Multi-substrate combining detection method based on laser measurement

A detection method and laser measurement technology, applied in the field of testing, can solve problems such as inability to adjust, large measurement error, difficult measurement, etc., and achieve the effects of convenient translation and rotation, improved measurement accuracy, and direct presentation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

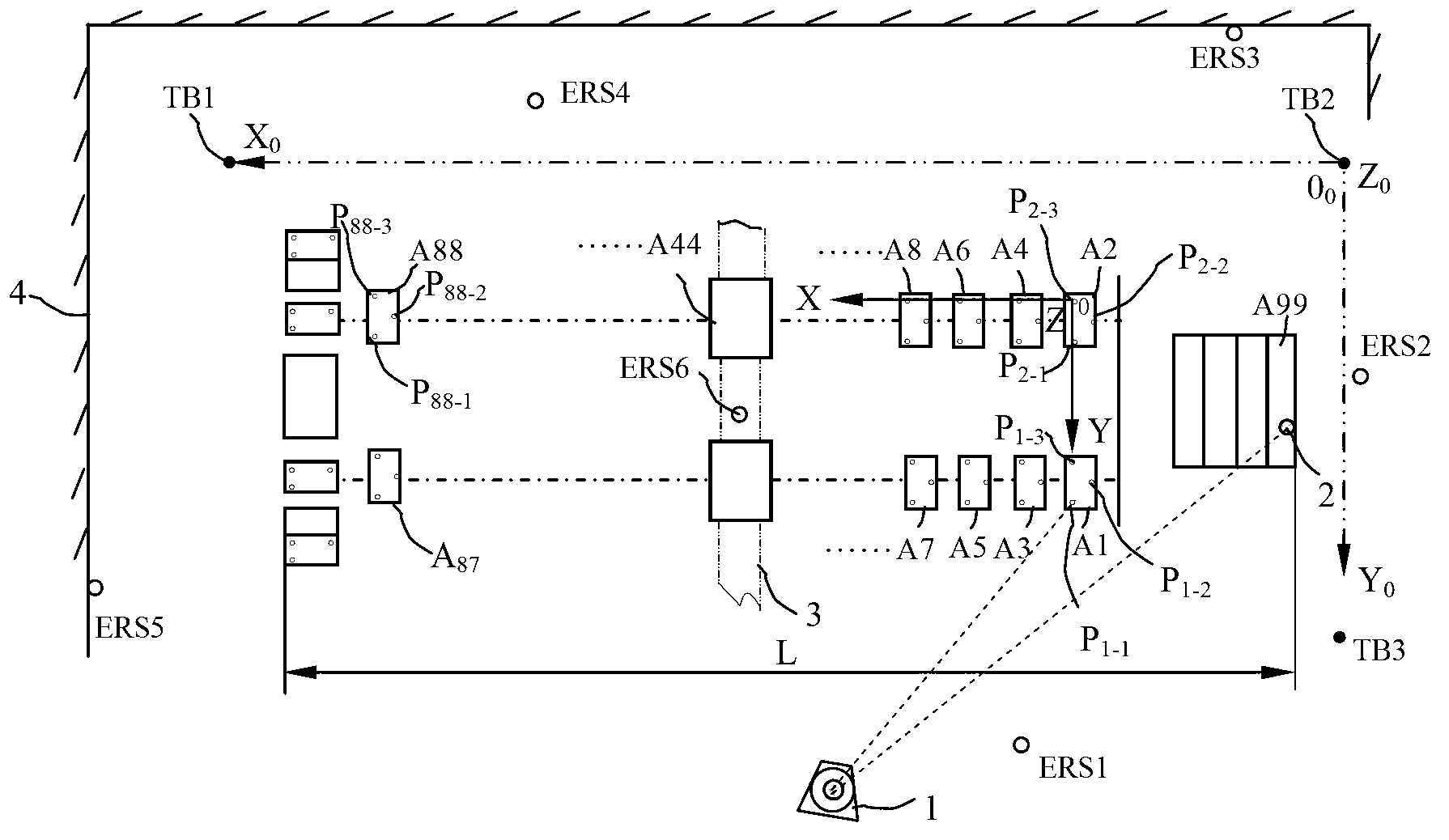

[0039] Example 1: figure 1 Shown: substrate (A1), ... [A99]; laser tracker (1); target ball (2); substrate mounting bracket (3); wall (4). Combine and detect the horizontal datum plane of a main structure. The target main body length L is 40m, which is composed of 99 substrates. Set up the LTD500 laser tracker (1) at the measurement station, and the static coordinate accuracy (2δ) of the laser tracker is ±10μm / m. Pre-lay the qualified substrate [A1] to substrate [A99] on the substrate support frame. The substrates are distributed in odd and even columns. It is agreed that the positioning holes on the substrate are numbered counterclockwise. The three positioning holes on the substrate [A1] numbered P 1-1 ,P 1-2 ,P 1-3 , determine the target offset and coordinate origin position, use the CATIA software to obtain the theoretical coordinates with the offset of the center of the target ball on the digital model, and import the theoretical coordinates into the application proc...

