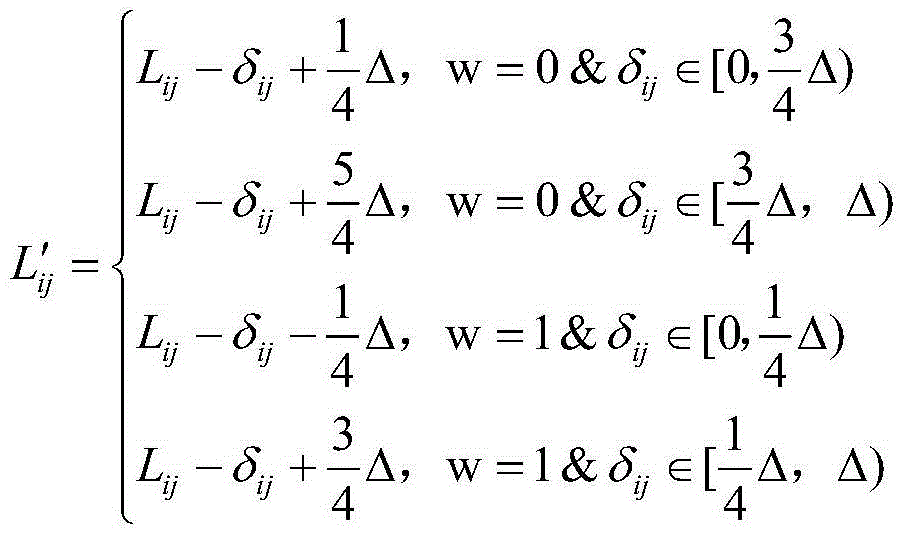

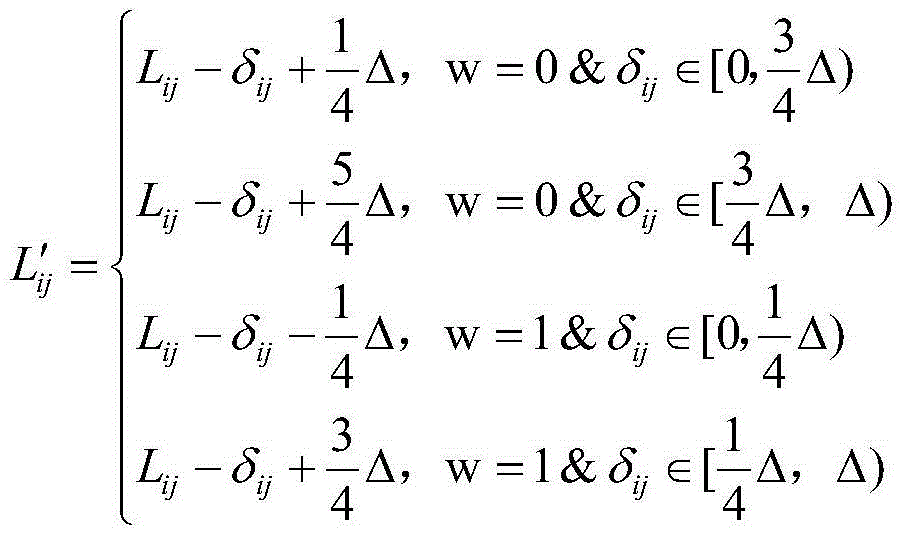

Multi-substrate combining detection method based on laser measurement

ActiveCN103292748AGive way directlyReduce contact areaUsing optical meansPhysicsAccuracy and precision

The invention belongs to the technical field of measurement, and particularly relates to a multi-substrate combining detection method based on laser measurement. A planeness combining detection method is improved into digital detection instructed by laser from traditional analog quantity detection; a laser tracker application processor visually displays adjustment amount; an adjustment amount displaying mode is direct, real-time and accurate; measuring points on substrates locate randomly; moving tracks of target ball measurement are random; contact area of a target ball and the planes of the substrates is small, number of collection points is large, and planeness of the combined substrates can be more comprehensively, vividly and accurately displayed as compared with that by traditional methods; translation and rotation of a coordinate system are facilitated, and origin of coordinates can be accurately defined to any position within the space of a measurement range; combining a coplane by multiple substrates, and in particular combining detection of any inclination angles and large planes are achieved fundamentally. With the multi-substrate combining detection method, operational procedures are simplified, measuring efficiency is improved by almost two times, and measuring accuracy is improved by more than three times.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

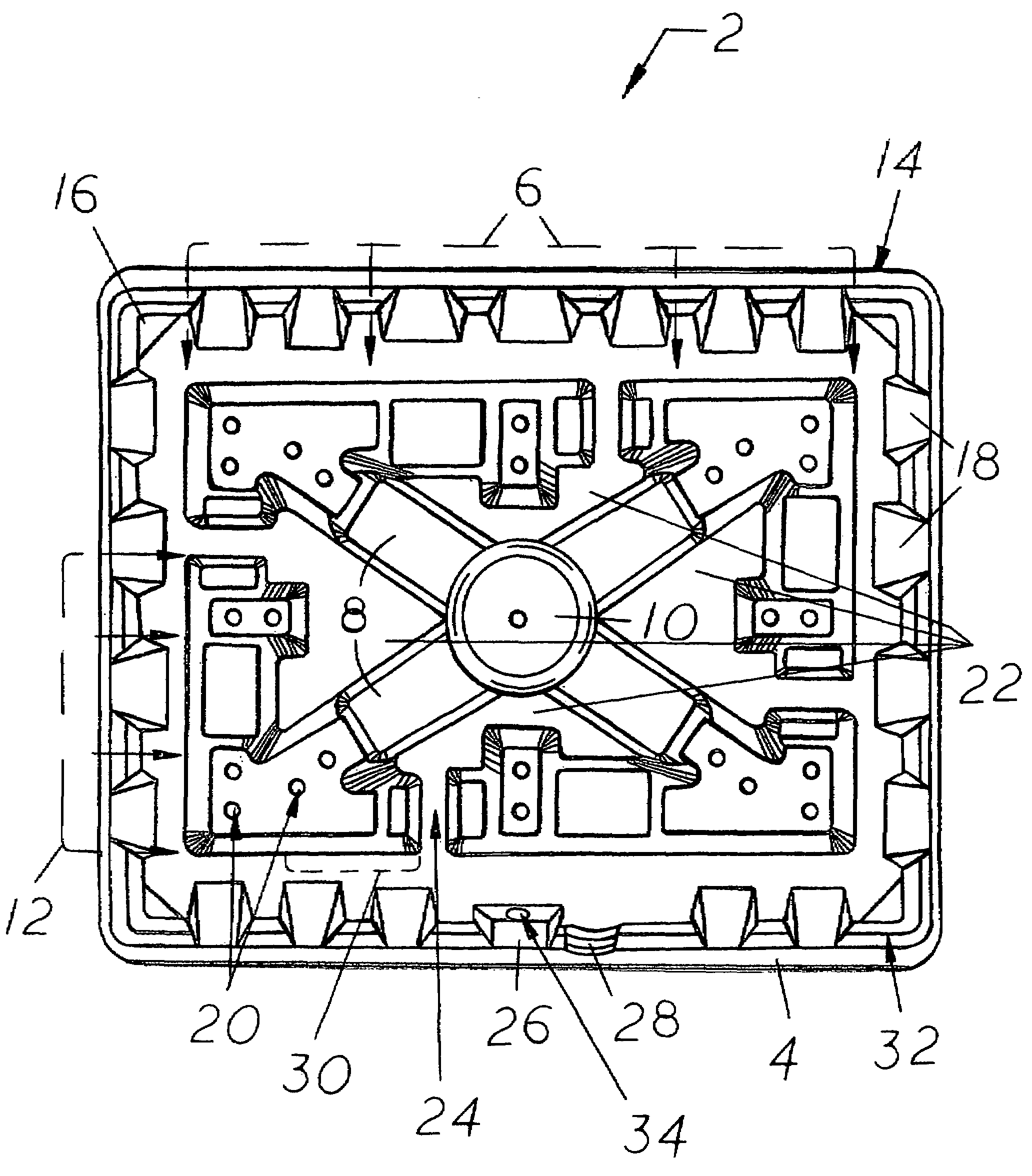

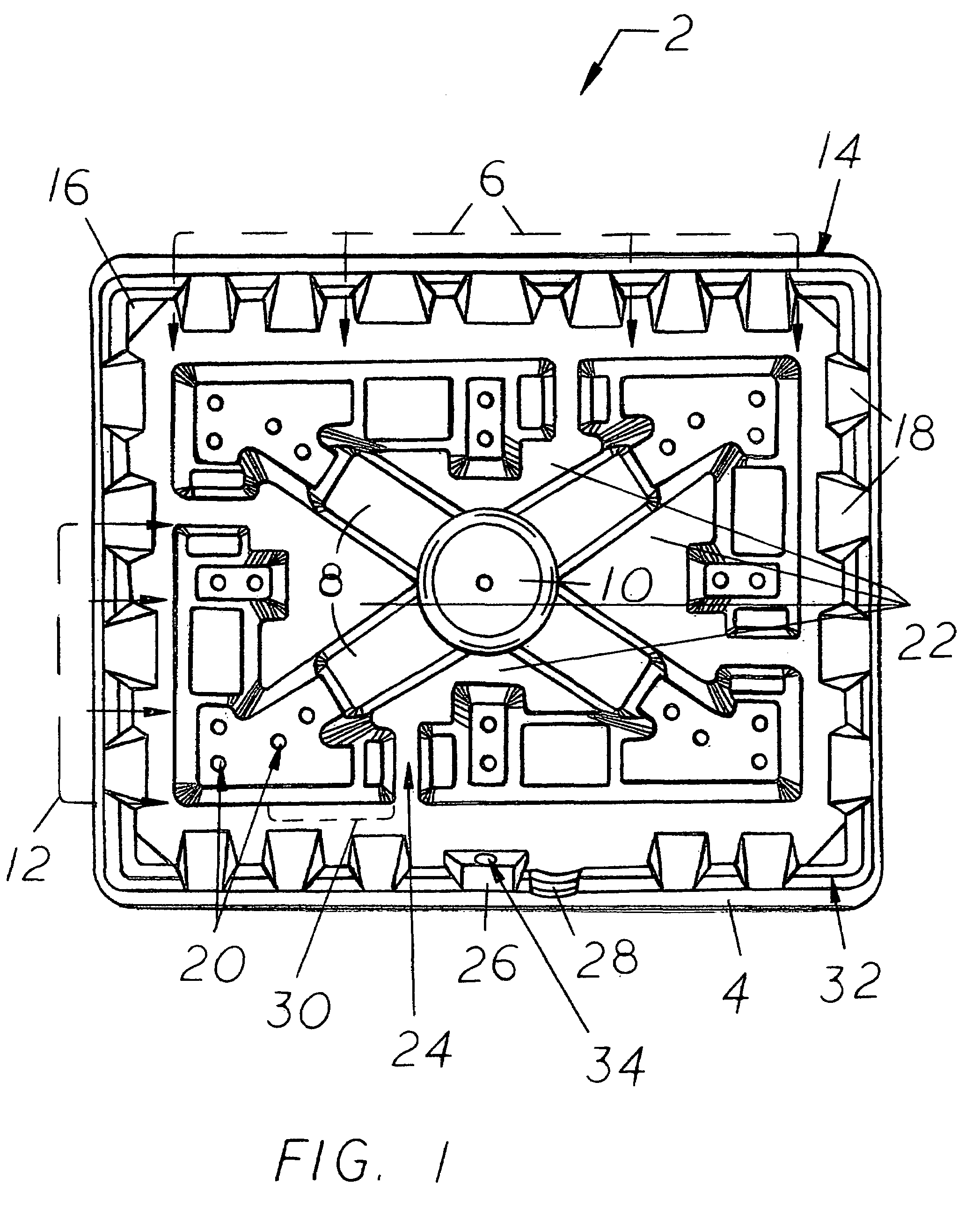

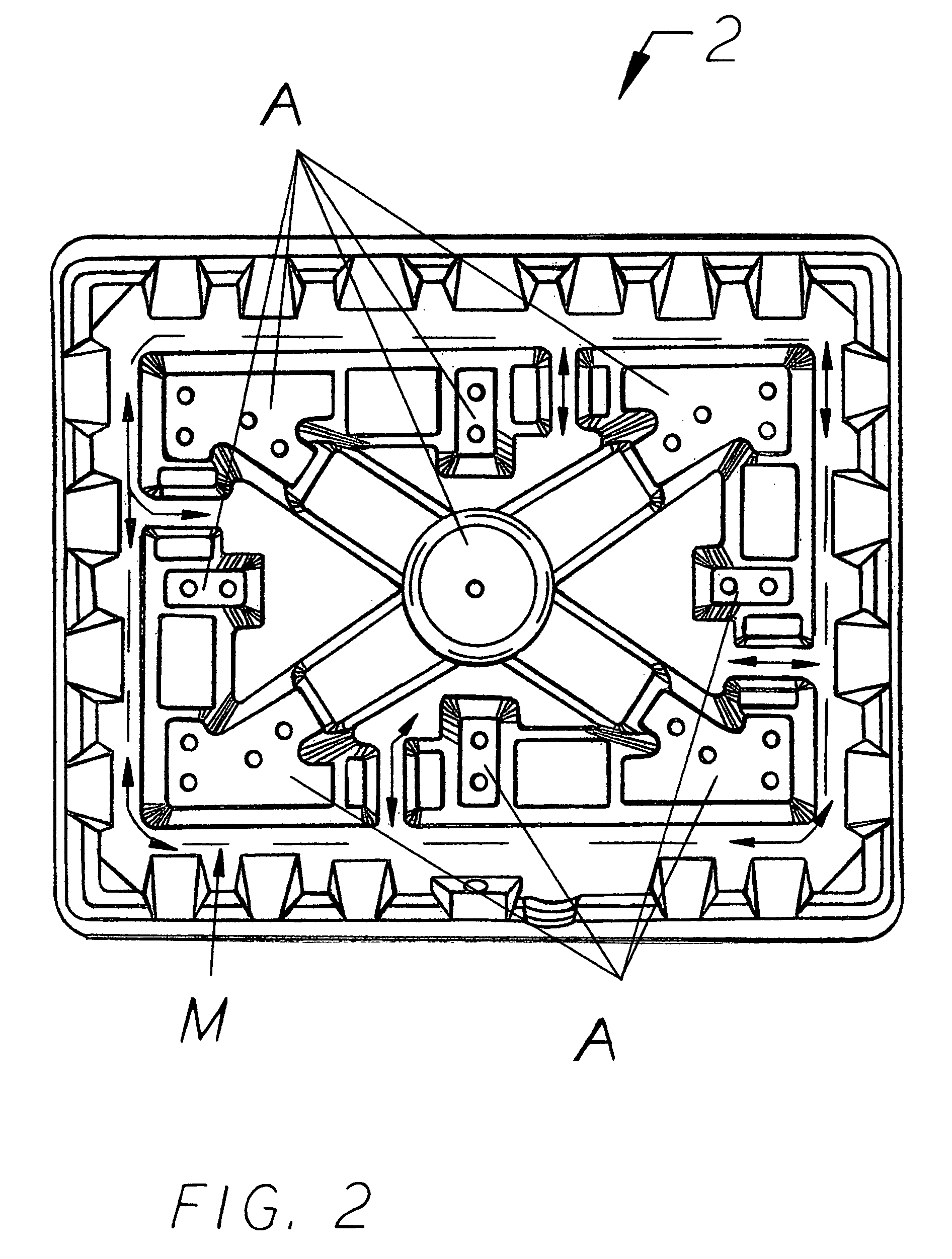

Fluid collection and drain pan with integrated strength-enhancing structure

InactiveUS7637387B1Cutting costsResisting permanent deformationInternal framesBoxesBlood collectionEngineering

A one-size-fits-all pan configured for supporting a fluid-producing unit. It has a perimeter wall spaced apart from a raised central structure to provide a moat-like area for flow of collected fluid toward a wall-mounted shut-off switch. When a desired maximum amount of fluid collection is exceeded, an electrical signal is sent to stop fluid production. The raised central structure comprises a hub with radially-extending ribs that each widens into a bent distal end having non-uniform height and width dimensions, and top indentations for receipt of vibration isolators that support the fluid-producing unit at a height above that of the perimeter wall. The non-raised areas around the ribs are all connected to the moat-like area to facilitate even fluid distribution within the pan. The pan further has an up-turned perimeter lip, staggered gussets, and angled corners for added strength, and may optionally have a nesting configuration for compact storage and transport.

Owner:RECTORSEAL LLC

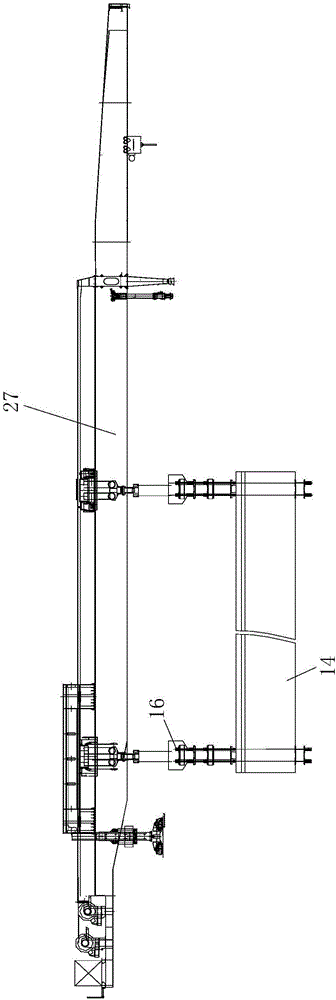

Full-set dismantling and installing construction method of bridge overpassing existing line

ActiveCN106149576ASimple stepsReasonable designBuilding repairsBridge erection/assemblyBuilding constructionEngineering

Owner:中铁二十局集团第三工程有限公司

DWT-SVD geometric attack prevention blind watermark method based on SIFT

ActiveCN103955878AGood resistance to attackGood attackImage data processing detailsSingular value decompositionWatermark method

The invention relates to a DWT-SVD geometric attack prevention blind watermark method based on SIFT. The method comprises a watermark embedding method and a watermark extraction method. The watermark embedding method includes the steps that discrete waterlet transformation is conducted on an original image, a low-frequency sub-band of the original image is divided into small blocks, singular value decomposition is conducted on each small block, chaotic encryption is conducted on watermarks to be embedded, and the watermarks are embedded into the maximum singular value of each small block through an optimal quantitative method, the SIFT feature points of a watermark image are stored as secret keys, the types of geometric attacks are judged according to the secret keys, and correction is conducted. The watermark extraction method is the inverse process of the watermark embedding method and includes the steps of correction of attacked images, watermark extraction and watermark decryption and restoration. According to the method, by the utilization of the rotation, zoom and translation invariance of the SIFT feature points and the combination of the advantages of DWT and SVD in the digital watermark aspect, robustness on geometric attacks is remarkably improved.

Owner:HANGZHOU DIANZI UNIV

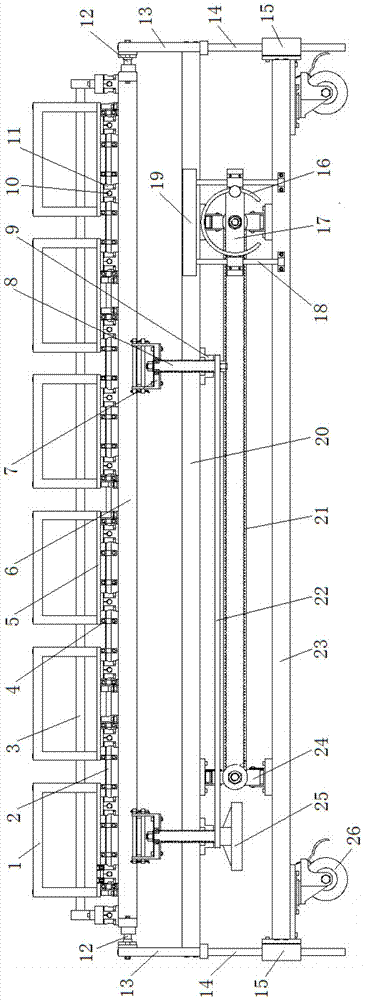

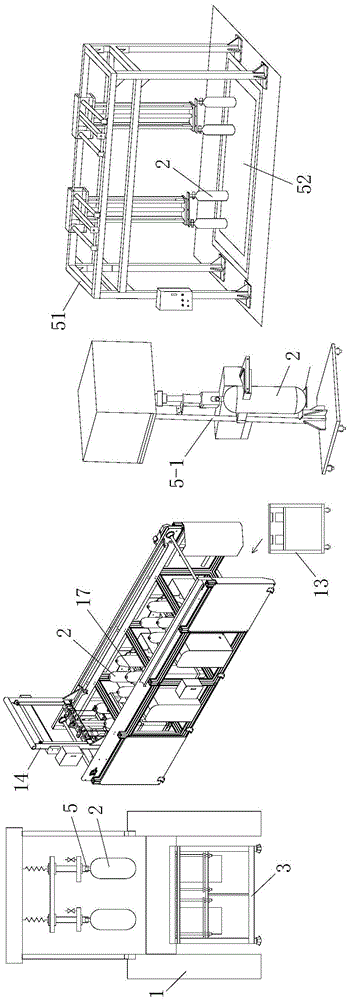

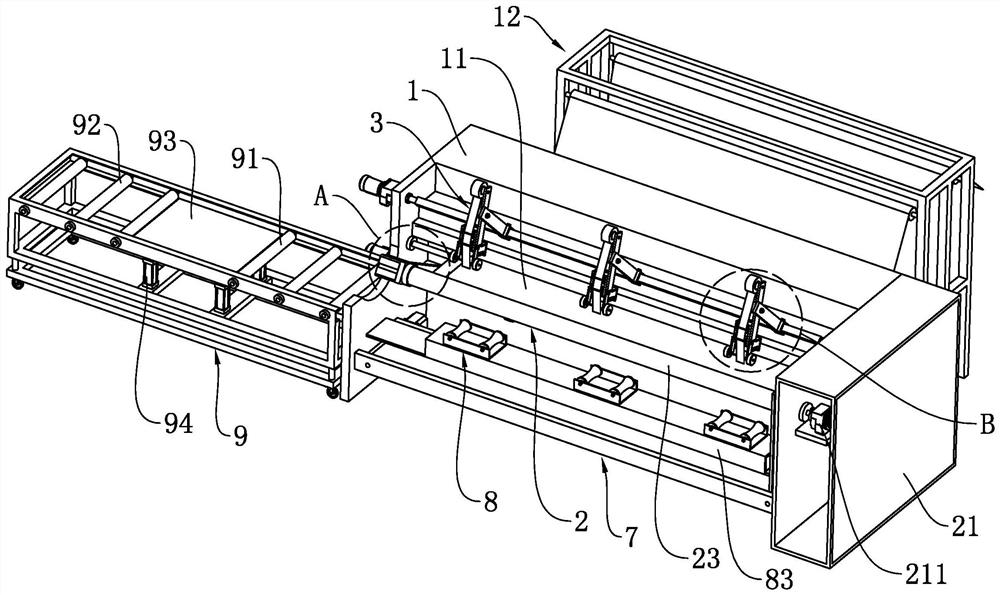

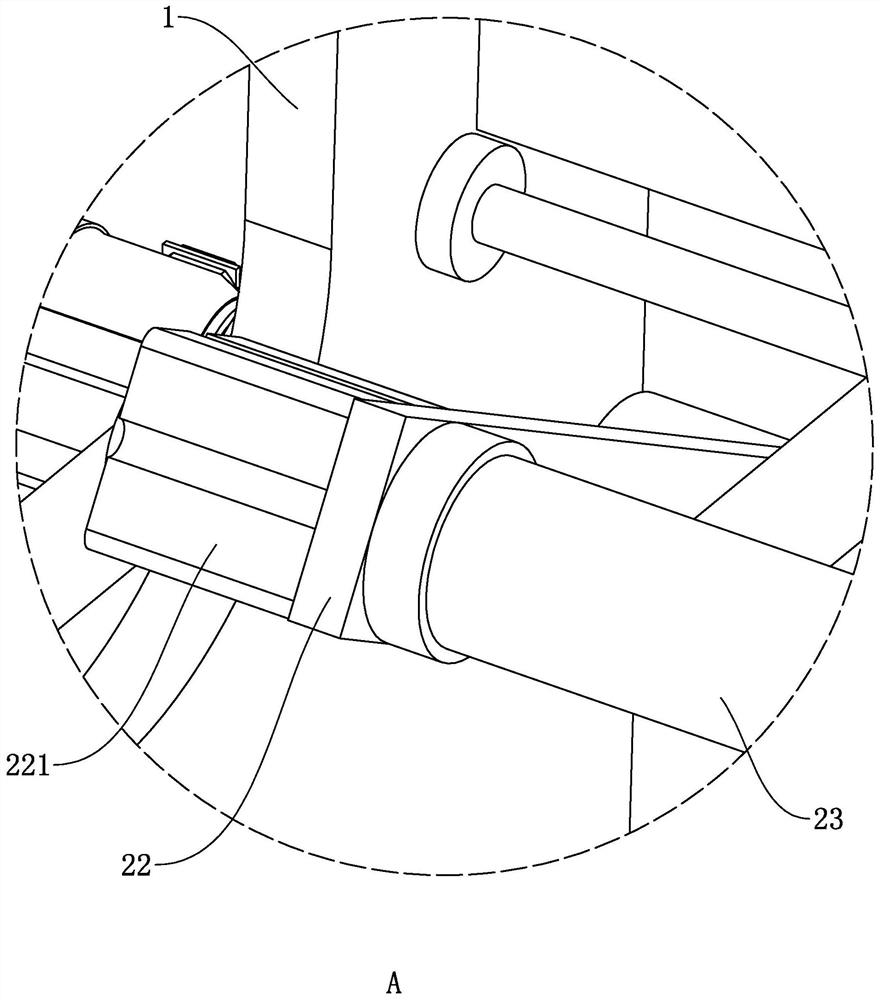

Automatic detection line and detection method of carbon fiber gas bottle

InactiveCN105466786ASimple structureCompact structureDetection of fluid at leakage pointDrying using combination processesEngineeringTest fixture

The invention discloses an automatic detection line and detection method of a carbon fiber gas bottle. The detection line comprises a water pressure testing device, an auxiliary water pressure testing device, a bottle valve loading and unloading machine and an air tightness experiment device, which are arranged from front to back, wherein the water pressure testing device comprises a testing rack, a testing operation platform, a pressurizing device, a testing box and a testing trolley; the auxiliary water pressure testing device comprises a gas bottle clamp, a conveying trolley, and gas bottle water pouring and drying treatment equipment; the bottle valve loading and unloading machine comprises a bottle valve loading and unloading rack, a control cabinet, a gas bottle fixing mechanism and a bottle valve screwing mechanism; the air tightness experiment device comprises an air tightness testing device and a second gas supplying device for supplying gas to a plurality of gas bottles to be tested. The detection method comprises the following steps: 1, testing water pressure; 2, carrying out water pouring and drying treatment; 3, assembling a bottle valve; 4, testing air tightness. The automatic detection line provided by the invention is reasonable in design, simple to use and operate and good in use effect, and can be used for simply, conveniently and rapidly finishing water pressure testing and air tightness testing processes of the plurality of carbon fiber gas bottles.

