Hydraulic supporting method for concrete replacement of shear walls in high-rise building

A high-rise building and hydraulic support technology, which is applied in construction, building maintenance, building construction, etc., can solve the problems of high investment cost, complicated construction process, and low utilization rate of scaffolding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

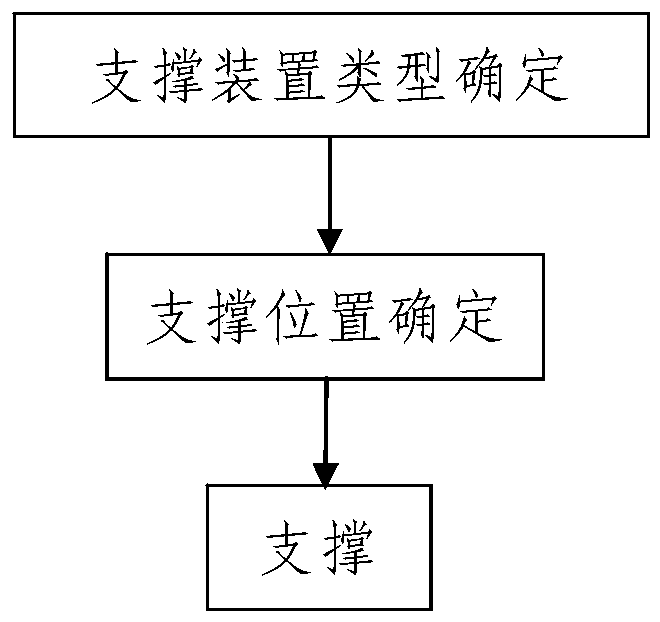

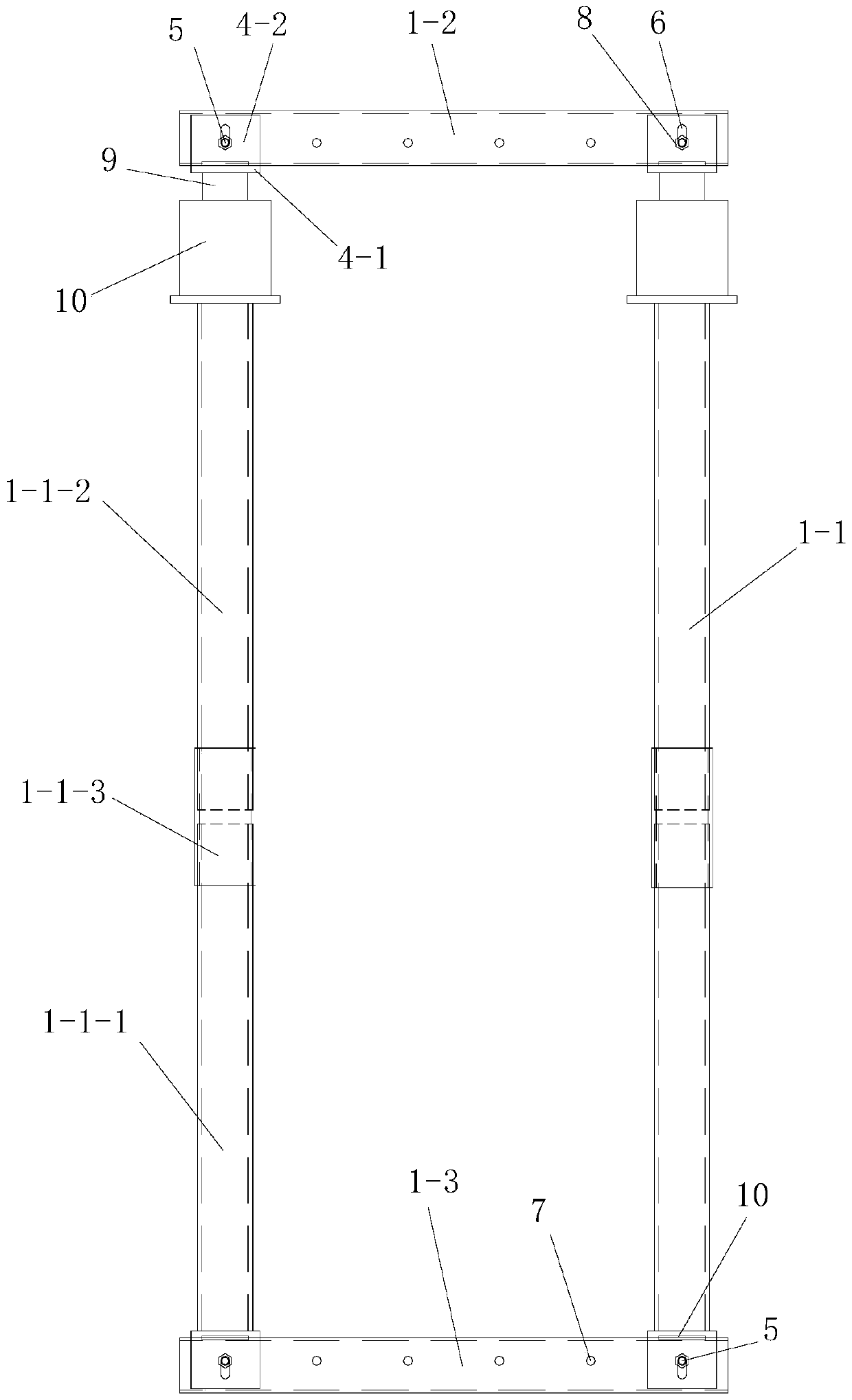

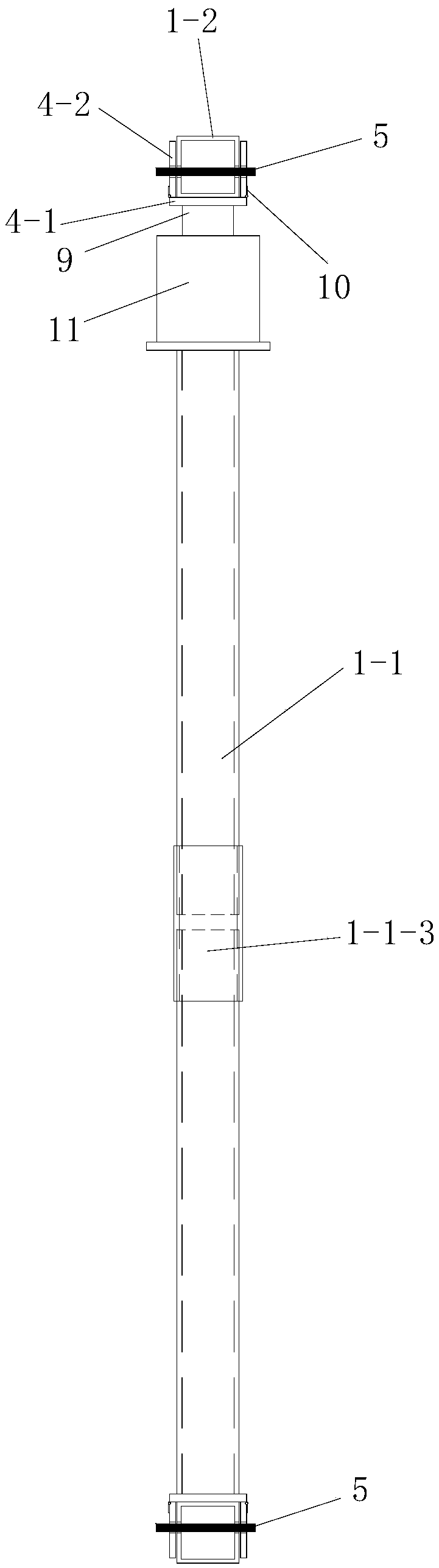

[0062] Such as figure 1 Shown is a hydraulic support method for the replacement of shear wall concrete in a high-rise building. The high-rise building to be constructed has a plurality of floors from bottom to top, and two adjacent floors are separated by floor slabs, and the floor slabs are steel bars. Concrete slabs are supported by shear walls between the upper and lower adjacent floor slabs; before the concrete replacement of the reinforced shear walls in the high-rise buildings to be constructed, support devices are used to support and the support process is as follows:

[0063] Step 1. Determination of the type of supporting device: According to whether the floor slab supported above the shear wall needs to be reinforced synchronously, the type of the supporting device is determined: when the floor slab supported above the shear wall needs to be reinforced synchronously, the adopted The type of support device is a support device for wall panel replacement; otherwise, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com