Omni-directional adjustable rapid abutting-connection device and method of slag-breaking machine installed on large gasifier in coal chemical industry

A technology of docking device and slag breaker, which is applied in the field of coal chemical industry, can solve the problems of wasting time, low installation efficiency, affecting the installation or maintenance period, etc., and achieve the effect of improving work efficiency, saving manpower, and avoiding large-scale use of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

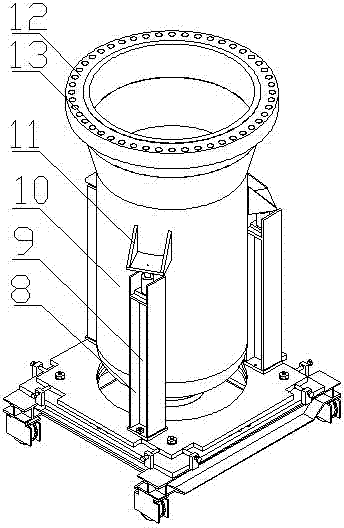

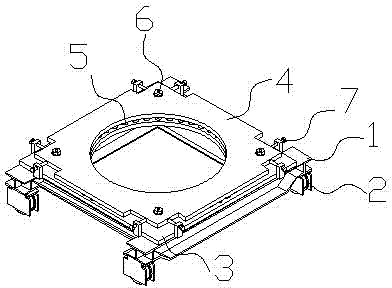

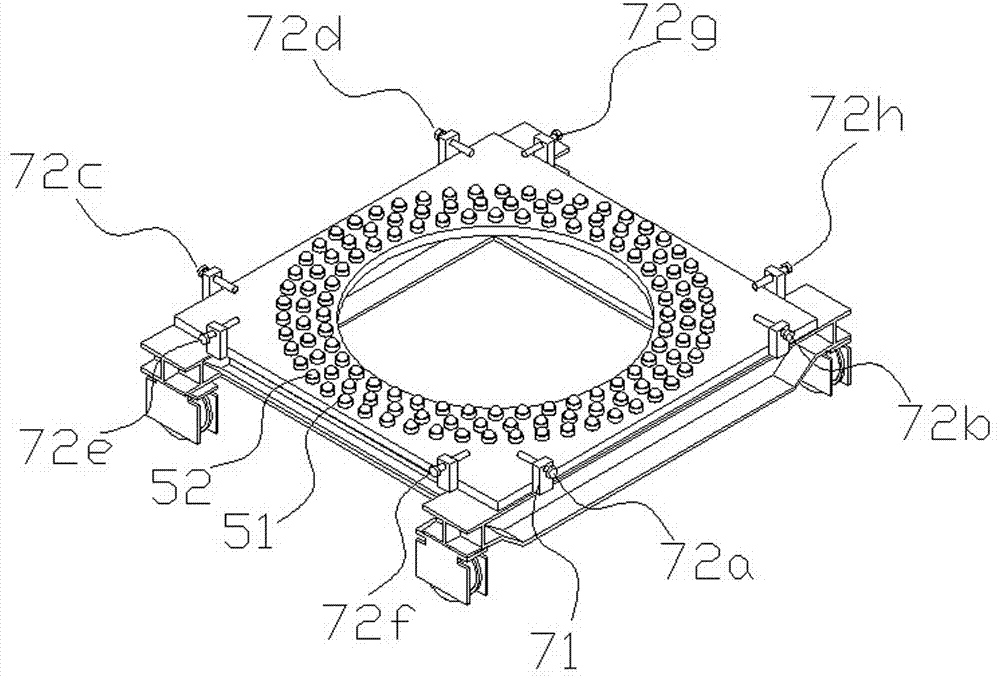

[0024] As shown in the figure, the all-round adjustable quick docking device for installing a slag breaker in a large gasification furnace for coal chemical industry includes a carriage frame body 1, rail wheels 2, bottom plate 3, supporting plate 4, rotating mechanism 5, locking bolts 6, The adjustment unit 7, the support frame 8 and the hydraulic jack 9, the four corners of the bottom of the trailer frame body 1 are respectively equipped with rail wheels 2, the rail wheels 2 are provided with brake devices, and the bottom plate 3 is welded on the top of the trailer frame body 1 , the top of the base plate 3 is provided with a supporting plate 4, and between the base plate 3 and the supporting plate 4 are provided with multiple sets of uniformly distributed rotating mechanisms 5, the rotating mechanism 5 includes a ball fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com