Owner:TECHN MONITORING CENT OF CHANGQING PETROLEUM EXPLORATION BUREAU

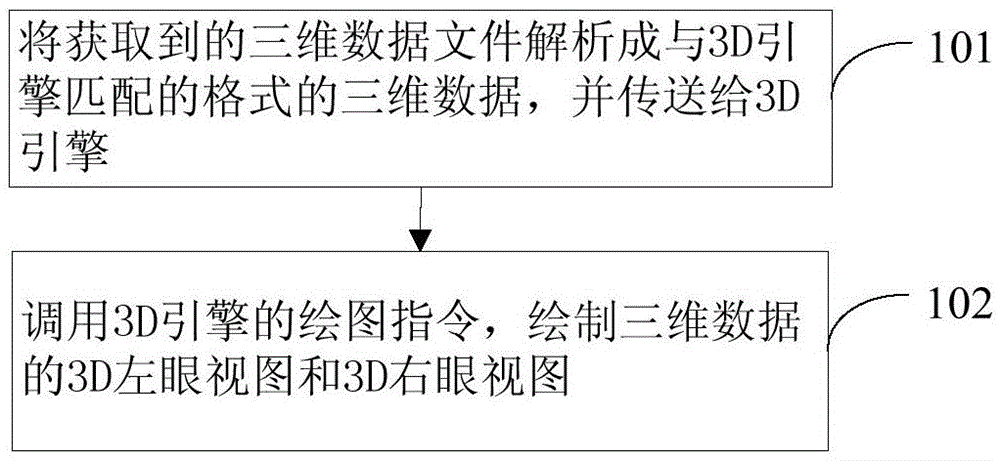

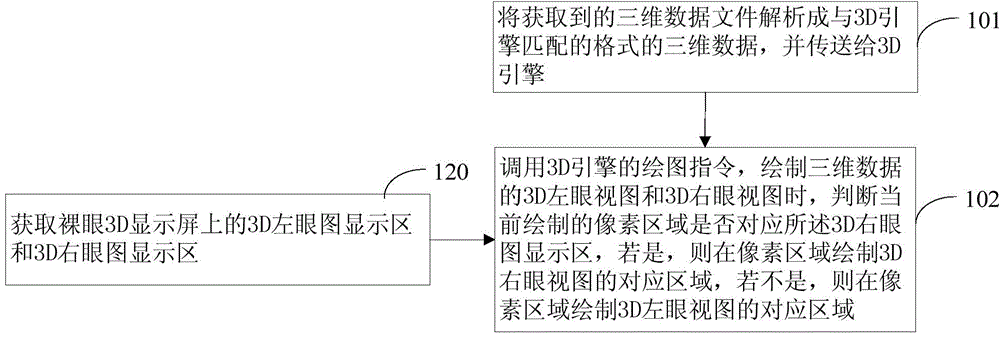

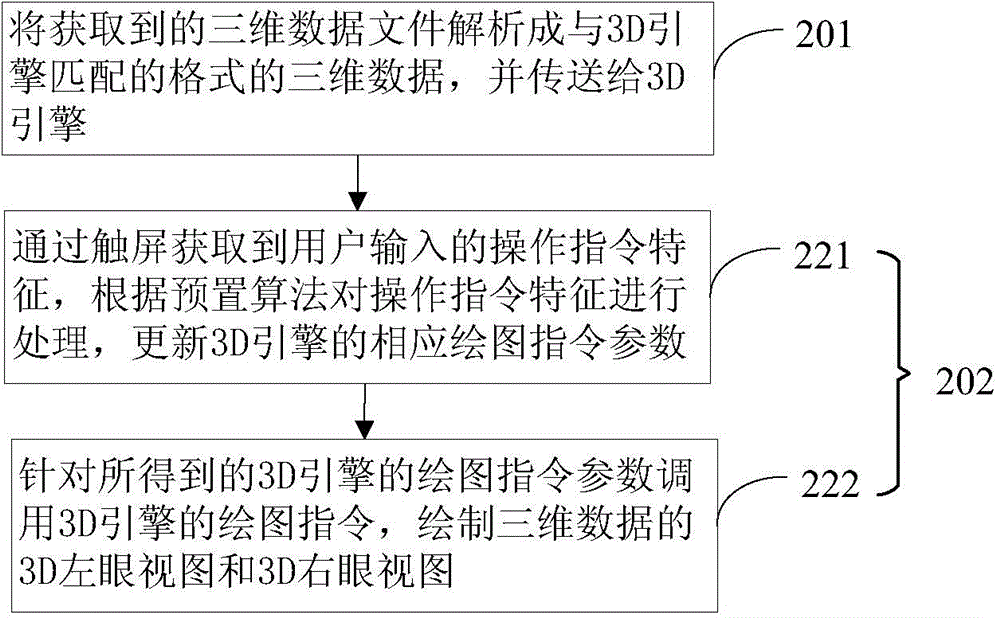

3D view drawing method and system of three-dimensional data

InactiveCN104915994AImprove experienceSmooth rotationImage data processingInteractive designComputer graphics (images)

The invention brings forward a 3D view drawing method and system of three-dimensional data. The method comprises: parsing an obtained three-dimensional data file into three-dimensional data matching a 3D engine and transmitting the data to the 3D engine; and invoking a drawing instruction of the 3D engine and drawing a 3D left-eye view and a 3D right-eye view of the three-dimensional data. According to the invention, on the basis of combination of the intelligent terminal with the 3D engine, a 3D view for carrying out combination to obtain a lifelike three-dimensional image of an object can be obtained; and the user can watch details in the complex three-dimensional object visually based on combination of the drawn 3D left-eye view and 3D right-eye view. The method and system can be realized in a mobile terminal without being limited by a geographical condition. Because of the interactive design, the 3D view drawn for the three-dimensional data can be rotated, translated, and zoomed conveniently by the user in real time based on gesture operations, so that the user experience can be improved.