Embodiment 2: pic 2:〔A1〕……〔A10〕;〔1〕;〔2〕、〔3〕。 test 。 and 。 and ,。 specific Embodiment approach

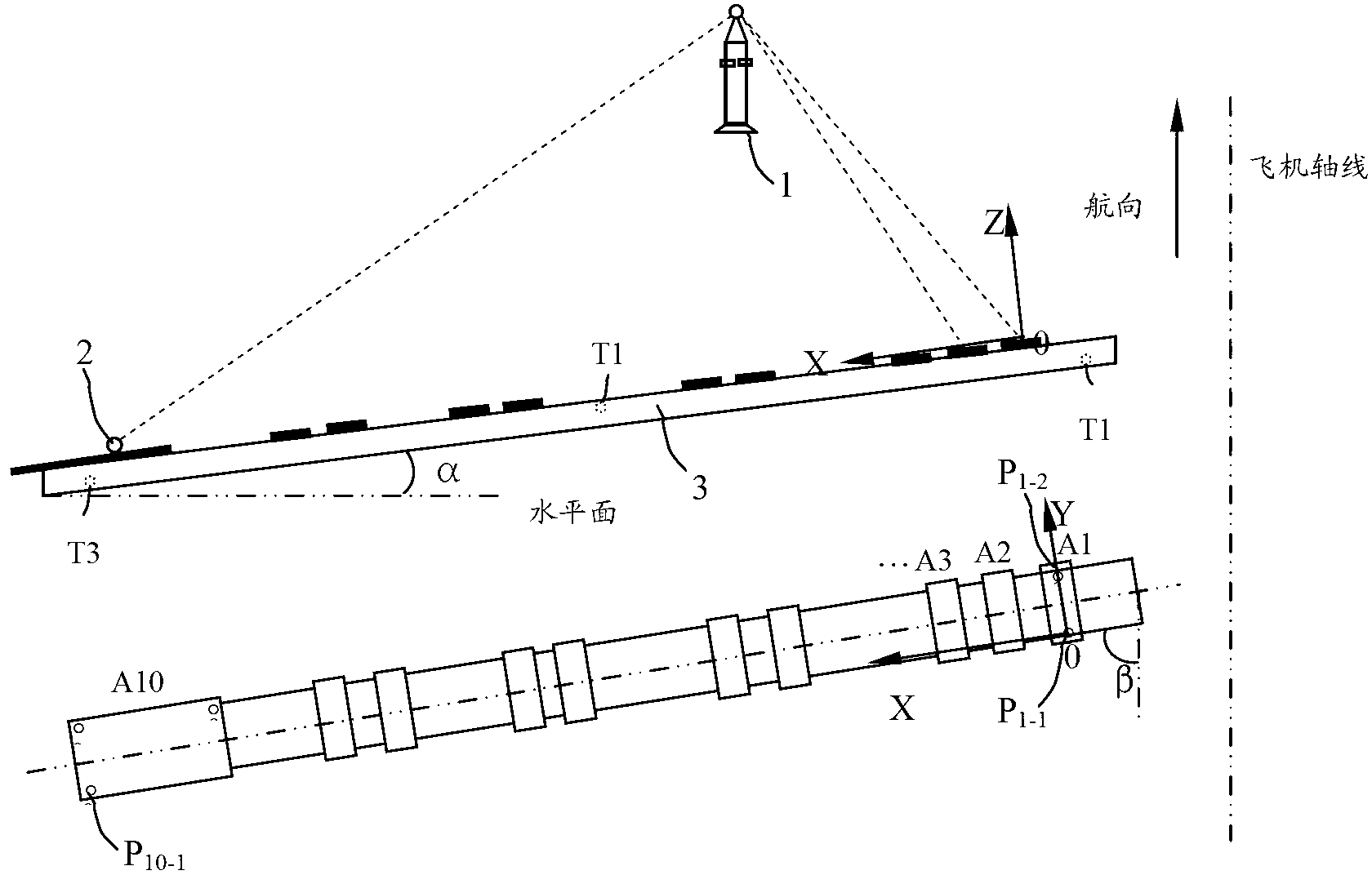

[0040] Example 2: figure 2 Shown: substrate (A1) ... [A10]; laser tracker (1); target ball (2), substrate mounting bracket (3). Assemble and install the installation datum plane of an aircraft wing control test bench. The measured plane is characterized in that the reference plane is in a compound angle relationship with each axis of the aircraft coordinate system. Therefore, it is necessary to use a laser tracker to initially install and debug the downturn and sweep angles of the mounting surface of the stand in the aircraft coordinate system, and then solve the problem of mounting flatness. The specific implementation is as follows:

[0041] The laser tracker (1) is set up at the root end of the wing control test bench, so that the laser beam emitted by it can be directly projected onto the surface of the measured object. Measure P in the aircraft coordinate system 1-1 ,P 1-2 ,P 10-1 point, the plane formed by three points is solved in the aircraft coordinate system f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com