Owner:WZ TECH

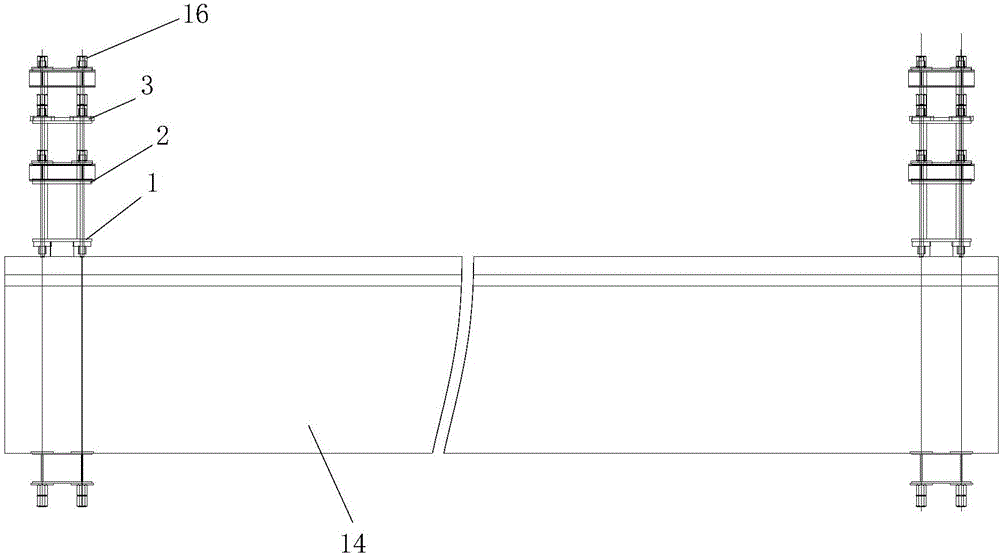

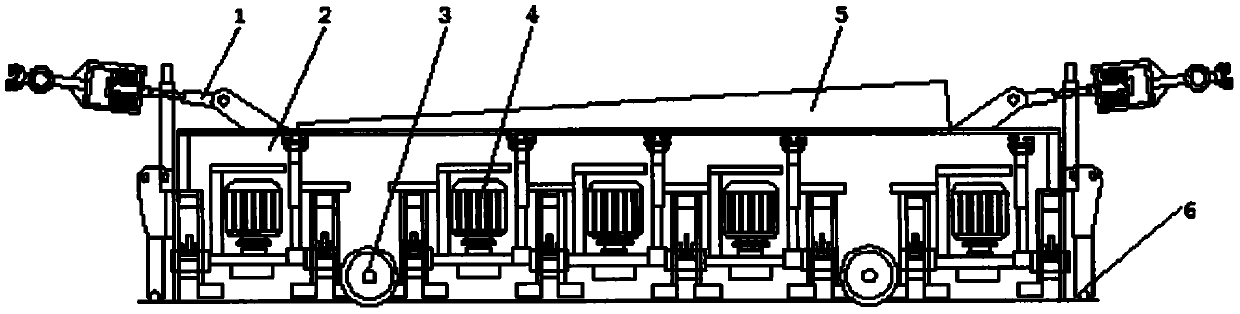

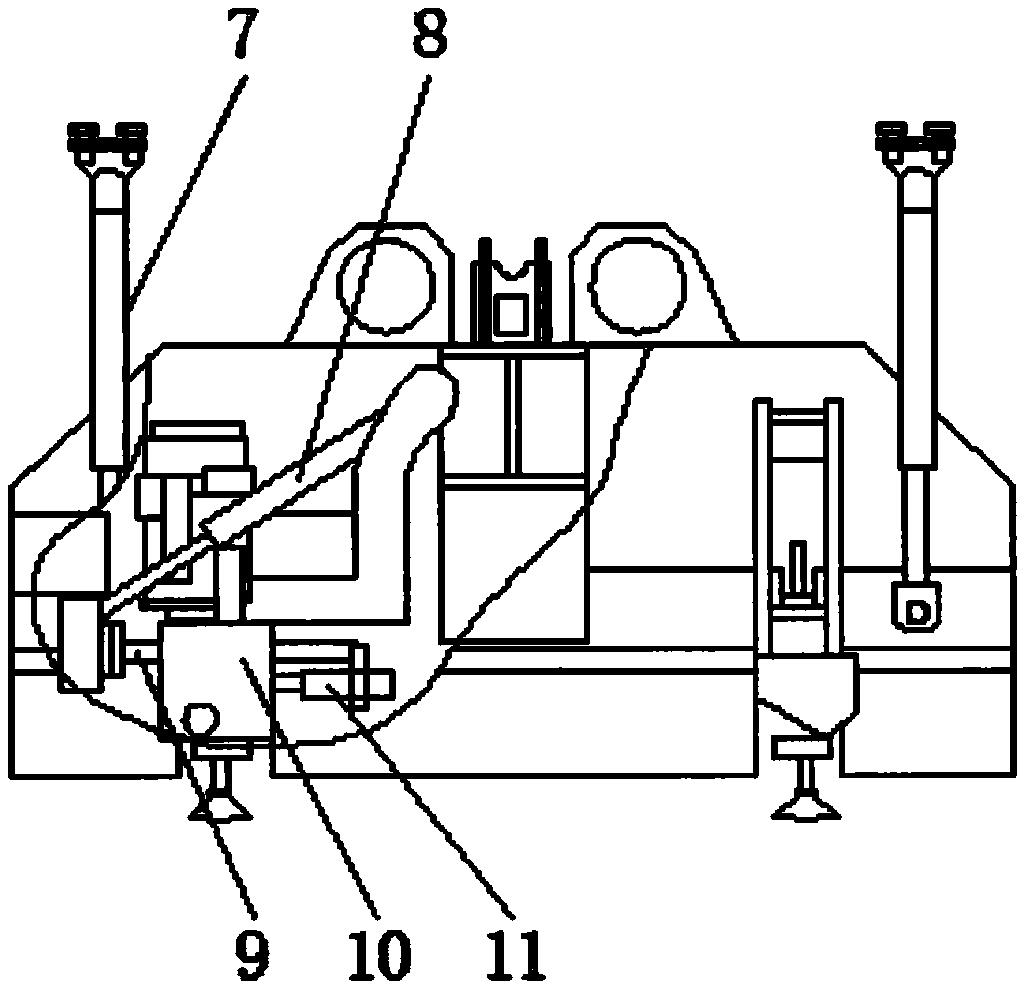

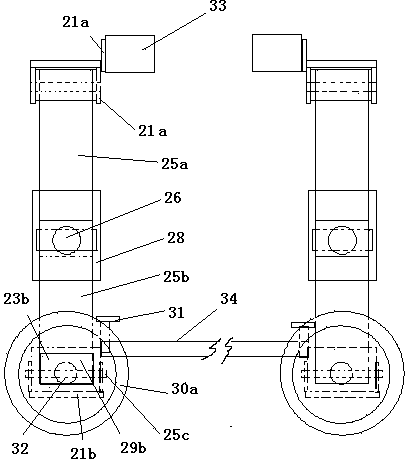

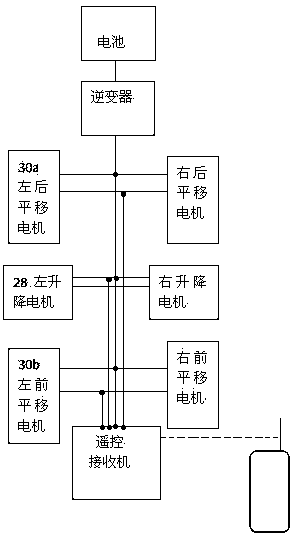

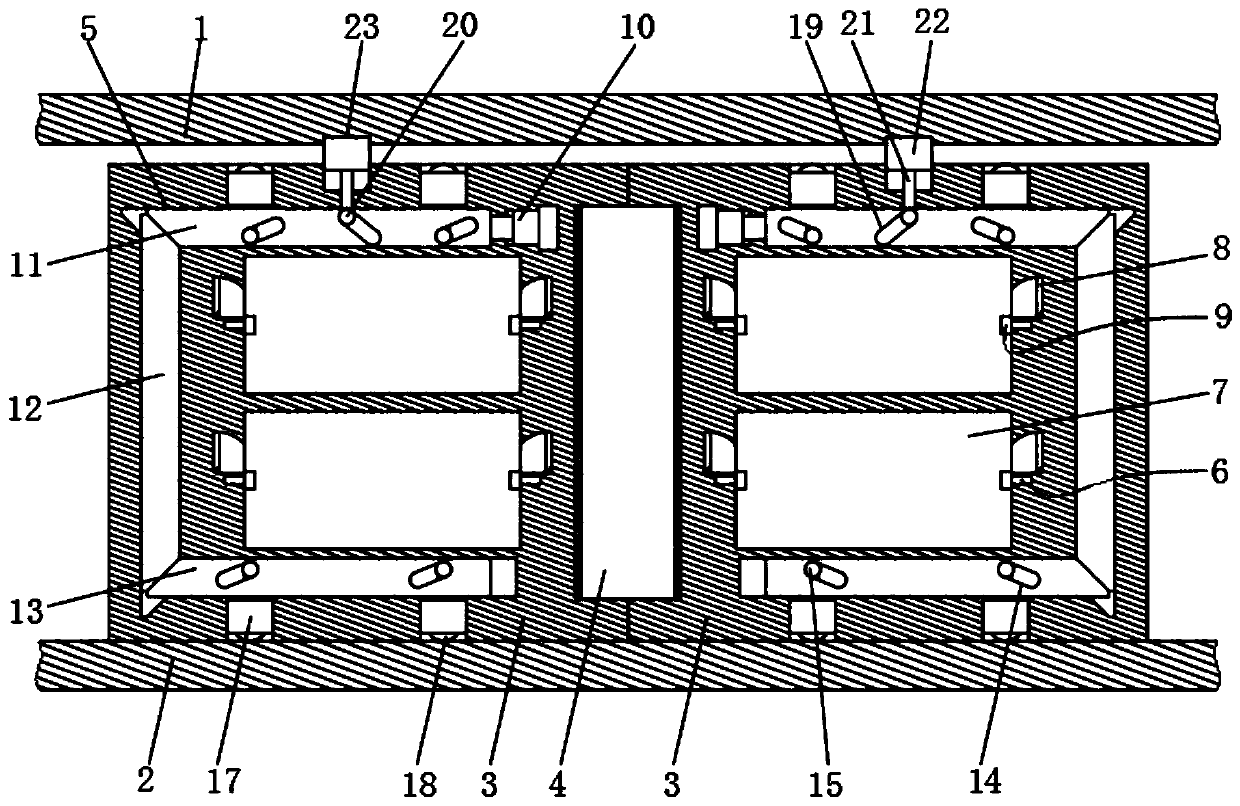

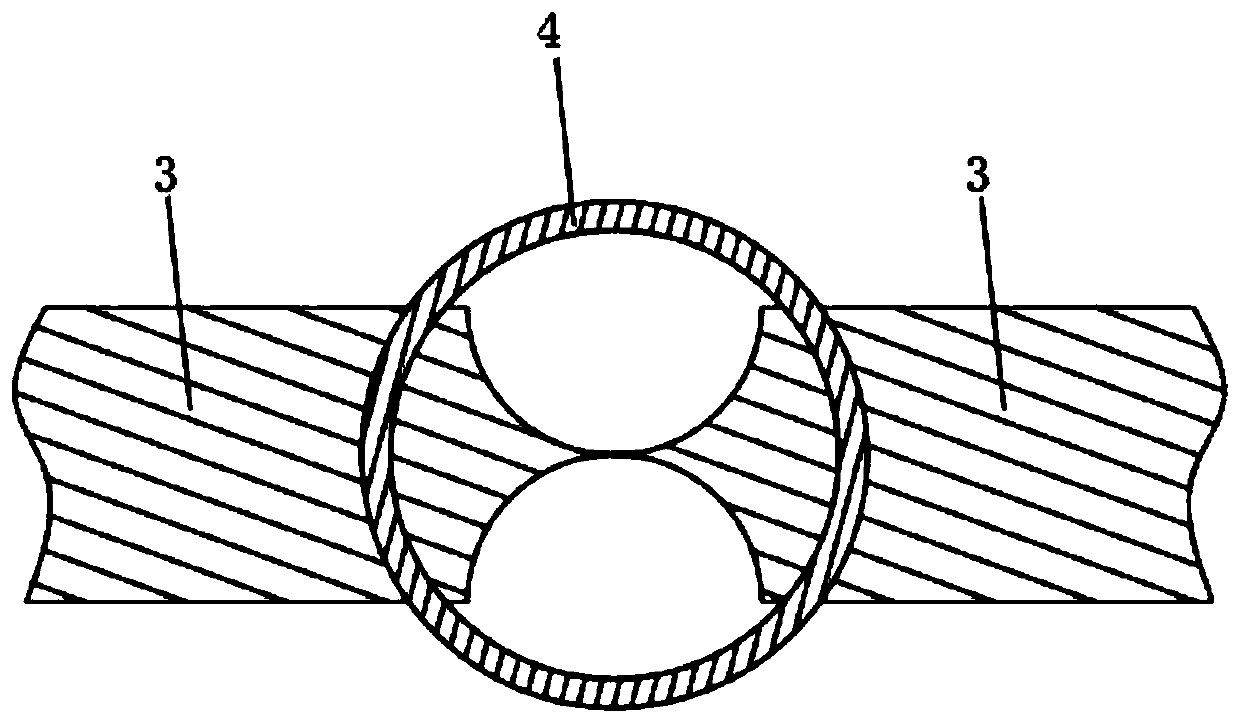

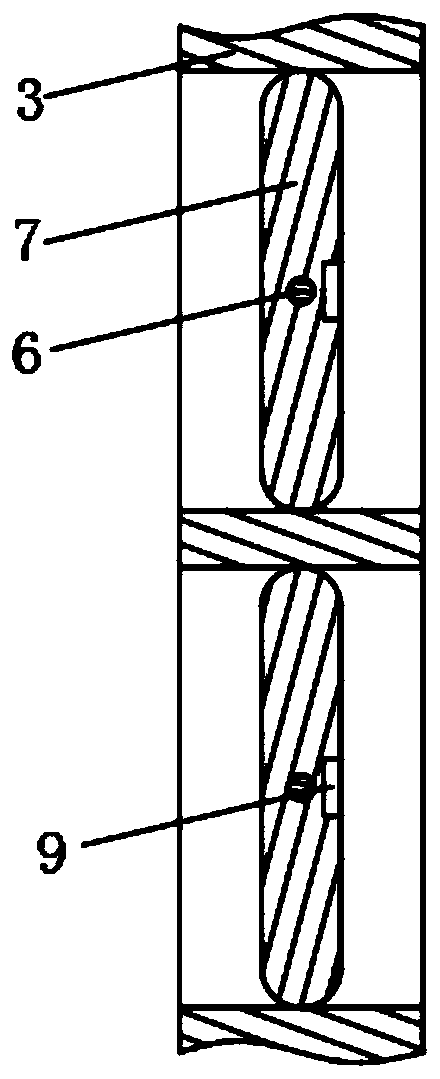

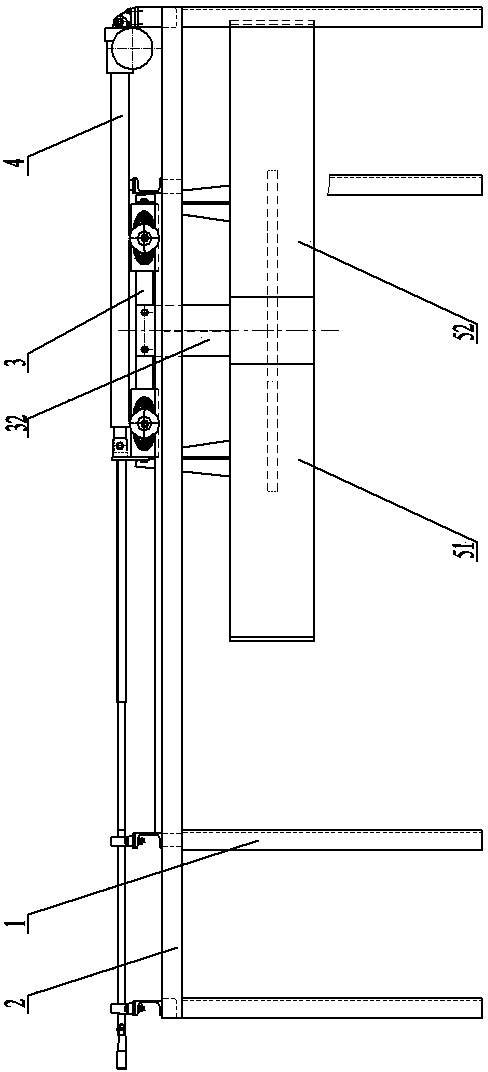

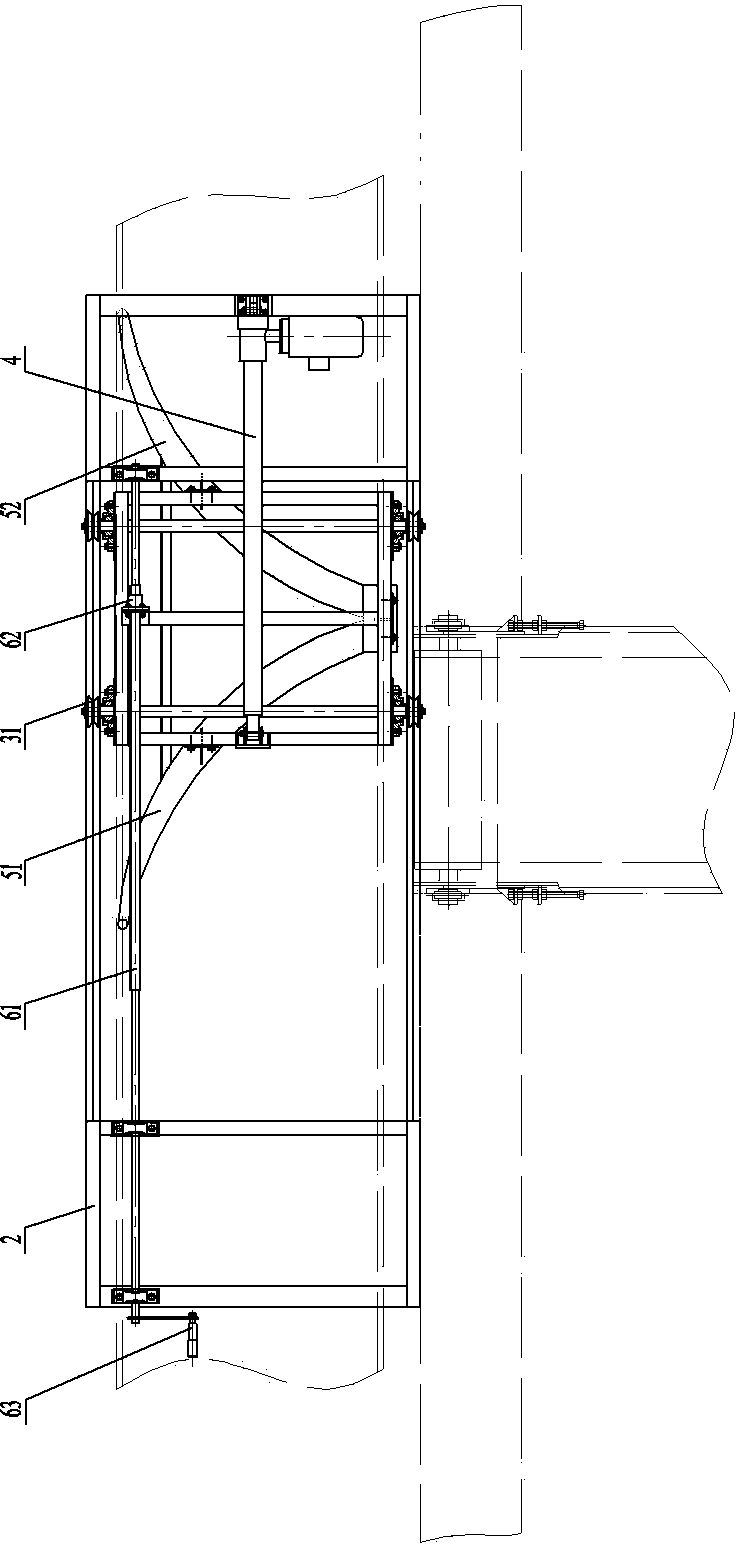

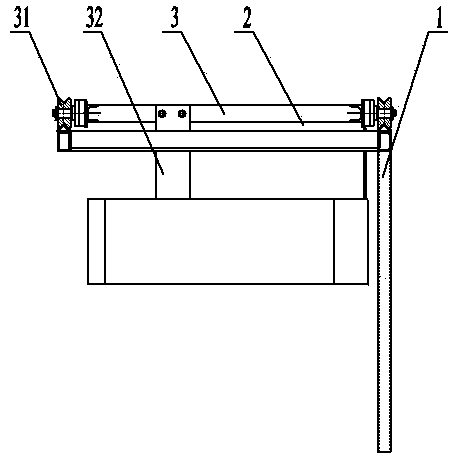

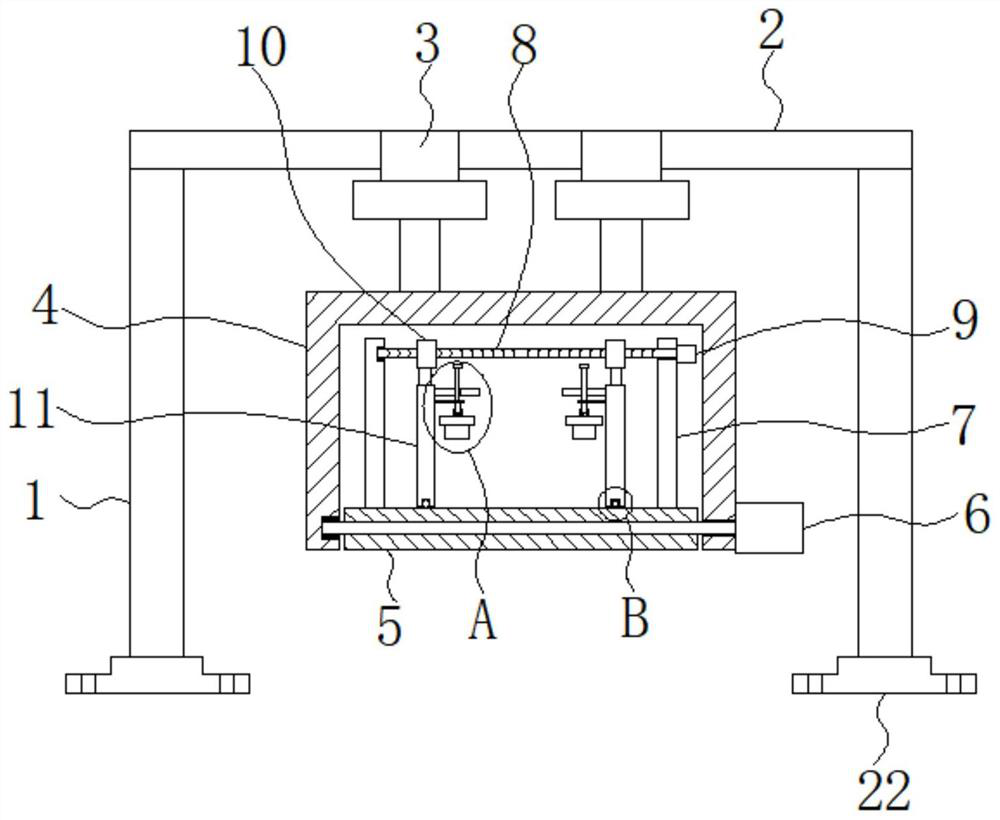

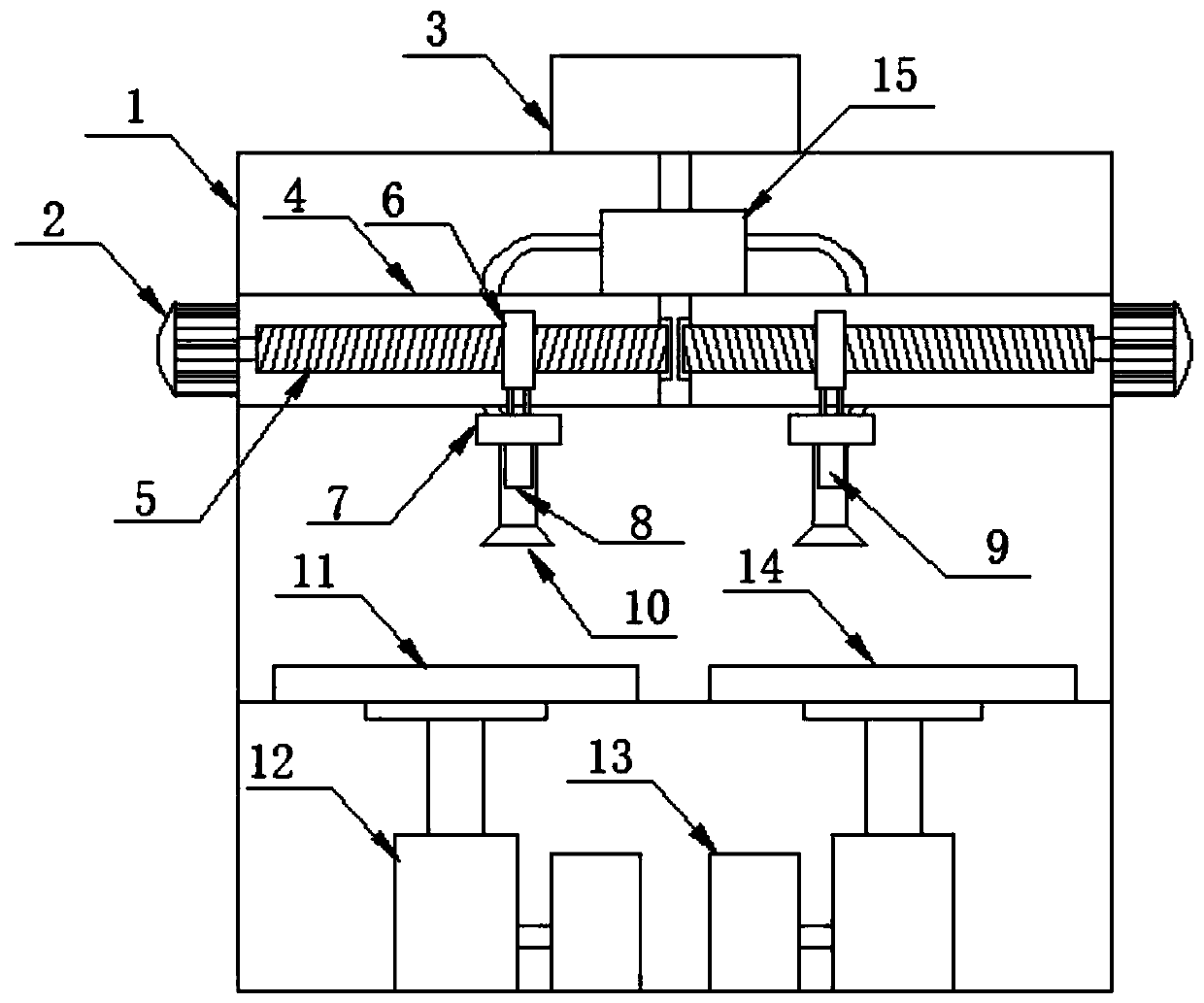

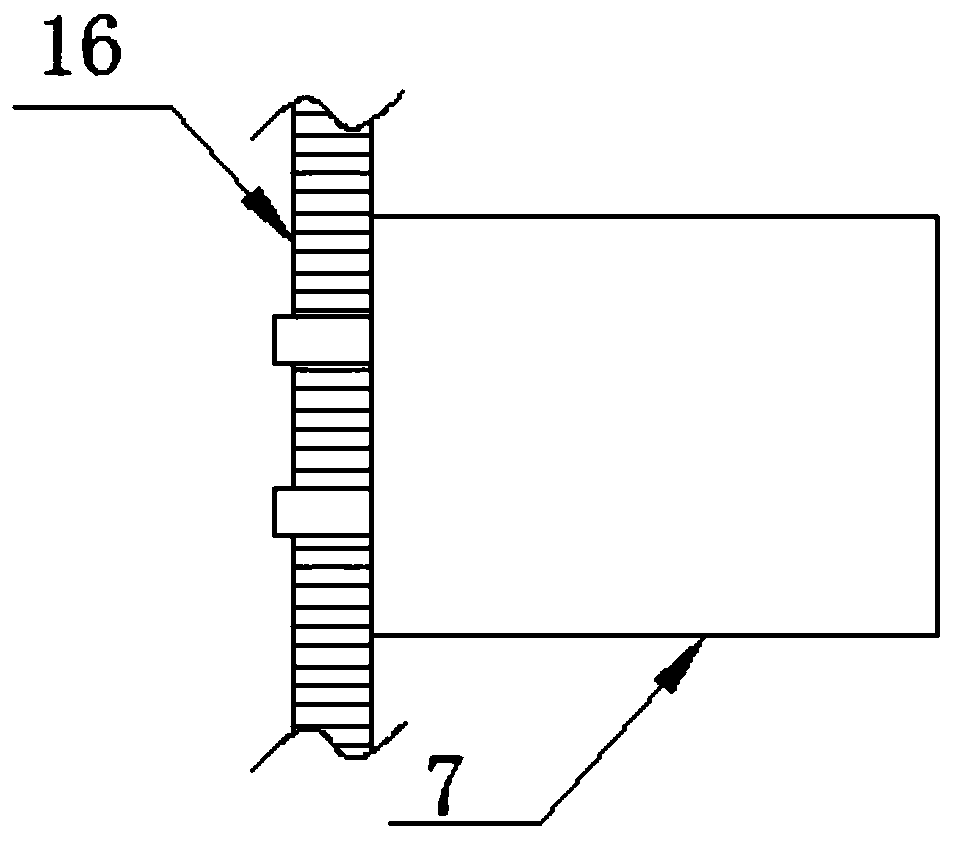

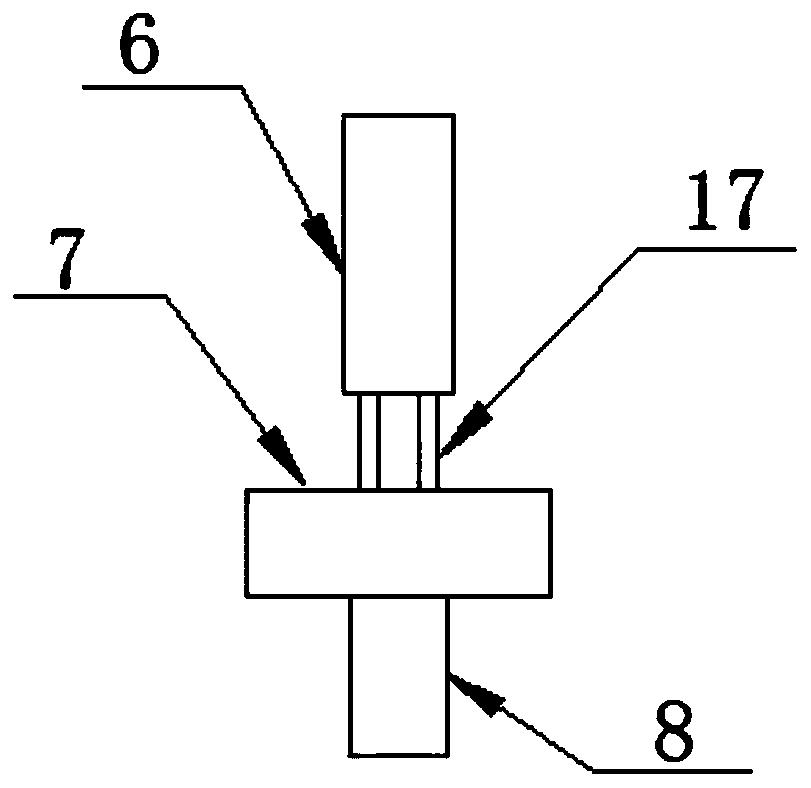

Rail grinding trolley

PendingCN109750566AEasy to panTraversing for easy panningRailway track constructionVehicle frameDerailment

The invention discloses a rail grinding trolley. The rail grinding trolley comprises a frame, a grinding unit and derailment protection devices, wherein traction rods are separately arranged on the upper two sides of the frame, walking wheels are fixed to the lower part of the frame, the grinding unit is arranged in the frame, a dust collection channel is arranged on the upper part of the frame, the derailment protection devices are fixed to the left side and right side of the frame, lifting devices are arranged on the two sides of the inner part of the frame, deflection electric cylinders arearranged below the lifting devices, guide rods are arranged on the lower parts of the deflection electric cylinders, guide seats are arranged on the outer sides of the guide rods, and electric cylinders are fixed to one side of the guide seats. The rail grinding trolley is provided with a transverse moving structure capable of moving horizontally conveniently, and the guide seats can move on theguide rods under the driving action of the electric cylinders, so that the transverse moving of the grinding unit is realized, obstacles on both sides of a rail are conveniently avoided during grinding, and the operation range is expanded.

Owner:长沙瀚鹏电子技术有限公司

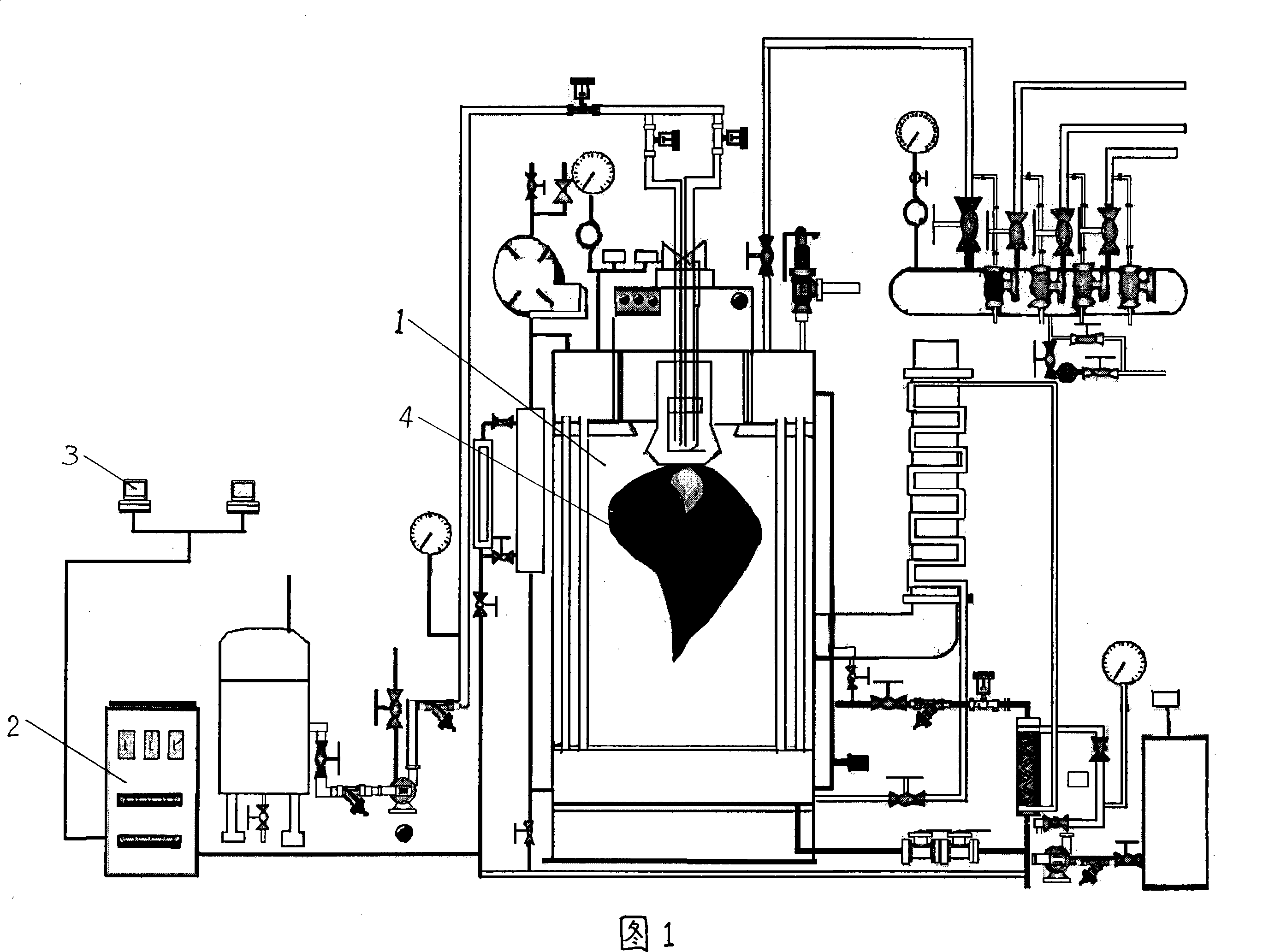

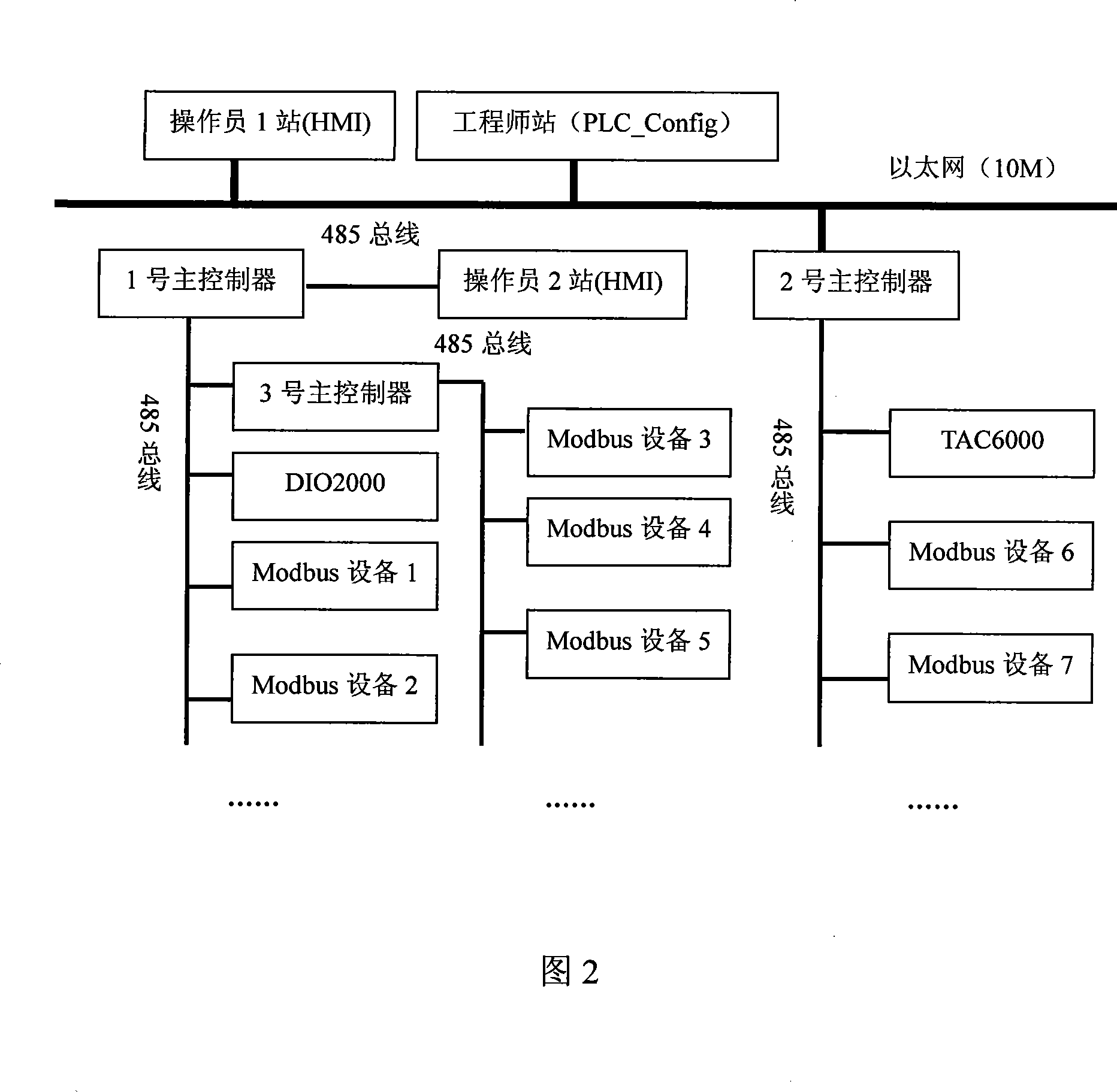

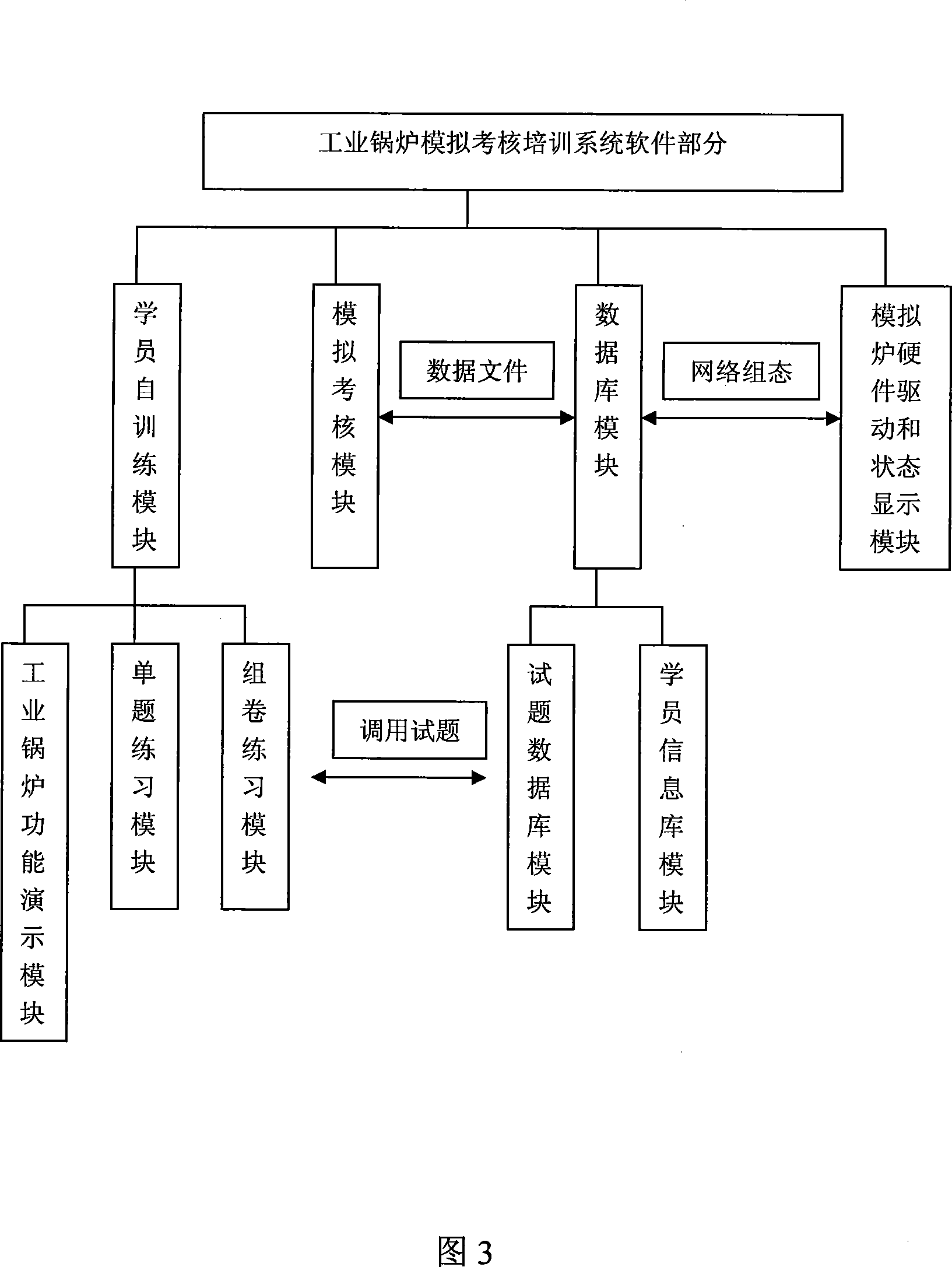

Practical operation examine analog machine of industrial boiler

InactiveCN101174370AReduce accident rateEasy to operateEducational modelsControl systemControl signal

The invention relates to a training and assessment system for boiler stokers, in particular to a training and assessment analog machine for industrial boiler actual operations, which mainly comprises an analog model machine and a computer system. The body and the internal structure of the analog model machine are lessened in proportion to the actual boiler; a plurality of operable components and a signal acquisition device can be arranged on the control point of training and assessment on the machine body, the operable component transmits control point signals, which are acquired by the signal acquisition system, converted by a control system and transmitted to the computer system. The invention highlights the analog machine for industrial boiler troubleshooting operations and emergency handling capability (training) assessment; the analog machine accomplishes the assessment for the emergency handling and troubleshooting capability in case of boiler faults, owns a set of test question library covering the safety accessory operation, load adjusting operation and troubleshooting operations; moreover, the analog machine comprises a dedicated training software fitted with the test questions; the software can control the control point on the analog machine to display relevant states, and receive the signals fed back from the analog machine to conduct corresponding processing. The invention has the advantages that: the software fulfills the function of freely extending the test questions, which can be operated directly on the analog machine for assessment.

Owner:大连市锅炉压力容器检验研究所 +1

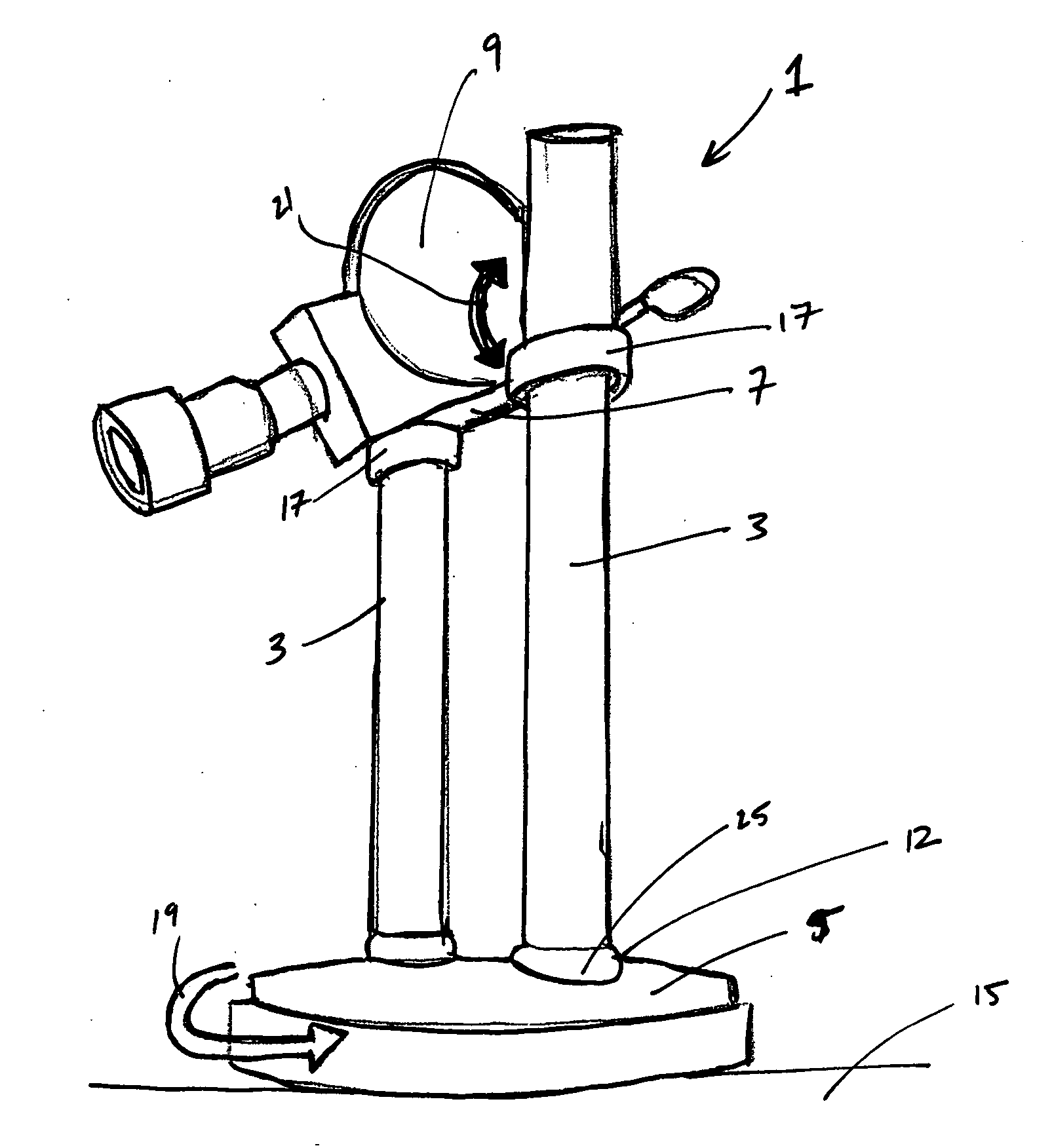

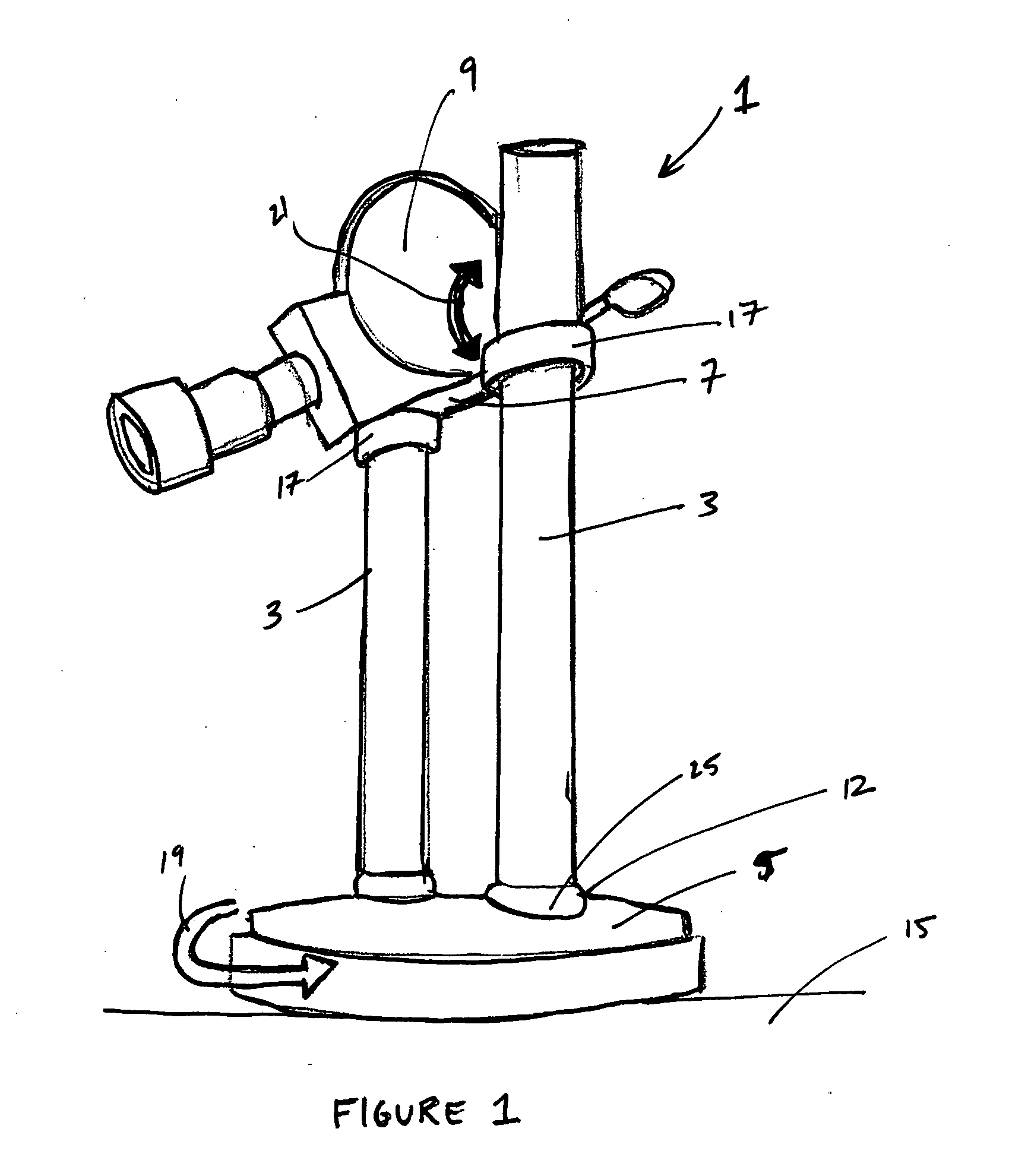

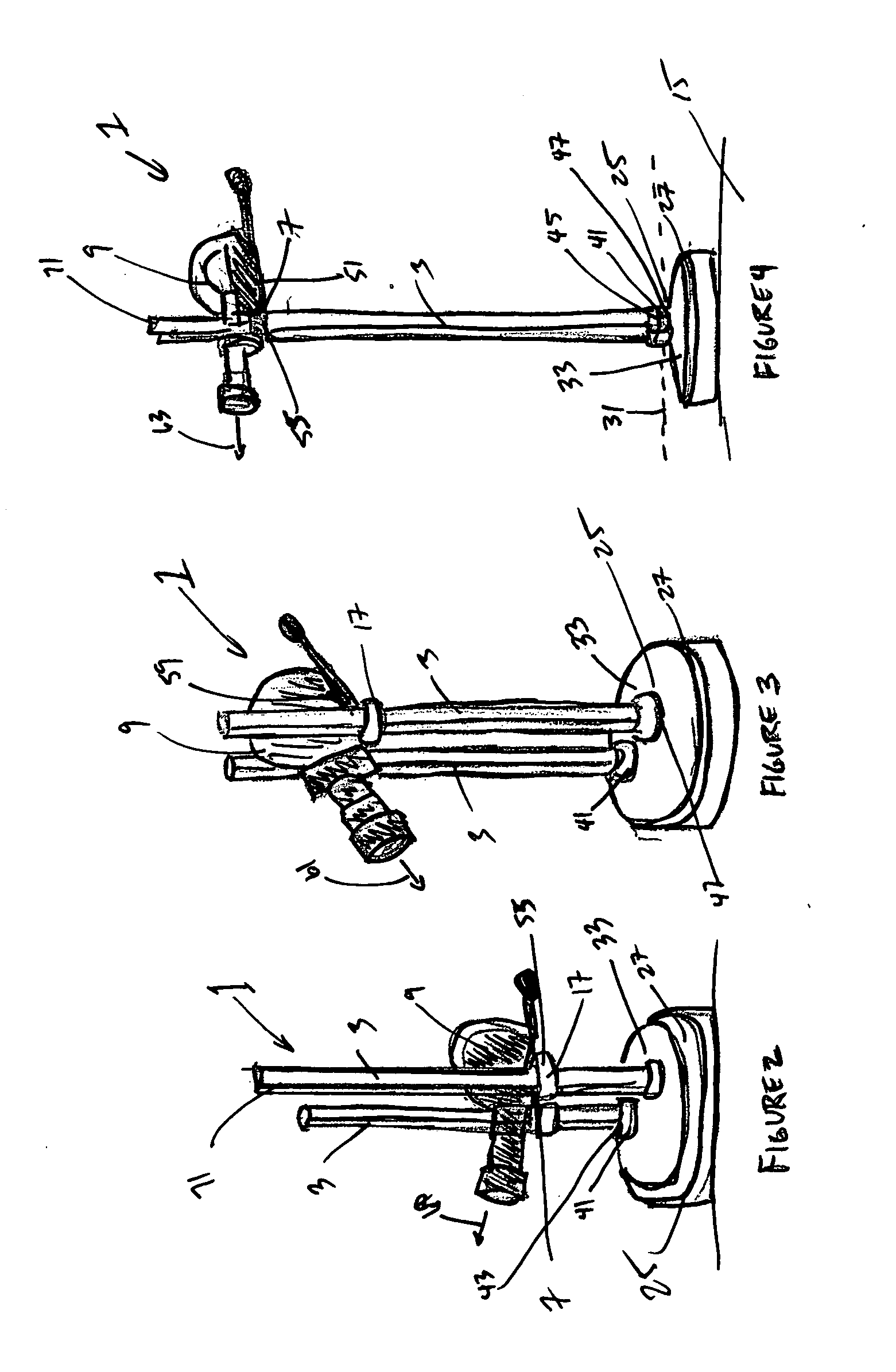

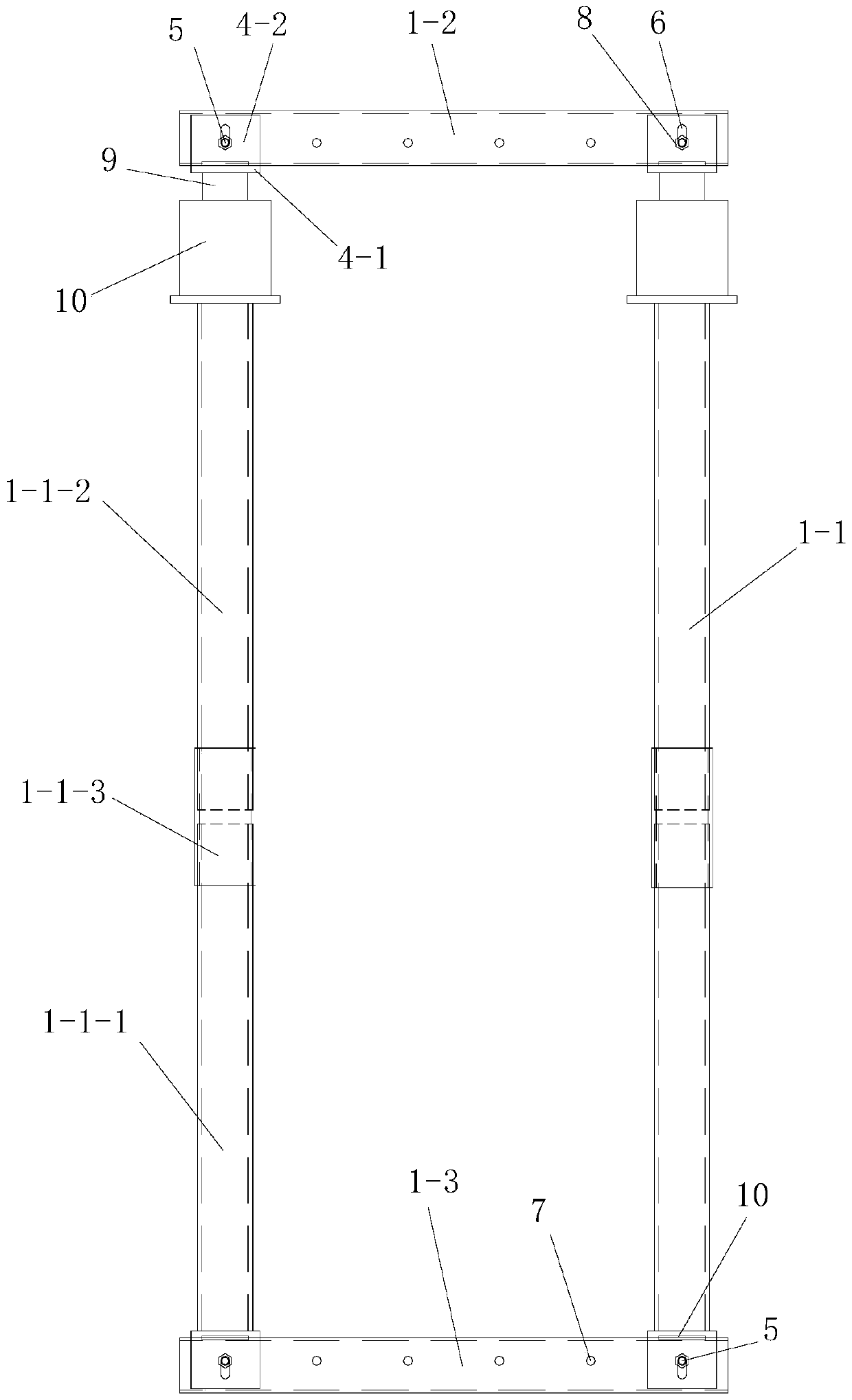

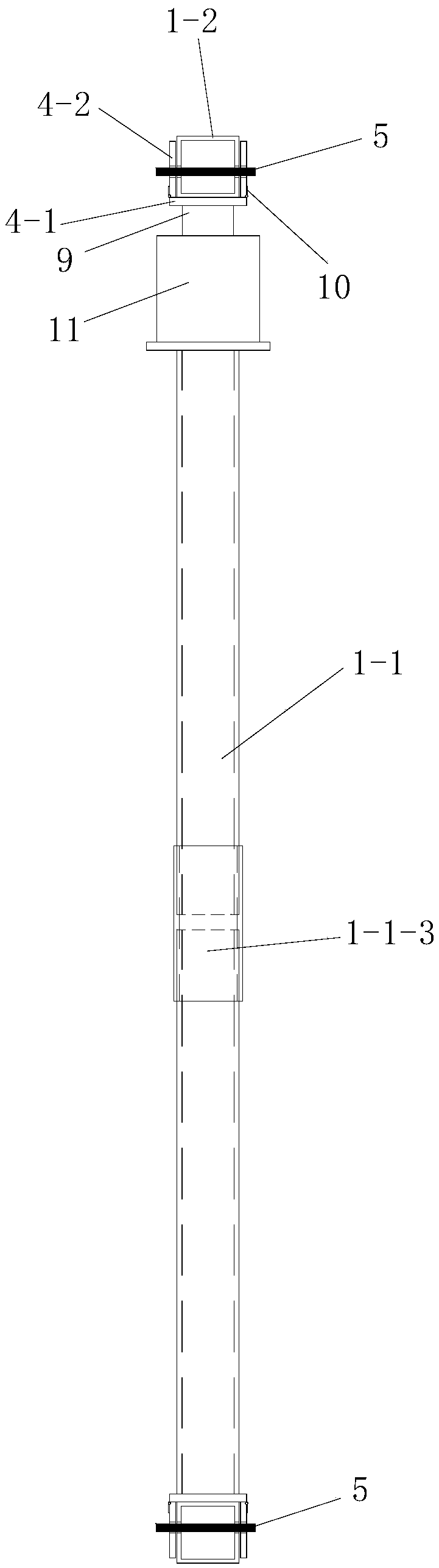

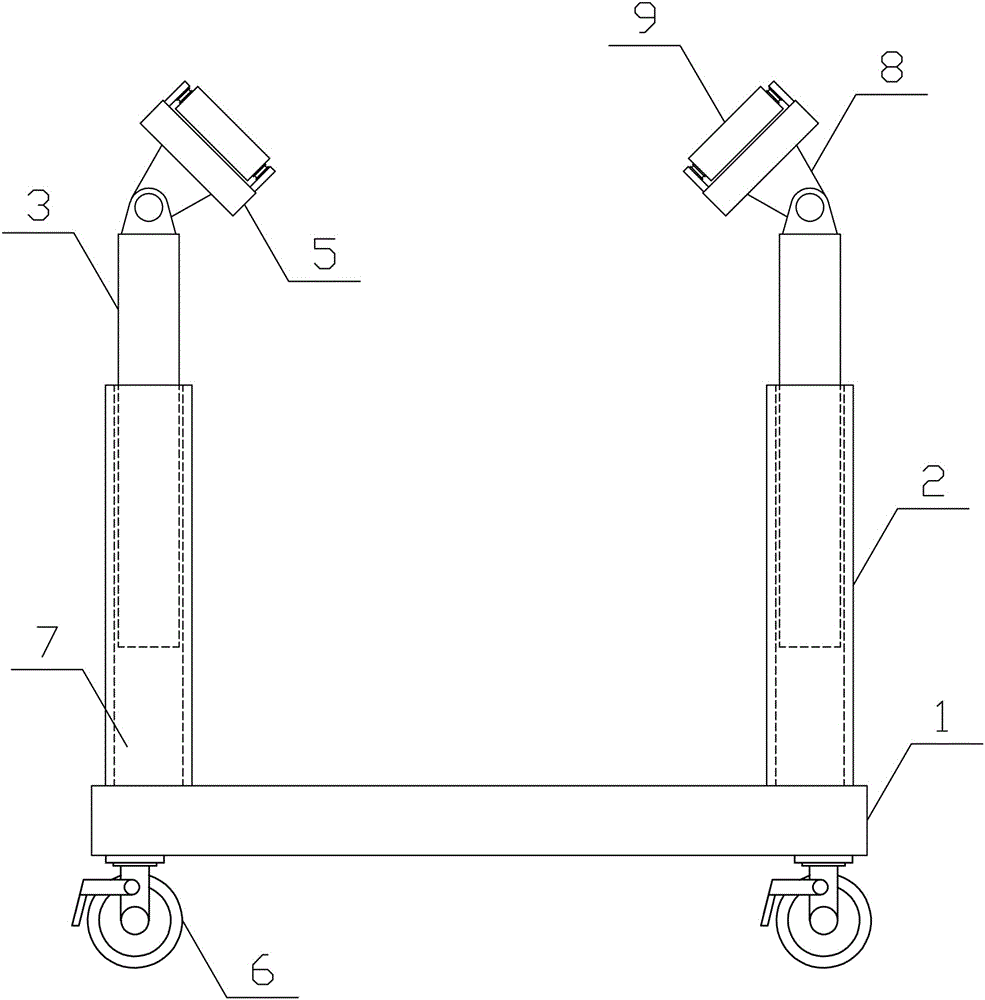

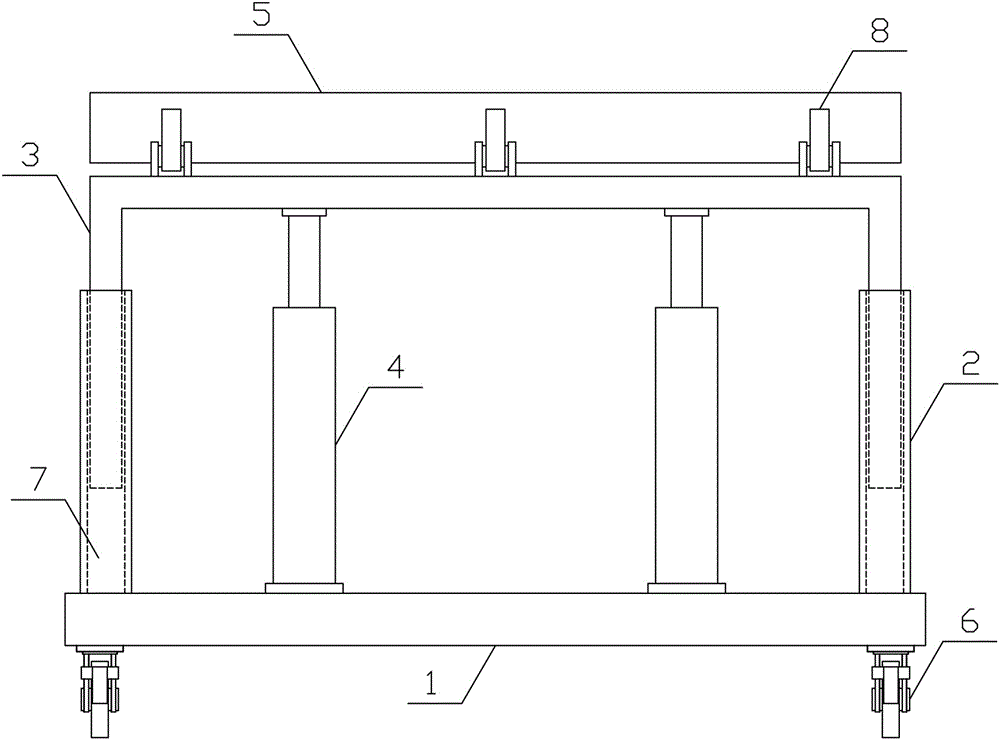

Bipod platform system for a camera

InactiveUS20060233544A1Easy to lowerEasily raisedStands/trestlesCamera body detailsEngineeringVideo camera

A platform system in which the camera is mounted on a platform is provided. The platform allows for a camera to be mounted thereon and whereby the camera may be raised or lowered along two substantially parallel legs. By providing a system in which the camera is positioned between the legs, the camera can be effectively lowered to the ground (or at least to the height of the base) and can be raised to almost any height without increasing the ground space. Additionally, this configuration allows the camera to raised and lowered during filming much the same as a boom.

Owner:COPPOLA ROMAN

Automatic vehicle hoisting and translating device

InactiveCN104192099AWill not affect drivingEasy to replaceVehicle cleaning apparatusAutomatic testingAutomotive engineering

Owner:郭军才

Modified Wheelchair Having Position Changing Function

InactiveCN104257469ASimple structural designEasy to operateWheelchairs/patient conveyanceNursing bedsWheelchairEngineering

The invention discloses a modified wheel chair having a position changing function. The wheel chair includes an electric motor unit, a first electric push rod, a second electric push rod, a third electric push rod and a position changing mechanism unit, wherein the first electric push rod, the second electric push rod, the third electric push rod and the position changing mechanism unit are utilized for lifting the electric wheel chair and changing a chair type to a bed type, so that convenience is made of a user to move from the wheel chair to a bed. The second electric push rod can change the height of the wheel chair through telescoping. The third electric push rod can control the telescoping of auxiliary wheels. The first electric push rod can change the wheel chair from the chair type to the bed type, so that great convenience is brought to patients.

Owner:北京市世纪康恒科技贸易有限公司

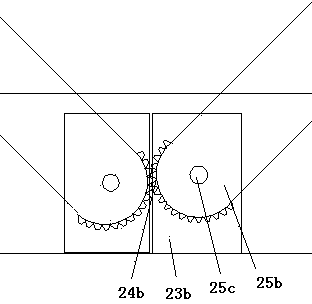

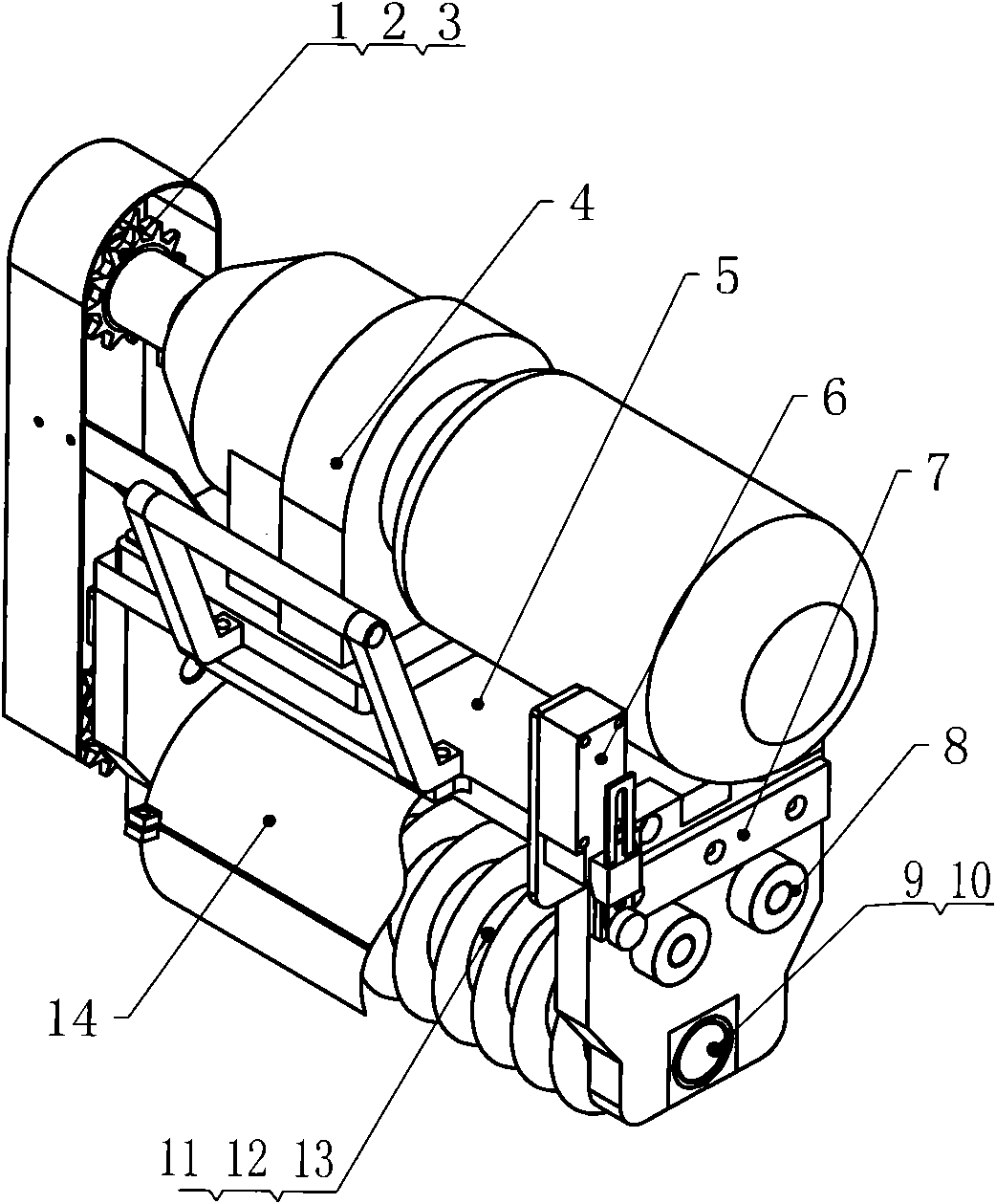

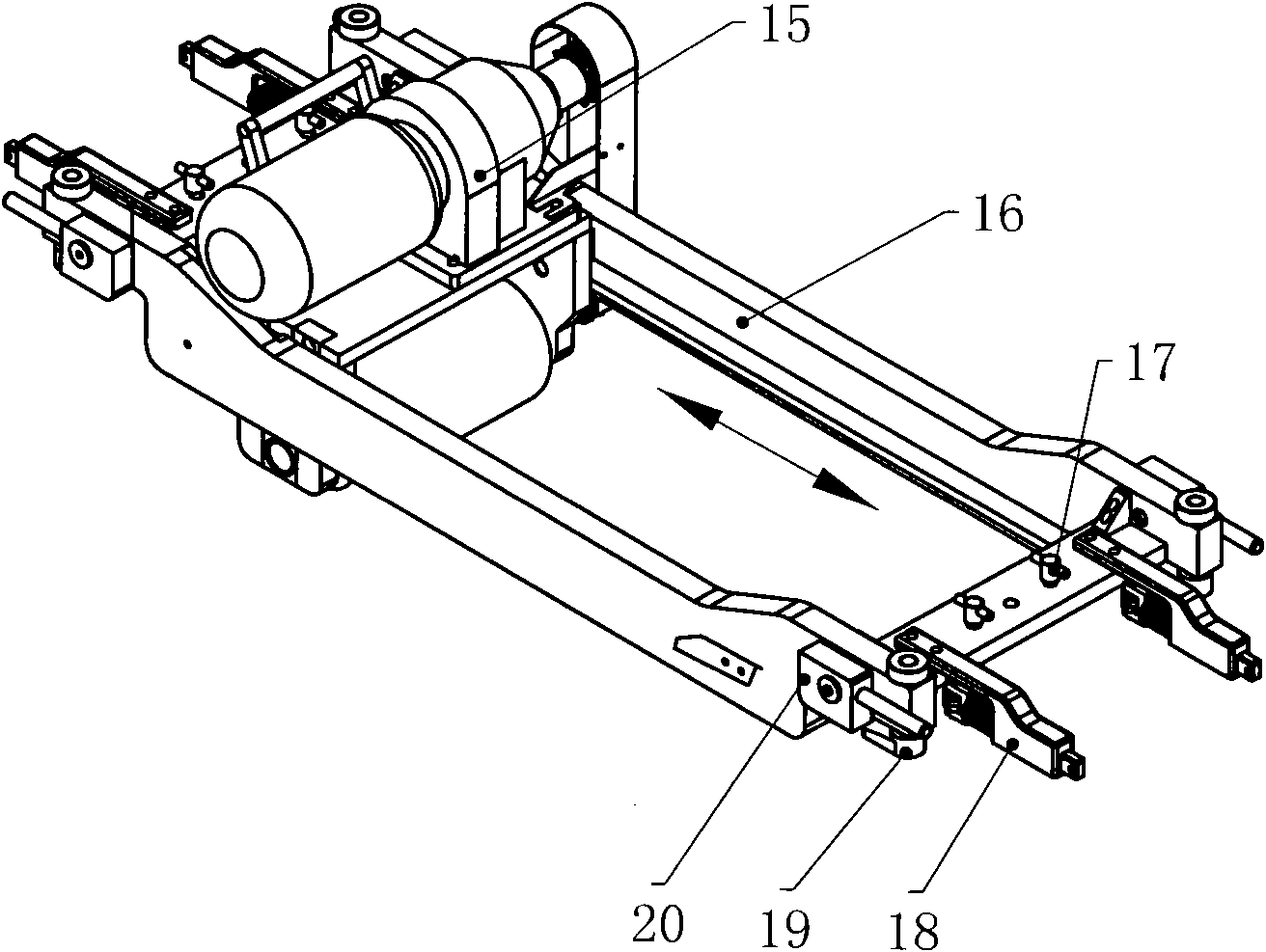

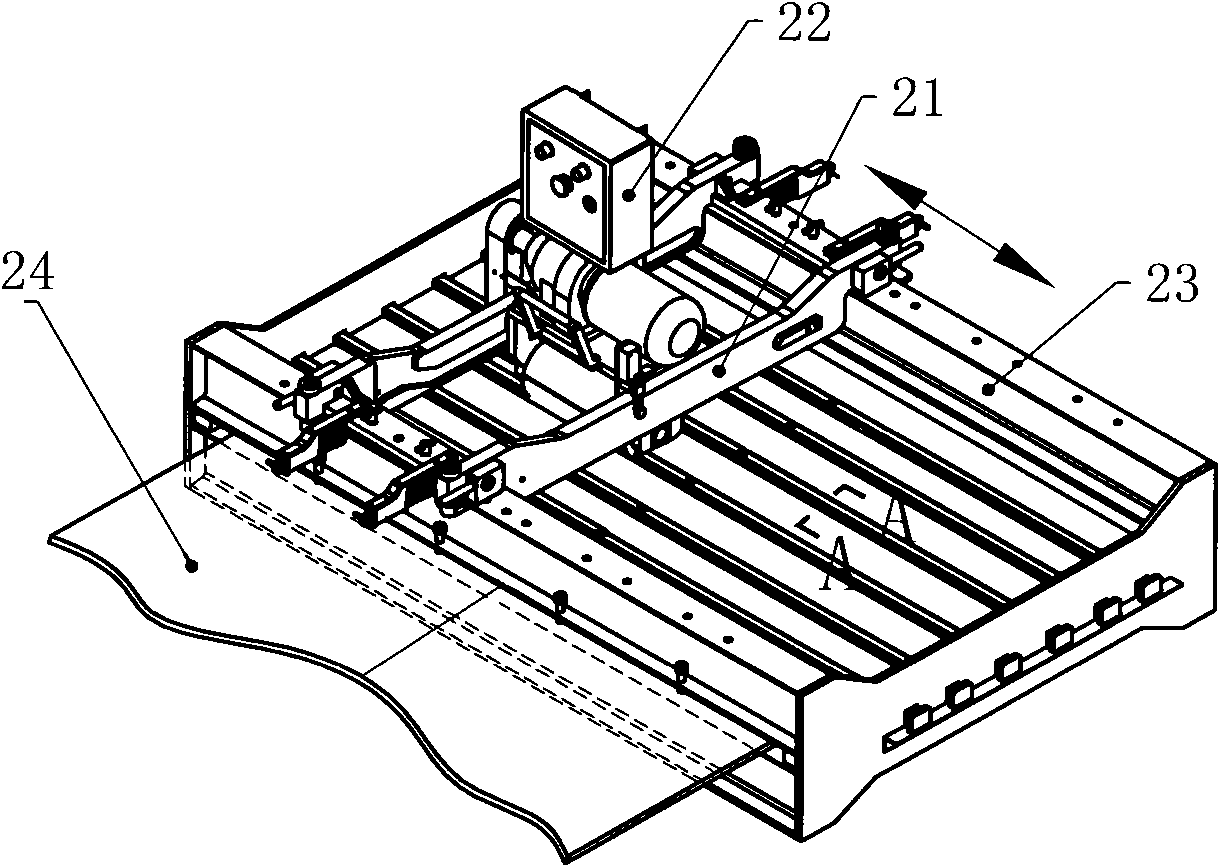

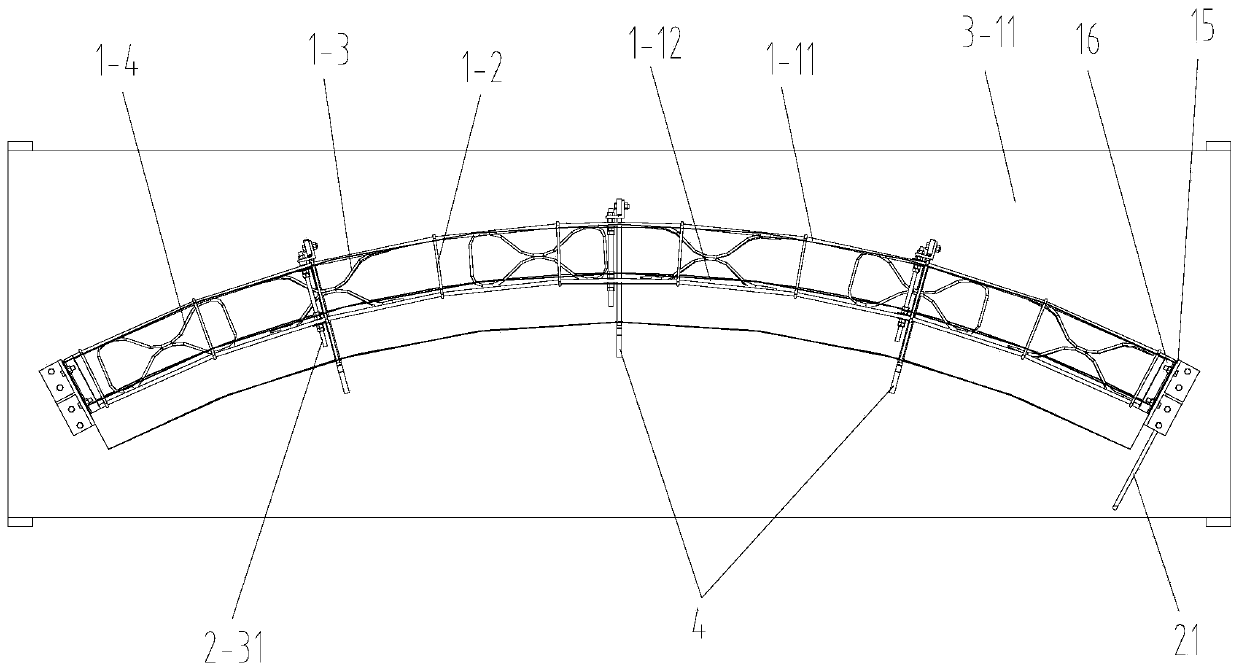

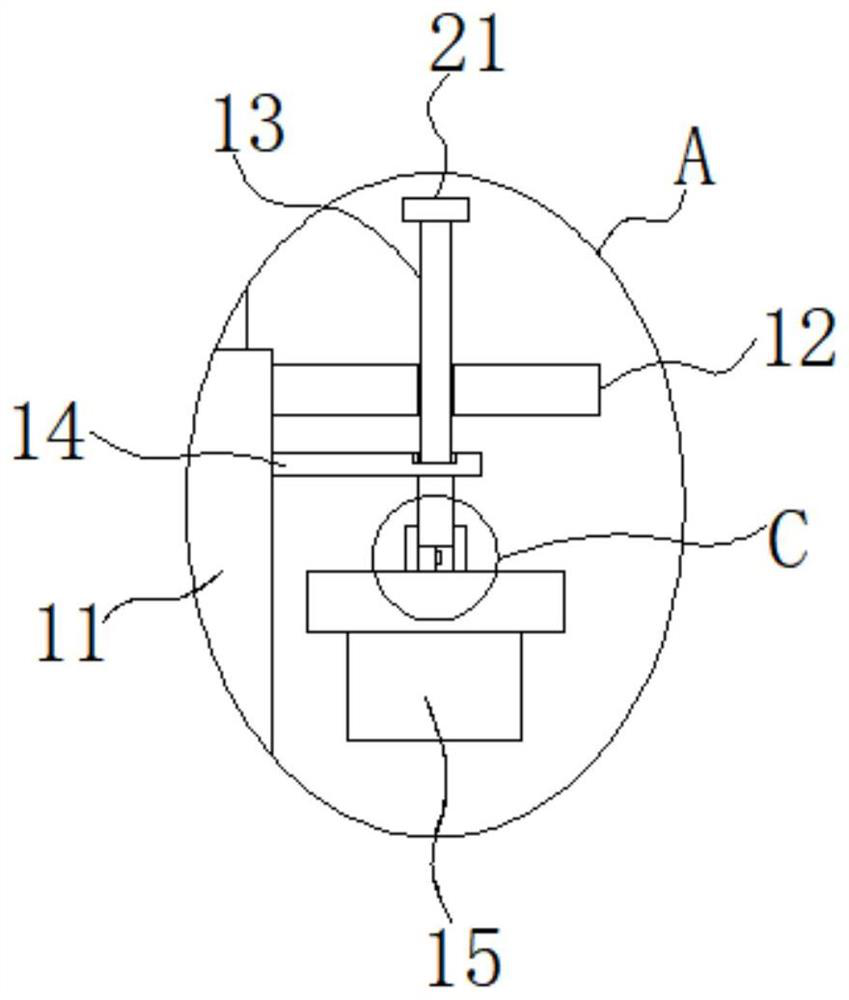

Whole-core conveyer belt tooth-shaped joint cutter

InactiveCN101913162AAchieve one-time cuttingQuality improvementMetal working apparatusSkill setsEngineering

The invention relates to a whole-core conveyer belt tooth-shaped joint cutter. At present, a conveyer belt is mostly connected by using a metal buckle so as to easily produce vibration and tear, obtain short service life and affect the production and safety of an enterprise. The invention aims to produce the whole-core conveyer belt tooth-shaped joint cutter. The structure of the cutter consists of a movable rail frame assembly (21) arranged on a base (23) and a movable tool rest assembly (15) arranged on the rail frame assembly (21) and is a detachable split connection structure. The cutter has the advantage that the cutter is widely applied to the industries of mines, power plants, cement plants, coking plants, docks and harbors and the like which use whole-core conveyer belts. The cutter improves the overall performance of whole-core conveyer belt tooth-shaped joint cutting operation, and avoids the previous problems of poor centering property, low cutting efficiency and poor whole-core conveyer belt connecting quality. The cutter has the advantages of multi-station and multi-blade precise cutting, split design, convenience for carrying, suitability for field operation, and no strict requirement for operator skills.

Owner:周鹏飞

Wall body capable of being translated and folded in building

The invention discloses a wall body capable of being translated and folded in a building. The wall body includes an indoor ceiling, an indoor floor, and two wall boards, wherein arc through grooves are formed in the opposite ends of the two wall boards, a circular pipe sleeves the two wall panels through the arc through grooves, translation mechanisms are fixedly installed on the inner walls of the two wall boards correspondingly, through grooves communicating mutually are formed in the front sides and the rear sides of the wall boards, rotating shafts are rotatably connected to the wall boards through the through holes, shaft arms of the rotating shafts are fixedly connected with supporting plates, and the inner walls of the wall boards are hinged to clamping blocks, and clamping groovesconnected with the clamping blocks in a fastening mode are formed in the front sides of the supporting plates. According to the wall body capable of being translated and folded in the building, through coordination of the structures, the wall boards are translated and folded conveniently, and the problem that people are often not satisfied with the living space, therefore, if the wall boards can be moved freely, thus the room area can be fully utilized as far as possible is solved.

Owner:NANTONG INST OF TECH

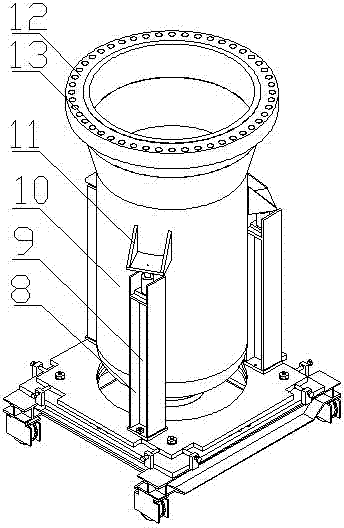

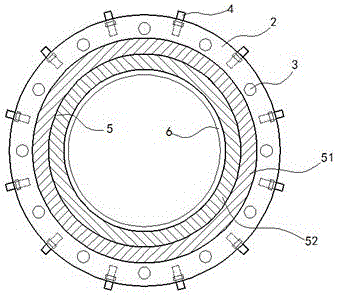

Omni-directional adjustable rapid abutting-connection device and method of slag-breaking machine installed on large gasifier in coal chemical industry

ActiveCN103878569AAvoid large use of equipmentSave human effortMetal working apparatusSlagVehicle frame

The invention relates to an omni-directional adjustable rapid abutting-connection device of a slag-breaking machine installed on a large gasifier in the coal chemical industry. The omni-directional adjustable rapid abutting-connection device of the slag-breaking machine installed on the large gasifier in the coal chemical industry comprises a carrying vehicle frame body, wherein four corners of the bottom of the carrying vehicle frame body are respectively provided with a rail wheel with a braking disc, the carrying vehicle frame body is welded to a base plate, a carrying plate is arranged above the base plate, three supporting frames evenly distributed on the carrying plate are respectively provided with a hydraulic lifting jack, a rotary mechanism is arranged between the carrying plate and the base plate and comprises three or more sleeve bodies or roller bodies, the sleeve bodies are installed on the base plate, the roller bodies are arranged on the sleeve bodies, and the carrying plate is supported on the roller body and is in a rolling friction state. A plurality of rolling balls are arranged between the base plate and the carrying plate, so that rolling friction is formed between the base plate and the carrying plate, and the carrying plate can rotate or move horizontally on the base plate. Therefore, fine adjustment of the abutting-connection device is achieved, large equipment does not need to be used, manpower is saved, and work efficiency is improved.

Owner:江苏双达泵业股份有限公司

Automatic winding device integrating winding, packing and unloading

PendingCN111807115AImprove post-processing efficiencyImprove processing efficiencyBinding material applicationWebs handlingAdhesive beltDrive by wire

The invention relates to the technical field of sheet finished product post-processing equipment and discloses an automatic winding device integrating winding, packing and unloading. The device comprises a frame. The frame is provided with a winding module, a packaging module and a blanking module. The winding module comprises a supporting plate, a rocker arm and a clamping shaft. The supporting plate is fixedly connected with the frame. The rocker arm is rotatably connected with the frame. One end of the clamping shaft is rotatably connected with the supporting plate, and the other end is against the rocker arm. A sheet enters the frame and is conveyed toward the clamping shaft side until the clamping shaft clamps the end of the sheet and winds the sheet. The packaging module comprises arotating frame and a tape roll. The rotating frame is rotatably connected to the frame and is located diagonally above the clamping shaft. The tape roll is rotatably connected to the rotating frame. The blanking module is located below the clamping shaft, and the blanking module comprises a linear driving member and a pushing member. The linear driving member drives the pushing member to move fromthe side of the supporting plate toward the side of the rocker arm. The device solves the problems of low post-processing efficiency and high labor cost of the sheet finished product.

Owner:常州新达力塑料机械有限公司

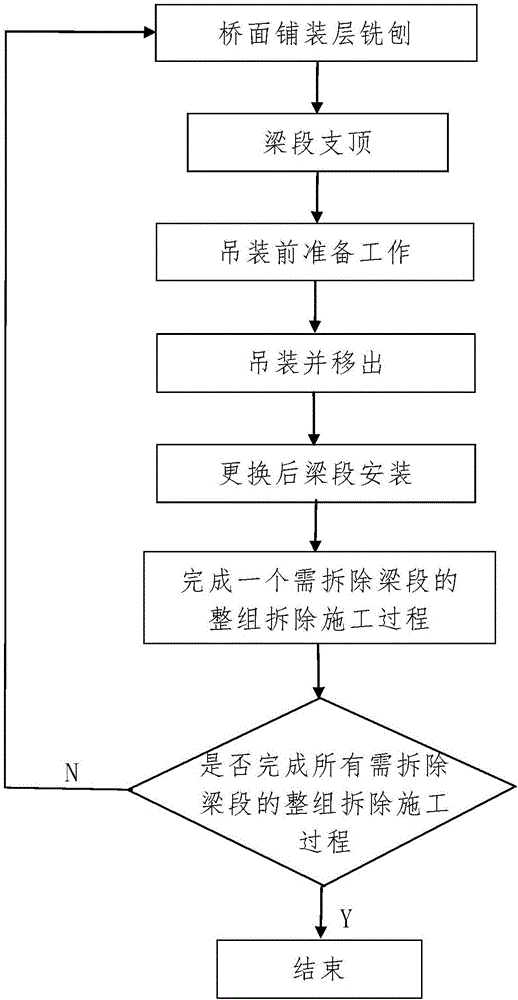

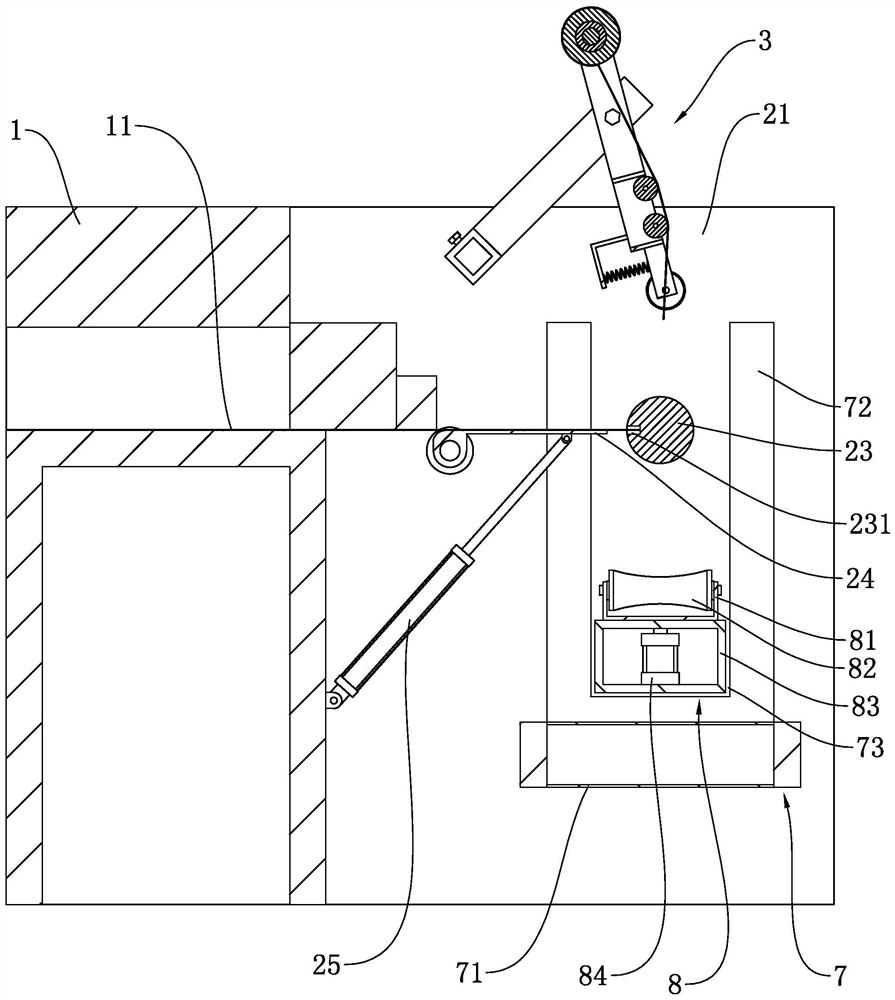

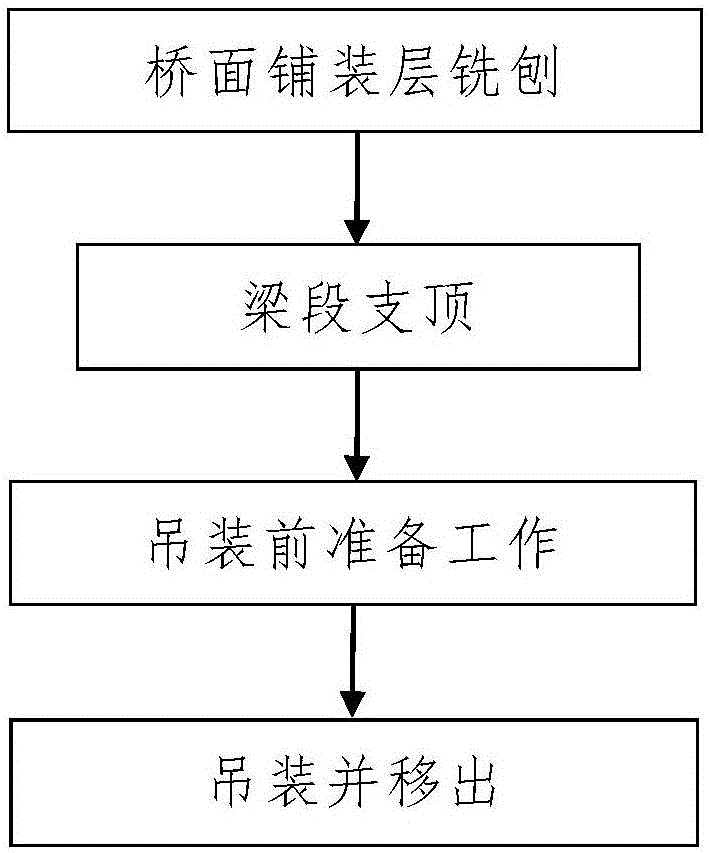

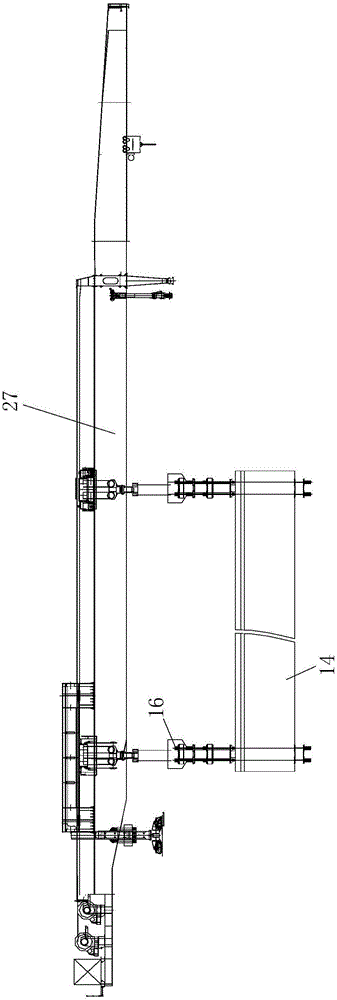

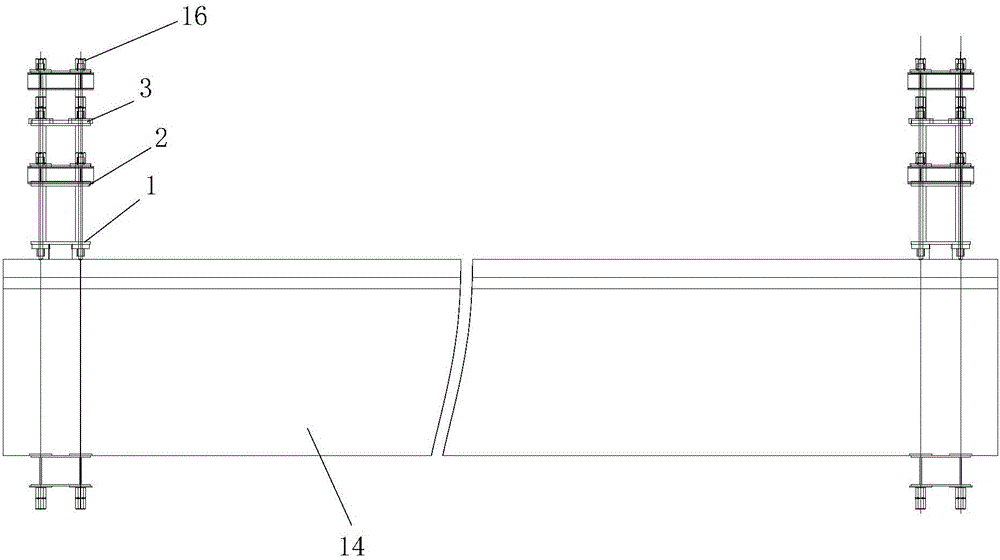

Crossing existing line bridge girder dismounting method

ActiveCN106284109ASimple stepsReasonable designBuilding repairsBridge strengtheningBridge deckRailway line

The invention discloses a crossing existing line bridge girder dismounting method. A dismounted bridge girder is a girder crossing an existing railway line and is formed by splicing a plurality of girder segments to be dismounted from front to back. During complete set dismounting construction of any segment to be dismounted, the process comprises the following steps that firstly, a bridge deck pavement is milled, specifically, the bridge deck pavement of the girder segment constructed currently is milled; secondly, the girder segment is jacked up, specifically, the girder segment constructed currently is horizontally jacked upwards through a vertical jacking device, so that the girder segment constructed currently is separated from two supporting piers; thirdly, preparation operation before hoisting is conducted; and fourthly, the girder segment constructed currently is horizontally hoisted upwards through a bridge girder erection machine and moved to the outer sides of the two supporting piers. The method is simple in step, reasonable in design, easy and convenient to construct and good in application effect, the complete set dismounting construction process of the crossing existing line bridge girder can be completed easily, conveniently and rapidly, and the construction process is safe and reliable, the construction period is short, and the method is economic and practical.

Owner:中铁二十局集团第三工程有限公司

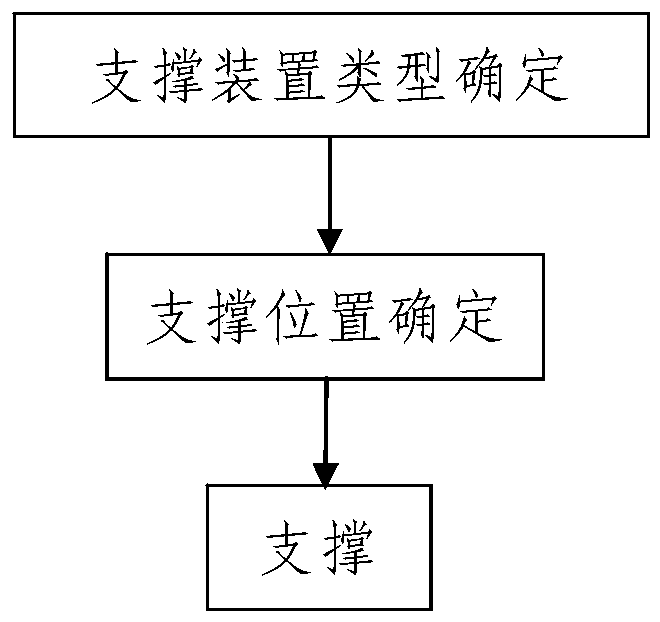

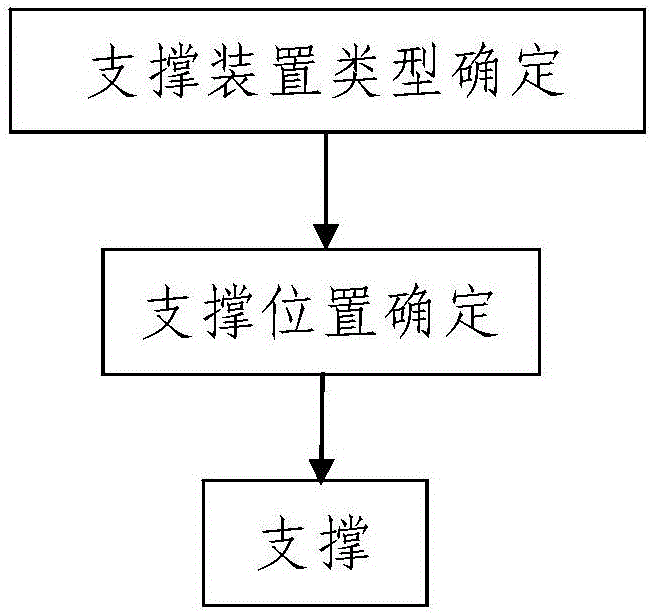

Hydraulic supporting method for concrete replacement of shear walls in high-rise building

InactiveCN105507612AThe method steps are simpleReasonable designBuilding repairsShoresDevice typeFloor slab

The invention discloses a hydraulic supporting method for concrete replacement of shear walls in a high-rise building. The high-rise building under construction is provided with a plurality of floors from bottom to top, each two adjacent floors are partitioned by a floor slab, and each two adjacent floor slabs are supported by one shear wall. Before concrete replacement for the shear walls, needing to be reinforced, in the high-rise building under construction, a supporting device is used for supporting. A supporting process includes firstly, determining a supporting device type, namely determining that the adopted supporting device is used for wall-floor replacement or shear wall replacement; secondly, determining a supporting position of the supporting device; thirdly, supporting the supporting device according to the supporting position determined in the step 2. The hydraulic supporting method has the advantages of simple steps, reasonable design, convenience and simplicity in supporting, good supporting effect, capability of supporting concrete floors around a concrete replacement area simply, conveniently and quickly, economy and practicality.

Owner:SHAANXI ACAD OF ARCHITECTONICS

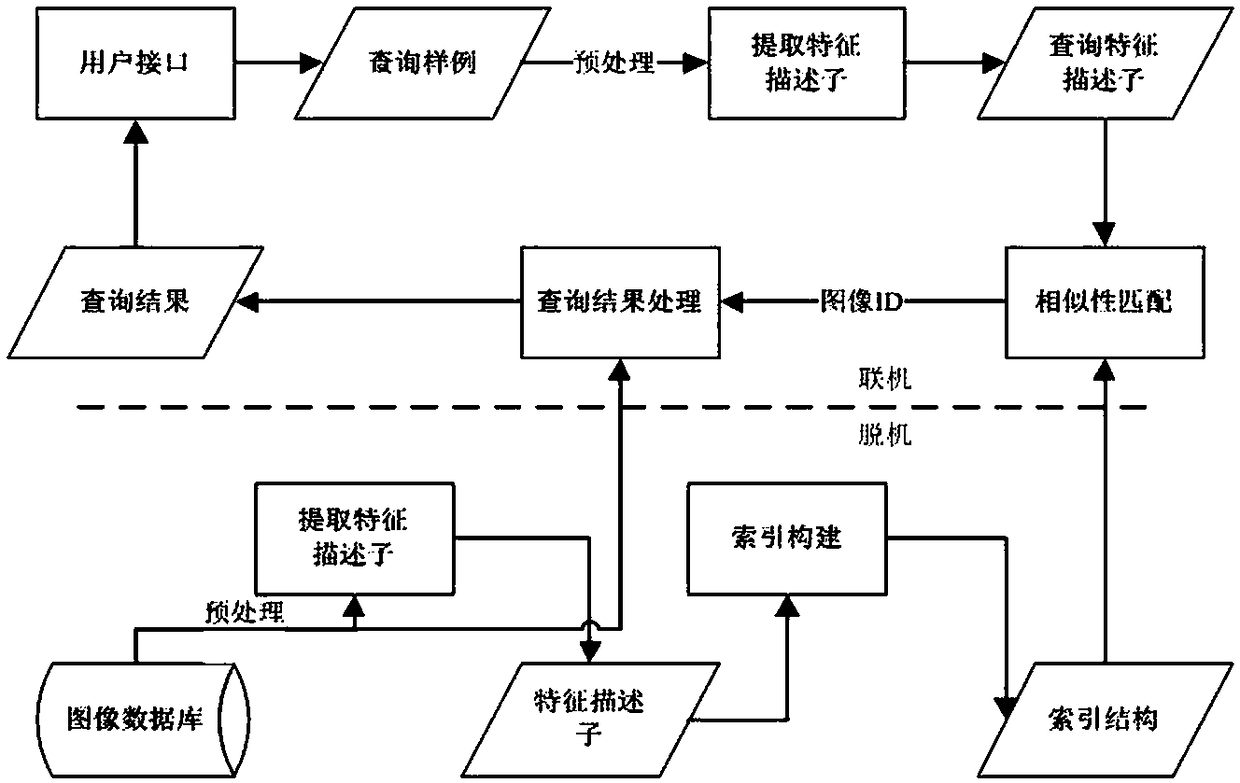

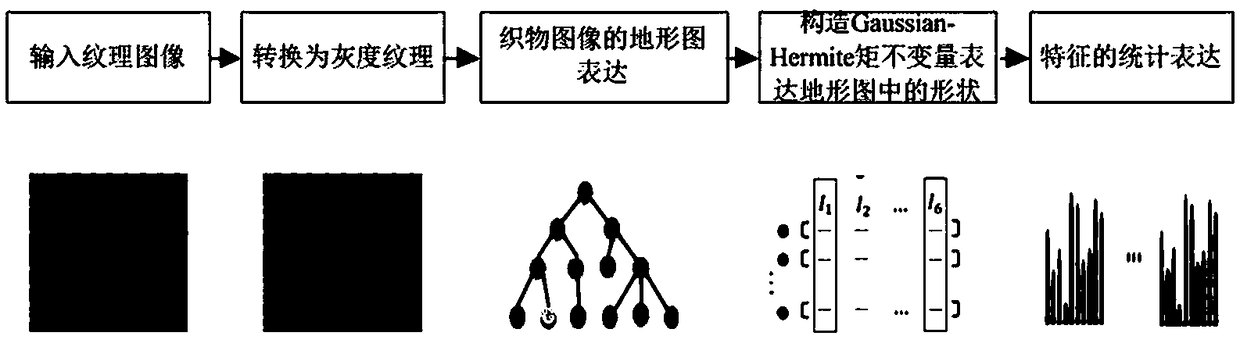

Fabric image retrieval method of locally invariant texture feature based on geometrical shape

ActiveCN108595649AEfficient retrievalIn line with visual perception mechanismImage enhancementImage analysisNODALFeature extraction

The invention discloses a fabric image retrieval method of a locally invariant texture feature based on a geometrical shape, comprising the following steps: 1, offline generating an index structure ofa fabric image database; 2, forming a user query: extracting a locally invariant texture feature based on the geometrical shape of a sample fabric image input via the user, and forming a query that the index database can be retrieved, wherein the step of extracting the locally invariant texture feature based on the geometrical shape is implemented according to the following steps: (1) conversionto a grayscale texture; (2) topographic map expression of the fabric image; (3) feature extraction: one is local expression of the image texture feature, the second one is an expression of structuralrelationship between nodes, and the third one is using a shape contrast feature to remove the influence of local contrast on features; (4) statistical expression of features; 3, calculating similarity, and outputting the result. The fabric image retrieval method provided by the invention proposes a locally invariant texture feature based on the geometrical shape, and the fabric image can be effectively retrieved by using the feature.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

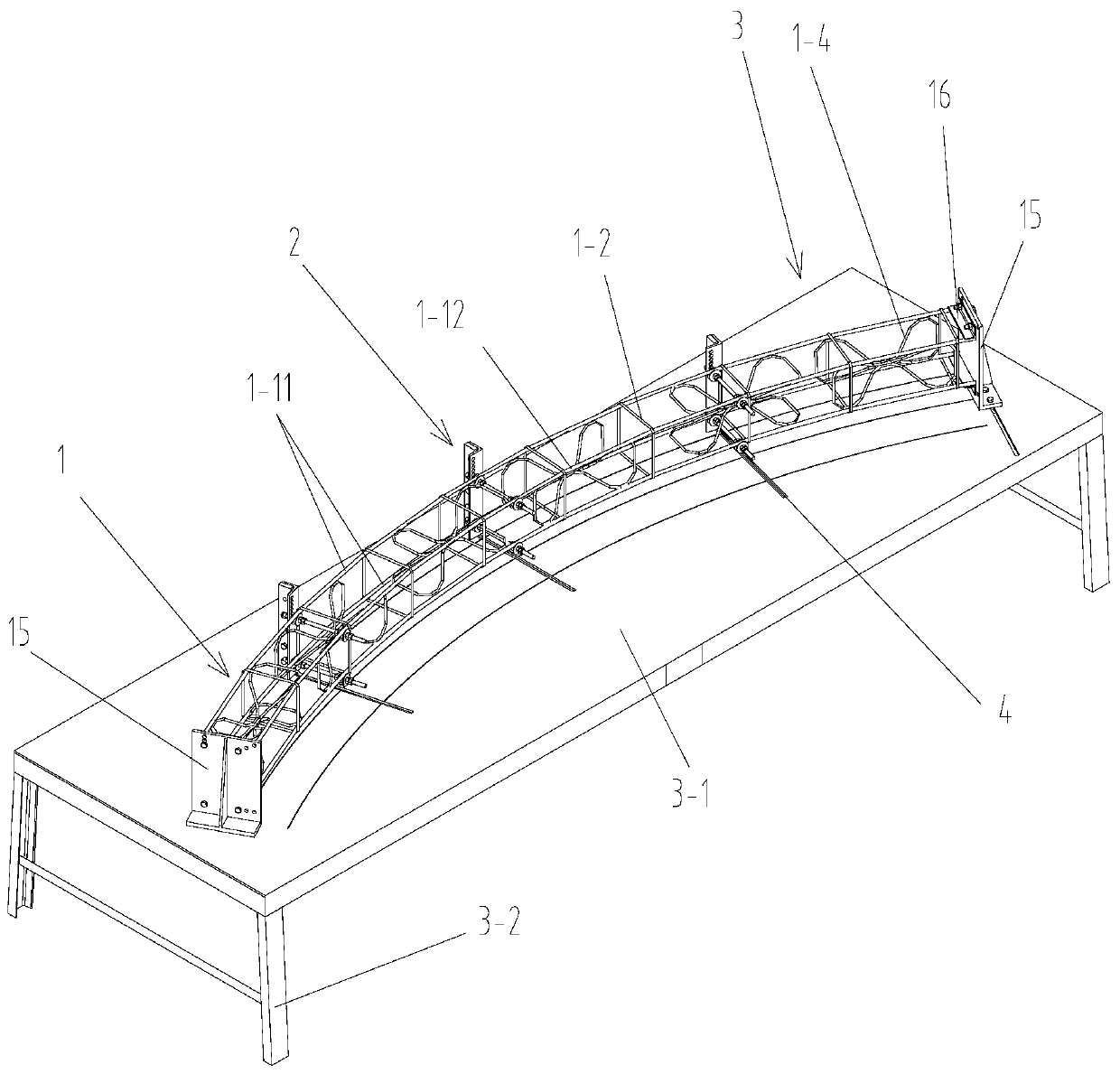

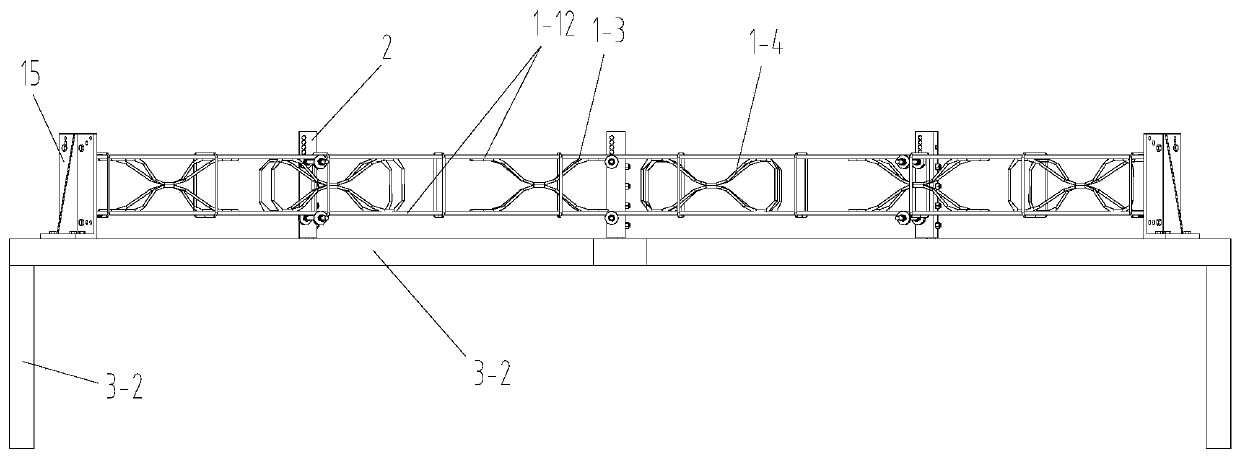

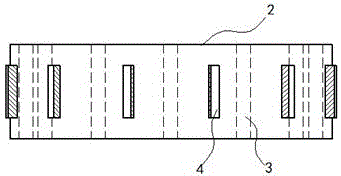

Rapid machining platform and method for grid steel frames

PendingCN110744219ASimple structureReasonable designUnderground chambersWelding/cutting auxillary devicesSteel frameRapid tooling

The invention discloses a rapid machining platform and method for grid steel frames. The machining platform comprises a horizontal support platform and a plurality of main reinforcement positioning moulds, wherein the plurality of main reinforcement positioning moulds are laid in the circumferential direction and all mounted on the horizontal support platform; the plurality of main reinforcement positioning moulds form a main reinforcement positioning device for positioning four main reinforcements in a to-be-machined steel frame segment; and each main reinforcement positioning mould comprisesa sliding seat, a connection seat and a main reinforcement positioning mechanism. The method comprises the steps of 1, adjusting the main reinforcement positioning mechanisms; 2, adjusting the positions of the main reinforcement positioning moulds; 3, mounting the main reinforcements; 4, fixing dowels of the main reinforcements; and 5, fixing rectangular stirrups. The machining platform and method are reasonable in design, simple and convenient in strengthening and good in using effect; and the plurality of movable main reinforcement positioning moulds are adopted to position the steel framesegments and the main reinforcement positioning mechanism on each main reinforcement positioning mould can be adjusted according to the widths and thicknesses of the machined steel frame segments, sothat the machining demands of the steel frame segments with different specifications can be satisfied.

Owner:CHINA RAILWAY 20 BUREAU GRP

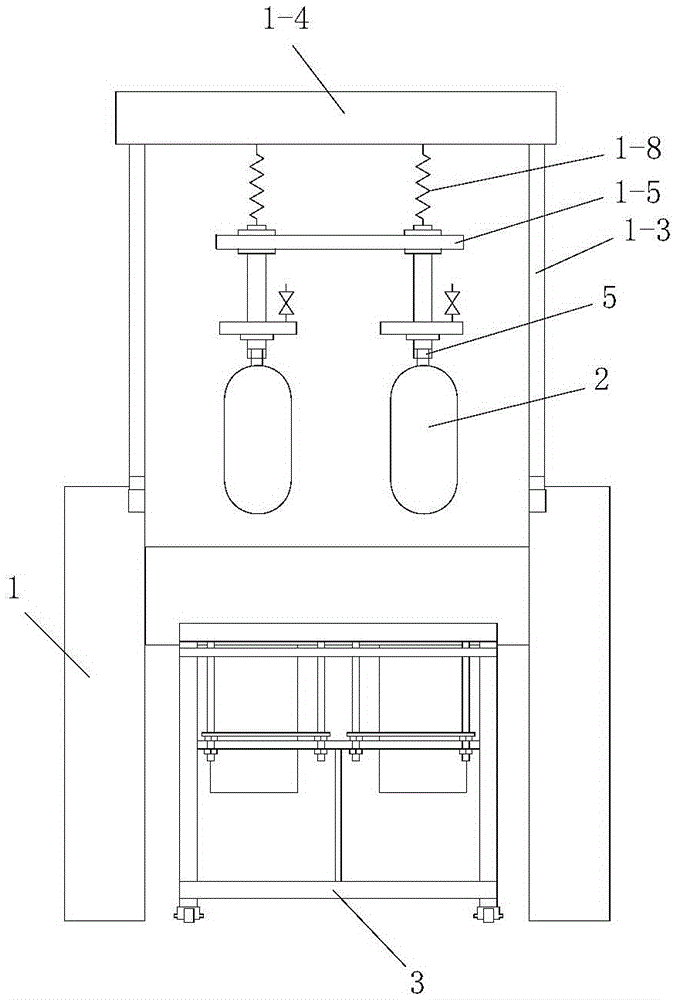

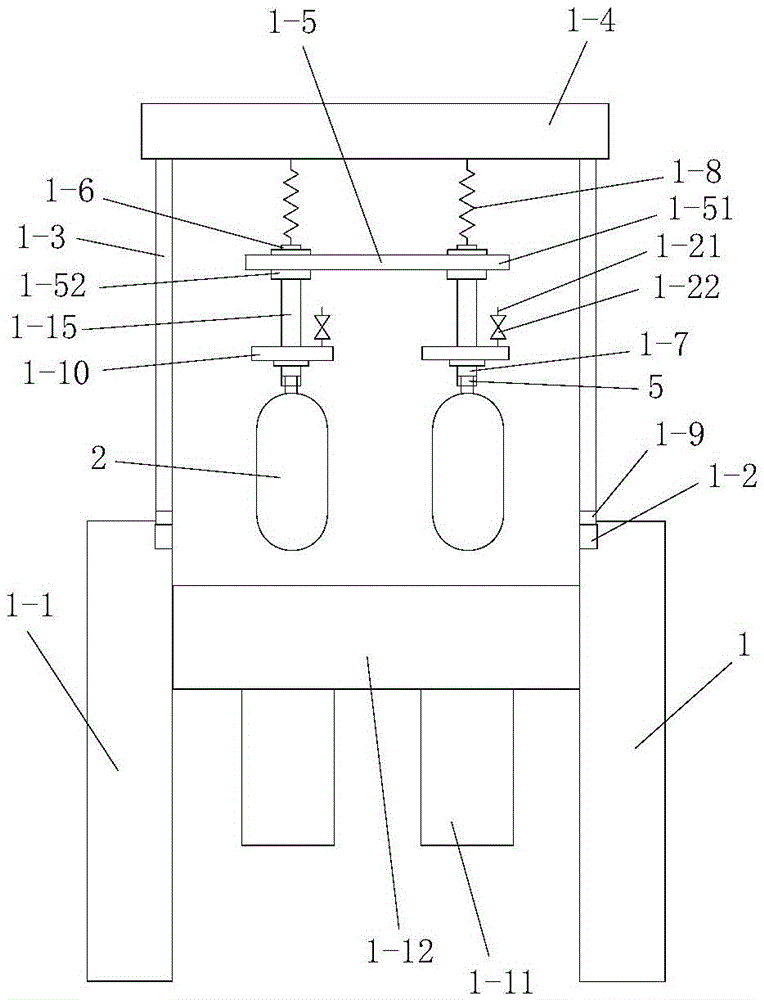

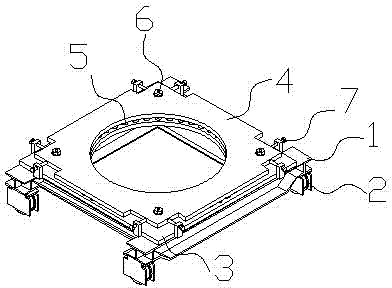

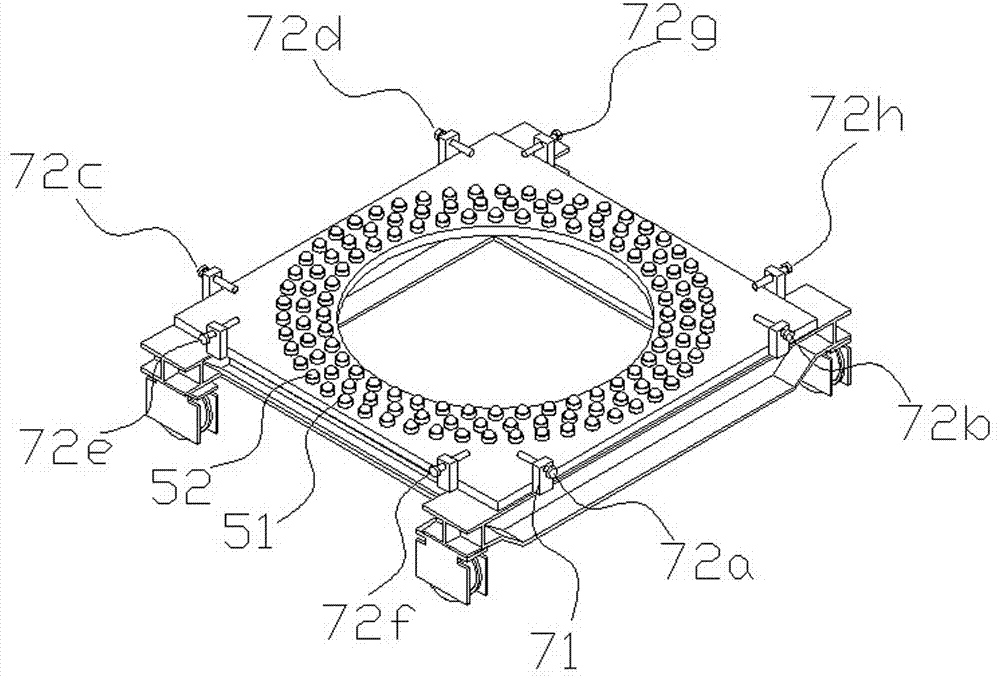

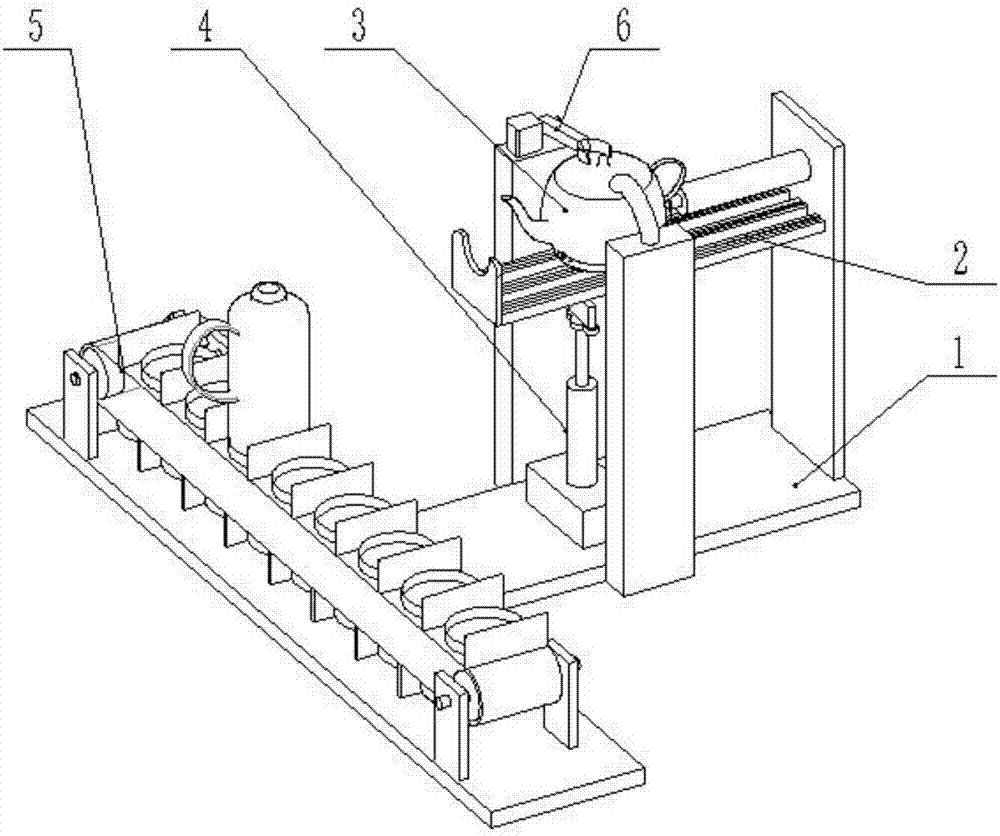

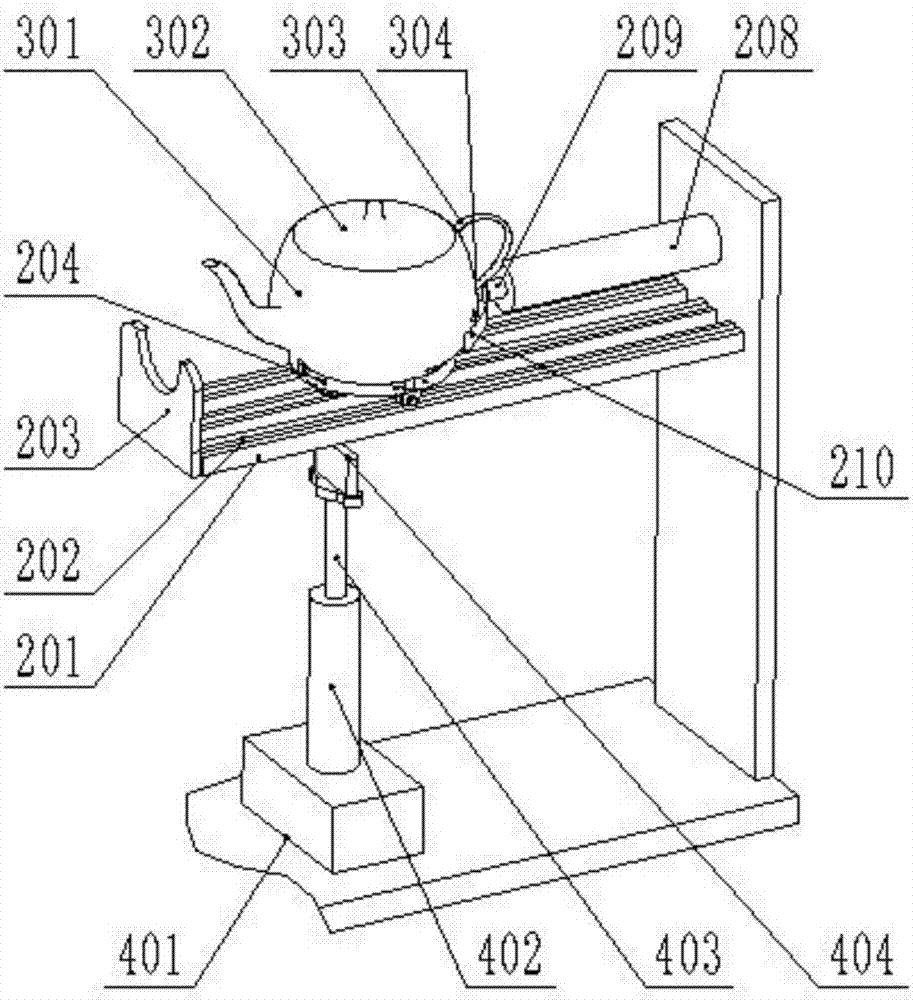

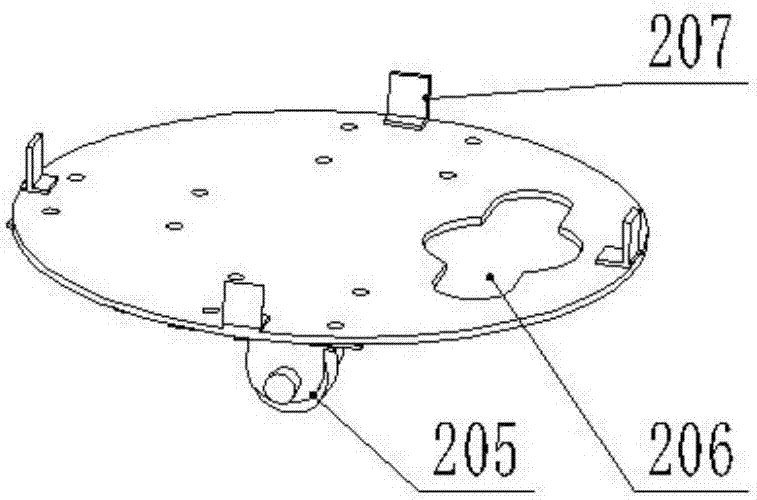

Automatic kettle-reversing equipment for boiling water

ActiveCN106923666AAchieve translationPanning is easy and convenientWater-boiling vesselsEngineeringWater bottle

Owner:HAIMEN MAOFA ART DESIGN CO LTD

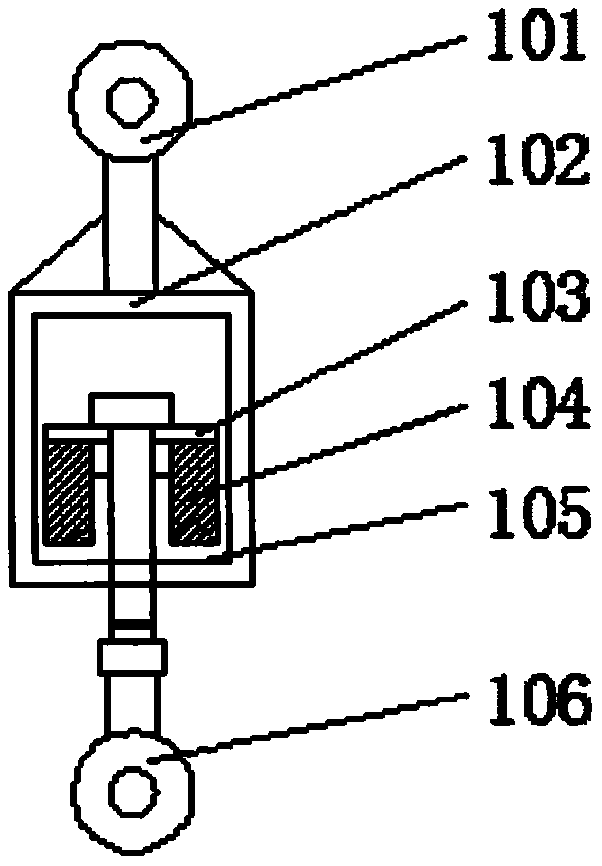

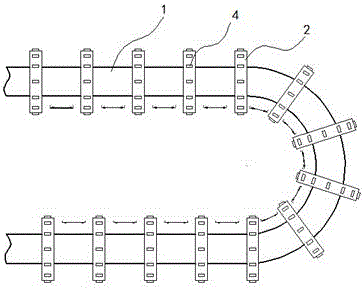

Bag locking steering device for material bags and stacker crane utilizing same

InactiveCN103395620AOvercome disassemblyOvercoming the Flip's DisadvantagesConveyor partsPalletizerFixed position

The invention discloses a bag locking steering device for material bags and a stacker crane utilizing the bag locking steering device, and belongs to the technical field of conveying machinery. The bag blocking steering device for the material bags comprises a fixed frame, wherein a movable frame which transversely moves leftward and rightward is arranged on the fixed frame, a pair of arc bag blocking steering plates which are arranged in an opposite mode are fixedly arranged below the movable frame, the steering plates are used for conducting bag blocking and steering from the left end of a storehouse main conveyor and the right end of the storehouse main conveyor toward the conveying direction of a stacking conveyor, the movable frame can move to two fixed positions on the fixed frame in a leftward and rightward mode, a concave face of each bag blocking steering plate is correspondingly arranged in each fixed position, and therefore the material bags can be turned by 90 degrees in the corresponding direction. The movable frame is controlled to drive the bag blocking steering plates which can turn the material bags by 90 degrees in the corresponding direction to move to corresponding positions according to the different conveying directions of the material bags on the storehouse main conveyor, and the bag blocking steering plates can conduct bag blocking and steering on the material bags. According to the bag locking steering device for the material bags and the stacker crane utilizing the bag blocking steering device, the defects that in the prior art, workers need to regularly climb a stacker crane travelling crane to detach and turn the bag blocking steering plates are overcome.

Owner:HENAN UNIV OF SCI & TECH

Novel tow chain cable

ActiveCN105575510AAvoid breakingPlay a protective effectInsulated cablesInsulated conductorsMagnetic polesEngineering

The invention relates to a novel tow chain cable. The novel tow chain cable comprises an electric wire core and tow chain rings. The tow chain rings are flat ring cylinder-shaped. Bar magnets extending along the axial direction of the tow chain rings are evenly arranged in the circumferential direction in the tow chain rings. All the bar magnets are consistent in the direction of magnetic pole arrangement. Translation wheels are also equidistantly installed on the external ring surface of the tow chain rings. The wheel surfaces of all the translation wheel pass through the axes of the tow chain rings. Annular lines are carved on the internal ring surfaces of the tow chain rings. The cable is simple in structure and convenient for storage and use; and rapid stretching and translation of the cable can be realized, and lateral movement of the cable can also be realized so that work efficiency can be substantially enhanced.

Owner:扬州市金鑫电缆有限公司

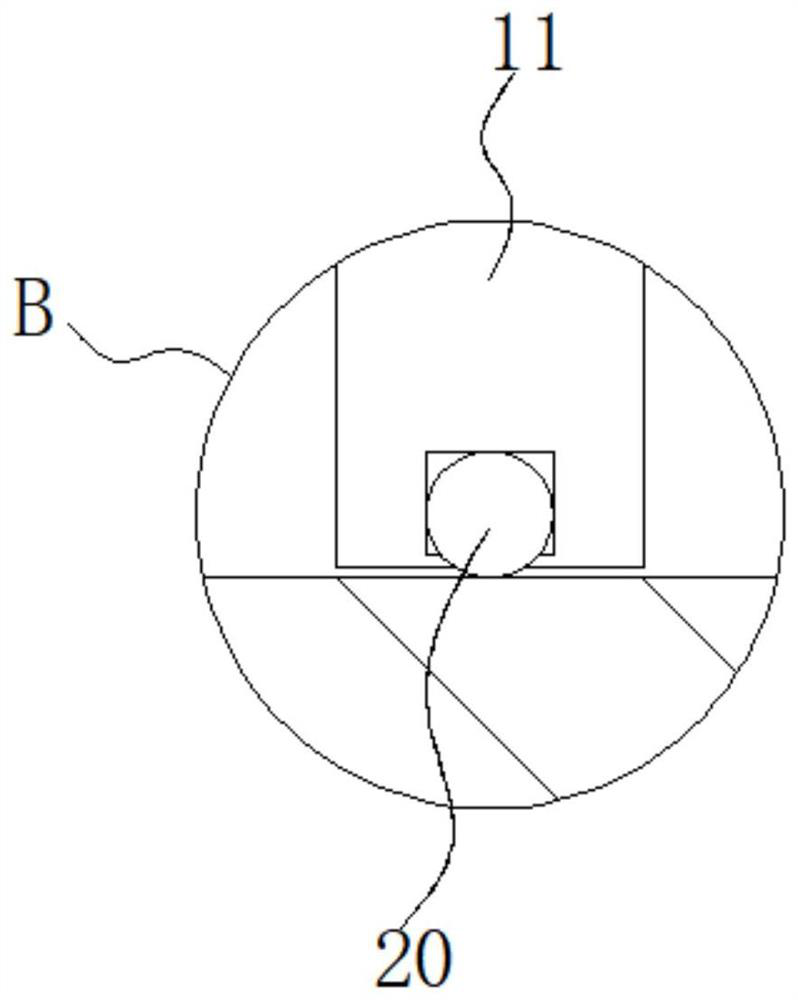

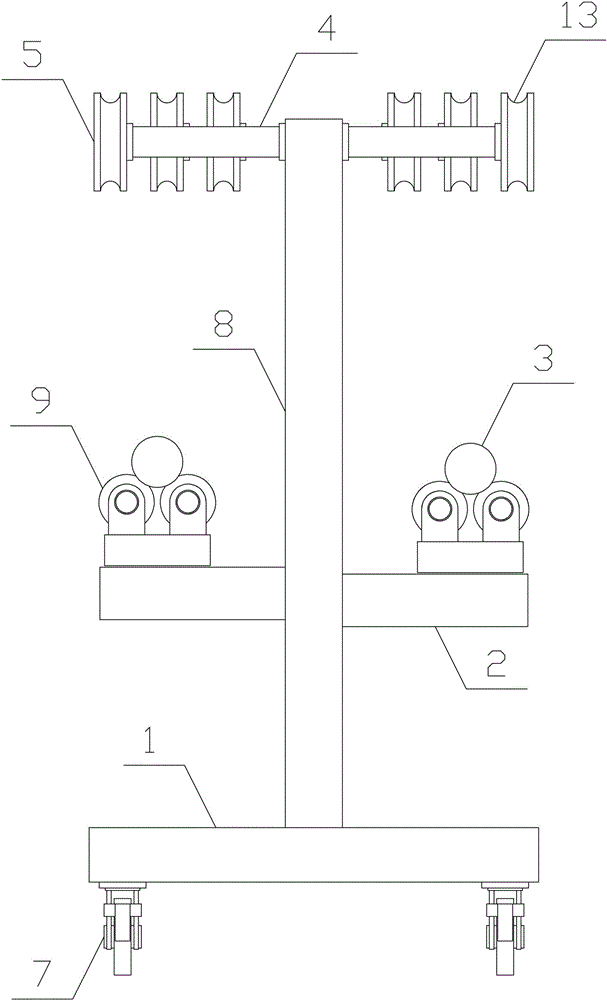

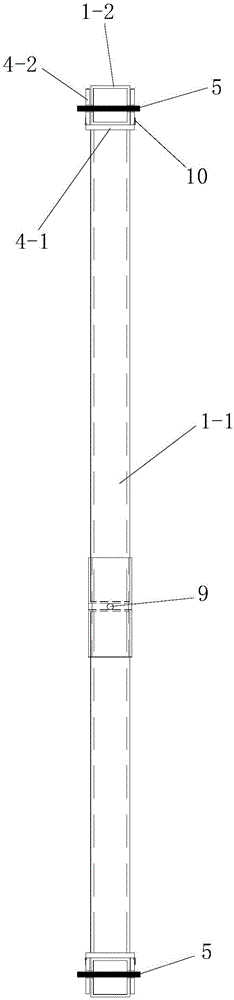

Aluminum roll lifting and translating mechanism

InactiveCN106115160AEasy to panSimple structureConveyorsSupporting framesHydraulic cylinderMechanical engineering

The invention discloses an aluminum roll lifting and translating mechanism and belongs to the field of aluminum material conveying machinery. The aluminum roll lifting and translating mechanism comprises a translation base, lifting sleeves, a lifting support, lifting hydraulic cylinders and an aluminum bearing plate. The lower side of the translation base is evenly provided with a plurality of universal wheels with brake devices. The lifting support is vertically arranged on the two sides of the upper portion of the translation base. The two ends of the lifting support are vertically arranged in the lifting sleeves on the two sides of the translation base correspondingly. Lifting channels matched with the lifting support are vertically formed in the lifting sleeves correspondingly. The two lifting hydraulic cylinders are vertically arranged between the two sides of the middle of the lifting support and the translation base. The aluminum bearing plate is horizontally arranged above the lifting support. The upper side of the aluminum bearing plate is evenly and rotationally connected with a plurality of translation rolls. The aluminum roll lifting and translating mechanism is reasonable in structure design and capable of rapidly, efficiently and conveniently lifting and translating aluminum rolls of various sizes and specifications to meet the requirements for production and use.

Owner:ZHEJIANG ZHONGSHI MACHINERY CO LTD

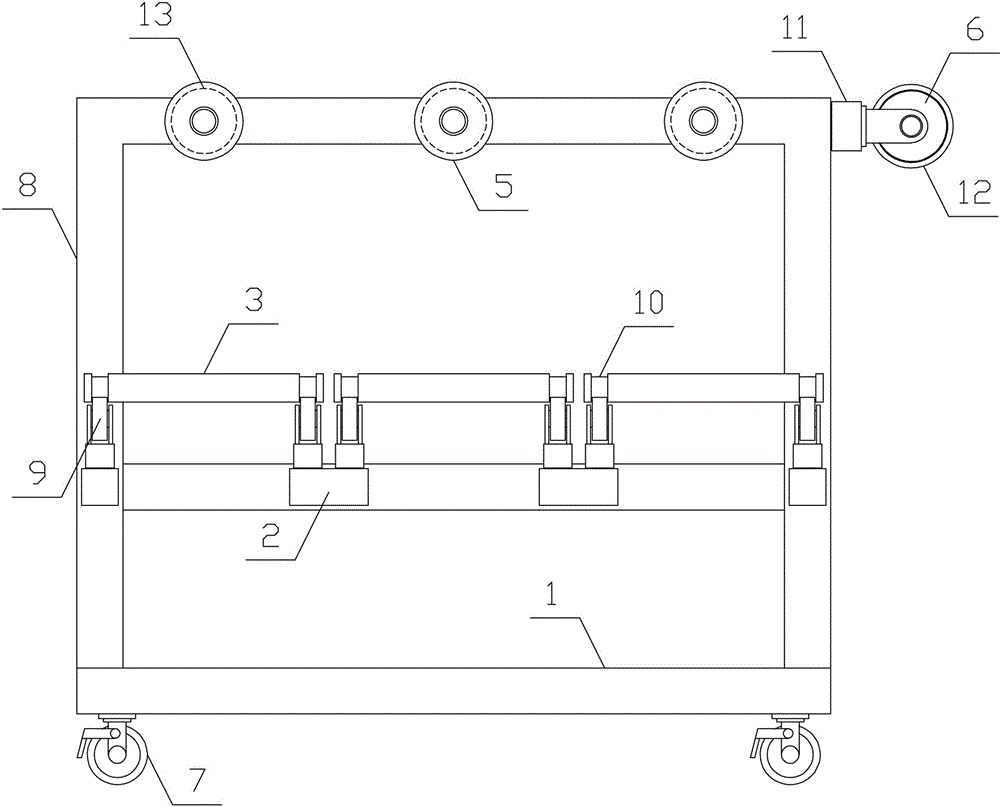

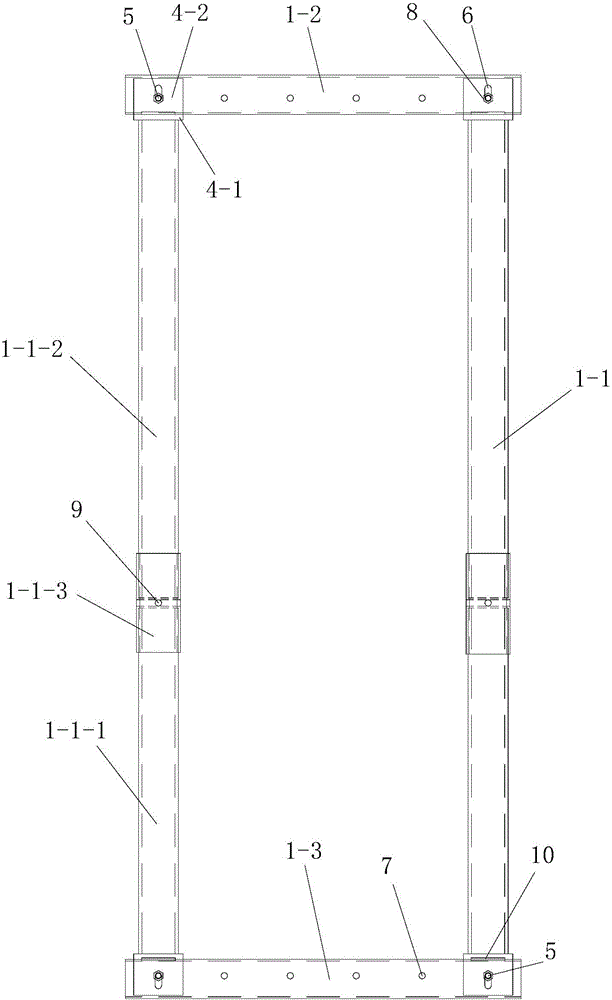

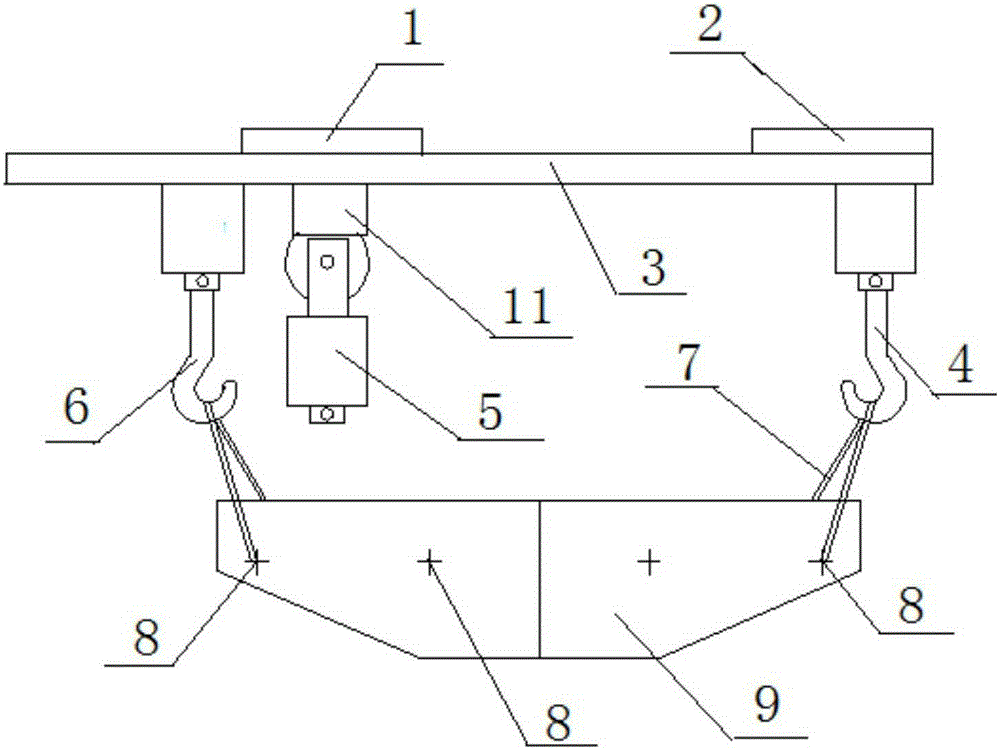

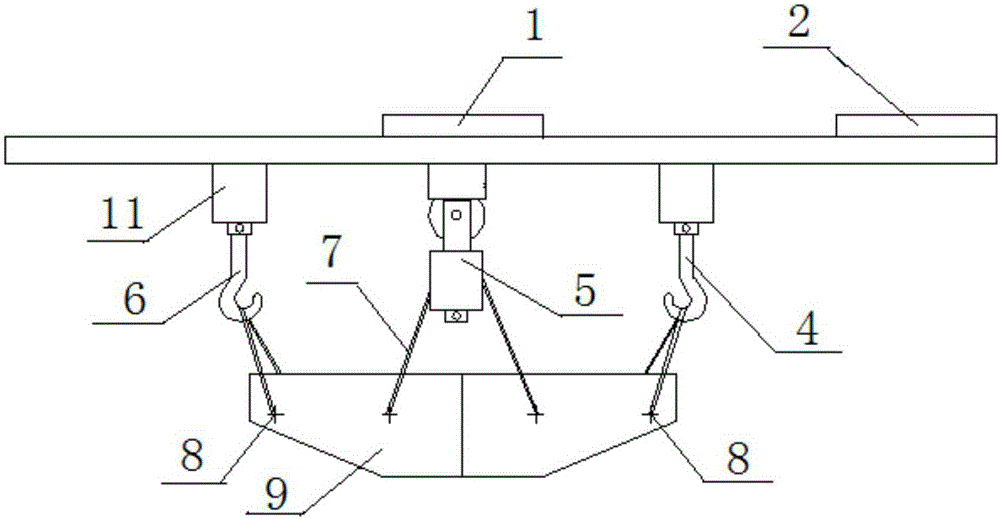

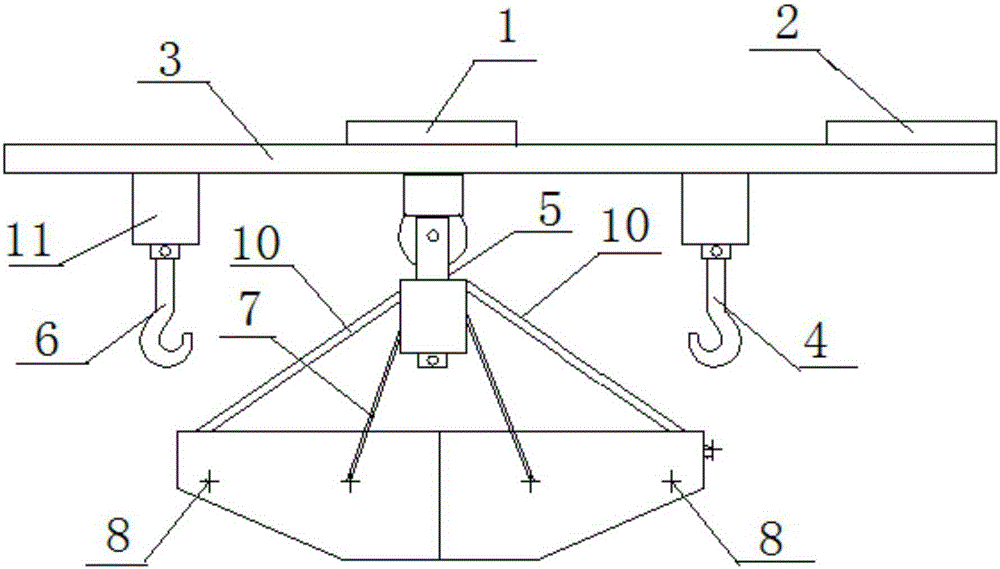

Lost foam casting mold flow painting device for casting machining

InactiveCN111889633AEasy flipEasy to clamp and positionMoulding toolsFoundry mouldsElectric machineEngineering

The invention relates to the technical field of casting machinery, and discloses a lost foam casting mold flow painting device for casting machining. The lost foam casting mold flow painting device comprises two symmetrically-arranged supporting frames, and a transverse beam is fixedly connected between the tops of the two supporting frames; synchronous electric hoists are symmetrically installedon the transverse beam, and the bottom ends of the two synchronous electric hoists are fixedly connected with the same U-shaped frame through vertical columns; the position, close to the bottom end, of the U-shaped frame is provided with a base, and the position of the outer side wall, close to the bottom end, of the U-shaped frame is fixedly provided with a turnover motor; a turnover shaft of theturnover motor penetrates through the base and is rotationally connected with the U-shaped frame through a first bearing, and the turnover shaft of the turnover motor is fixedly connected with the base; the upper surfaces of the positions, close to the two ends, of the base are symmetrically and fixedly connected with fixing columns, and the positions, close to the top ends, of the two fixing columns are rotationally connected with screw rods through second bearings. The lost foam casting mold flow painting device for casting machining can conveniently fix different types of lost foam castingmolds, and the applicability is effectively improved.

Owner:马鞍山庞博铸业股份有限公司

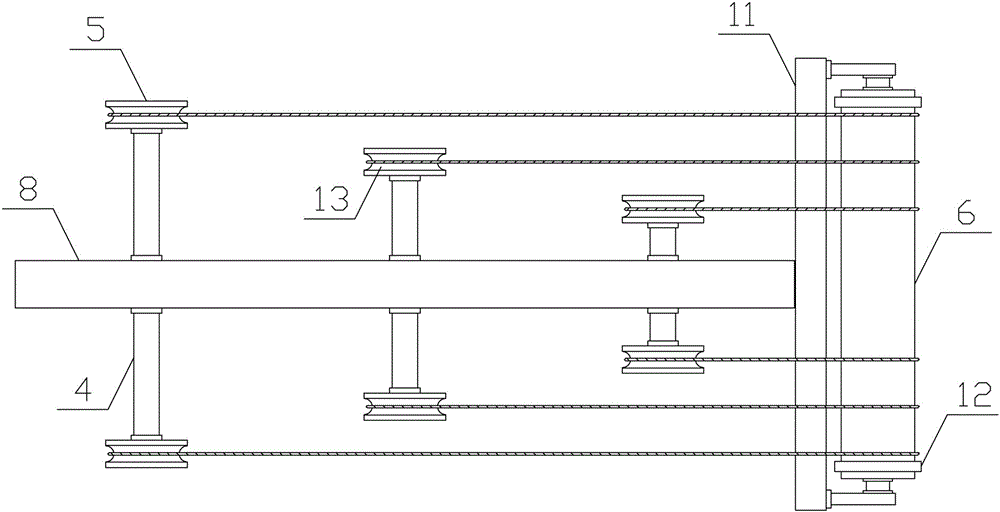

Bobbin yarn guiding mechanism

The invention discloses a bobbin yarn guiding mechanism, and belongs to the field of textile processing machinery. The bobbin yarn guiding mechanism comprises a translation support, a plurality of supporting plates, a plurality of bobbin placing rolls, a plurality of yarn guiding rods, a plurality of yarn guiding wheels and a yarn guiding roll, wherein a plurality of universal wheels with brakes are uniformly arranged on the lower side of the translation support; a yarn guiding support is vertically arranged in the middle of the upper side of the translation support; the supporting plates are horizontally and uniformly arranged on two sides of the middle of the yarn guiding support respectively; two sides of the upper part of each supporting plate are vertically and rotatably connected with roll supporting wheels respectively; the bobbin placing rolls are horizontally arranged on two sides of the yarn guiding support; two ends of each bobbin placing roll are horizontally arranged on the upper sides of the two corresponding roll supporting wheels respectively; the yarn guiding rods are horizontally and uniformly arranged on two sides of the upper part of the yarn guiding support respectively; one end of each yarn guiding rod is vertically and rotatably connected with the corresponding yarn guiding wheel; and the yarn guiding roll is horizontally and rotatably connected to one side of a fixed support. The bobbin yarn guiding mechanism is reasonable in structural design, a plurality of bobbins can be used for synchronously and stably guiding yarns quickly and efficiently, and requirements of production and use are met.

Owner:徐晓伟

Supporting method for high-rise building shear wall concrete replacement

InactiveCN105672693AThe method steps are simpleReasonable designBuilding repairsFloor slabEngineering

The invention discloses a supporting method for high-rise building shear wall concrete replacement. The constructed high-rise building is provided with multiple floors from bottom to top; two adjacent floors are separated through floor slabs; two adjacent upper and lower floor slabs are supported through a shear wall; before a shear wall needing to be reinforced in the constructed high-rise building is subjected to concrete replacement, a supporting device is used for supporting, and the supporting process comprises the following steps: 1, determination of type of the supporting device, namely determining the type of the supporting device, wherein the type of the adopted supporting device is a supporting device for wall floor replacement or a supporting device for shear wall replacement; 2, determination of supporting position, namely determining the supporting position of the supporting device; 3, support, namely supporting the supporting device according to the supporting position determined in the step 2. The method disclosed by the invention is simple in steps, reasonable in design, simple and convenient to support, good in supporting effect, capable of simply, rapidly and reliably supporting concrete floor slabs around a concrete replacement area, economical and practical.

Owner:SHAANXI ACAD OF ARCHITECTONICS

Method for replacing ladle turret rotary arm of continuous casting machine

The invention discloses a method for replacing a ladle turret rotary arm of a continuous casting machine, and belongs to the technical field of maintenance of ladle turrets of large-tonnage continuous casting machines. The method comprises the steps of mounting of fixed pieces, hoisting between two spans, horizontal movement, molten steel below-span hoisting, balance locking, hoisting landing, reassembling and the like. The ladle turret rotary arm of the continuous casting machine is moved to the position where a molten steel span crane main hoist can operate through a continuous casting crane main hoist and a molten steel span crane auxiliary hoist of existing facilities on site; a chain block is used for balance locking before molten steel span crane hoisting, and the situation that the rotary arm loses balance after the molten steel span crane auxiliary hoist is loosened is avoided; and after steel wire rope hanging of the molten steel span crane main hoist, balance locking of the chain block and stressing of the molten steel span crane main hoist, the molten steel span crane auxiliary hoist and the continuous casting crane main hoist are loosened, and then the molten steel span crane main hoist is used for hoisting landing. The aims of safely and effectively replacing the ladle turret rotary arm of the continuous casting machine, reducing the influence on production and improving maintenance efficiency are achieved.

Owner:ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

Laser engraving machine with double engraving heads

InactiveCN110449742AEasy to panConvenient for carving in different positionsLaser beam welding apparatusLaser engravingEngineering

The invention discloses a laser engraving machine with double engraving heads. The laser engraving machine comprises a rack, a first laser engraving head, a second laser engraving head, the two sidesof the rack are correspondingly provided with a servo motor, wherein a dust collecting box is arranged at the top of the rack; a supporting plate is fixedly arranged in the rack, and the supporting plate is of a hollow structure; a plurality of screw rods are arranged in the supporting plate, and each screw rod is rotationally connected with the servo motor through a motor shaft; the screw rods are rotationally connected with the inner threads of sliding nuts, the bottoms of the sliding nuts are connected with laser engraving devices through connecting shafts, and the first laser engraving head and the second laser engraving head are correspondingly arranged on each laser engraving device; a dust collection pipeline is arranged on one side of the laser engraving device; and one end of thedust collection pipeline is connected with a dust suction opening, and the other end of the dust collection pipeline is connected with a dust collection fan. According to the laser engraving machine with the double engraving heads, the working efficiency of laser engraving of the machine is improved through the arrangement of the first laser engraving head and the second laser engraving head.

Owner:李东方

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com